Mitsubishi Lancer Evolution IX. Manual — part 349

AC406359

1

7

6

4

8

5

10

9

11

AB

3

9.0 ± 1.0 N·m

12

13

14

15

16

17

18

11 ± 1 N·m

22 ± 4 N·m

24 ± 4 N·m

44 ± 10 N·m

20 ± 2 N·m

5.0 ± 1.0 N·m

8.8 ± 1.0 N·m

13 ± 1 N·m

N

9.0 ± 1.0 N·m

2

5.0 ± 1.0 N·m

(Engine oil)

Removal steps

1.

Fuel injector connectors

2.

Accelerator cable connection

<<

A

>>

3.

Fuel injector, delivery pipe, fuel

return pipe and fuel pressure

regulator assembly

4.

Insulators

5.

Insulators

6.

Fuel pressure solenoid valve

connector

7.

Fuel pressure solenoid valve

8.

Detonation sensor connector

9.

Purge control solenoid valve

connector

10. Purge control solenoid valve

11. Oil level gauge and guide assembly

12. O-ring

<<

B

>>

13. Drive belt

14. Alternator connector and terminal

•

Engine front mounting bracket

(Refer to GROUP 32, Engine

Mounting

).

<<

C

>>

15. Alternator

16. Water pump pulley

17. Crank angle sensor connector

18. Alternator bracket

CHARGING SYSTEM

ENGINE ELECTRICAL

16-13

Removal steps (Continued)

CHARGING SYSTEM

ENGINE ELECTRICAL

16-14

REMOVAL SERVICE POINTS

<<A>> FUEL INJECTOR, DELIVERY PIPE,

FUEL RETURN PIPE AND FUEL PRES-

SURE REGULATOR ASSEMBLY

REMOVAL

After loosening the delivery pipe mounting bolts,

move the fuel injector, delivery pipe, fuel return pipe

and the fuel pressure regulator as an assembly aside

in order to make room for the alternator removal.

<<B>> DRIVE BELT REMOVAL

The following operations will be needed due to the

introduction of the serpentine drive system with the

drive belt auto-tensioner.

AC210996 AB

Auto-

tensioner

Hole A

Hole B

1. Securely insert the spindle handle or ratchet

handle with a 12.7 mm insertion angle into the jig

hole of the auto-tensioner.

2. Rotate the auto-tensioner anti-clockwise and align

hole A with hole B.

CAUTION

To reuse the drive belt, draw an arrow indicating

the rotating direction (clockwise) on the back of

the belt using chalk, etc.

AC210998AB

L-shaped

hexagon

wrench

Auto-

tensioner

3. Insert an L-shaped hexagon wrench, etc. into the

hole to fix and then remove the drive belt.

<<C>> ALTERNATOR REMOVAL

Raise the engine with a floor jack and remove the

alternator upward from the engine room.

CHARGING SYSTEM

ENGINE ELECTRICAL

16-15

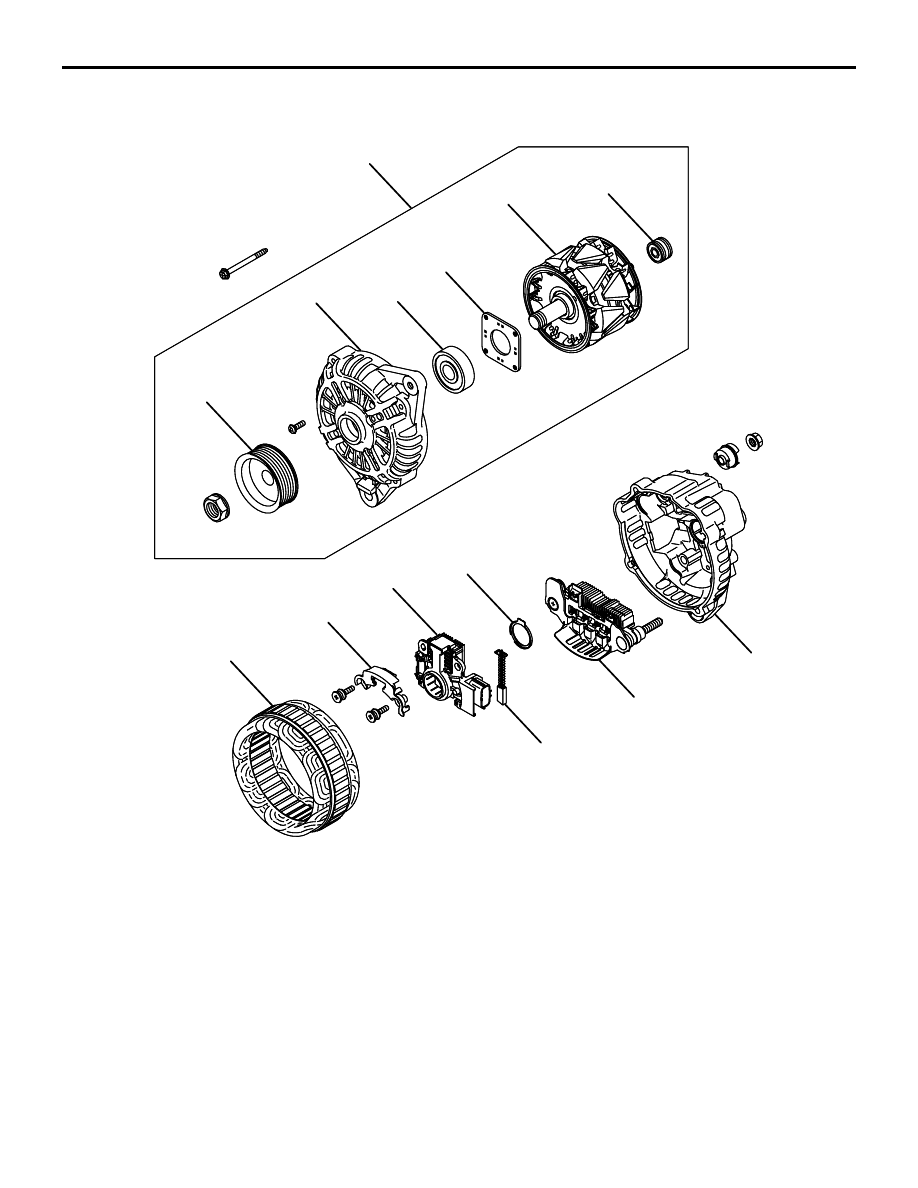

DISASSEMBLY AND REASSEMBLY

M1161001600199

AK202845

1

2

3

4

5

6

7

8

9

10

11

12

13

14

AB

Disassembly steps

<<

A>>

1. Front bracket assembly

<<

B>>

2. Alternator pulley

>>B

<< 3. Rotor

4. Rear bearing

5. Bearing retainer

6. Front bearing

7. Front bracket

<<

C>>

8. Stator

9. Plate

<<

C>> >>A

<< 10. Regulator assembly

11. Brush

12. Rubber packing

13. Rectifier

14. Rear bracket

Disassembly steps (Continued)

CHARGING SYSTEM

ENGINE ELECTRICAL

16-16

DISASSEMBLY SERVICE POINTS

<<A>> FRONT BRACKET ASSEMBLY

REMOVAL

AK202718

CAUTION

Do not insert the screwdriver blades too deep.

Doing so could damage the stator coil.

Insert the blades of screwdrivers between the front

bracket assembly and stator core, and pry and sepa-

rate them with the screwdrivers.

<<B>> ALTERNATOR PULLEY REMOVAL

AK202714

CAUTION

Perform operation carefully not to damage the

rotor.

Clamp the rotor in a vise with the pulley facing up to

remove the pulley.

<<C>> STATOR / REGULATOR

ASSEMBLY REMOVAL

AK202778

Solder

Solder

Rectifier

assembly

AB

CAUTION

• Use a 180 − 250 W soldering iron, and finish

unsoldering within four seconds. Diodes will

be damaged by heat if unsoldering time is too

long.

• Avoid applying undue force to the diode

leads.

1. Unsolder the stator leads from the main diode of

the rectifier assembly when the stator is removed.

2. When removing the rectifier assembly from the

regulator assembly, undo the soldered points on

the rectifier assembly.

REASSEMBLY SERVICE POINTS

>>A<< REGULATOR ASSEMBLY INSTAL-

LATION

AK202779

Wire

AB

AK202830

Rear bracket

Brush

Wire

AB

After installing the regulator assembly, insert a piece

of wire through the hole in the rear bracket while

pressing the brush to keep the brush against move-

ment.

NOTE: Holding the brush with the wire facilities

installation of the rotor.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст