Mitsubishi Lancer Evolution IX. Manual — part 352

STARTING SYSTEM

ENGINE ELECTRICAL

16-25

BRUSHES

AK202846

Brush

height

AB

1. Check the commutator contacting surface of each

brush for abnormal roughness. Also check the

height of the brush. Replace the brush holder if

the height is lower than the limit.

Limit: 7.0 mm

2. When the contact surface of the brush is rectified

or the brush holder is replaced, recondition the

contact surface with sandpaper wrapped around

the commutator.

ARMATURE COIL

1. Check the armature coil for short circuit as

follows:

AK202733

Growler

AB

2. Set the armature in a growler.

CAUTION

Clean the surface of the armature thoroughly

before performing the test.

3. While holding a thin strip of iron against the

armature in parallel with its axis, turn the armature

slowly. The armature is normal if the iron strip is

not attracted to the armature or it does not vibrate.

AK202734

4. Check the insulation between commutator

segments and armature coils. The armature coils

are properly insulated if no continuity is present.

AK202713

5. Check continuity between a segment and another.

There is no open circuit in the tested coil if there is

continuity.

MAGNETIC SWITCH

AK202891

A

M terminal

AB

1. Coil open circuit test

• Check that there is continuity between the M ter-

minal and body A.

• If there is no continuity, replace the magnetic

switch.

AK202892

M terminal

B terminal

AB

IGNITION SYSTEM

ENGINE ELECTRICAL

16-26

2. Contact fusion check

• Check that there is no continuity between the B

terminal and M terminal.

•

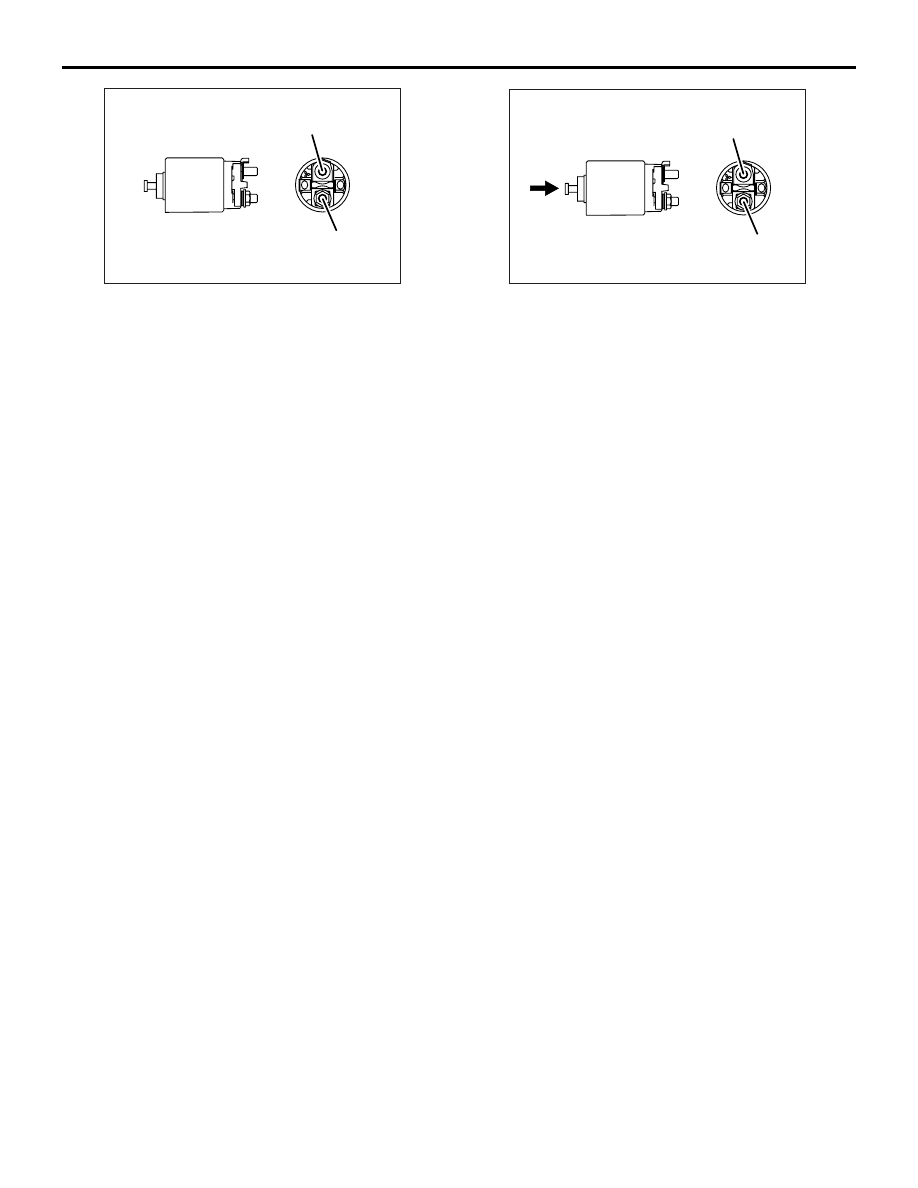

AK202893

M terminal

B terminal

AB

If there is continuity, replace the magnetic switch.

3. Switch contact check

• Push the indicated end of the magnetic switch

with a strong force to close the internal contacts.

Without releasing the switch end, check that

there is continuity between the B terminal and M

terminal.

• If there is no continuity, replace the magnetic

switch.

IGNITION SYSTEM

GENERAL INFORMATION

M1163000100614

This system is equipped with two ignition coils (A and

B) with built-in power transistors for the No. 1 and

No. 4 cylinders and the No. 2 and No. 3 cylinders

respectively.

Interruption of the primary current flowing in the pri-

mary side of ignition coil A generates a high voltage

in the secondary side of ignition coil A. The high volt-

age thus generated is applied to the spark plugs of

No. 1 and No. 4 cylinders to generate sparks. At the

time that the sparks are generated at both spark

plugs, if one cylinder is at the compression stroke,

the other cylinder is at the exhaust stroke, so that

ignition of the compressed air/fuel mixture occurs

only for the cylinder which is at the compression

stroke.

In the same way, when the primary current flowing in

ignition coil B is interrupted, the high voltage thus

generated is applied to the spark plugs of No. 2 and

No. 3 cylinders.

The engine-ECU turns the two power transistors

inside the ignition coils alternately on and off. This

causes the primary currents in the ignition coils to be

alternately interrupted and allowed to flow to fire the

cylinders in the order 1-3-4-2.

The engine-ECU determines which ignition coil

should be controlled by means of the signals from

the camshaft position sensor which is incorporated in

the camshaft and from the crank angle sensor which

is incorporated in the crankshaft. It also detects the

crankshaft position in order to provide ignition at the

most appropriate timing in response to the engine

operation conditions. It also detects the crankshaft

position in order to provide ignition at the most

appropriate timing in response to the engine opera-

tion conditions.

When the engine is cold or operated at high alti-

tudes, the ignition timing is slightly advanced to pro-

vide optimum performance.

IGNITION SYSTEM

ENGINE ELECTRICAL

16-27

SYSTEM DIAGRAM

AK101074

Air flow sensor

Intake air temperature

sensor

Engine coolant

temperature sensor

Camshaft position

sensor

Crank angle sensor

Barometric pressure

sensor

Detonation sensor

Vehicle speed

sensor

Ignition switch-ST

Engine-ECU

Ignition coil B

Cylinder No.

2

3

4

AH

1

Spark plug

Ignition coil A

Ignition

switch

Battery

IGNITION COIL SPECIFICATION

Item

Specification

Type

Molded 2-coil

SPARK PLUG SPECIFICATIONS

Item

Specifications

NGK

ILFR7H

SERVICE SPECIFICATIONS

M1163000300403

IGNITION COIL

Item

Standard value

Secondary coil resistance k

Ω

8.5

− 11.5

SPARK PLUG

Item

Standard value

Limit

Spark plug gap mm

0.5

− 0.6

0.75

SPARK PLUG CABLE

Item

Standard value

Limit

Resistance k

Ω

−

Maximum 19

IGNITION SYSTEM

ENGINE ELECTRICAL

16-28

SPECIAL TOOL

M1163000600288

Tool

Number

Name

Use

MD998773

Detonation sensor

wrench

Detonation sensor

removal and installation

ON-VEHICLE SERVICE

IGNITION COIL (WITH BUILT-IN POWER TRANSISTOR) CHECK

M1163001200614

Check by the following procedure, and replace if

there is a malfunction.

SECONDARY COIL RESISTANCE CHECK

AKX01264

Measure the resistance between the high-voltage

terminals of the ignition coil.

Standard value: 8.5

− 11.5 kΩ

PRIMARY COIL AND POWER TRANSIS-

TOR CONTINUITY CHECK

NOTE:

.

•

AK501917

1 2 3

AB

1.5 V

+

–

An analogue-type circuit tester should be used.

•

Connect the negative (-) prove of the circuit tester

to terminal No. 1.

CAUTION

This test must be performed quickly (in less than

10 seconds) to prevent coil from burning and

power transistor from breakage.

1.5 V power supply

between 2

− 3

Continuity between 1

−

2

When current is flowing

Continuity

When current is not

flowing

No continuity

IGNITION COIL RELAY CHECK <RH

DRIVE VEHICLES>

M1163006500029

CAUTION

The top and bottom of the ignition coil relay are

difficult to identify. The triangle mark on the relay

surface should be uppermost.

AC311402AB

1. Removal the ignition coil relay.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст