Defender (1993+). Manual — part 48

LT77S

MANUAL GEARBOX

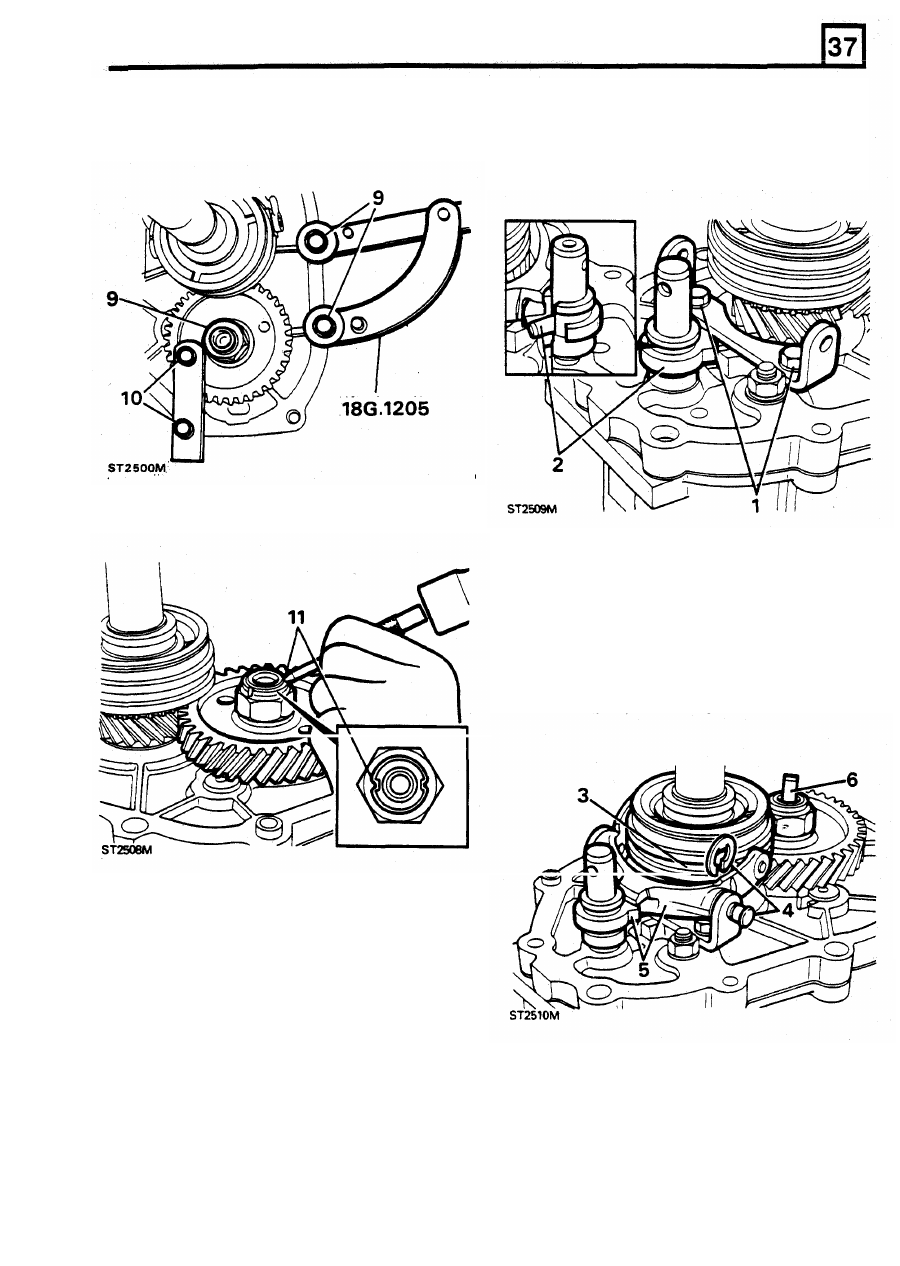

10.

Secure

tool

“A“

to

gear and gear case and

using a suitable torque wrench tighten the

nut

to

the correct torque.

FIFTH

GEAR SELECTOR FORK ASSEMBLY

1.

Fit fifth gear selector fork bracket.

2.

Fit the fifth gear spool long end towards

centre plate.

11.

Using a round nose punch, form the collar into

the layshaft

slots.

3.

Fit slippers to selector fork.

4.

Fit fork to synchromesh and secure with pins

and

“E” clips.

NOTE: Before fitting pins and clips cover holes

in centre plate to prevent them falling into

casing.

5. Engage tongue

of

spool in selector fork.

6.

Fit oil pump drive

to

layshaft.

REISSUED:

FEB

1993

33

LT77S

MANUAL GEARBOX

EXTENSION CASE

1. Release centre plate from workstand and fit

gasket on joint face.

2. Fit extension case while aligning oil pick-up

pipe. Remove guide studs and secure to main

case.

NOTE:

Do not use farce,

if necessary remove

case and re-align

oil

pump drive

if case does not

fit first time.

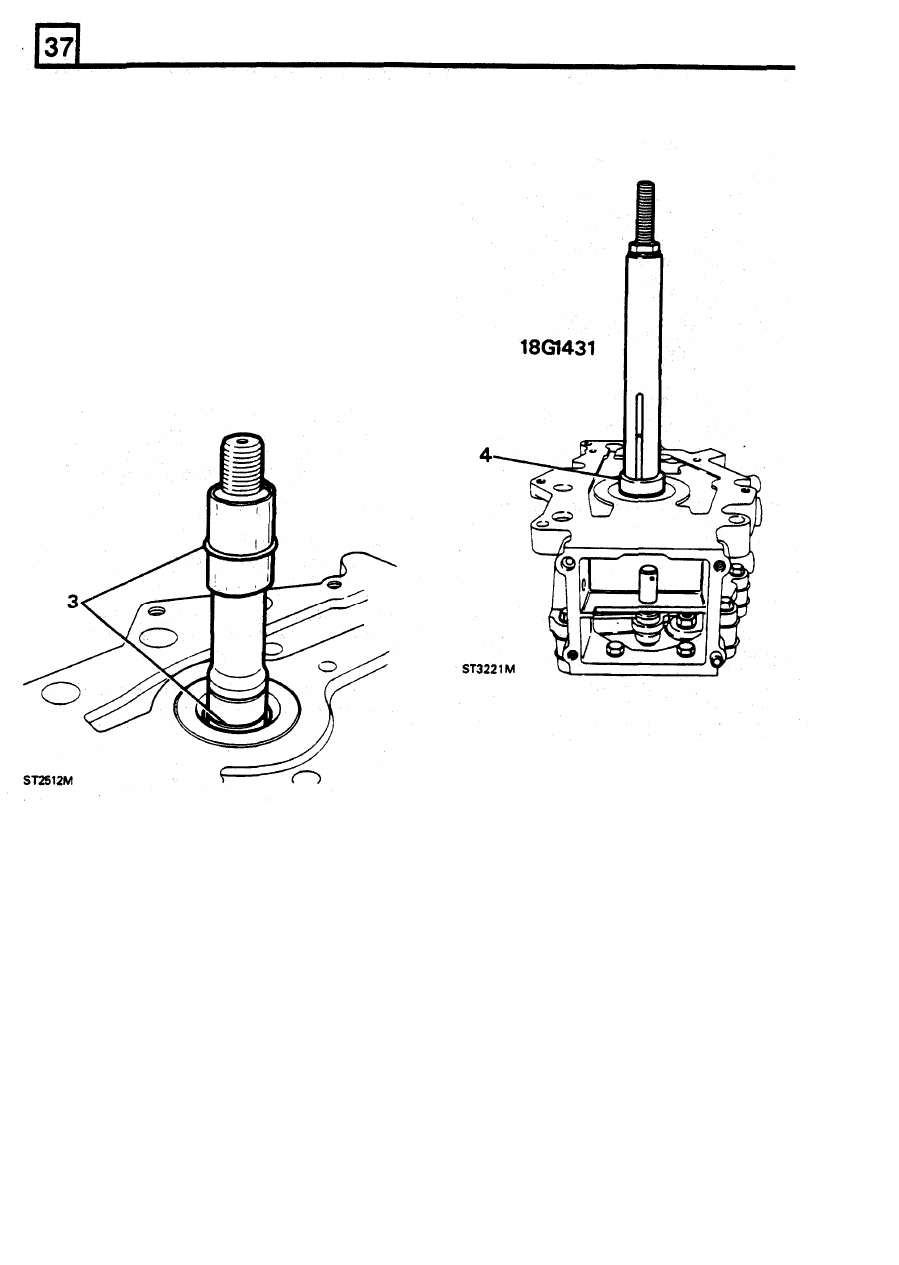

CAUTION:

To protect "O" ring while fitting, cover

mainshaft

splines with smooth tape.

3. Fit " O " ring to mainshaft groove.

4. Fit “O” ring collar to mainshaft using 18G

1431.

34

REISSUED: FEB

1993

LT77S MANUAL GEARBOX

INPUT-MAINSHAFT BEARING ADJUSTMENT

Mainshaft selective washers

1 .

Turn gearbox over with input shaft uppermost.

Part number

Thickness(mm)

Remove layshaft support plate.

FRC 4327

1,51

NOTE: Correct shimming of the input shaft

FRC 4329

1,57

bearing is vital to ensure that the mainshaft

FRC 4331

1,63

assembly has the design intended end float,

and

FRC 4333

1,69

FRC 4337

1,81

2. Measure the thickness of a new front cover

FRC 4339

1,87

the bearings are not pre-loaded.

FRC 4335

1,75

gasket.

FRC 4341

1,93

3. Place the original shim on mainshaft bearing

FRC 4343

1,99

and finger tighten the bolts.

FRC 4345

2,05

4. Measure the clearance between front cover

FRC 4347

2,11

FRC 4349

2,17

and gearcase with

two

feeler gauges.

FRC 4351

2,23

FRC 4353

2,29

FRC 4355

2,35

FRC 4357

2,41

FRC 4359

2,47

FRC 4361

2,53

FRC 4363

2,59

FRC 4365

2,65

FRC 4367

2,67

FRC 4369

2,77

LAYSHAFT BEARING ADJUSTMENT

1.

Place original selective washer on layshaft

bearing,

fit

front cover without gasket, and

finger tighten bolts.

2. Measure clearance, with

two

feeler gauges,

between cover and gearcase. Select a shim

that will provide a clearance

equal to the

thickness

of the gasket that was selected and

measured when calculating the adjustment of

5.

I

I

f

r

e

q

u

i

r

e

d

,

If required,

change the selective washer to

provide a clearance of 0,35mm to 0,085mm

(0.001 to 0.003ins) less than the gasket

the input and mainshaft bearing.

thickness.

NOTE: This will ensure that when the gasket and

cover

is fitted

to

the correct torque, the

input

and mainshaft bearings will have no pre-load and

not more than 0,06mm (0.0025in) end float.

6. Remove front cover and keep gasket and

selective washer together.

REISSUED: FEB 1993

35

LT77S

MANUAL GEARBOX

NOTE: This will ensure zero layshaft bearing end

GEAR LEVER AND REMOTE HOUSING

float and not more than 0,025mm (0.001in)

ASSEMBLY

pre-load once the cover and gasket are fitted and

bolts correctly torqued.

3. Remove cover and selected washer and

fit

4. Fit mainshaft and layshaft selected washers

to neutral

position.

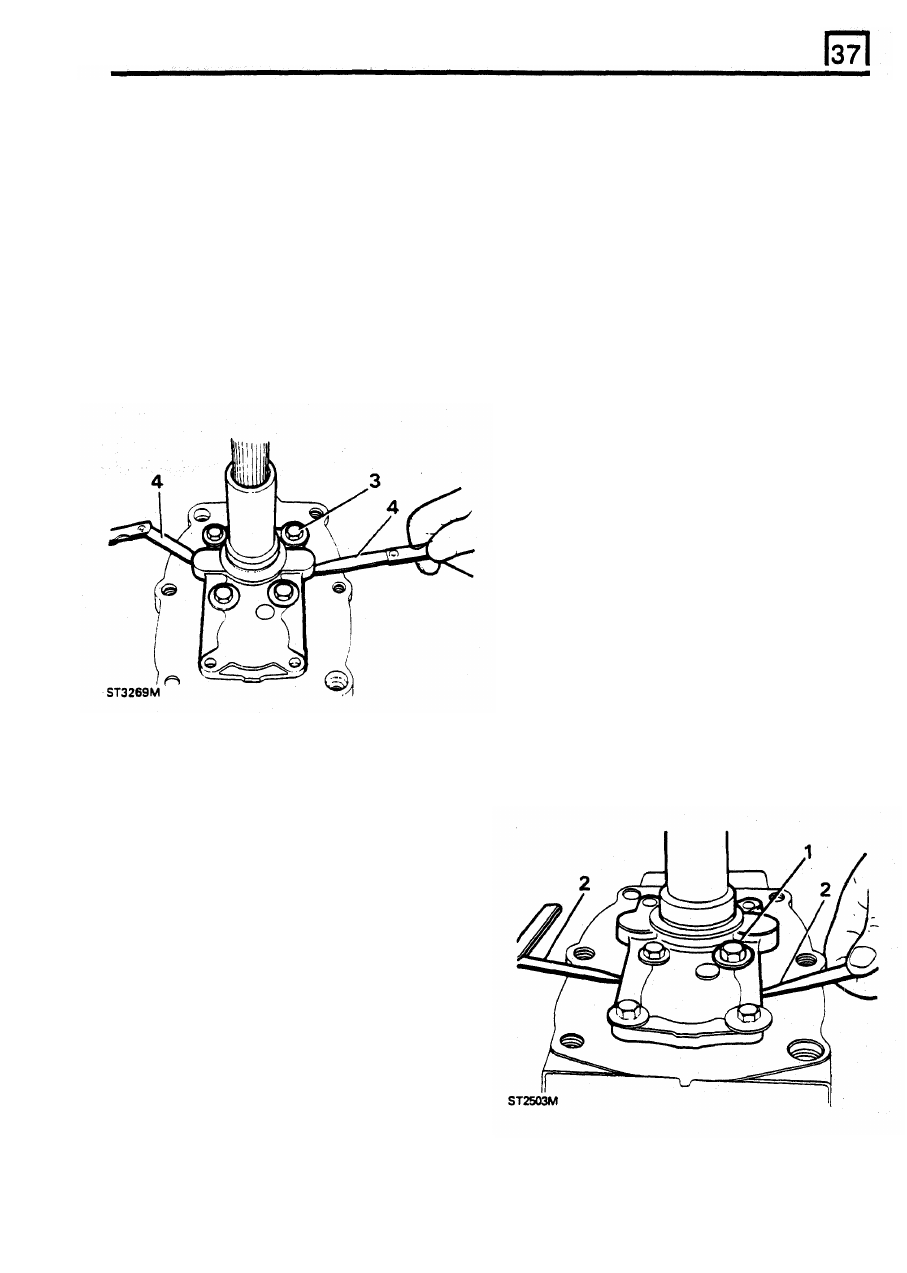

1.

Fit

quadrant to selector shaft with new roll pin,

NOTE: Push shaft forward, fit quadrant

so

ledge

is

to

the left viewing

box

from rear. Return shaft

new oil seal, lip towards gearcase.

and gasket.

2. With a new gasket,

fit

remote housing locating

5 . Wrap protective tape round input shaft splines.

over dowels.

6. Apply Hylomar

PL

32 to bolt threads and

secure cover.

NOTE: Ensure rollers locate

in quadrant fork.

Layshaft selective washers.

3. Fit transfer gear change housing.

Part number

Thickness(mm)

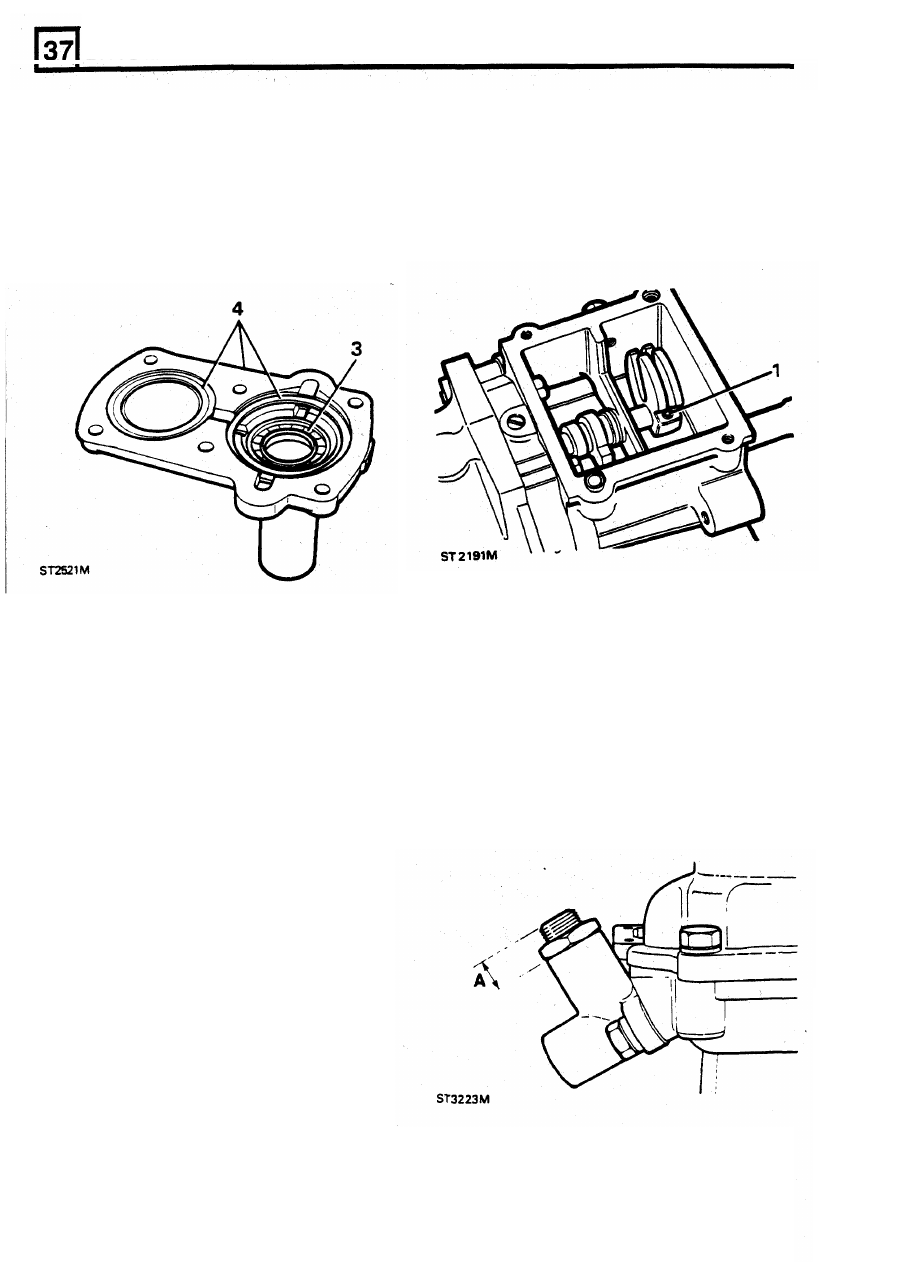

Reverse gear plunger adjustment.

FTC 0262

1,36

1.

Fit plunger with original shims and tighten

FTC 0264

1,42

bolts.

FTC 0266

1,48

2. Slacken locknut, turn adjuster screw

so that

FTC 0268

1.54

dimension

“A”

is approximately 12 rnm

(0.50

FTC 0270

1,60

in). Tighten locknut.

FTC 0272

1,66

FTC 0274

1,72

FTC 0276

1,78

FTC

0278

1,84

FTC 0280

1,90

FTC 0282

1,96

FTC 0284

2,02

FTC 0286

2,08

FTC

0288

2,14

FTC 0290

2,20

FTC 0292

2,26

FTC 0294

2,32

FTC 0296

2,38

36

REISSUED:

FEB

1993

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст