Mitsubishi Lancer Evolution IX. Manual — part 315

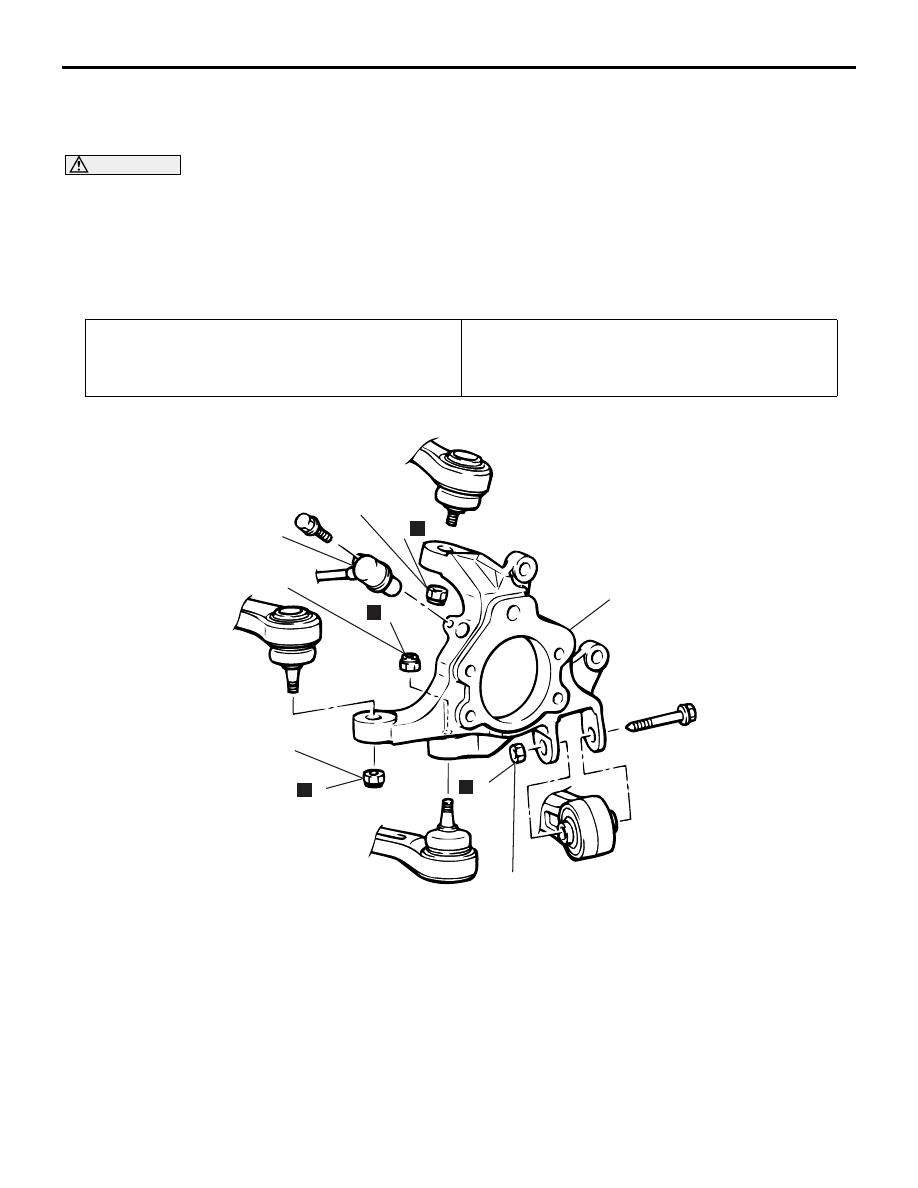

KNUCKLE

REAR AXLE

27-35

KNUCKLE

REMOVAL AND INSTALLATION

M1271003000265

CAUTION

• Be careful not to strike the pole piece at the tip of the rear ABS sensor with tools during servicing

work.

• During maintenance, take care not to contact the parts or tools to the caliper because the paint of

caliper will be scratched. And if there is brake fluid on the caliper, wipe it off quickly.

•

Pre-removal Operation

• Rear Wheel Hub Assembly Removal (Refer to

).

Post-installation Operation

• Check the ball joint dust cover for cracks or damage by

pushing it with your finger.

• Rear Wheel Hub Assembly Installation (Refer to

).

AC211951

N

4

2

1

5

6

N

3

N

N

88 ± 10 N·m*

81 ± 6 N·m*

AB

81 ± 6 N·m

81 ± 6 N·m

Removal steps

1.

Rear ABS sensor

<<

A

>>

2.

Self-locking nut (trailing arm

connection)

3.

Self-locking nut (lower arm

connection)

<<

A

>>

4.

Self-locking nut (toe control arm

connection)

<<

A

>>

5.

Self-locking nut (upper arm

connection)

6.

Knuckle

*

: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle

on the ground in the unladen condition.

Removal steps (Continued)

DRIVESHAFT ASSEMBLY

REAR AXLE

27-36

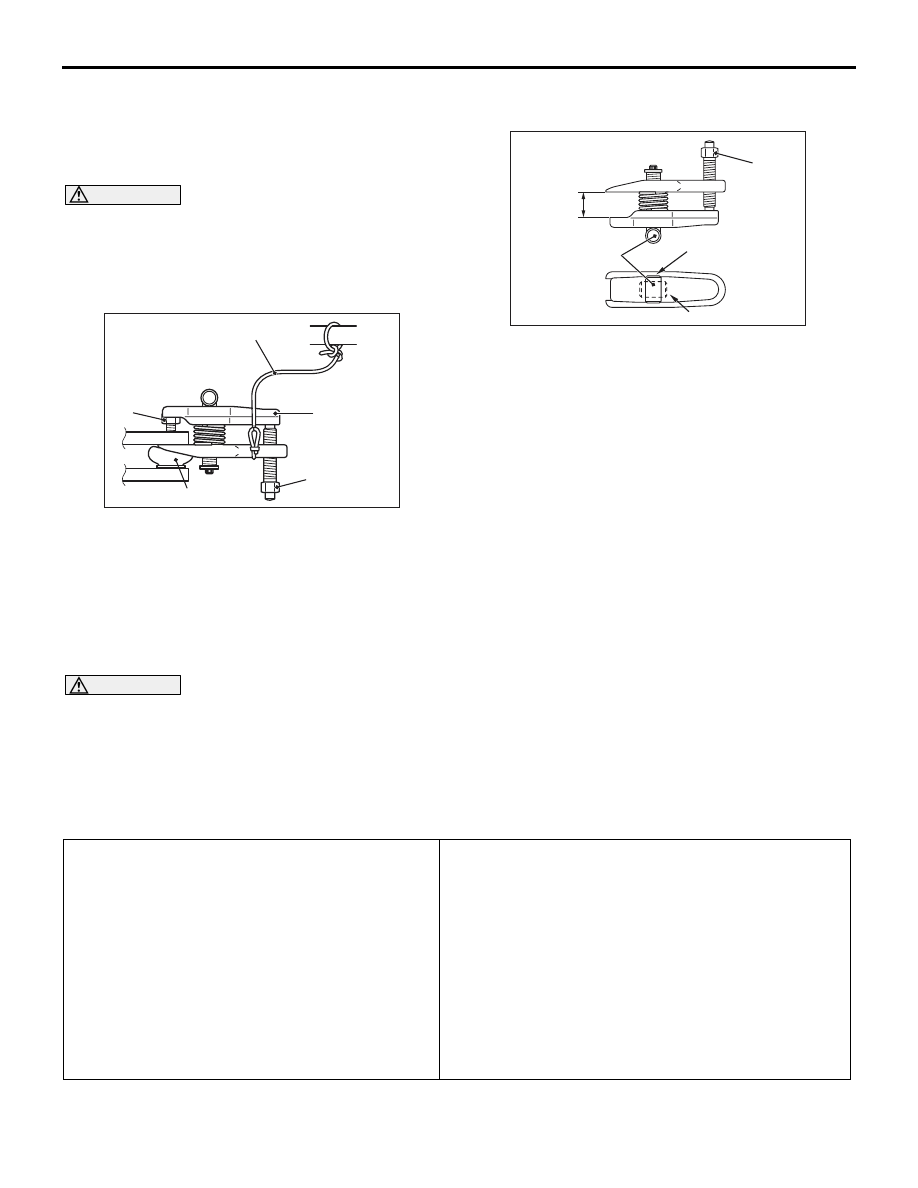

REMOVAL SERVICE POINT

<<A>>SELF-LOCKING NUT (TRAILING

ARM, TOE CONTROL ARM AND UPPER

ARM CONNECTION) REMOVAL

CAUTION

• Do not remove the nut from ball joint. Loosen

it and use the special tool to avoid possible

damage to ball joint threads.

•

AC208247AJ

Cord

Bolt

MB991897

or

MB992011

Nut

Ball joint

Hang the special tool with cord to prevent

them from falling.

1. Install special tool ball joint remover (MB991897

or MB992011) as shown in the figure.

AC106821

Knob

Parallel

Bolt

Correct

Wrong

AD

2. After turning the bolt and knob to adjust the arms

of special tool in parallel, tighten the bolt by hand

and confirm that the arms are parallel.

NOTE: When adjusting the arms in parallel, turn

the knob so that it is at right angles to the arms.

3. Tighten the bolt with a wrench to disconnect the

ball joint and remove the self-locking nut.

INSPECTION

M1271003100154

Check the knuckle for wear or cracks.

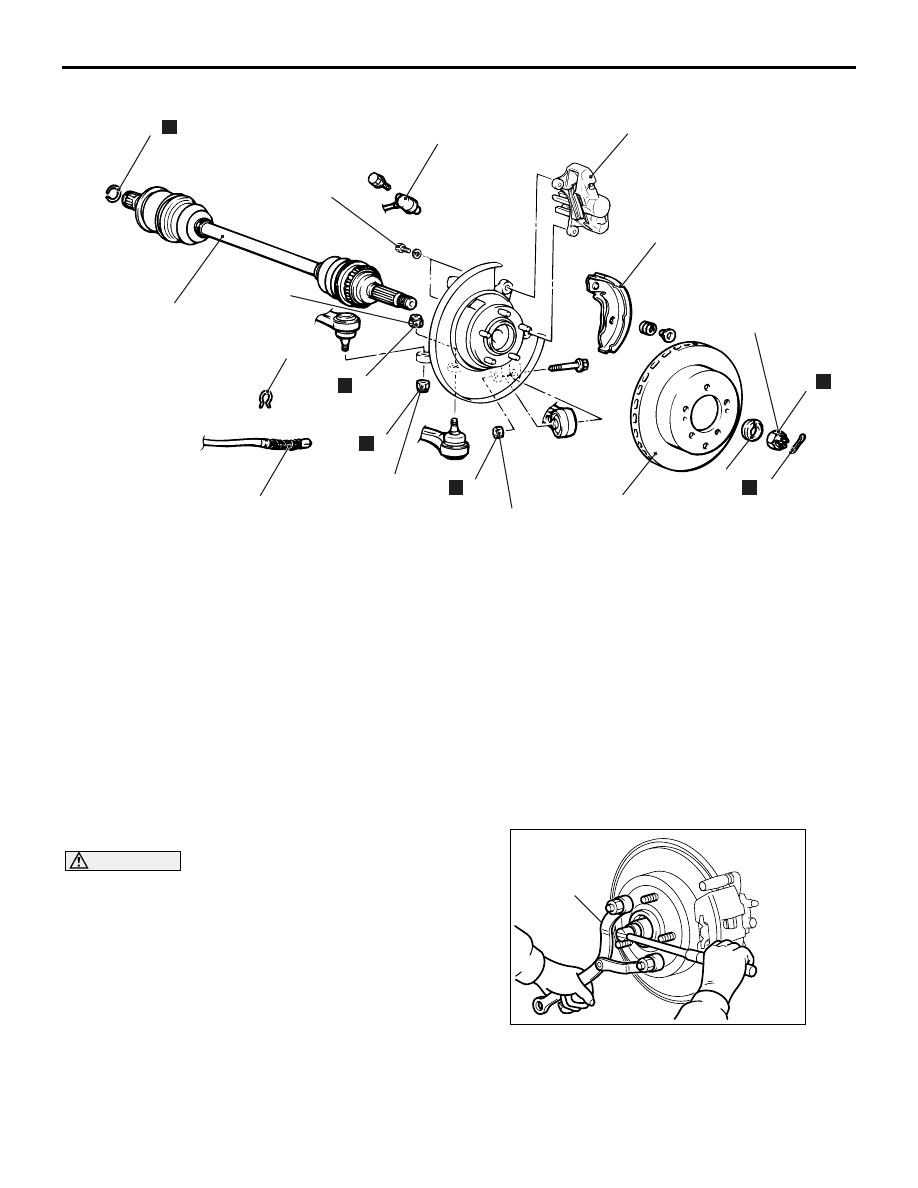

DRIVESHAFT ASSEMBLY

REMOVAL AND INSTALLATION

M1271003300266

CAUTION

• Do not strike the ABS rotors installed to the EBJ outer race of driveshaft against other parts when

removing or installing the driveshaft. The ABS rotors will be damaged.

• Be careful not to strike the pole piece at the tip of the rear ABS sensor with tools during servicing

work.

•

Pre-installation Operation

• Centre Exhaust Pipe Removal (Refer to

GROUP15, Exhaust Pipe and Main Muffler

).

Post-installation Operation

• Check the dust cover for cracks or damage by

pushing it with your finger.

• Centre Exhaust Pipe Installation (Refer to GROUP

15, Exhaust Pipe and Main Muffler

).

• Gear Oil Filling (Refer to

).

• Parking Brake Lever Stroke Adjustment (Refer to

GROUP 36, On-vehicle Service

− Parking Brake

Lever Stroke Check and Adjustment

• Rear Wheel Alignment Check and Adjustment

(Refer to GROUP34, On-vehicle Service

−Rear

Wheel Alignment Check and Adjustment

During maintenance, take care not to contact the parts or tools to the caliper because the paint of

caliper will be scratched. And if there is brake fluid on the caliper, wipe it off quickly.

AC211952

N

N

1

4

5

225 ± 25 N·m

AB

2

3

N

6

7

13

14

8

9

11

N

12

N

10

N

88 ± 10 N·m*

81 ± 6 N·m*

81 ± 6 N·m

54 ± 5 N·m

Removal steps

1. Split pin

<<

A

>> >>

B

<< 2. Driveshaft nut

>>

B

<< 3. Washer

4. Rear ABS sensor

<<

B

>>

5. Caliper assembly

6. Brake disc

7. Parking brake shoe and lining

assembly (Refer to GROUP 36,

Parking brake lining and drum

8. Clip

9. Parking brake cable connection

<<

C

>>

10. Self-locking nut (trailing arm

connection)

<<

C

>>

11. Self-locking nut (lower arm

connection)

<<

C

>>

12. Self-locking nut (toe control arm

connection)

<<

D

>> >>

A

<< 13. Driveshaft

14. Circlip

DRIVESHAFT ASSEMBLY

REAR AXLE

27-37

REMOVAL SERVICE POINTS

<<A>> DRIVESHAFT NUT REMOVAL

CAUTION

Do not apply pressure to wheel bearing by the

vehicle weight to avoid possible damage to

wheel bearing before tightening driveshaft nut

fully.

AC205988

MB990767

AB

Use special tool front hub and end yoke holder

(MB990767) to fix the hub and remove the driveshaft

nut.

Removal steps (Continued)

DRIVESHAFT ASSEMBLY

REAR AXLE

27-38

<<B>> CALIPER ASSEMBLY REMOVAL

CAUTION

During maintenance, take care not to contact the

parts or tools to the caliper because the paint of

caliper will be scratched.

Secure the removed caliper assembly with wire, etc.

<<C>>SELF-LOCKING NUT (TRAILING

ARM, LOWER ARM AND TOE CONTROL

ARM CONNECTION) REMOVAL

CAUTION

• Do not remove the nut from ball joint. Loosen

it and use the special tool to avoid possible

damage to ball joint threads.

•

AC208247AJ

Cord

Bolt

MB991897

or

MB992011

Nut

Ball joint

Hang the special tool with cord to prevent

them from falling.

1. Install special tool ball joint remover (MB991897

or MB992011) as shown in the figure.

AC106821

Knob

Parallel

Bolt

Correct

Wrong

AD

2. After turning the bolt and knob to adjust the arms

of special tool in parallel, tighten the bolt by hand

and confirm that the arms are parallel.

NOTE: When adjusting the arms in parallel, turn

the knob so that it is at right angles to the arms.

3. Tighten the bolt with a wrench to disconnect the

ball joint and remove the self-locking nut.

<<D>> DRIVESHAFT REMOVAL

AC205989

MB991354

MB990244

(Three)

MB990242

MB990767

AB

1. Use the following special tools to push out the

driveshaft from the hub.

• Puller shaft (MB990242)

• Puller bar (MB990244)

• Puller body (MB991354)

• Front hub and end yoke holder (MB990767)

CAUTION

• Do not pull on the driveshaft. Doing so will

damage the TJ. Be sure to use the pry bar.

• When pulling the driveshaft out from the dif-

ferential carrier, be careful that the spline part

of the driveshaft does not damage the oil seal.

AC102552 AE

TJ assembly

Pry bar

Differential carrier

2. Remove the driveshaft from the differential carrier

by using a pry bar.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст