Mitsubishi Eclipse / Eclipse Spyder (2000-2002). Service and repair manual — part 141

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <2.4L ENGINE>

13A-263

STEP 24. Check for clogging in the evaporator line from

hose E and hose F.

(1) Remove the fuel tank. (Refer to GROUP 13C, Fuel Tank

(2) Carry out the clogging test with a hand vacuum pump on

each hose from hose E and hose F.

Q: Are there any clogs?

YES : Replace that hose, reinstall the fuel tank. Then go to

Step 26.

NO : Go to Step25.

STEP 25. Check for clogging in the evaporative emission

canister.

(1) Connect a hand vacuum pump to the vent nipple of the

evaporative emission canister.

(2) Plug the other two nipples or loop a hose between the other

nipples.

(3) Apply vacuum. When each nipple is unplugged, the vacuum

should fluctuate.

Q: Does the vacuum pump gauge reading fluctuate?

YES : Reinstall the fuel tank. Then go to Step 26.

NO : Replace the evaporative emission canister, reinstall

the fuel tank. Then go to Step 26.

STEP 26. Test the OBD-II drive cycle.

(1) Carry out a test drive with the drive cycle pattern. (Refer to

, Procedure 1

−

Evaporative Emission Control

system Leak Monitor.)

(2) Read the diagnostic trouble code P0450 does not reset.

Q: Are the DTCs reset?

YES : This diagnosis is complete. (If no malfunctions are not

found in all steps, an intermittent malfunction is

suspected.) Refer to GROUP INTRODUCTION, How

to Use Troubleshooting/Inspection Service Points

−

How to Cope with Intermittent Malfunction

NO : Replace the ECM or PCM.

AC002037

HOSE E

HOSE F

AF

AC000191AB

VENT

NIPPLE

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <2.4L ENGINE>

13A-264

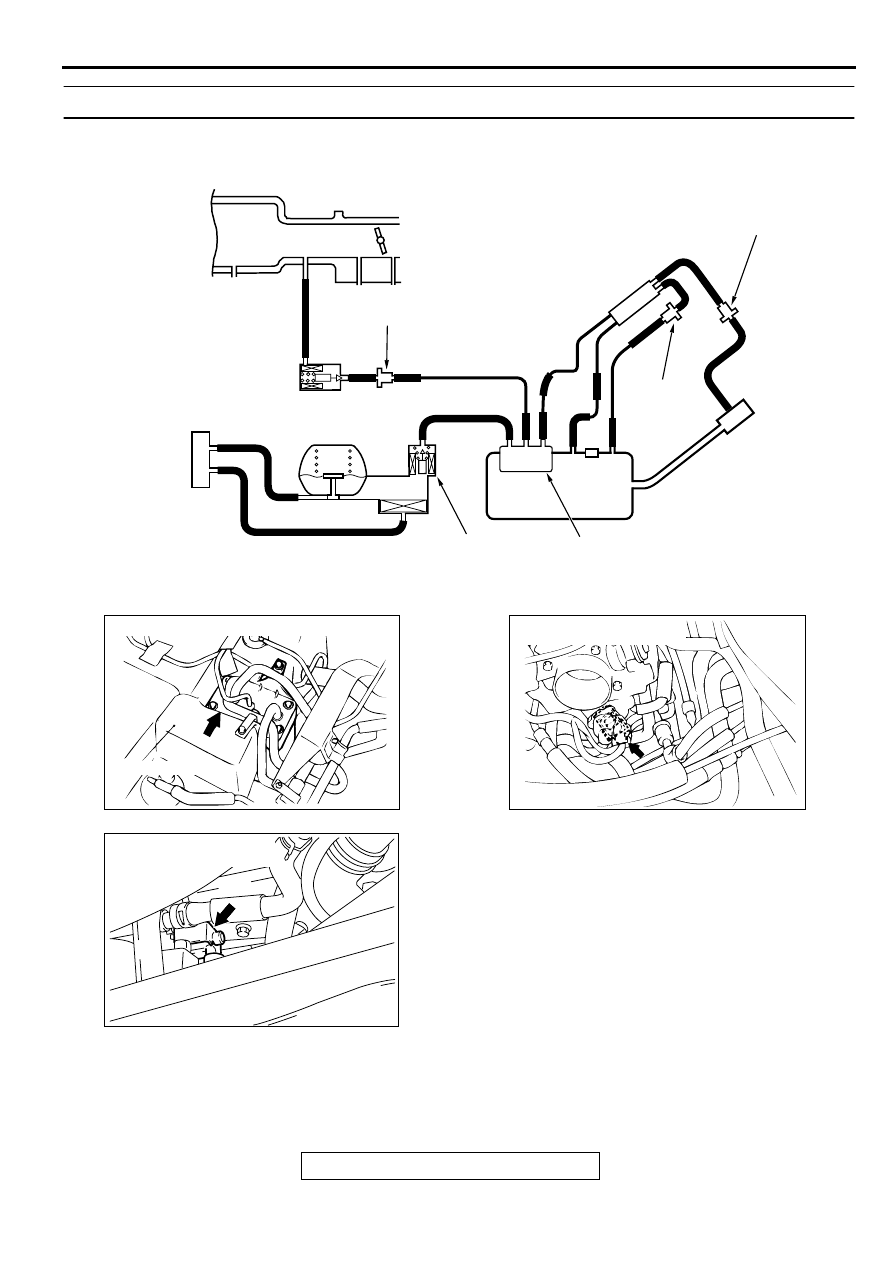

DTC P0455: Evaporative Emission Control System Leak Detected (Gross Leak)

TECHNICAL DESCRIPTION

•

To judge if there is leak or clog in the fuel system,

the ECM <M/T> or PCM <A/T> measures the

change of the pressure inside the fuel tank.

•

The ECM <M/T> or PCM <A/T> turns on the

evaporative emission ventilation solenoid to shut

off the evaporative emission canister outlet port.

AC001943AB

A

B

C

EVAPORATIVE EMISSION

PURGE SOLENOID

EVAPORATIVE

EMISSION CANISTER

EVAPORATIVE

EMISSION

VENTILATION

SOLENOID

FUEL TANK

CHECK VALVE A

CHECK

VALVE B

INTAKE MANIFOLD

SYSTEM DIAGRAM

D

E

F

G

I

H

L

N

M

K

J

O

P

CHAMBER

AC000183AB

EVAPORATIVE EMISSION CANISTER

FUEL TANK

AC000182

EVAPORATIVE EMISSION

PURGE SOLENOID

AB

AC002035AB

EVAPORATIVE EMISSION

VENTILATION SOLENOID

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <2.4L ENGINE>

13A-265

•

Then the evaporative emission purge solenoid is

driven to set the fuel system into a negative

pressure.

•

When the fuel system develops a vacuum of 2

kPa (0.29 psi), the evaporative emission purge

solenoid is turned "off" and the fuel system

vacuum is maintained at 2 kPa (0.29 psi.)

•

The ECM <M/T> or PCM <A/T> determines if

there is leak or clog in the fuel system by

measuring the change of vacuum inside the fuel

tank.

•

The test is stopped when fuel vapor pressure is

judged as too high.

DTC SET CONDITIONS

Test Conditions A: At Start up

•

Intake air temperature is 30

°

C (86

°

F) or less

when the engine is started.

•

The engine coolant temperature is 30

°

C (86

°

F) or

less when the engine is started.

Test Conditions B: For Test to Run

•

With in 16 minutes after the engine is started.

•

Engine coolant temperature is higher than 60

°

C

(140

°

F.)

•

Engine speed is 1,600 r/min or more.

•

Power steering pressure switch: "OFF."

•

Barometric pressure is above 76 kPa (11 psi.)

•

Volumetric efficiency is between 20 and 80

percent.

•

Vehicle speed is 30 km/h (18.7 mph) or more.

Test Conditions C: For Test to Stop

•

Intake air temperature is less than 5

°

C (41

°

F.)

•

When the evaporative emission purge solenoid

and evaporative emission ventilation solenoid are

closed, the pressure rises to 451 Pa (0.065 psi.)

•

The pressure fluctuation width is less than 647

Pa (0.094 psi.)

•

Fuel tank differential pressure sensor output

voltage 1

−

4 V.

Judgment Criteria

•

The fluctuation of fuel tank internal pressure is

less than 324 Pa (0.047 psi) in 20 seconds after

the evaporative emission purge solenoid had

been driven when the fuel tank and vapor line

were closed.

NOTE: The monitoring time (75

−

125 seconds.)

depends on the fuel level and the temperature in the

fuel tank.

TROUBLESHOOTING HINTS

The most likely causes for this code to be set are:

•

Loose fuel cap.

•

Fuel cap relief pressure is incorrect.

•

Fuel overflow limiter valve failed.

•

Purge line or vapor line is clogged.

•

Fuel tank, purge line or vapor line seal failed.

•

Evaporative emission purge solenoid failed.

•

Evaporative emission ventilation solenoid failed.

•

Fuel tank differential pressure sensor failed.

•

Evaporative emission canister seal is faulty.

•

Evaporative emission canister is clogged.

OVERVIEW OF TROUBLESHOOTING

•

To determine the cause of DTC P0455, a

performance test is needed. The performance

test uses a mechanical vacuum gauge and scan

tool MB991502 set on the fuel tank differential

pressure sensor (TANK PRES SNER 73.) The

mechanical gauge reading is used to verify scan

tool MB991502 reading. A comparison of the

mechanical gauge reading to the scan tool

MB991502 reading determines the reading

problem in the system.

•

Prior to doing the performance test, several

simple inspections are needed to exclude some

possibilities of the symptom.

DIAGNOSIS

Required Special Tool:

MB991502: Scan Tool (MUT-II)

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <2.4L ENGINE>

13A-266

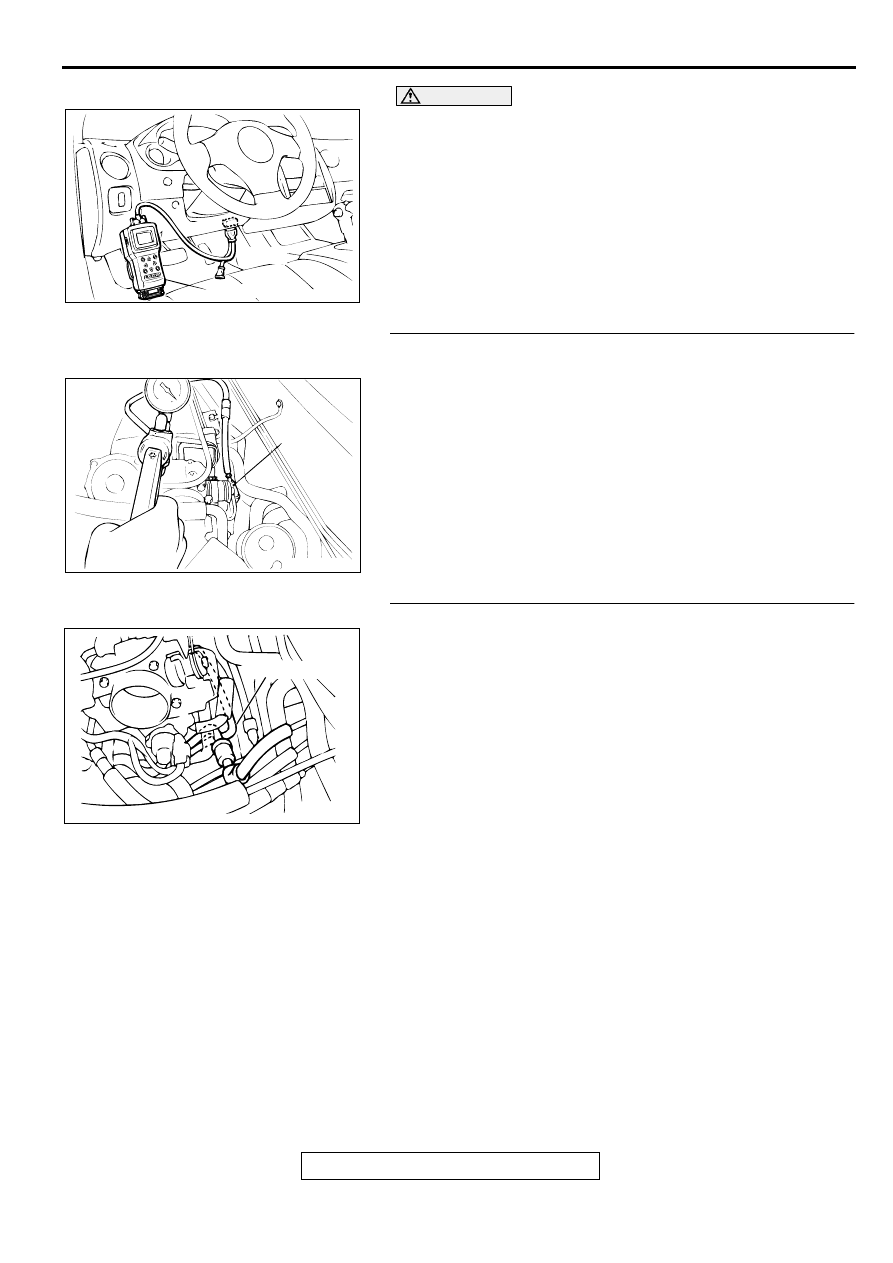

CAUTION

To prevent damage to scan tool MB991502, always turn the

ignition switch to the "LOCK" (OFF) position before

connecting or disconnecting scan tool MB991502.

In this procedure, scan tool MB991502 should be used in the

metric mode (showing the value in kPa). If not, set scan tool

MB991502 by selecting the "System Setup" at the main menu.

STEP 1. Check for leaks in the evaporator line hose A and

evaporative emission purge solenoid valve.

(1) Disconnect hose A at the intake manifold side, and then

connect a hand vacuum pump to the hose.

(2) Apply vacuum.

NOTE: The vacuum should be 40 kPa (5.8 psi) or less.

Q: Is the vacuum maintained?

YES : Go to Step 4.

NO : Go to Step 2.

STEP 2. Check for leaks in the evaporator line hose A.

(1) The leakage test with a hand vacuum pump on hose A.

Q: Are there any leaks?

YES : Replace that hose. Then go to Step 34.

NO : Go to Step 3.

AC001252

MB991502

16 PIN

AB

AC000222

HOSE A

AB

AC000223

HOSE A

AB

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст