Defender (1993+). Manual — part 47

LT77S

MANUAL GEARBOX

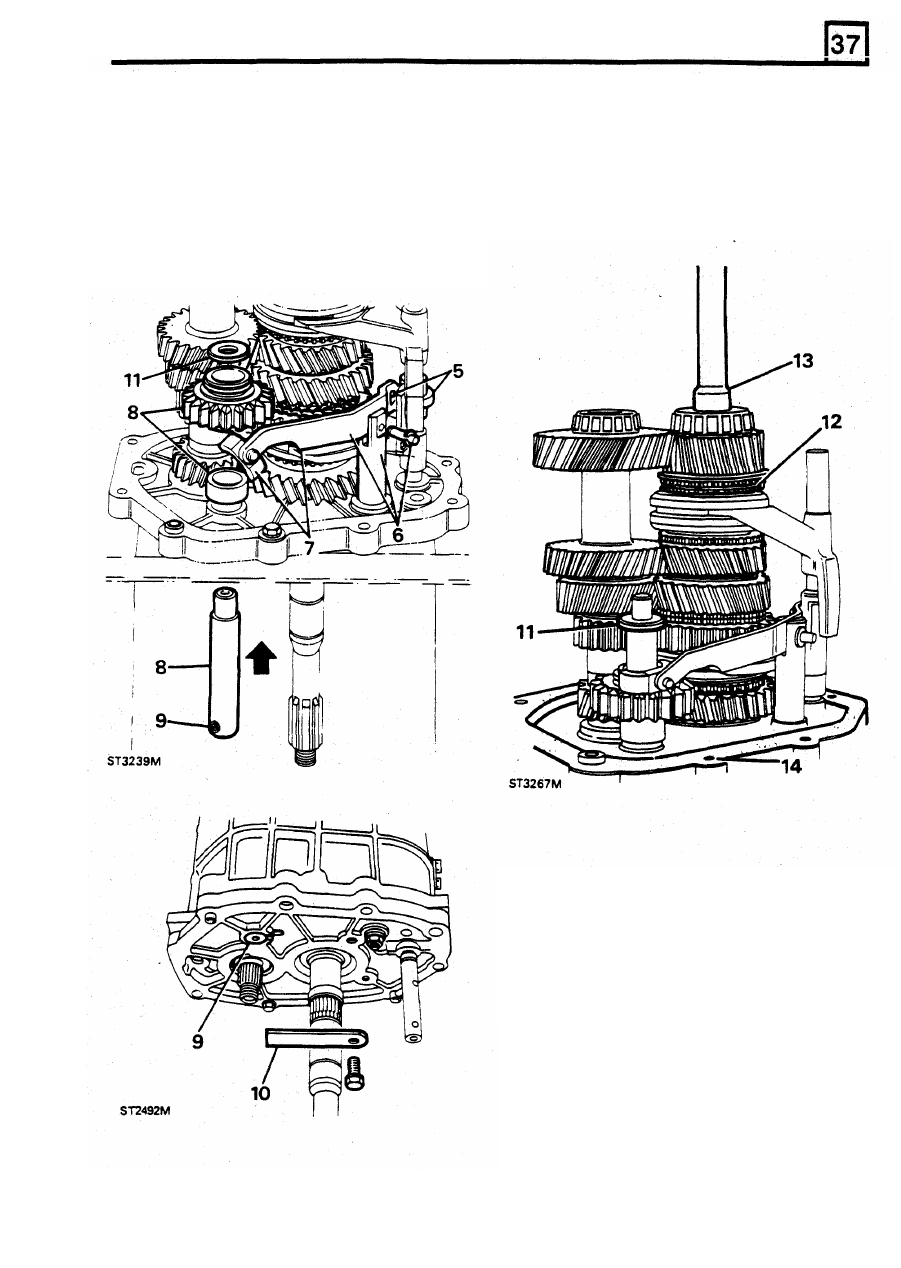

4.

Fit layshaft while lifting mainshaft to clear

10.

Secure reverse shaft with manufactured tool

5.

Turn selector shaft and interlock spool to

11.

Fit reverse gear thrust washer to shaft.

allow reverse lever to engage spool flange.

6.

Fit reverse lever

to

pivot post and secure with

pin and circlip.

7.

Fit slipper pad to lever.

gasket.

8. Fit reverse gear shaft, spacer and gear.

9. Fit slipper to

reverse

gear and ensure roll pin

in

shaft engages

in slot in

centre plate.

layshaft rear bearing.

"A".

12.

Fit fourth gear baulk ring.

13.

Lubricate spigot bearing and

fit

input shaft.

14.

Remove centre plate workstand bolt and fit

REISSUED: FEB 1993

29

LT77S MANUAL

GEARBOX

FITTING

GEARBOX

CASING

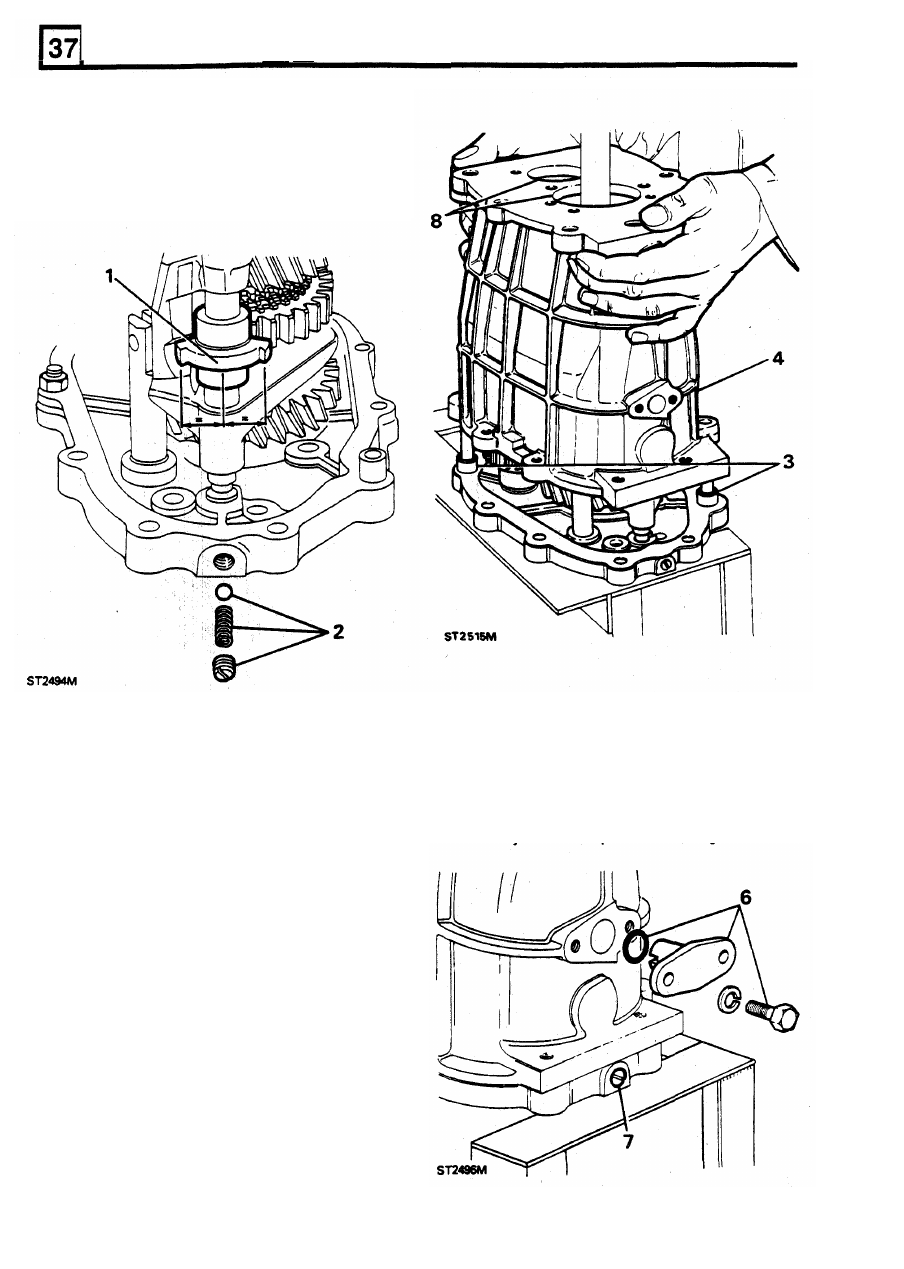

1.

Turn selector shaft and spool to neutral

2.

Fit out-board detent ball and spring and

position.

secure with plug.

CAUTION: Do not use force to fit retainer.

Provided the spool has not been disturbed the

retainer will slide into position. If not, remove the

gear case and reposition spool or shaft.

3. Fit guide studs to casing and check oil scoop

is correctly fitted.

4. Without using force, fit gearcase.

NOTE: Ensure that the centre plate dowels and

selector shaft are properly located.

7. Remove detent plug, apply Loctite 290 or

Hylomar PL 32 to thread, refit and stake.

8

Fit layshaft and input shaft bearing tracks.

5. Secure centre plate and gearcase to

workstand with two 8 x 35mm bolts.

6. Apply PL 32 to joint face and bolt threads and

fit spool retainer.

30

REISSUED: FEB 1993

LT77S MANUAL GEARBOX

FITTING

FIFTH GEAR

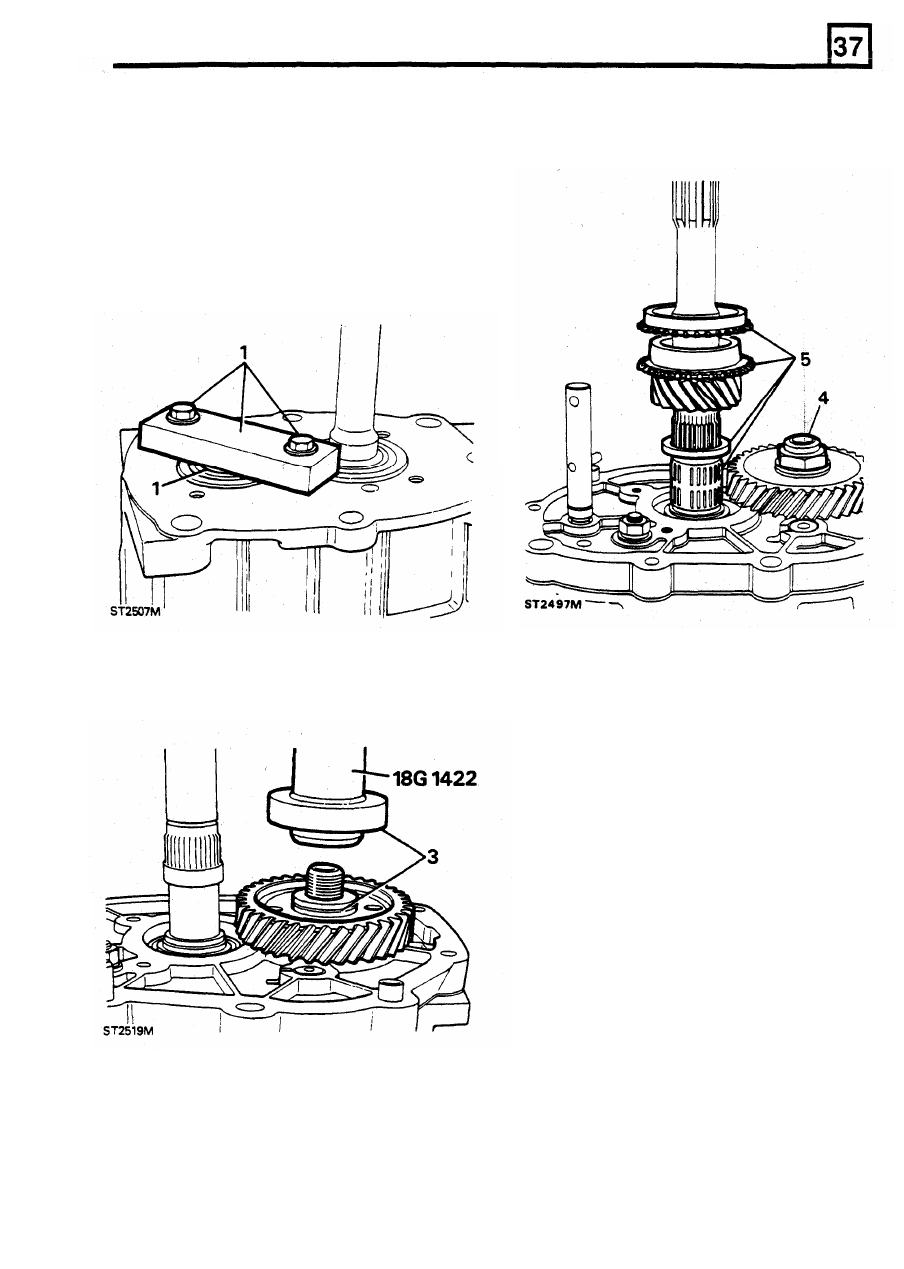

CAUTION: Since the fifth gear is a tight fit on the

layshaft, the force, when pressing the gear, must

not be transferred to the layshaft front bearing.

Tool "D" and packing disc should be made to the

dimensions given to absorb the force. The plate

also retains the input shaft bearing outer track.

4.

Fit a new stake nut but

do

not

tighten.

5.

Fit

fifth gear assembly to mainshaft.

1.

Secure Tool

"D" with two 8x25mm bolts.

Insert disc between Tool "D" and layshaft.

2.

Release and invert gearbox and remove

reverse shaft retainer plate.

3.

With the extraction groove uppermost, drive

fifth gear on to layshaft using

18G

1422.

REISSUED:

FEB

1993

31

LT77S MANUAL GEARBOX

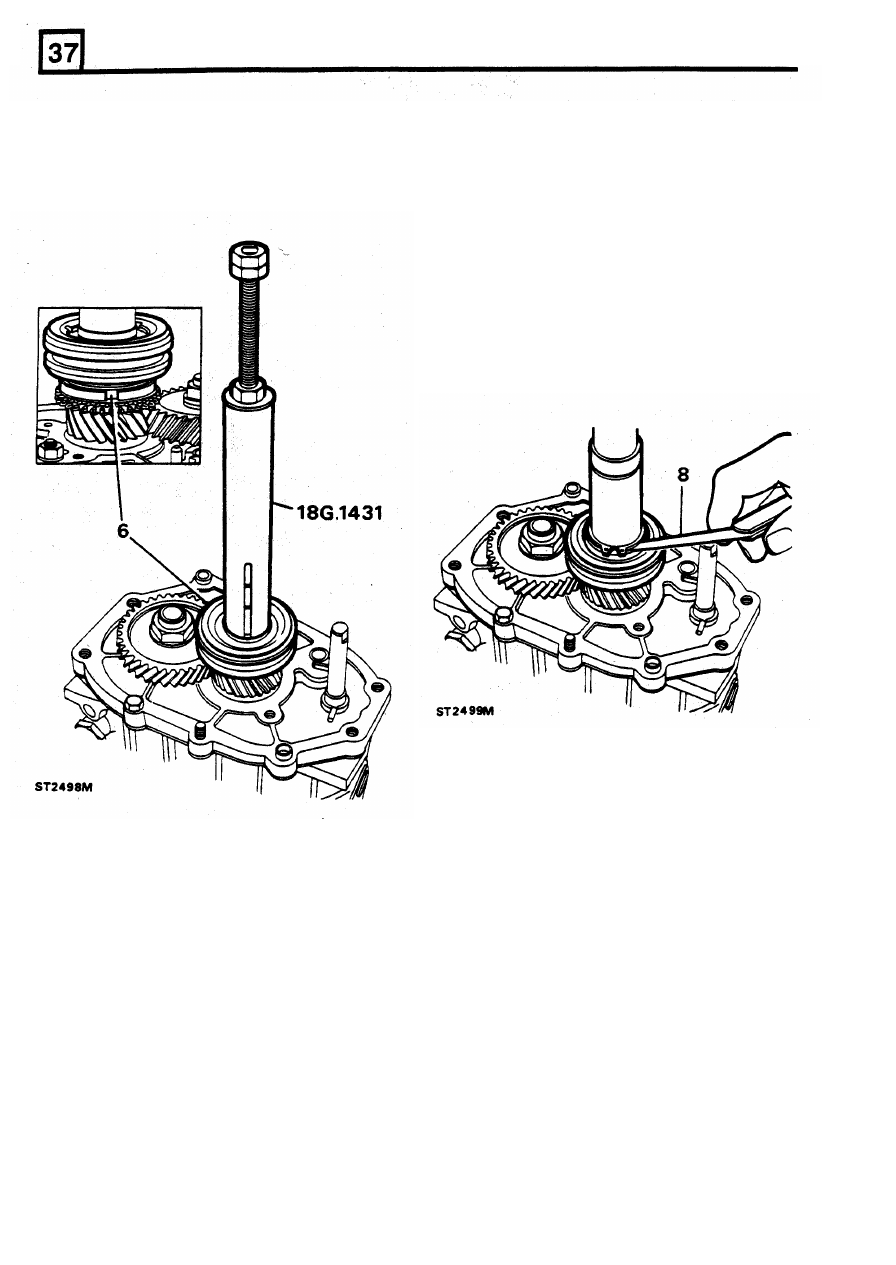

6.

Press

fifth

gear synchromesh assembly

to

Part number

Thickness

mainshaft using 18G 1431.

FRC 5284

5,10

CAUTION: Before pressing the assembly fully

FRC 5286

5,16

home, ensure that the slipper

pads locate in the

FRC 5288

5,22

baulk ring slots.

FRC 5290

5,38

FRC 5292

5,34

FRC 5294

5,40

FRC 5296

5,46

FRC 5298

5,52

FRC 5300

5,58

FRC 5302

5,64

7. Fit the thinnest washer and secure with circlip.

8. Measure clearance between circlip and

washer.

9. Tighten layshaft stake nut using 18G 1205.

CAUTION: The practice of locking gears to

provide a restraint to tighten the nut is not

acceptable due to

high torque figure required.

NOTE:

Only

limited

movement

of

the

synchromesh inner member on the main-shaft i s

permissable. The maximum clearance i s 0,005mm

t o 0,055mm (0.0002in

to

0.002in) and t o achieve

this

the following selective washers are available.

32

REISSUED: FEB 1993

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст