Mitsubishi Eclipse / Eclipse Spyder (2000-2002). Service and repair manual — part 143

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <2.4L ENGINE>

13A-271

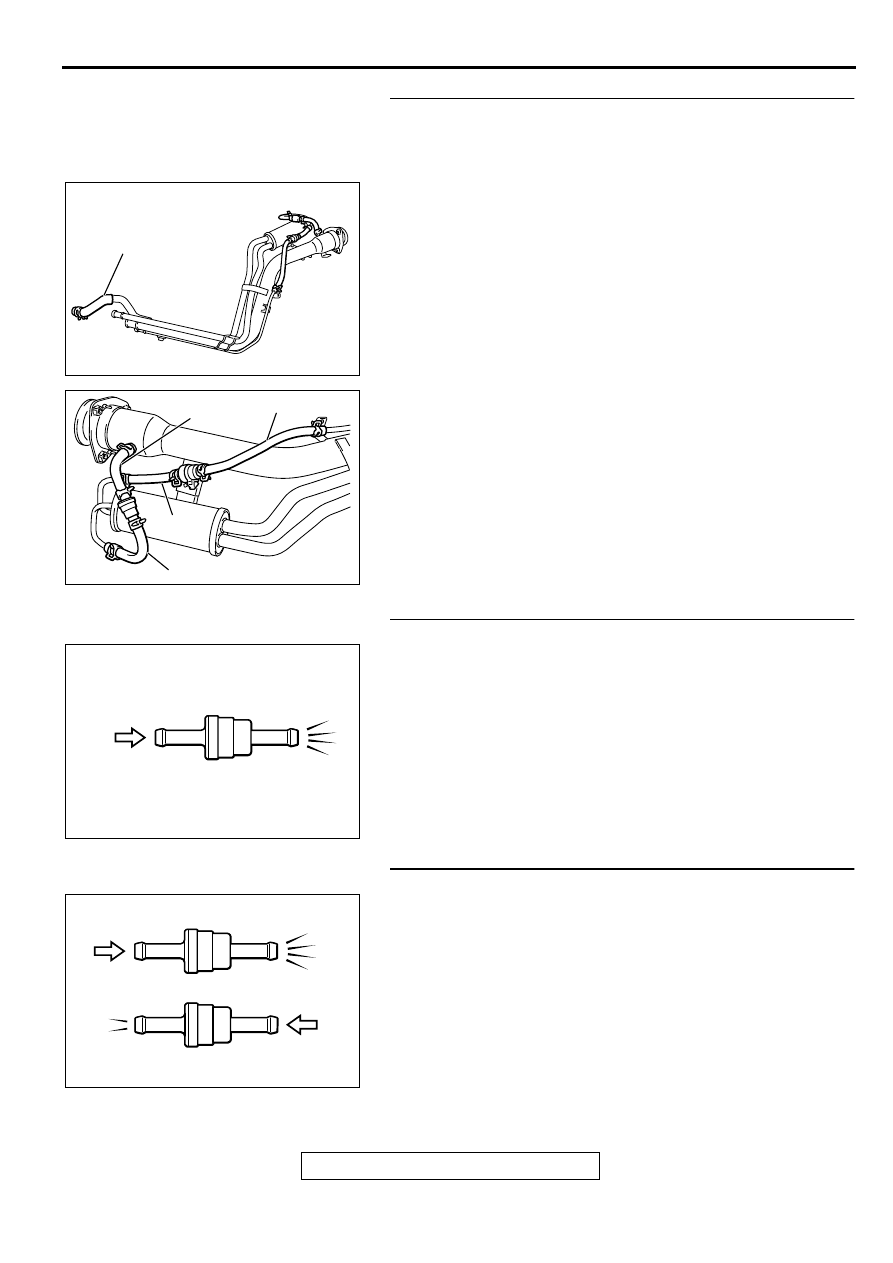

STEP 13. Check for leaks in the evaporator line hose G, J,

K, L and hose M.

(1) Remove the filler neck assembly. (Refer to GROUP 13C,

Fuel tank

(2) Sequentially apply vacuum with a hand vacuum pump

connected to hose G, J, K, L and hose M.

Q: Can the leaks be pinpointed?

YES : Replace that hose, reinstall the filler neck assembly.

Then go to Step 34.

NO : Go to Step 14.

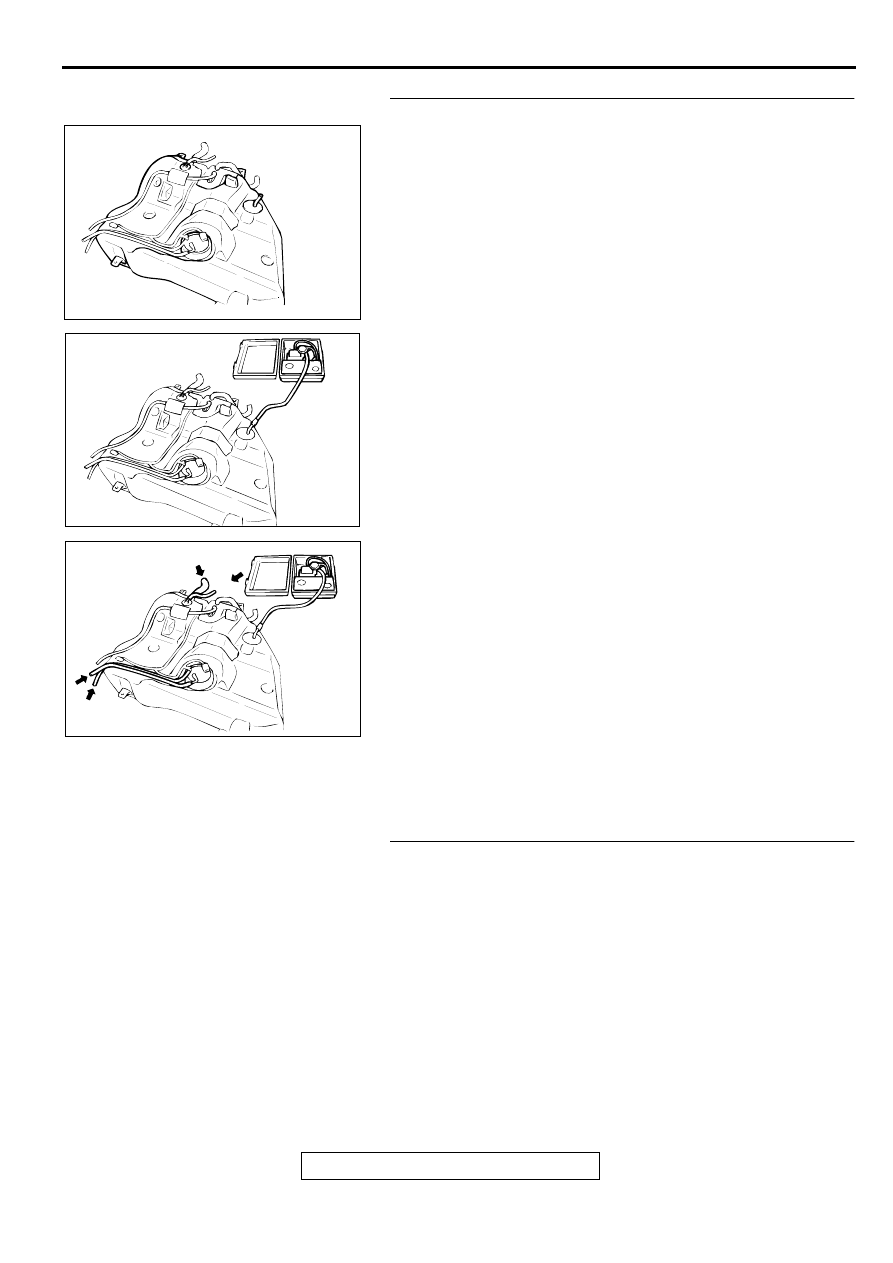

STEP 14. Check the check valve A.

(1) Only when you blow the check valve from the direction

shown, it should pass air.

(2) When you blow the check valve, on air should leak from the

check valve body.

Q: Is there any failure?

YES : Replace it, reinstall the filler neck assembly. Then go

to Step 34.

NO : Go to Step 15.

STEP 15. Check the check valve B.

(1) When you blow the check valve from the arrow direction

shown above, it should pass more air.

(2) When you blow the check valve from the arrow direction

shown below, it should pass less air.

(3) When you blow the check valve, on air should leak from the

check valve body.

Q: Is there any failure?

YES : Replace it, reinstall the filler neck assembly and filler

neck protector. Then go to Step 34.

NO : Go to Step 16.

AC002032

AB

HOSE G

AC

AC002039

AB

HOSE L

AC

HOSE K

HOSE M

HOSE J

AC002076 AB

CHECK VALVE A

AC002078

CHECK VALVE B

AB

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <2.4L ENGINE>

13A-272

STEP 16. Check for leaks in the evaporator line from hose

H to hose I.

(1) Disconnect hose H at the liquid separator side, and then

connect a hand vacuum pump to the hose.

(2) Disconnect hose I at the fuel tank side, and then plug the

hose.

(3) Apply vacuum by using the hand vacuum pump.

Q: Is the vacuum maintained inside the evaporator line?

YES : Go to Step 17.

NO : Go to Step 20.

STEP 17. Check for leaks in the evaporator line from hose

N.

(1) Remove the fuel tank. (Refer to GROUP 13C, Fuel Tank

(2) The leakage test with a hand vacuum pump on each hose

from hose N.

Q: Can the leaks be pinpointed?

YES : Replace that hose. Then go to Step 34.

NO : Go to Step 18.

AC02040 AC

HOSE H

AC002038

HOSE I

AC

AC000195

HOSE N

AD

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <2.4L ENGINE>

13A-273

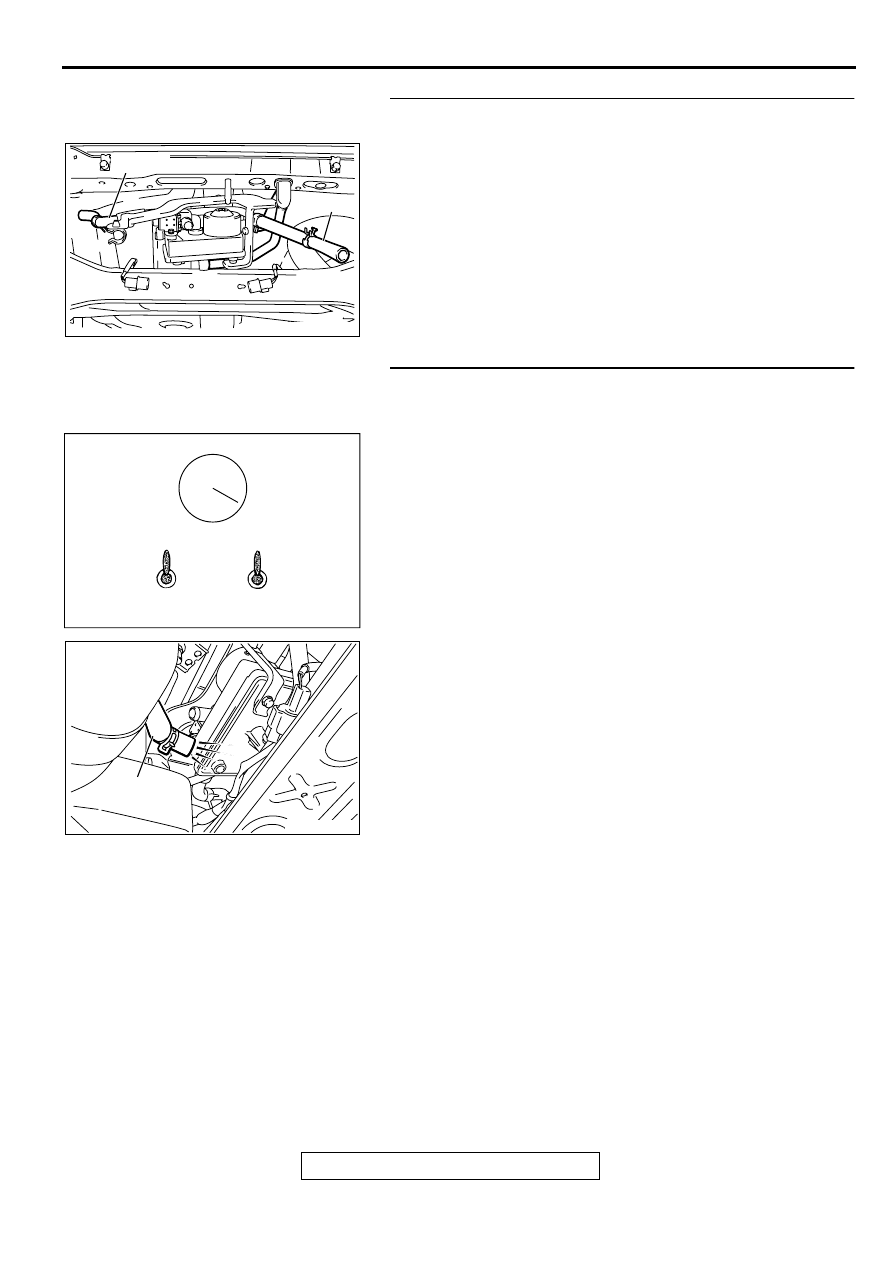

STEP 18. Check for leaks in the fuel tank.

(1) Visually check for cracks and leaks, etc.

NOTE: Carefully check the fuel pump assembly and the

inner pressure sensor installation section in the fuel tank.

(2) Connect an evaporative emission system pressure pump to

the leveling valve nipple.

(3) Plug the filler hose, feed pipe, return pipe and rollover valve

nipple connected to the fuel tank.

NOTE: If these items are not securely plugged here, the

fuel could leak in the next step.

(4) Apply pressure with the evaporative emission system

pressure pump.

(5) In the pressurized state, check for the leak by applying soap

water, etc. to each section.

Q: Can the leaks be pinpointed?

There is leaks at the fuel pump assembly or the inner

pressure sensor installation section : Reassemble the

parts, check again that there are no leaks, reinstall

the fuel tank. Then go to Step 34.

There is leaks at another section : Go to Step 19.

STEP 19. Visually check for cracks in the fuel tank filler

neck.

(1) Visually check for cracks in the fuel tank filler neck.

Q: Can the leaks be found out?

YES : Replace the fuel tank filler neck assembly and

reinstall the fuel tank. Then go to Step 34.

NO : Reinstall the fuel tank.Then go to Step 34.

AC000196

AC000197

AC000198

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <2.4L ENGINE>

13A-274

STEP 20. Check for leaks in the evaporator line from hose

H to hose I.

(1) The leakage test with a hand vacuum pump on each hose

from hose H to hose I.

Q: Can the leaks be pin pointed?

YES : Replace that hose, and go to Step 34.

NO : Go to Step 34.

STEP 21. Check for clogging in the evaporator line from

hose E to hose G.

(1) Unplug hose E.

(2) On the EVAP pressure pump, set the pressure/hold valve to

OPEN, and set the vent valve to CLOSED. Turn the pump

timer to ON. You can reset the timer as required. (These

settings are listed under "Leak Test" in the pump

instructions.)

(3) Air should pass through hose E.

Q: Does air pass through hose E?

YES : Go to Step 25.

NO : Go to Step 22.

AC002033 AD

HOSE H

HOSE I

OPEN

OPEN

CLOSED

CLOSED

Pressure

Hold

Vent

ACX01806

AC002029

HOSE E

AC

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст