Mitsubishi Lancer Evolution IX. Manual — part 298

TRANSMISSION CASE

MANUAL TRANSMISSION OVERHAUL

22B-37

REASSEMBLY SERVICE POINTS

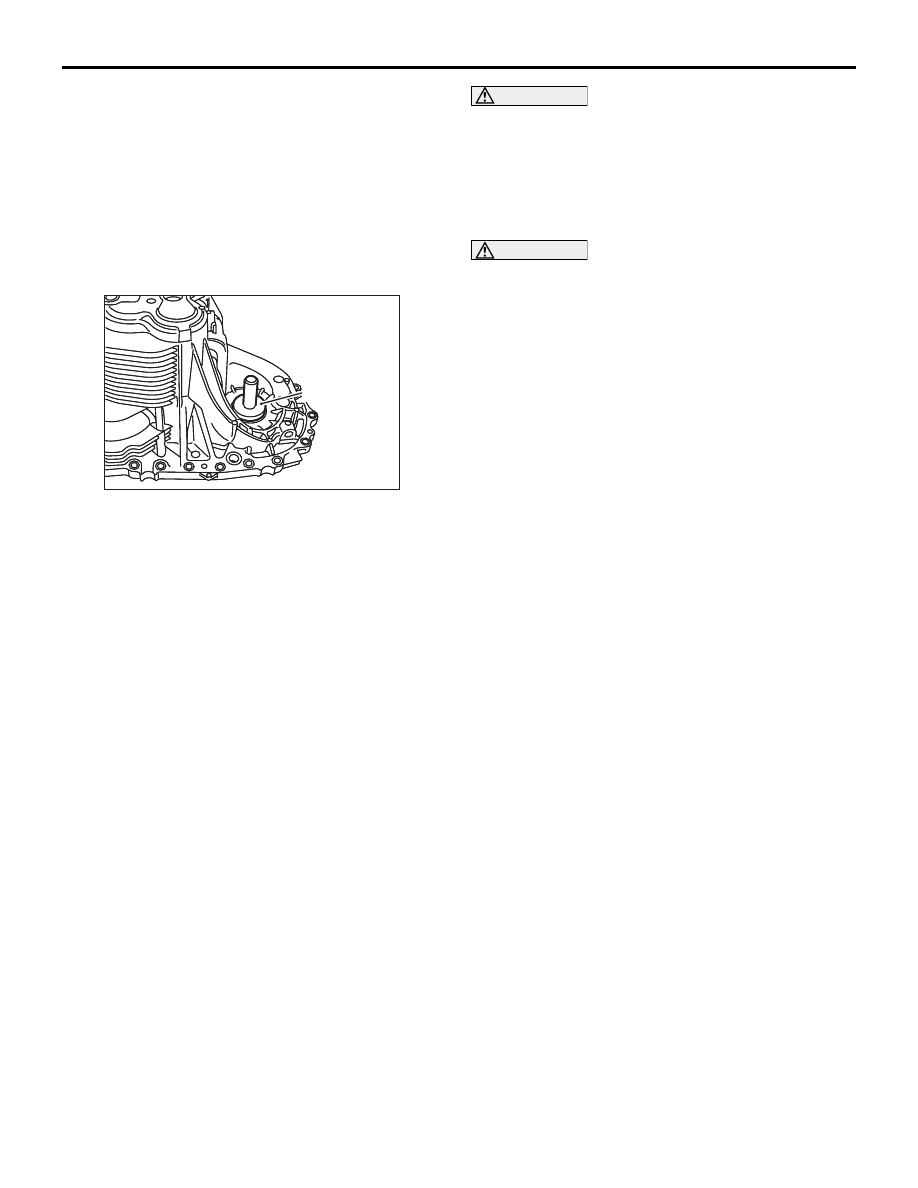

>>A<< AIR BREATHER INSTALLATION

1. Apply sealant to the entire air breather fitting

surface of the transaxle case.

Specified sealant: 3M 8513 or equivalent

2. Install the air breather on the transaxle case.

>>B<< DIFFERENTIAL OIL SEAL

INSTALLATION

AK203788

AK203788AC

MD998800

CAUTION

The oil seal is not reusable.

Using the special tool Oil seal installer (MD998800),

install the differential oil seal into the transaxle case.

>>C<< BAFFLE PLATE / OIL GUTTER

INSTALLATION

CAUTION

Apply Vaseline to the claws of the baffle plate

and oil gutter to prevent both parts from falling

off.

Install the baffle plate and oil gutter on the transaxle

case.

CENTRE DIFFERENTIAL

MANUAL TRANSMISSION OVERHAUL

22B-38

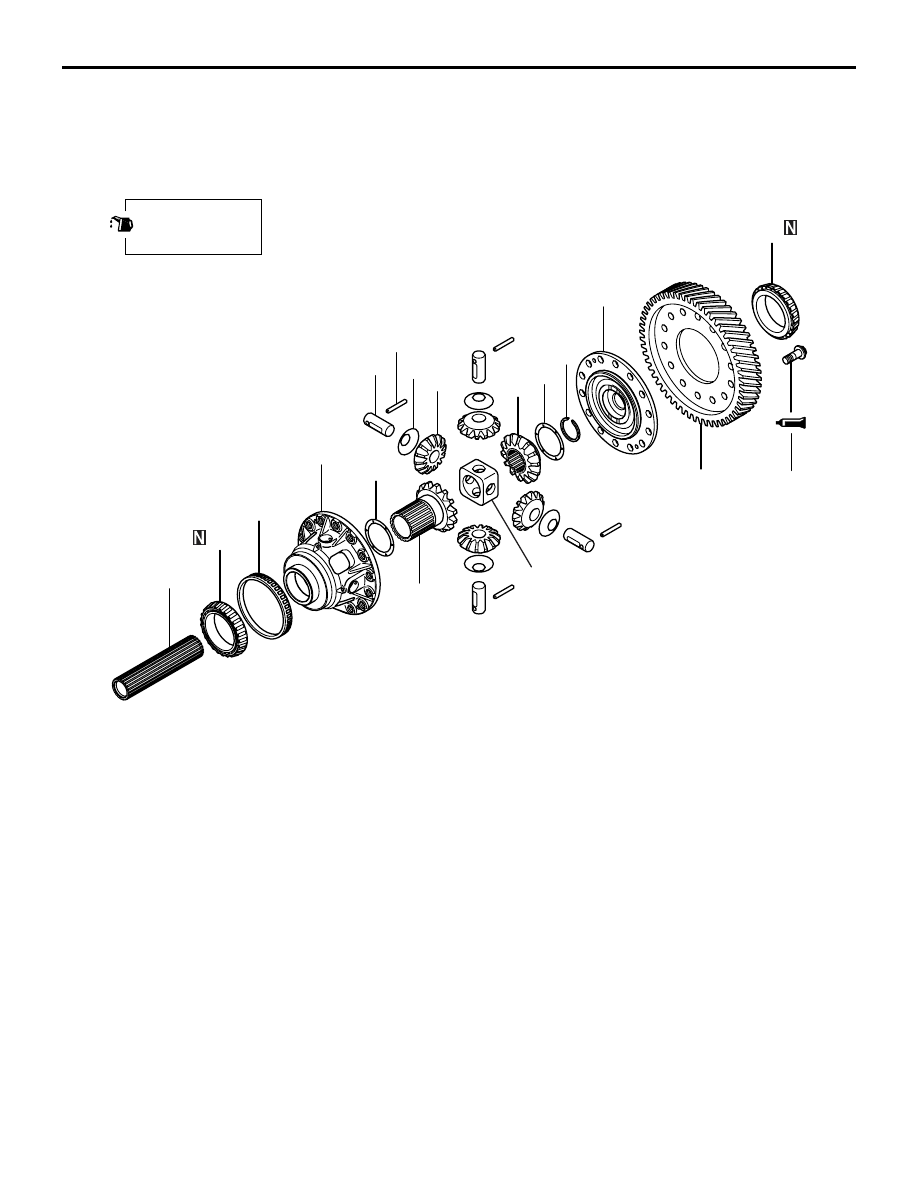

CENTRE DIFFERENTIAL

DISASSEMBLY AND REASSEMBLY

M1222010600030

AK204087AC

3

1

4

5

7

2

158 ± 7 N·m

6

8

9

10

11

12

13

14

15

16

17

Apply gear oil to

all moving parts

before installation.

Disassembly steps

>>

D

<<

1.

Center differential drive gear

<<

A

>>

>>

C

<<

2.

Taper roller bearing

>>

B

<<

3.

Center differential flange

>>

B

<<

4.

Snap ring

>>

B

<<

5.

Front output shaft

>>

B

<<

6.

Spacer

>>

B

<<

7.

Side gear

>>

B

<<

8.

Lock pin

>>

B

<<

9.

Pinion shaft

>>

B

10. Pinion shaft holder

>>

B

11. Pinion

>>

B

12. Washer

>>

B

13. Side gear

>>

B

14. Spacer

<<

B

>>

>>

A

15. Taper roller bearing

16. Speedometer drive gear

17. Differential case

Disassembly steps (Continued)

CENTRE DIFFERENTIAL

MANUAL TRANSMISSION OVERHAUL

22B-39

DISASSEMBLY SERVICE POINTS

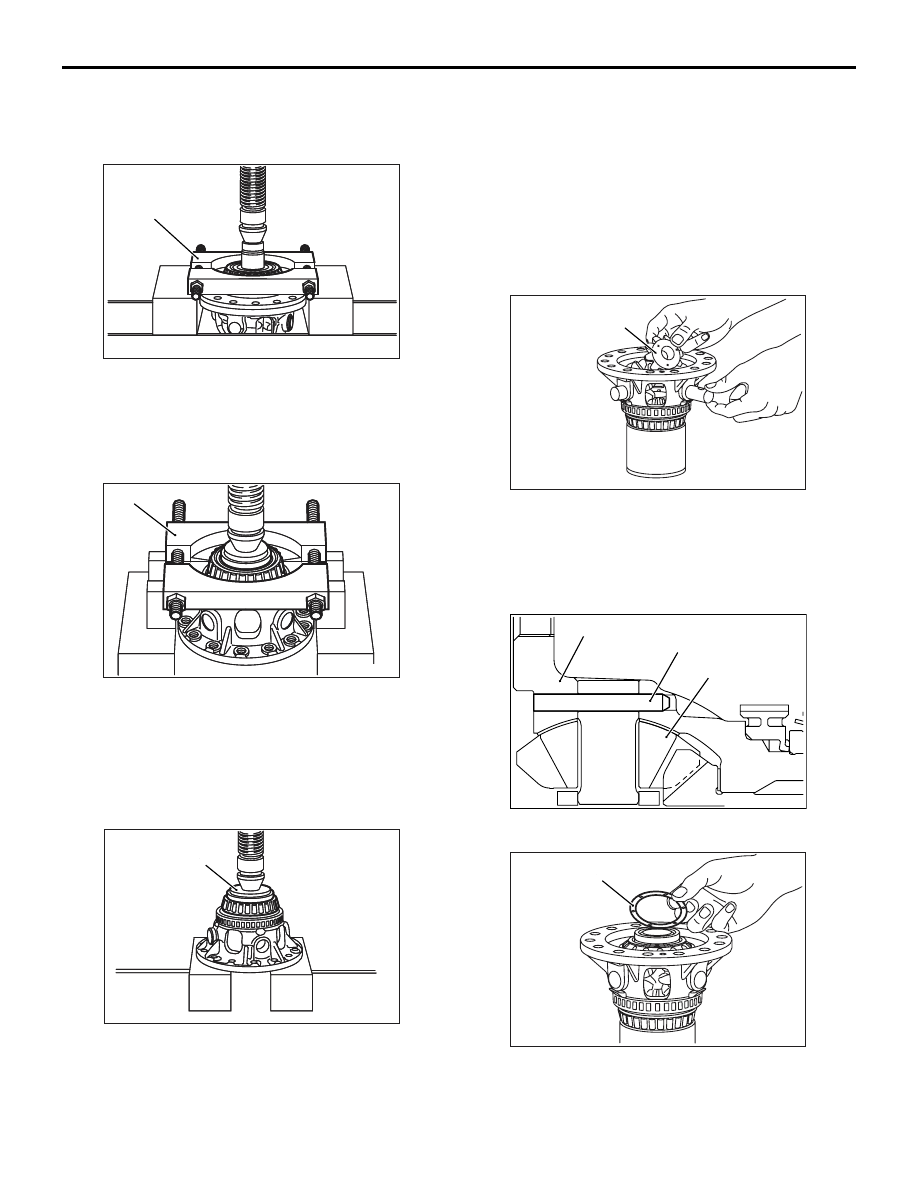

<<A>> TAPER ROLLER BEARING

REMOVAL

AK203789

AK203789AC

MD998801

Using the special tool Bearing remover (MD998801),

remove the taper roller bearing.

<<B>> TAPER ROLLER BEARING

REMOVAL

AK203790

AK203790 AC

MD998801

Using the special tool Bearing remover (MD998801),

remove the taper roller bearing.

REASSEMBLY SERVICE POINTS

>>A<< TAPER ROLLER BEARING

INSTALLATION

AK203791

AK203791AC

MB990936

Using the special tool installer adapter (MB990936),

install the taper roller bearing.

>>B<< SPACER / SIDE GEAR / WASHER /

PINION / PINION SHAFT HOLDER /

PINION SHAFT / LOCK PIN / FRONT

OUTPUT SHAFT / SNAP RING / CENTER

DIFFERENTIAL FLANGE INSTALLATION

1. Install the spacer on each side gear, then install

the side gears into the center differential case.

NOTE: When installing new side gears, use spac-

ers of a medium thickness (0.66

−

0.73 mm).

AK203793AC

Washer

2. Install a washer on the backside of each pinion.

Simultaneously engage all four pinions with the

side gears, and install them into position while

rotating, then install the pinion shaft holder.

3. Insert the pinion shafts into the pinions.

AK204147AC

Differntial case

Lock pin

Pinion

4. Install the lock pins as indicated in the illustration.

AK203794 AC

Spacer

5. Insert the front output shaft into each side gear,

then install the snap ring.

6. Install the spacer on each side gear. Next, install

the side gears into the center differential case.

CENTRE DIFFERENTIAL

MANUAL TRANSMISSION OVERHAUL

22B-40

NOTE: When installing new side gears, use spac-

ers of a medium thickness (0.66

−

0.73 mm).

AK203796AC

Match

marks

7. Install the center differential flange on the

differential case while aligning the match marks.

Secure it temporarily in place using machine

screws in four places.

AK203797

8. Measure the backlash between the side gears

and pinions.

Standard value: 0.025

− 0.150 mm

9. If the backlash does not fall within the standard

value range, select other appropriate spacers,

replace the existing spacers with them, and

measure the backlash once again.

NOTE: Adjust the backlash on each side so that it

is equal to the backlash on the other side.

>>C<< TAPER ROLLER BEARING

INSTALLATION

AK203792

AK203792 AC

MB990936

Using the special tool Installer adapter

(MB9900936), install the taper roller bearing.

>>D<< CENTER DIFFERENTIAL DRIVE

GEAR INSTALLATION

AK204150

AK204150AC

1. Apply sealant to the entire threaded part on the

bolts.

Specified sealant: 3M STUD Locking No.

4170 or equivalent

AK204149

AK204149AC

4

5

6

1

2

3

7

8

9

14

11

12

13

10

2. Tighten bolts to the specified torque of 158

± 7

N

⋅m in the order indicated in the illustration.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст