Mitsubishi Lancer Evolution IX. Manual — part 296

INPUT SHAFT

MANUAL TRANSMISSION OVERHAUL

22B-29

INSPECTION

M1222001700147

INPUT SHAFT

AK204168

AK204168AC

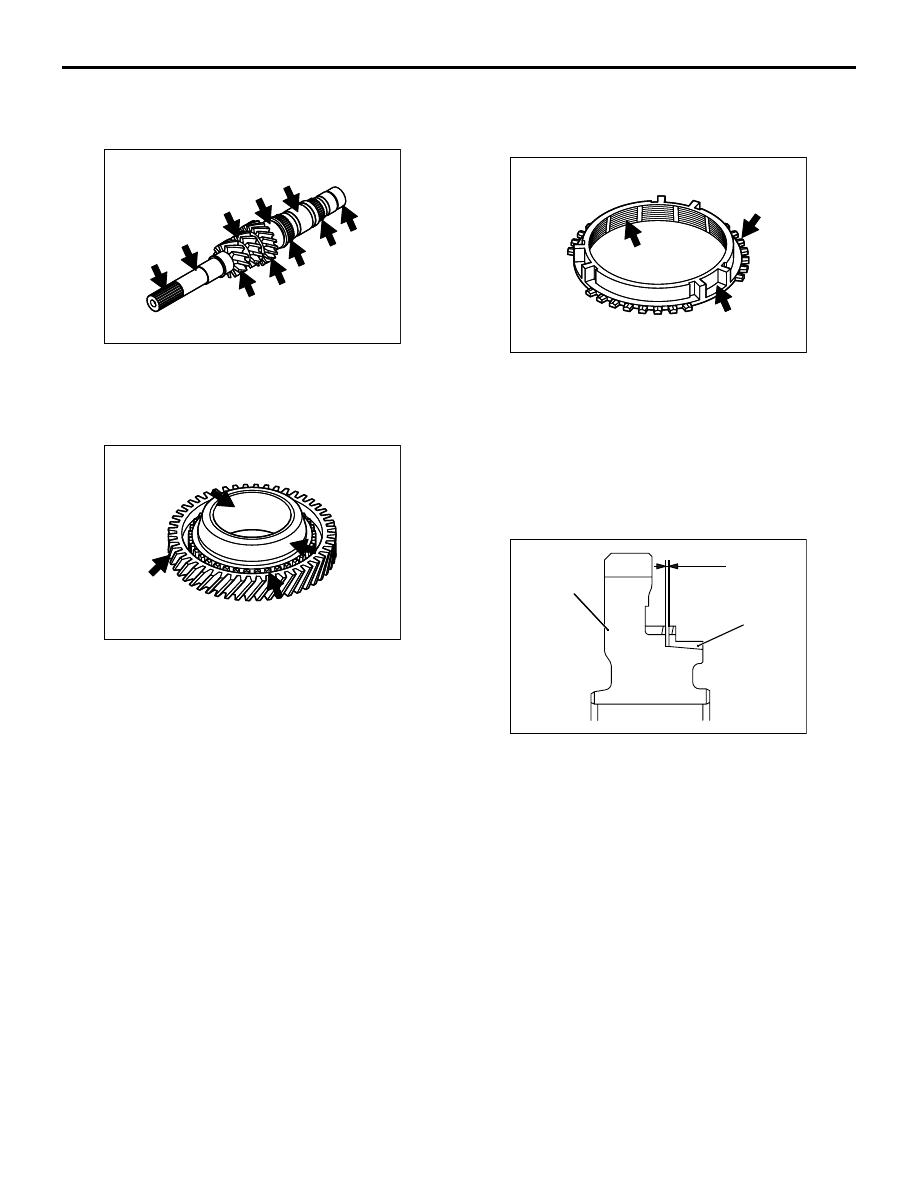

Check the input shaft for damage, flaking, dents,

uneven wear, bend, and other defects.

SPEED GEARS

AK204169

AK204169AC

1. Check the helical gear teeth and clutch gear teeth

of each speed gear for damage and excessive

wear.

2. Check the synchronizer cone surface of each

speed gear for roughness, damage, and

excessive wear (3rd gear excepted).

3. Check the inside surface and front and back sides

of each speed gear for damage and excessive

wear.

NEEDLE ROLLER BEARINGS

1. Combine each needle roller bearing with the input

shaft, corresponding sleeve, and gear. Rotate the

assembly, checking for smooth rotation,

looseness, and noise.

2. Check the retainer for deformation.

SINGLE CONE SYNCHRONIZER RING

AK204170

AK204170AC

1. Check the clutch gear on the synchronizer ring for

damaged and missing teeth.

2. Check the synchronizer ring inner cone surface

for damage or wear. Also check that the inside

ridges are intact.

3. Check the synchronizer key contact surfaces of

the synchronizer ring for damage, and excessive

wear.

AK204104

A

AE

Speed gear

Synchronizer ring

4. Press the synchronizer ring against the cone of

the adjacent speed gear, and check clearance A.

Replace the synchronizer ring if the clearance is

below the limit.

Limit: 0.7 mm

INPUT SHAFT

MANUAL TRANSMISSION OVERHAUL

22B-30

DOUBLE CONE SYNCHRONIZER RING

AK204172AC

Inner synchronizer ring

Synchronizer ring

cone

Outer synchronizer ring

1. Check the clutch gear on the outer synchronizer

ring for damaged and missing teeth.

2. Check the contact surfaces between each

synchronizer ring and synchronizer cone for

damage and wear. Also check that the cone

ridges are intact.

3. Check the synchronizer key contact surfaces of

the outer synchronizer ring for damage and

excessive wear.

AK204173 AC

A

B

Inner synchronizer ring

Synchronizer ring cone

Outer synchronizer ring

4. Combine the synchronizer rings and synchronizer

cone, and check clearances A and B shown in the

illustration. Replace them if either of the

clearances is greater than the limit.

Limit: 0.2 mm

SYNCHRONIZER KEYS

AK204174

AK204174AC

Check the synchronizer hub contact surfaces of each

synchronizer key for damage and excessive wear.

SYNCHRONIZER SPRINGS

Check the synchronizer springs for loss of tension,

deformation, and breakage.

REVERSE IDLER GEAR

MANUAL TRANSMISSION OVERHAUL

22B-31

REVERSE IDLER GEAR

DISASSEMBLY AND REASSEMBLY

M1222012500125

AK204079

AK204079

4

5

6

2

3

7

8

9

11

13

14

10

AC

1

12

Apply gear oil to

all moving parts

before installation.

Disassembly steps

1. Rear reverse idler gear assembly

2. Rear reverse idler gear

<<A>> >>B<<

3. Reverse idler gear sleeve

>>A<<

4. Insert spring

5. Synchronizer ring

6. Needle bearing

7. Washer

8. Thrust bearing

9. Front reverse idler gear

10. Needle bearing

11. Washer

12. Thrust bearing

13. Pin

14. Reverse idler fear shaft

Disassembly steps (Continued)

REVERSE IDLER GEAR

MANUAL TRANSMISSION OVERHAUL

22B-32

DISASSEMBLY SERVICE POINTS

<<A>> REVERSE IDLER GEAR SLEEVE

REMOVAL

AK204113AC

Match marks

CAUTION

Meshing problems may occur if the original

spline engagement phase is changed during

reassembly.

Make match marks on the reverse idler gear sleeve

and reverse idler gear hub.

REASSEMBLY SERVICE POINTS

>>A<< INSERT SPRING INSTALLATION

AK204114AC

Clutch

housing

side

Install each insert spring on the reverse idler gear

sleeve, making sure to insert it in the right direction.

>>B<< REVERSE IDLER GEAR SLEEVE

INSTALLATION

AK204113AC

Match marks

CAUTION

Meshing problems may occur if the spline

engagement phase is changed during reassem-

bly.

Align the match marks when engaging the splines.

INSPECTION

M1222012400043

REVERSE IDLER SHAFT

AK204101

AK204101AC

Check the reverse idler shaft for damage, flaking,

dents, uneven wear, bend, and other defects.

THRUST BEARING

1. Check the thrust bearing for smooth rotation,

without looseness or noise, when rotated together

with the washers.

2. Check the retainer for deformation.

NEEDLE BEARING

1. Check the needle bearing for smooth rotation,

without looseness or noise, when rotated together

with the reverse idler gear and shaft.

2. Check the retainer for deformation.

FRONT REVERSE IDLER GEAR

AK204102

AK204102AC

1. Check the helical gear teeth and clutch gear teeth

of the reverse idler gear for damage and

excessive wear.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст