Mitsubishi Lancer Evolution IX. Manual — part 350

CHARGING SYSTEM

ENGINE ELECTRICAL

16-17

>>B<< ROTOR INSTALLATION

AK202779

Wire

AB

Remove the brush holding wire after the rotor has

been installed.

INSPECTION

M1161001700129

ROTOR

AK202735

1. Measure the resistance between the two slip rings

of the rotor coil to check the continuity between

them.

Replace the rotor if the resistance is not within the

standard value range.

Standard value: 3

− 5 Ω

2. Check the continuity between the slip rings and

core.

AK202736

3. If continuity is present, replace the rotor.

STATOR

AK202716

1. Check the continuity between coil leads.

If there is no continuity, replace the stator.

AK202717

2. Check the continuity between coil and core.

If there is no continuity, replace the stator.

RECTIFIER ASSEBMLY

AK202803

1. Check the condition of the (+) heat sink by

checking continuity between the (+) heat sink and

each of the stator coil lead connecting terminals.

If continuity is present for both terminals, the

diode is shorted. Replace the rectifier assembly.

AK202802

STARTING SYSTEM

ENGINE ELECTRICAL

16-18

2. Check the condition of the (

−) heat sink by

checking continuity between the (

−) heat sink and

each of the stator coil lead connecting terminals.

If continuity is present in both directions, the diode

is shorted. Replace the rectifier assembly.

AK202804

3. Check the condition of the diode trio by testing

continuity of each of the three diodes using a

circuit tester connected to both sides of the diode.

Connect in a polarity and then reverse the polarity

for each test.

If continuity exists or no continuity exists for both

polarities, the diode is defective. Replace the

rectifier assembly if any of the diodes is defective.

BRUSH

AK202808

Protrusion

length

AB

1. Measure the length of the protrusion of the brush.

Replace the brush if the protrusion length is

shorter than the limit.

Limit: 2 mm minimum

2. Unsolder the lead of the brush. The brush will

come out, becoming ready for removal.

AK202834

Solder

AB

3. Install a new brush by pushing it into the holder as

shown in the drawing and soldering the lead.

STARTING SYSTEM

GENERAL INFORMATION

M1162000100309

If the ignition switch is turned to the "START" posi-

tion, current flows in the pull-in and holding coils pro-

vided inside magnetic switch, attracting the plunger,

When the plunger is attracted, the lever connected to

the plunger is actuated to engage the starter clutch.

On the other hand, attracting the plunger will turn on

the magnetic switch, allowing the "B" terminal and

"M" terminal to conduct. Thus, current flows to

engage the starter motor.

When the ignition switch is returned to the "ON" posi-

tion after starting the engine, the starter clutch is dis-

engaged from the ring gear.

An overrunning clutch is provided between the pinion

and the armature shaft, to prevent damage to the

starter.

STARTING SYSTEM

ENGINE ELECTRICAL

16-19

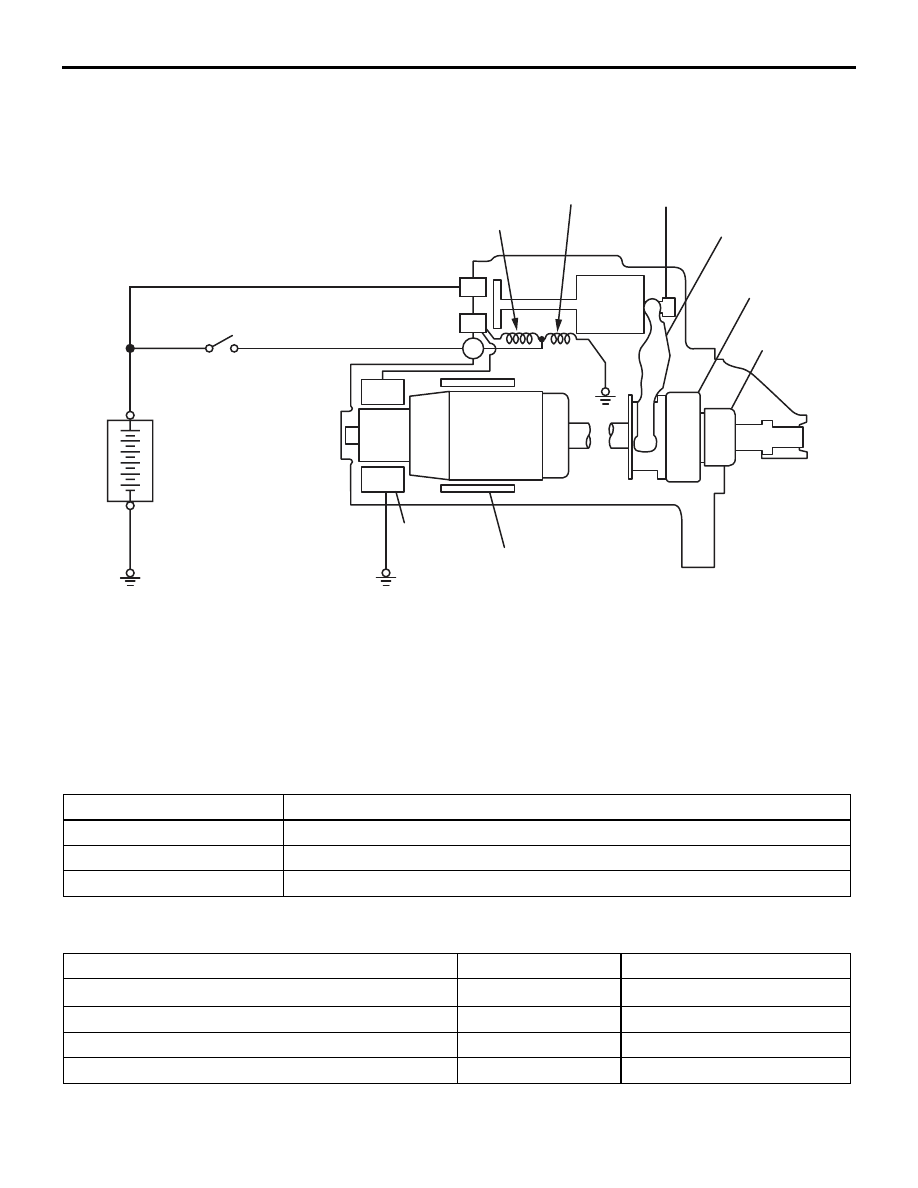

SYSTEM DIAGRAM

AK202970

Pull-in coil

Holding coil

Plunger

Lever

Pinion gear

Overrunning clutch

Yoke

Brush

Armature

Ignition switch

Battery

+

–

AB

B

M

S

STARTER MOTOR SPECIFICATIONS

Item

Specifications

Type

Reduction drive with planetary gear

Rated output kW/V

1.2/12

No. of pinion teeth

8

SERVICE SPECIFICATIONS

M1162000300080

Item

Standard value

Limit

Pinion gap mm

0.5

− 2.0

−

Commutator run-out mm

0.05

0.1

Commutator diameter mm

29.4

28.8

Undercut depth mm

0.5

0.2

STARTING SYSTEM

ENGINE ELECTRICAL

16-20

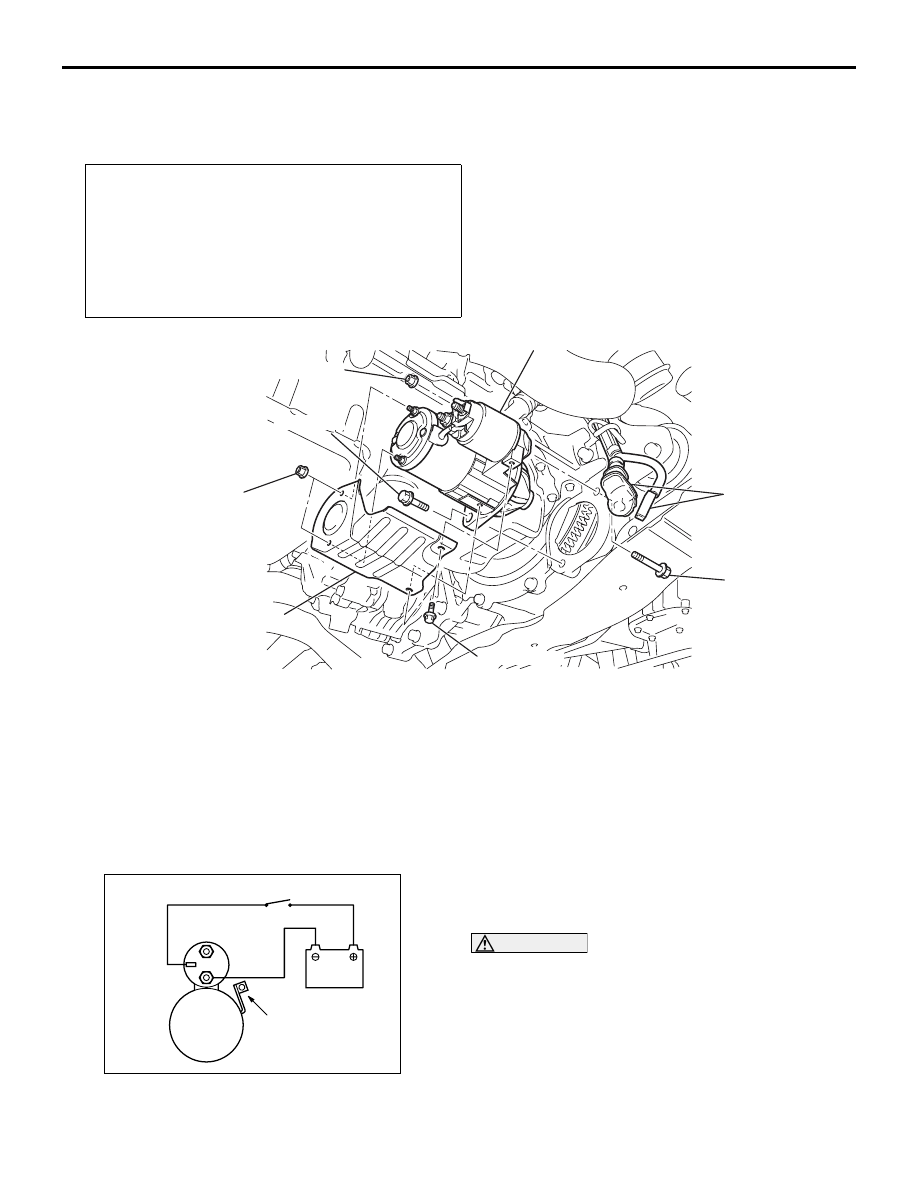

STARTER MOTOR ASSEMBLY

REMOVAL AND INSTALLATION

M1162001000781

Pre-removal and Post-installation Operation

• Under Cover Removal and Installation (Refer to GROUP

51, Front Bumper

• Crossmember Bar Removal and Installation (Refer to

GROUP 32, Engine Roll Stopper and Centremember

).

• Front Exhaust Pipe Assembly Removal and Installation

(Refer to GROUP 15, Exhaust Pipe and Main Muffler

AC210296

3

2

1

AB

4.9 ± 1.0 N·m

30 ± 3 N·m

30 ± 3 N·m

13 ± 2 N·m

4.9 ± 1.0 N·m

Removal steps

1.

Starter cover

2.

Starter connector and terminal

3.

Starter assembly

STARTER MOTOR ASSEMBLY INSPECTION

M1162001100249

PINION GAP ADJUSTMENT

AKX01239

B

M

S

Battery

Switch

Starter

motor

Wire

AF

1. Disconnect the field coil wire from the M-terminal

of the magnetic switch.

2. Connect a 12-volt battery between the S-terminal

and M-terminal.

CAUTION

This test must be performed quickly (in less than

10 seconds) to prevent the coil from burning.

3. Set the switch to "ON", and the pinion will move

out.

Removal steps (Continued)

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст