Defender (1993+). Manual — part 46

LT77S MANUAL GEARBOX

CAUTION: Ensure that the slots in the baulk ring

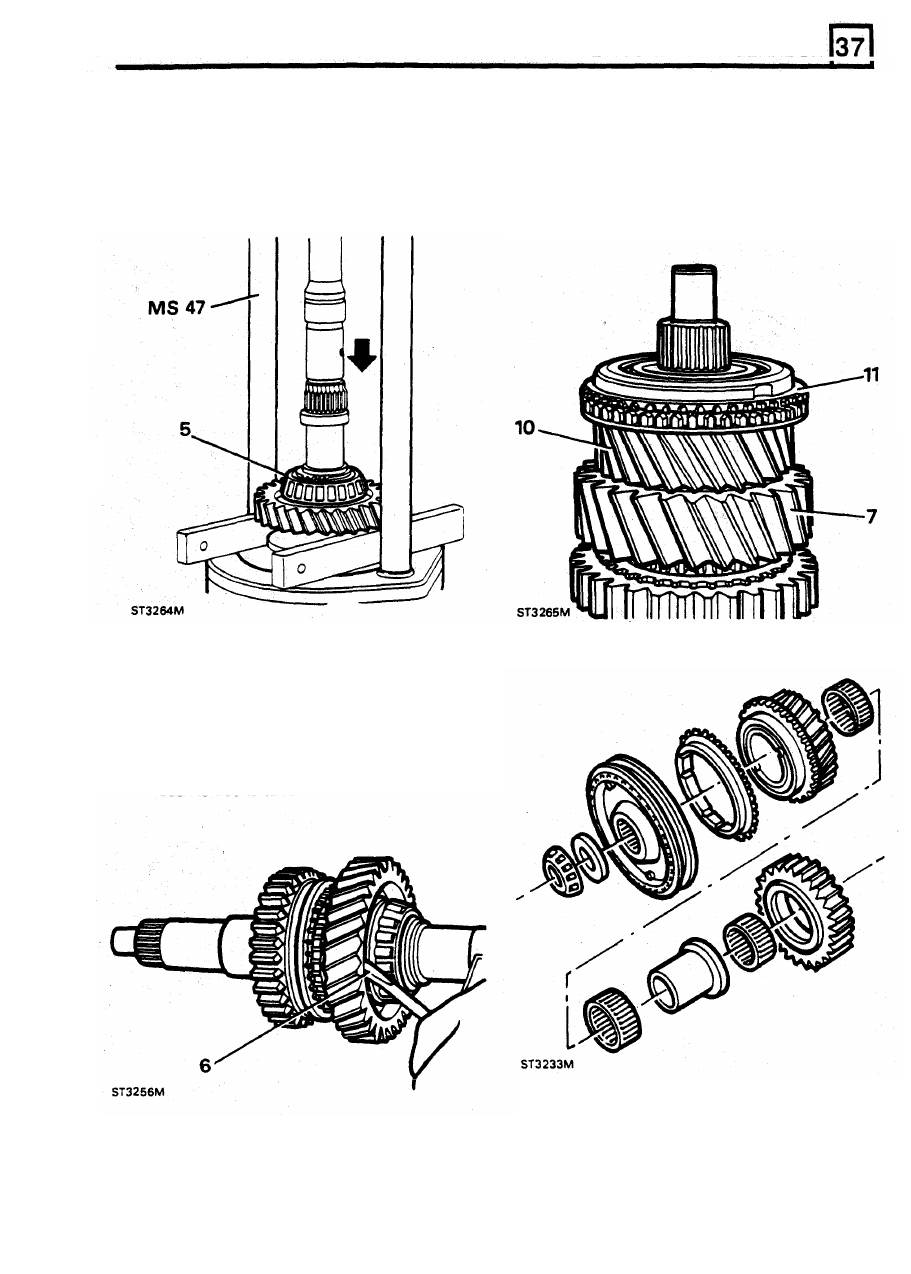

7.

Position mainshaft in

vice,

rear

end

align with the synchromesh slippers while

downwards and

fit

second gear needle roller,

pressing on the bearing.

and second gear.

8.

Fit third gear bush.

5.

Invert mainshaft and press assembly back

9. Fit third gear needle rollers.

against circlip.

10.

Fit third gear.

11.

Fit third gear baulk ring.

NOTE: Instruction 5 is necessary since

it

is

probable that when pressing on the bearing it

will have clamped the first gear bush preventing

it from turning.

6. Reposition mainshaft in vice and using a

screw driver blade check that the first gear

bush is free to turn.

Third-fourth synchomesh

assembly

REISSUED: FEB 1993

25

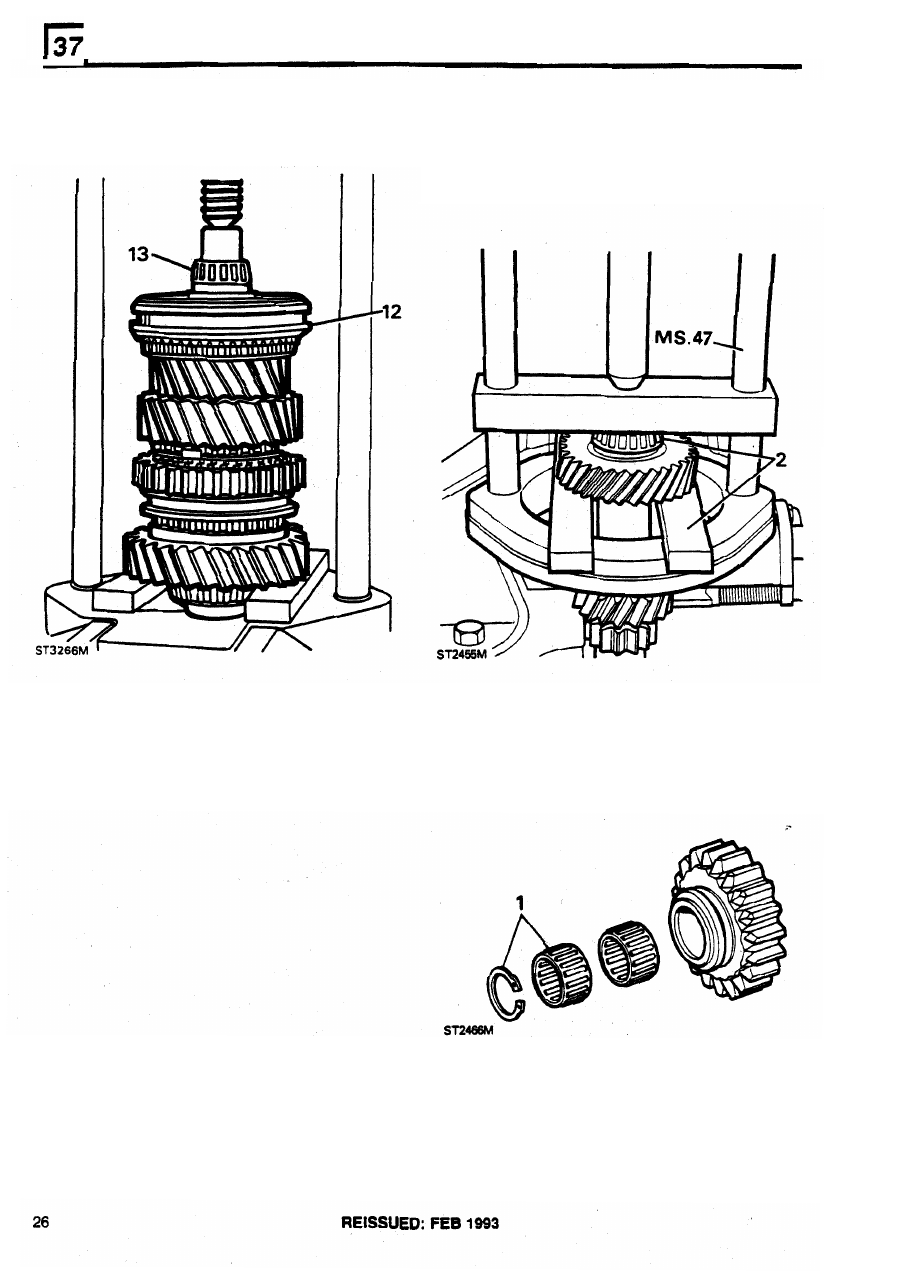

LT77S MANUAL

GEARBOX

REVERSE GEAR AND

SHAFT

1.

Remove one circlip

from

the

idler gear and

remove bearings.

12.

Fit

third-fourth gear synchromesh hub.

13. Using

MS

47

with supports under first gear,

press the spigot bearing on to shaft.

LAYSHAFT

1.

Examine the layshaft for wear and damage.

2.

Press bearings on to layshaft using MS 47

and supporting bars.

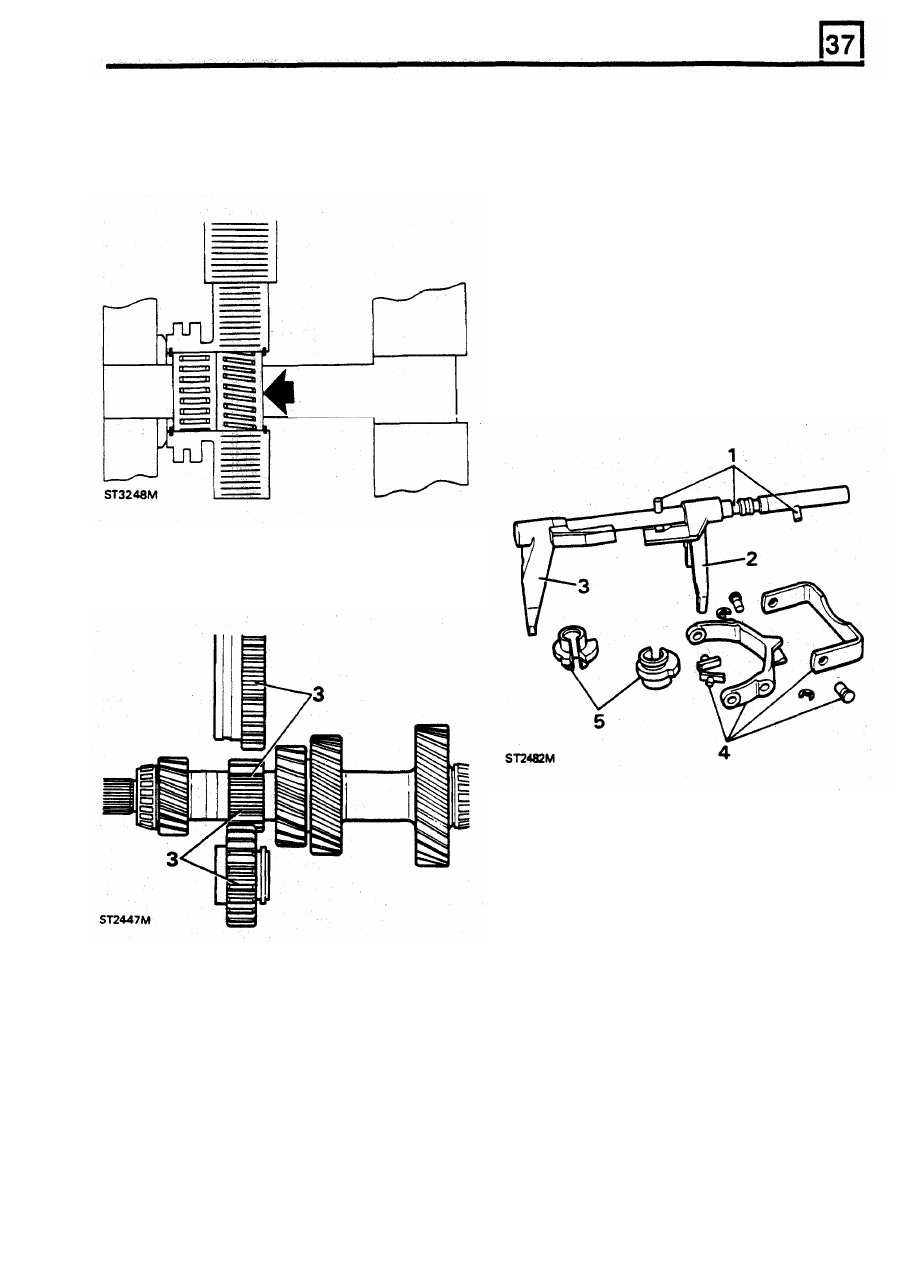

LT77S

MANUAL

GEARBOX

NOTE:

One

bearing cage

is twisted

in

SELECTORS

manufacture. The twist causes the gear to tilt on

the shaft forcing the gear into engagement.

1.

Examine selector rail and pins for wear and

Renew bearings if worn

or

if

the gear jumps out

2.

Examine first-second selector fork for wear

of engagement.

damage.

cracks and damage

NOTE: The selector rail and fork is only supplied

as a complete assembly.

3. Examine third-fourth selector fork for wear,

4.

Examine fifth gear selector fork, pads and

5.

Examine interlock spools for wear and

cracks and damage.

pivot pins.

damage.

2.

Fit the bearings either way round and secure

with the circlip.

3.

Check condition

of

idler gear and mating teeth

on layshaft and synchromesh outer member.

6. Renew retaining circlips if distorted.

4.

Examine idler shaft for wear, scores and

pitting.

REISSUED:

FEB

1993

27

LT77S MANUAL GEARBOX

Assembling selectors.

ASSEMBLING GEARBOX SHAFTS TO

CENTRE

PLATE

Fitting gears to centre

plate

7. Rest first-second fork and shaft assembly on

bench and locate pin in jaw of fork.

8. Fit interlock spool and third-fourth fork and

engage spool in jaw

of

fork.

1. Secure centre plate to workstand, fit bearing

tracks and inboard detent ball and spring.

9. Slide spool and fork towards first- second

selector until slot

in

spool locates over pin

keeping the spool engaged in third-fourth fork

jaw.

28

REISSUED:

FEB 1993

2.

Check both synchromesh units are

in

neutral

and fit selector shaft assembly.

3. f i t mainshaft and selectors to centre plate and

align pin with slot in plate.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст