Mitsubishi Lancer Evolution IX. Manual — part 351

AKX00198

Stopper

Pinion gap

Pinion

AC

STARTING SYSTEM

ENGINE ELECTRICAL

16-21

4. Check the pinion-to-stopper clearance (pinion

gap) with a feeler gauge.

Standard value: 0.5

− 2.0 mm

AKX00199

5. If the pinion gap is out of specification, adjust by

adding or removing gasket(s) between the

magnetic switch and front bracket.

MAGNETIC SWITCH PULL-IN TEST

AKX01243

B

M

S

Battery

Starter

motor

Wire

AF

1. Disconnect the field coil wire from the M-terminal

of the magnetic switch.

CAUTION

This test must be performed quickly (in less than

10 seconds) to prevent the coil from burning.

2. Connect a 12-volt battery between the S-terminal

and M-terminal.

3. If the pinion moves out, the pull-in coil is good. If it

doesn't, replace the magnetic switch.

MAGNETIC SWITCH HOLD-IN TEST

AKX01245

B

M

S

Battery

Starter

motor

Wire

AF

1. Disconnect the field coil wire from the M-terminal

of the magnetic switch.

CAUTION

This test must be performed quickly (in less than

10 seconds) to prevent the coil from burning.

2. Connect a 12-volt battery between the S-terminal

and body.

3. Manually pull out the pinion as far as the pinion

stopper position.

4. If the pinion remains out, everything is in order. If

the pinion moves in, the hold-in circuit is open.

Replace the magnetic switch.

FREE RUNNING TEST

AKX01247

S

M

B

Ammeter

Carbon-pile

rheostat

Battery

Starter

motor

Voltmeter

AF

A

V

1. Place the starter motor in a vise equipped with

soft jaws and connect a fully-charged 12-volt

battery to the starter motor as follows:

2. Connect a test ammeter (100-ampere scale) and

carbon pile rheostat in series between the positive

battery terminal and starter motor terminal.

3. Connect a voltmeter (15-volt scale) across the

starter motor.

4. Rotate the rheostat to full-resistance position.

5. Connect the battery cable from the negative

battery terminal to the starter motor body.

6. Adjust the rheostat until the battery positive

voltage shown on the voltmeter is 11 V.

STARTING SYSTEM

ENGINE ELECTRICAL

16-22

7. Confirm that the maximum amperage is within the

specifications and that the starter motor turns

smoothly and freely.

Current: maximum 95 Amps

MAGNETIC SWITCH RETURN TEST

AKX01249

B

M

S

Battery

Starter

motor

Wire

AF

1. Disconnect the field coil wire from the M-terminal

of the magnetic switch.

CAUTION

This test must be performed quickly (in less than

10 seconds) to prevent the coil from burning.

2. Connect a 12-volt battery between the M-terminal

and body.

WARNING

Be careful not to get your fingers caught

when pulling out the pinion.

3. Pull the pinion out and release. If the pinion

quickly returns to its original position, everything is

operating properly. If it doesn't, replace the

magnetic switch.

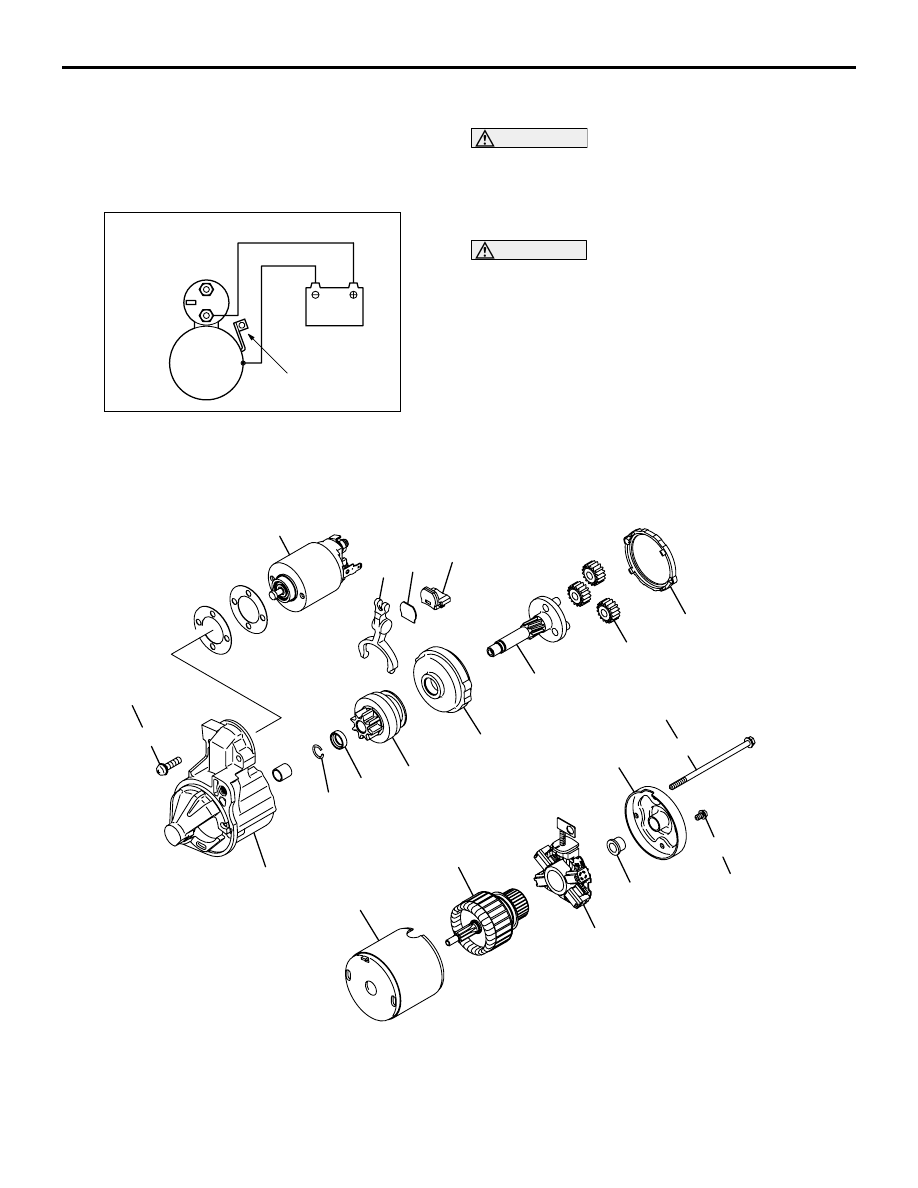

DISASSEMBLY AND REASSEMBLY

M1162001200246

AK304626AB

2

16

17

18

19

15

13

12

21

4

14

11

1

5

6

8

7

9

10

3

5.8 ± 1.6 N·m

5.8 ± 1.6 N·m

3.4 ± 1.0 N·m

Disassembly steps

1. Screw

<<

A

>>

2. Magnetic switch

3. Screw

4. Bolt

5. Rear bracket

6. Brush holder

7. Rear bearing

8. Armature

9. Yoke assembly

10. Packing A

11. Packing B

12. Plate

13. Planetary gear

14. Lever

<<

B

>> >>

A

<< 15. Snap ring

<<

B

>> >>

A

<< 16. Stop ring

17. Overrunning clutch

18. Internal gear

19. Planetary gear shaft

20. Front bracket

STARTING SYSTEM

ENGINE ELECTRICAL

16-23

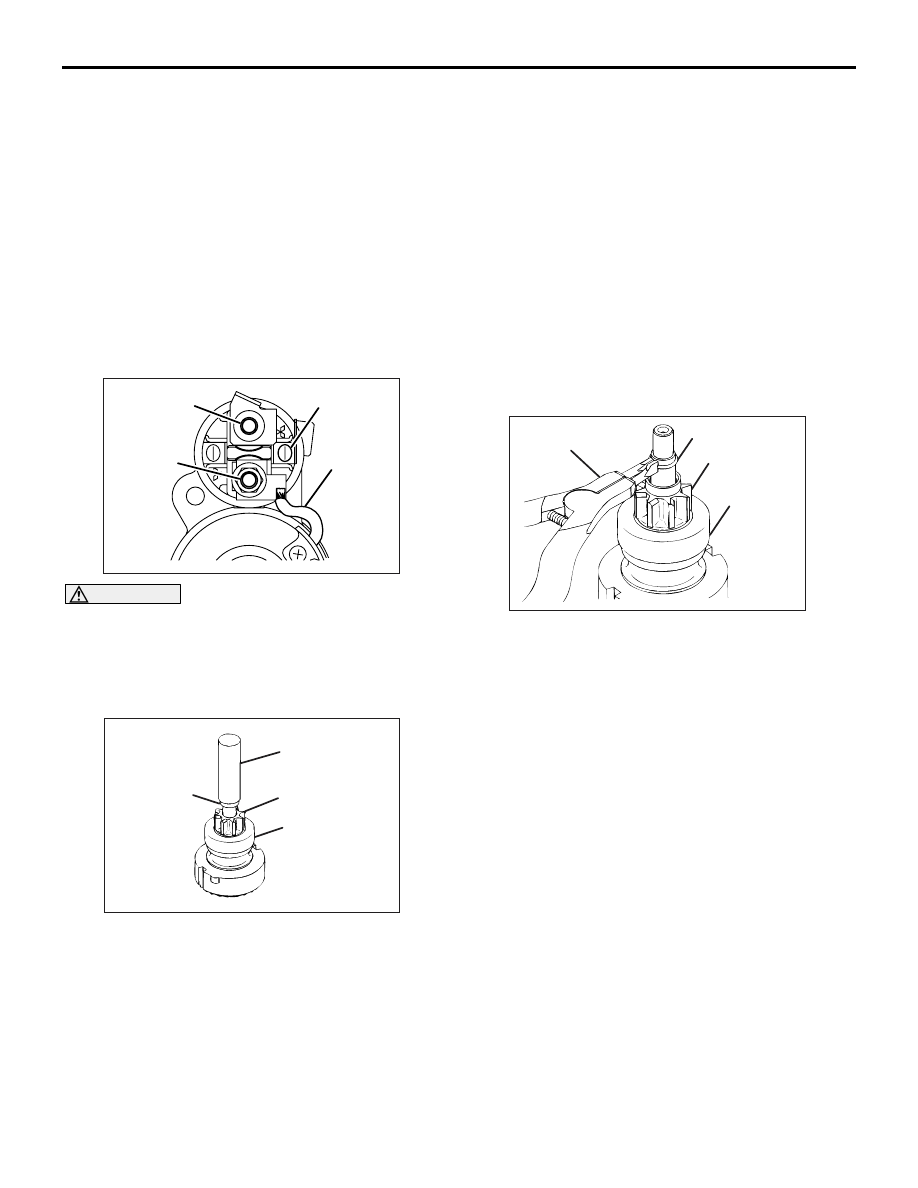

DISASSEMBLY SERVICE POINTS

<<A>> MAGNETIC SWITCH REMOVAL

AK202890

B terminal

M terminal

S terminal

Field coil

lead

AB

CAUTION

Do not clamp the yoke assembly with a vise.

Disconnect the lead from the M terminal of the mag-

netic switch.

<<B>> SNAP RING/STOP RING REMOVAL

AK202790

Socket wrench

Stop ring

Pinion Gear

Overrunning

clutch

AB

1. Apply a long socket wrench of an appropriate size

to the stop ring and strike the wrench to drive out

the stop ring toward the pinion gear side.

AK202791

Snap ring

pliers

Snap ring

Pinion gear

Overrunning

clutch

AB

2. Remove the snap ring with snap ring pliers, then

remove the stop ring and overrunning clutch.

STARTER MOTOR PARTS CLEANING

Never clean in a solvent such starter motor parts as

the magnetic switch, brush holder, and armature.

If they are soaked in a solvent, their insulation

could be impaired. When these parts require

cleaning, wipe off contamination with cloth.

1. Never soak the drive unit in a solvent. If it is

washed in a solvent, the grease having been

packed in the overrunning clutch at the factory will

be washed out. Wipe the drive unit with cloth if it

requires cleaning.

Disassembly steps (Continued)

STARTING SYSTEM

ENGINE ELECTRICAL

16-24

REASSEMBLY SERVICE POINTS

>>A<< STOP RING/SNAP RING INSTAL-

LATION

AK202911

Overrunning

clutch

Stop ring

Snap ring

Stop ring

AB

Use a suitable puller to pull the stop ring until it gets

over the snap ring.

INSPECTION

M1162001300180

COMMUTATOR

AK202712

1. Support the armature with a pair of V block and

turn it to measure the runout of the surface not

rubbed by the brushes using a dial gauge.

Standard value: 0.05 mm or less

Limit: 0.1 mm

AK202715

2. Measure the diameter of the commutator.

Standard value: 29.4 mm

Limit: 28.8 mm

AK202711

Segment

Undercut

Mica

AB

3. Measure the depth of the undercut between

segments.

Standard value: 0.5 mm

Limit: 0.2 mm

BRUSH HOLDER

AK202897

Push the brush into the brush holder to make sure

that the spring is working on the brush.

If the spring is not working, replace the brush holder.

OVERRUNNING CLUTCH

AK202710

Free

Lock

AB

1. Make sure that the pinion cannot be turned

counterclockwise and can be turned clockwise

freely.

2. Check the pinion for abnormal ware and damage.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст