Mitsubishi Lancer Evolution IX. Manual — part 314

ON-VEHICLE SERVICE

REAR AXLE

27-31

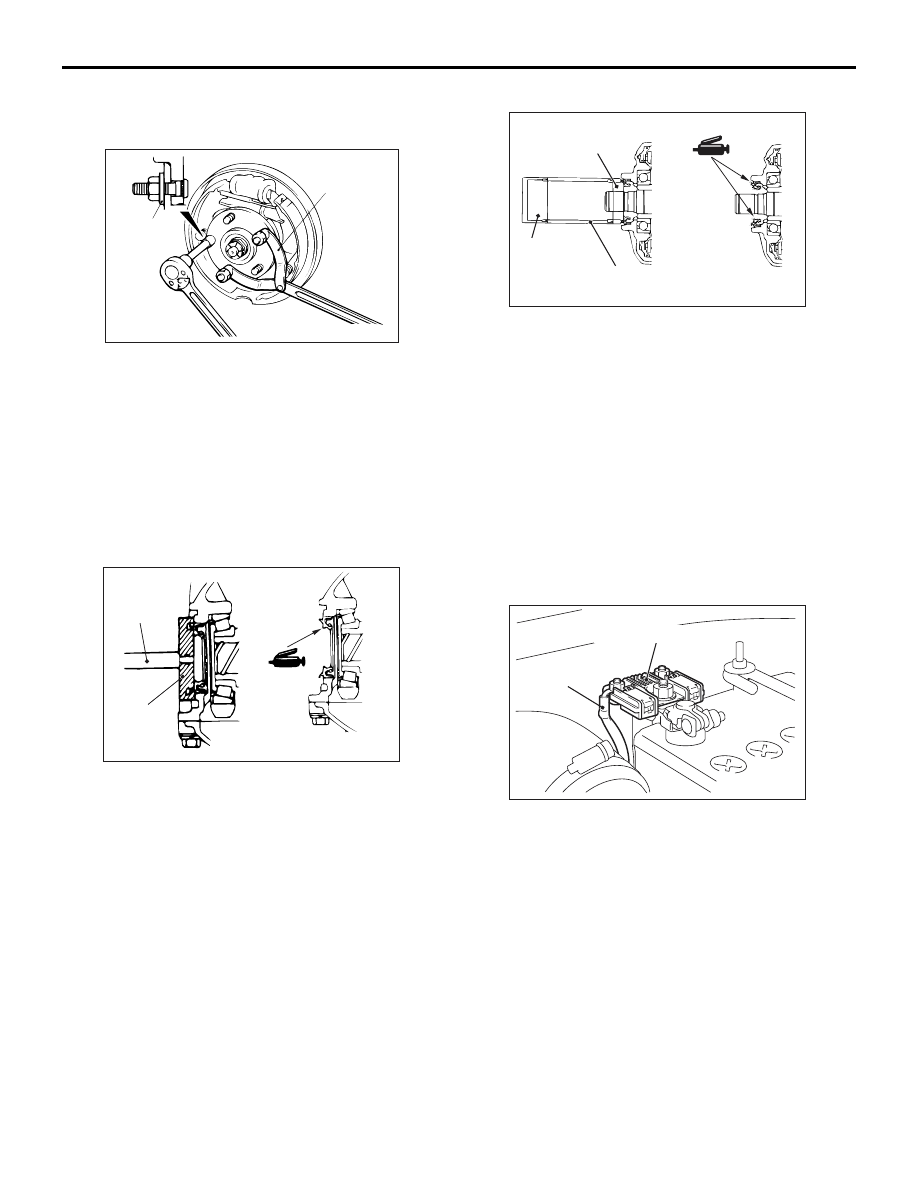

NOTE: To retain a space for removing the hub

bolts, remove near the retainer spring mounting

position.

AC001183

MB990767

AB

Plain

washer

3. Install the plain washer to the new hub bolt, and

install the bolt with a nut.

DIFFERENTIAL CARRIER OIL SEAL

REPLACEMENT

M1272001300133

DIFFERENTIAL PART

1. Remove the driveshaft from the differential carrier.

(Refer to

).

2. Remove the differential carrier oil seal.

AC102740

MB990938

MB991115

AC

3. Use the following special tools to press-fit a new

oil seal.

• Installer bar (MB990938)

• Oil seal installer (MB991115)

4. Apply multi-purpose grease to the oil seal lip and

driveshaft oil seal seating area.

5. Replace the driveshaft circlip with a new one, and

install the driveshaft to the differential carrier.

(Refer to

).

TORQUE TRANSFER MECHANISM PART

1. Remove the driveshaft from the differential carrier.

(Refer to

).

2. Remove the differential carrier oil seal.

AC310759AB

MD998829

MD998813

MD998812

3. Use the following special tools to press-fit a new

oil seal.

• Installer cap (MD998812)

• Installer 100 (MD998813)

• Installer adaptor (MD998829)

4. Apply specified grease to the oil seal lip and

driveshaft oil seal seating area.

Specified grease: Vaseline

5. Replace the driveshaft circlip with a new one, and

install the driveshaft to the differential carrier.

(Refer to

).

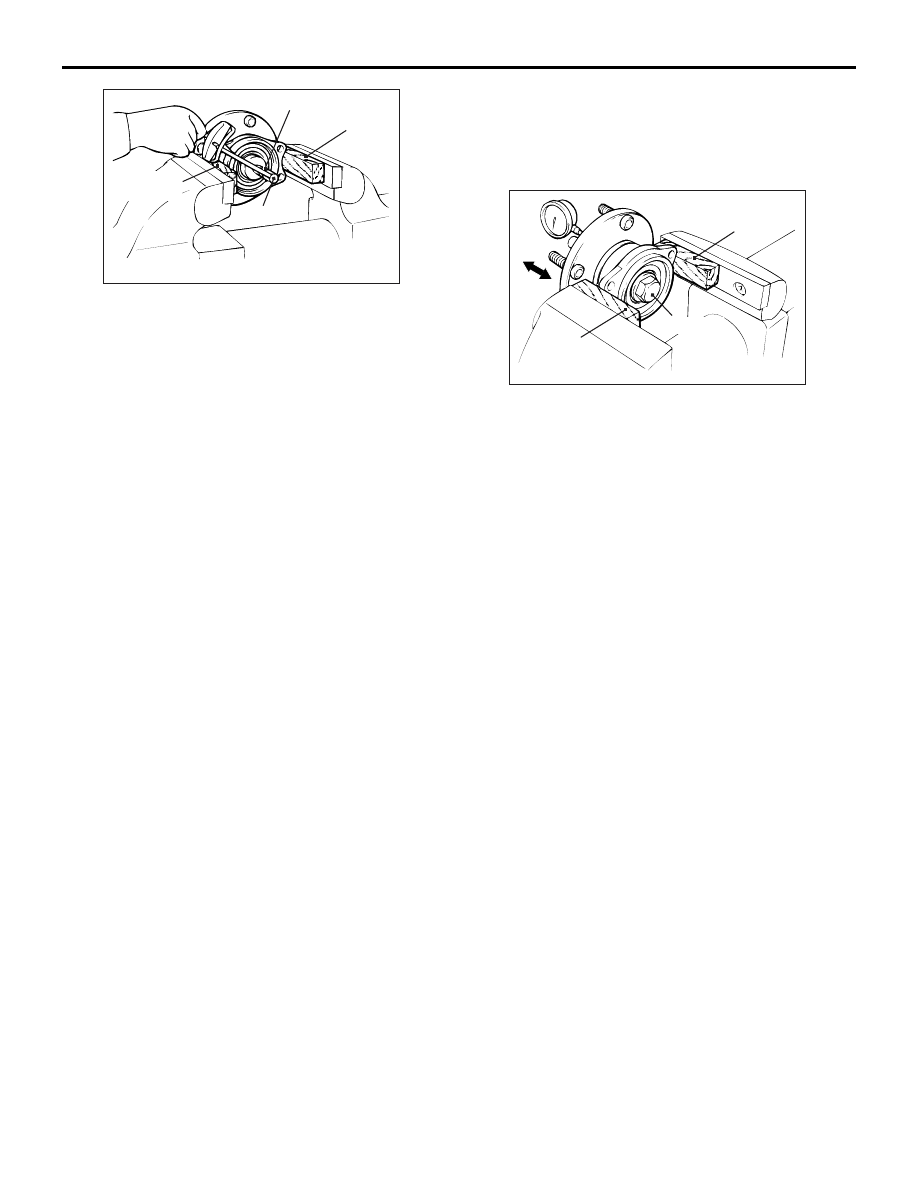

REMEDY FOR A DISCHARGED BATTERY

M1272005100023

AC310768 AB

Battery cable

for AYC

Battery fuse assembly

When the engine is started using a booster cable

where the battery has completely run down and you

attempt to start the vehicle without waiting for the

battery to recover a certain charge, the engine can

misfire and you just cannot start to move it. In such

cases, charge the battery sufficiently; or, remove the

AYC battery cable from the battery fuse assembly to

make AYC inactive before attempting to start the

vehicles. When the battery cable is removed, the

ACD mode indicator lamp lights up. After the battery

has been recharged, fit the battery cable back again

and start the engine to ensure that the ACD mode

indicator lamp is off.

REAR AXLE HUB ASSEMBLY

REAR AXLE

27-32

REAR AXLE HUB ASSEMBLY

REMOVAL AND INSTALLATION

M1271002000466

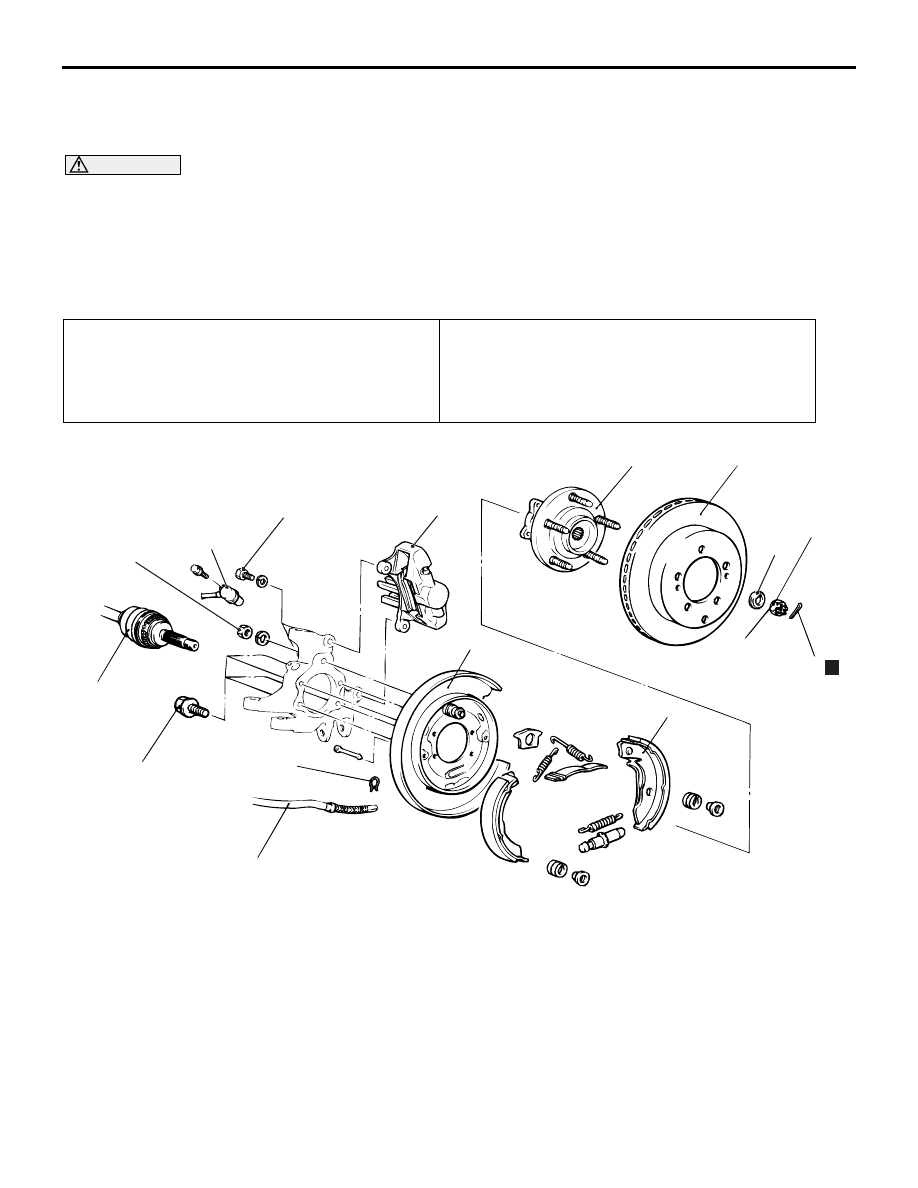

CAUTION

• Do not strike the ABS rotors installed to the EBJ outer race of driveshaft against other parts when

removing or installing the driveshaft. Otherwise the ABS rotors will be damaged.

• Be careful not to strike the pole piece at the tip of the rear ABS sensor with tools during servicing

work.

•

Pre-installation Operation

Post-installation Operation

• Gear Oil Filling (Refer to

).

• Parking Brake Lever Stroke Adjustment (Refer

to GROUP 36, On

−vehicle Service − Parking

Brake Lever Stroke Check

).

AC211950 AC

225 ± 25 N·m

8

7

10

11

9

2

3

4

5

1

N

6

12

54 ± 5 N·m

118 ± 19 N·m

71 ± 7 N·m

Removal steps

1. Split pin

<<

A

>> >>

A

<< 2. Driveshaft nut

>>

A

<< 3. Washer

4. Rear ABS sensor

<<

B

>>

5. Caliper assembly

6. Brake disc

7. Parking brake shoe and lining

assembly (Refer to GROUP 36,

Parking brake lining and drum

).

8. Clip

9. Parking brake cable connection

10. Rear driveshaft assembly

<<

C

>>

11. Rear wheel hub assembly

12. Backing plate

During maintenance, take care not to contact the parts or tools to the caliper because the paint of

caliper will be scratched. And if there is brake fluid on the caliper, wipe out quickly.

Removal steps (Continued)

REAR AXLE HUB ASSEMBLY

REAR AXLE

27-33

REMOVAL SERVICE POINTS

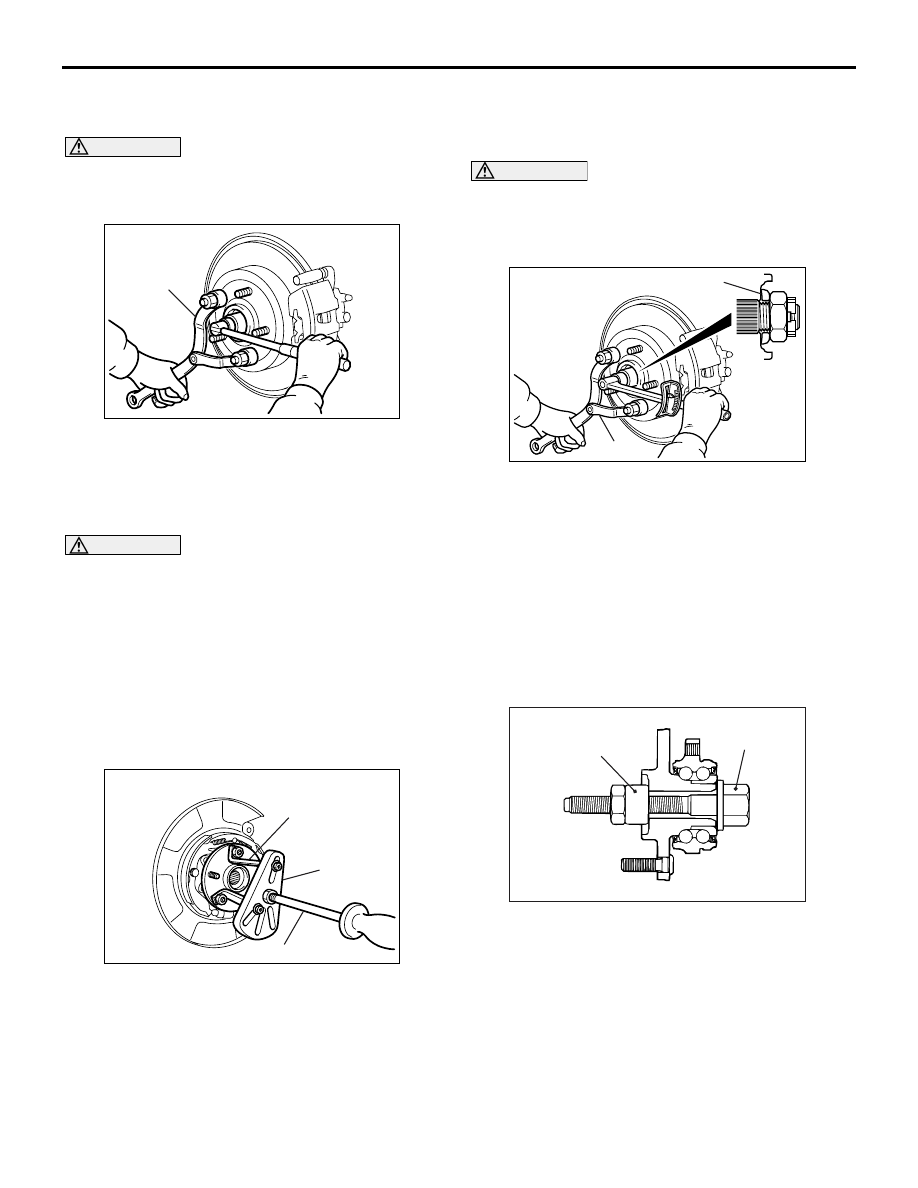

<<A>> DRIVESHAFT NUT REMOVAL

CAUTION

Do not apply pressure to the wheel bearing by

the vehicle weight to avoid possible damage

when the driveshaft nut is loosened.

AC205988

MB990767

AB

Use special tool front hub and end yoke holder

(MB990767) to fix the hub and remove the driveshaft

nut.

<<B>> CALIPER ASSEMBLY REMOVAL

CAUTION

During maintenance, take care not to contact the

parts or tools to the caliper because the paint of

caliper will be scratched.

Secure the removed caliper assembly with wire, etc.

<<C>> REAR WHEEL HUB REMOVAL

If the rear wheel hub is seized, remove the rear

wheel hub as follows.

1. Remove the knuckle with rear wheel hub and fix

them with a vise (Refer to

).

AC207000

AB

MB990211

MB991354

MB990244

2. Use the following special tools to pull out the rear

wheel hub from the knuckle.

• Puller bar (MB990244)

• Puller body (MB991354)

• Slide hammer (MB990211)

INSTALLATION SERVICE POINT

>>A<< WASHER/ DRIVESHAFT NUT

INSTALLATION

CAUTION

Before securely tightening the driveshaft nuts,

make sure there is no load on the wheel bear-

ings. Otherwise the wheel bearings will be dam-

aged.

AC205992

AC

MB990767

Washer

1. Be sure to install the driveshaft washer in the

specified direction.

2. Using special tool front hub and end yoke holder

(MB990767), tighten the driveshaft nut to the

specified torque.

Tightening torque: 225

± 25 N⋅m

INSPECTION

M1271002100300

WHEEL BEARING ROTATION STARTING

TORQUE AND AXIAL PLAY CHECK

AC212015 AB

MB991000

MB991017

1. Tighten the following special tools to the specified

torque.

• Front hub remover and installer (MB991017)

• Spacer (MB991000)

Tightening torque: 225

± 25 N⋅m

2. Rotate the rear hub in order to seat the bearing.

AC206090 AD

MB990326 Wooden

block

MB990685

Wooden

block

REAR AXLE HUB ASSEMBLY

REAR AXLE

27-34

3. Hold the rear wheel hub assembly with wooden

blocks.

4. Measure the wheel bearing rotation starting

torque by using the following special tools.

• Preload socket (MB990326)

• Torque wrench (MB990685)

Limit: 1.0 N

⋅m

5. If the rotation starting torque is not within the limit

range while the nut is tightened to 225

± 25 N⋅m,

replace the front wheel bearing assembly. If there

are any signs of binding or tight spots when the

wheel bearing turns, replace it.

AC206091AG

Wooden

block

Wooden

block

MB991017

6. Measure to determine whether the wheel bearing

axial play is within the specified limit or not.

Limit: 0.05 mm

7. If the play is not within the limit range while the nut

is tightened to 225

± 25 N⋅m, replace the rear

wheel hub assembly.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст