Defender (1993+). Manual — part 45

LT77S MANUAL GEARBOX

INPUT SHAFT

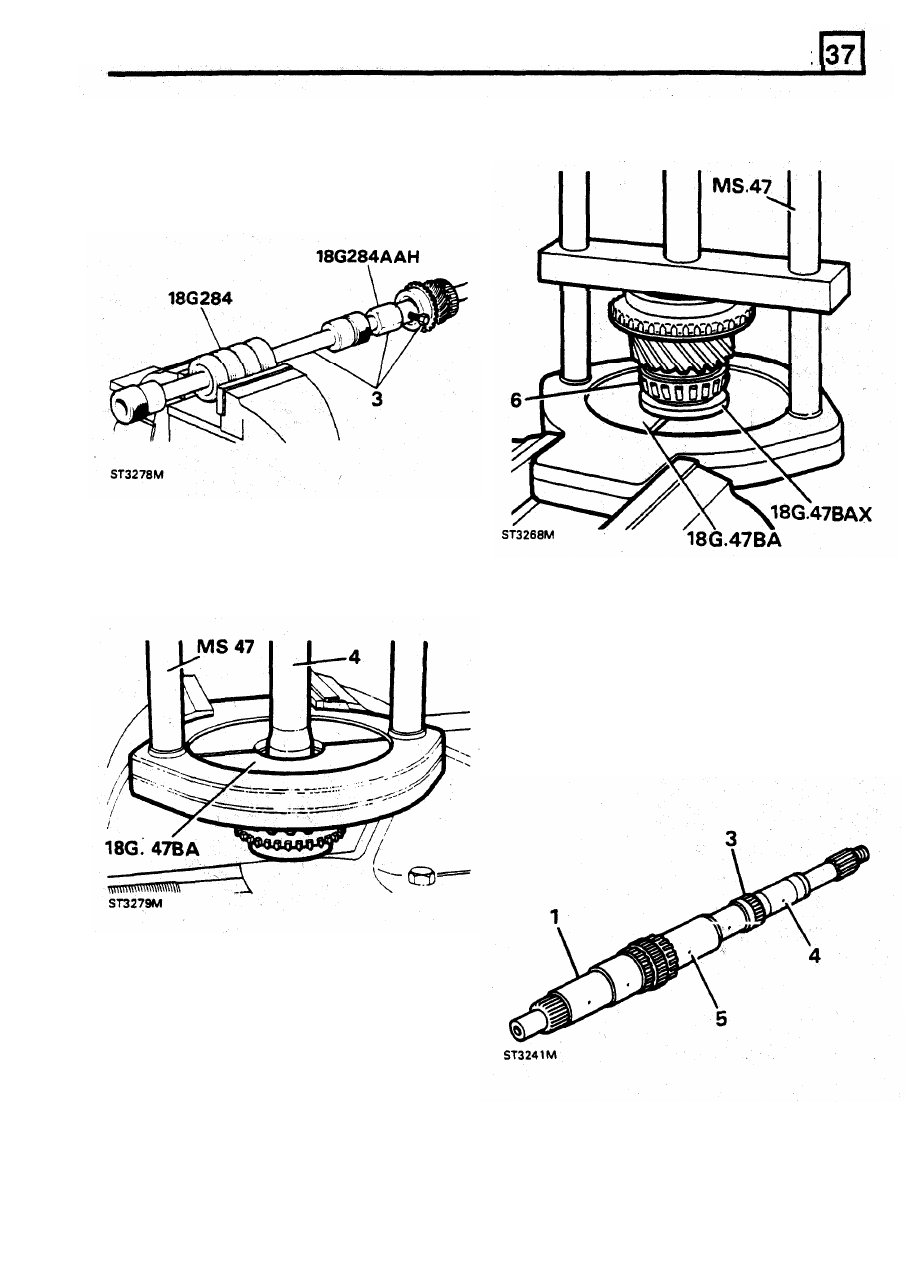

6. Using Press MS 47, Collets 18G 47B and

adaptor 18G 47 BAX fit a new taper bearing.

1. Examine the gear and dog teeth for wear and

damage.

2. Polish oil seal track if necessary.

3. Using 18G 284 AAH and 18G 284 remove

pilot bearing track.

4.

Using 18G 47BA and MS 47 remove taper

bearing.

NOTE: Ensure that the bearing is supported by

the lip inside

18G 47

BA.

MAINSHAFT

1.

Examine bearing journals for wear and scores.

2. Check condition

of

circlip grooves.

3. Examine splines for wear and damage.

4.

Use an air line to check that the main oil feed

from

the pump is clear and feed to spigot

bearing.

5.

Check

oil

feed holes to roller bearings are

clear.

5.

Support the shaft under MS 47 and press in a

new track.

REISSUED: FEB 1993

21

LT77S MANUAL GEARBOX

MAINSHAFT GEAR

END FLOAT CHECKS

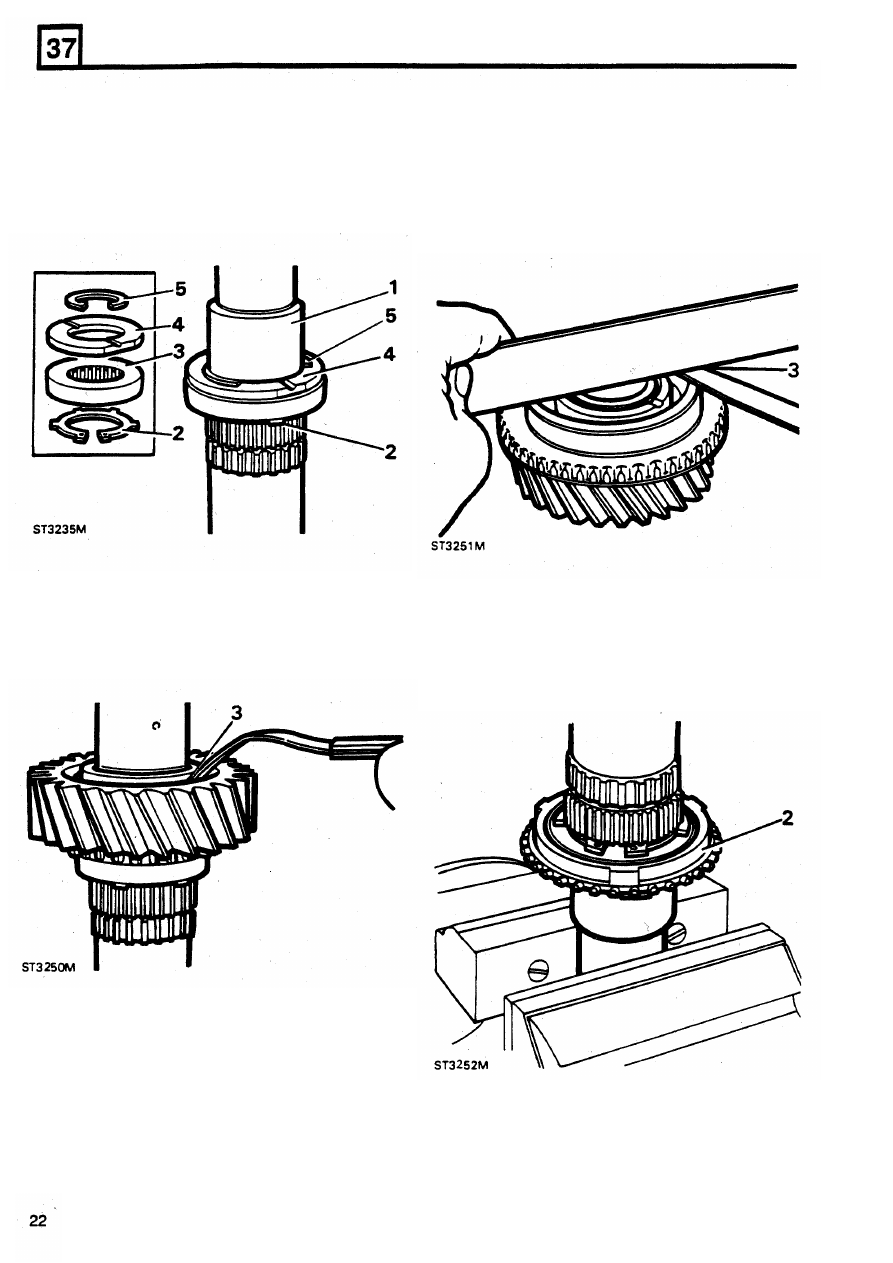

Third gear end-float.

1.

Hold mainshaft in vice front end downwards.

1.

Fit needle roller to third gear.

2.

Fit front circlip for first-second synchromesh.

2.

Fit third gear bush to third gear.

3.

Fit second gear cone.

3. Place gear on flat surface, bush flange

4.

Fit spacer.

downwards, and with a straight edge across

5.

Fit snap ring.

gear check clearance between straight edge

and gear. Not to exceed

0,20

(0.008in).

Second gear end-float.

First gear

bush end-float.

1.

Fit needle roller and second gear.

2.

Fit third gear bush.

1.

Invert mainshaft rear end uppermost.

2.

Fit inner and outer second gear baulk rings.

3. Check clearance between second gear and

bush flange. Not to exceed

0,20

(0.008in).

4.

Remove above components.

REISSUED: FEB 1993

LT77S MANUAL GEARBOX

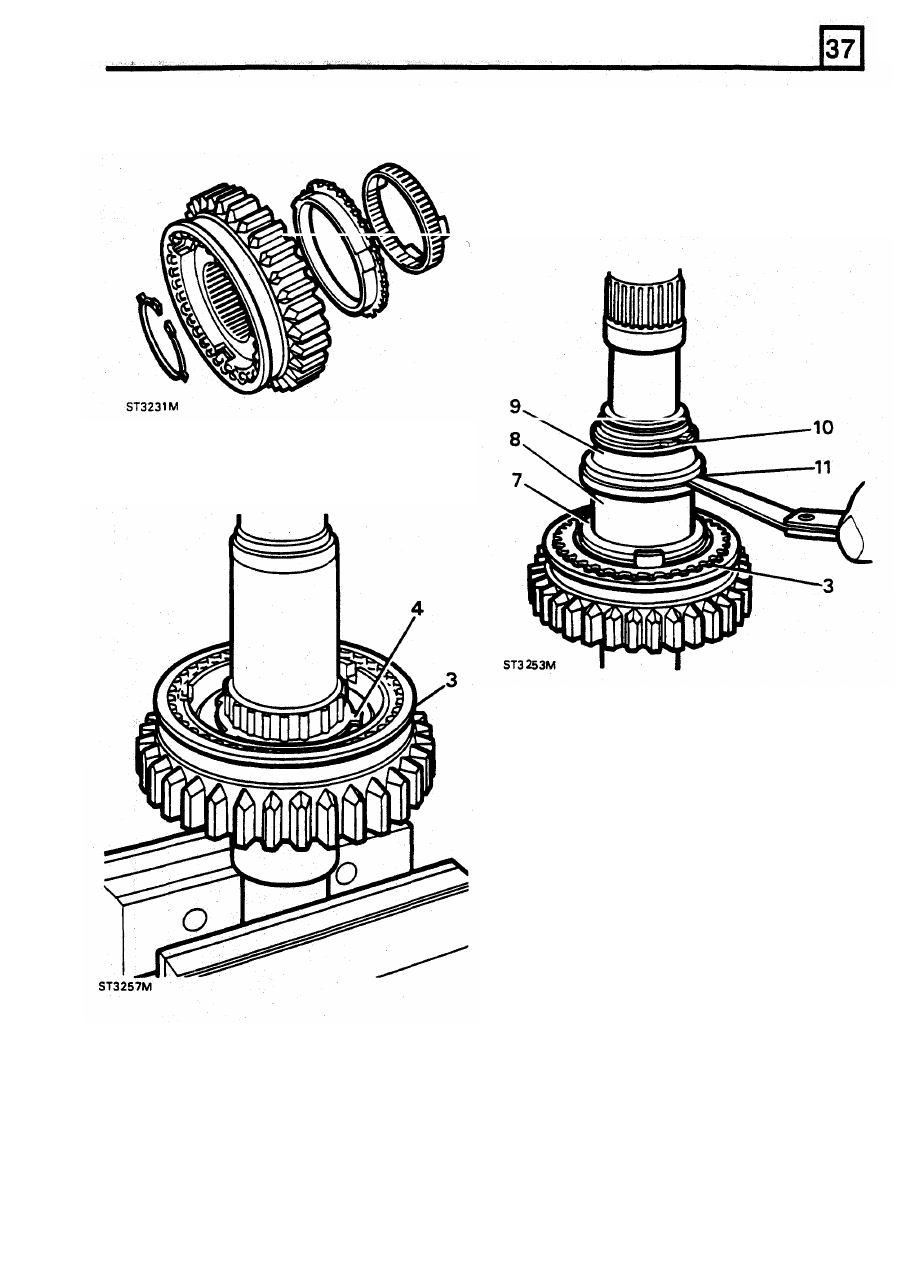

3.

Fit first-second synchromesh hub, fork groove

8.

Fit first gear bush.

4.

Fit circlip.

10. Fit circlip.

uppermost.

9.

Fit dummy bearing.

11.

Check

clearance between dummy bearing and

bush. Not to exceed 0,75mm (0.003in).

12. Remove circlip, dummy bearing and bush.

First-second synchromesh assembly

Selective first gear bush

Part

number

Thickness

FTC2005

30,905/30,955

FTC2006

30,955/31,005

FTC2007

31,005/31,055

FTC2008

31,055/31,105

FTC2009

31,105/31,155

Check first gear to bush end-float.

1. Fit roller bearing and bush to first gear.

2.

Place bush flange side downwards on a

raised block on a flat surface.

NOTE: the block should be approximately the

same diameter as the bush flange

so

that the

gear is suspended and does not rest

on

the flat

5.

Fit first gear inner and outer baulk ring.

6.

Fit cone.

7. Fit spacer.

surface.

REISSUED:

FEB

1993

23

LT77S

MANUAL GEARBOX

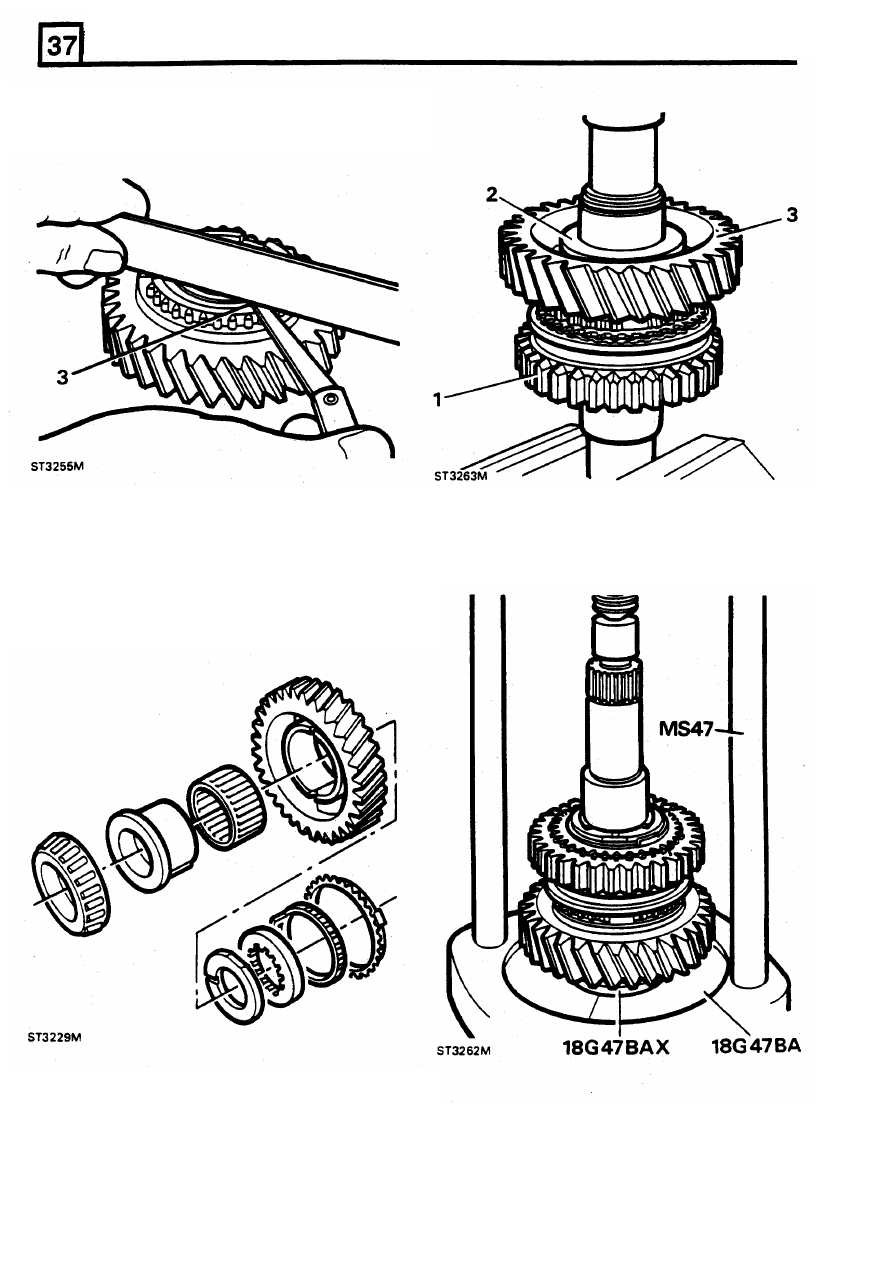

3.

Place straight edge across gear and check

clearance between gear and straight edge. Not

to

exceed 0,20mm (0.008in).

ASSEMBLING MAINSHAFT

4. Fit the taper bearing to mainshaft using MS

47, collets 18G 47 BA and adaptor 18G 47

1.

With the first-second synchromesh hub and

BAX.

spacer

in

position, assemble the rear end

of

the shaft.

2.

Fit the roller bearing and bush to first gear.

3 . Fit first gear to mainshaft.

First gear assembly

24

REISSUED: FEB 1993

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст