Mitsubishi Eclipse / Eclipse Spyder (2000-2002). Service and repair manual — part 137

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <2.4L ENGINE>

13A-247

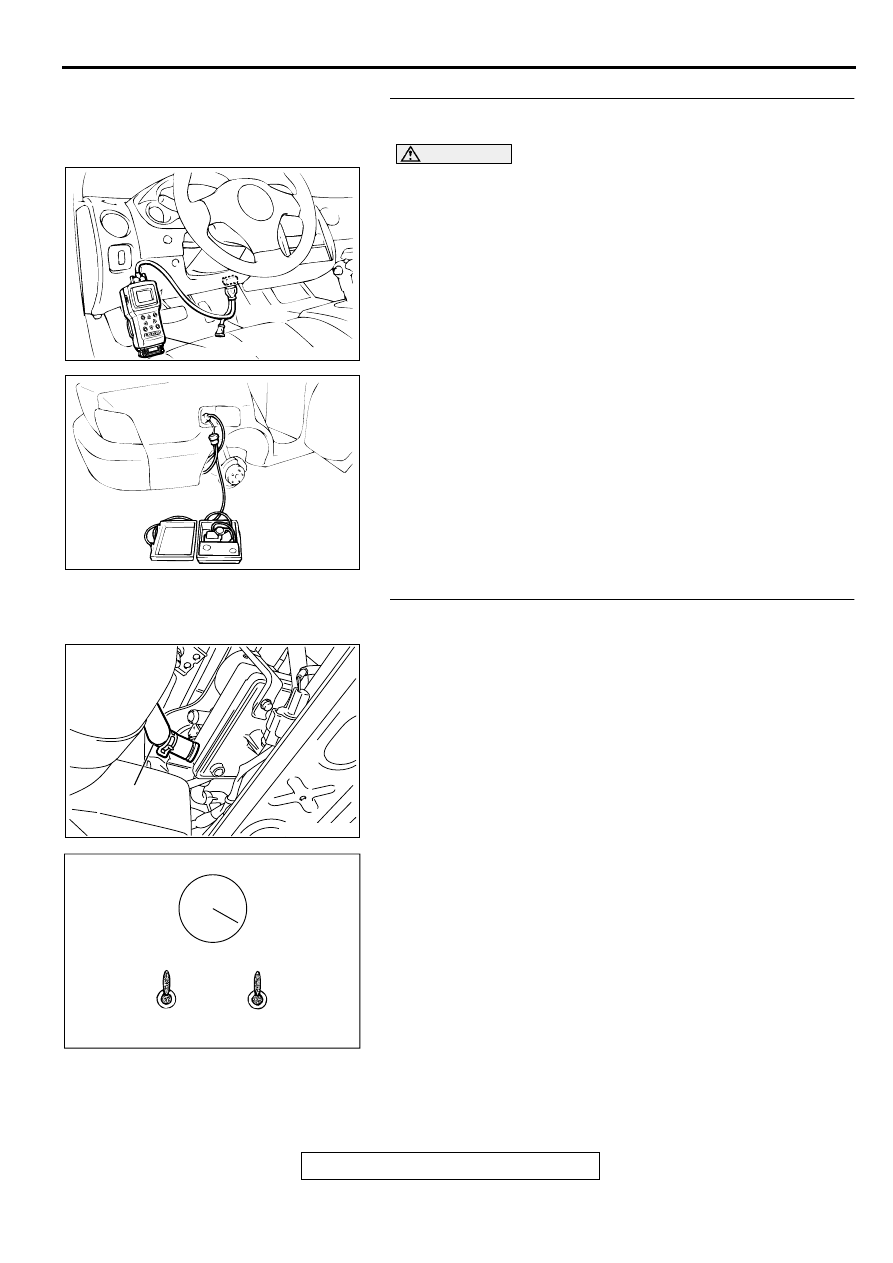

STEP 19. Using scan tool MB991502, check data list item

73: Fuel Tank Differential Pressure Sensor.

CAUTION

To prevent damage to scan tool MB991502, always turn the

ignition switch to "LOCK" (OFF) position before

connecting or disconnecting scan tool MB991502.

(1) Connect scan tool MB991502 to the data link connector.

(2) Turn the ignition switch to the "ON" position.

(3) Remove the fuel cap.

(4) Set scan tool MB991502 to the data reading mode for item

73, Fuel Tank Differential Pressure Sensor.

•

The fuel tank pressures should be

−

1.5 to 1.5kPa.

(5) Connect an evaporative emission system pressure pump to

the fuel filler neck, and apply pressure.

•

The scan tool reading should increase.

Q: Is the scan tool reading within the specified value?

YES : Go to Step 26.

NO : Replace the ECM or PCM. Then go to Step 26.

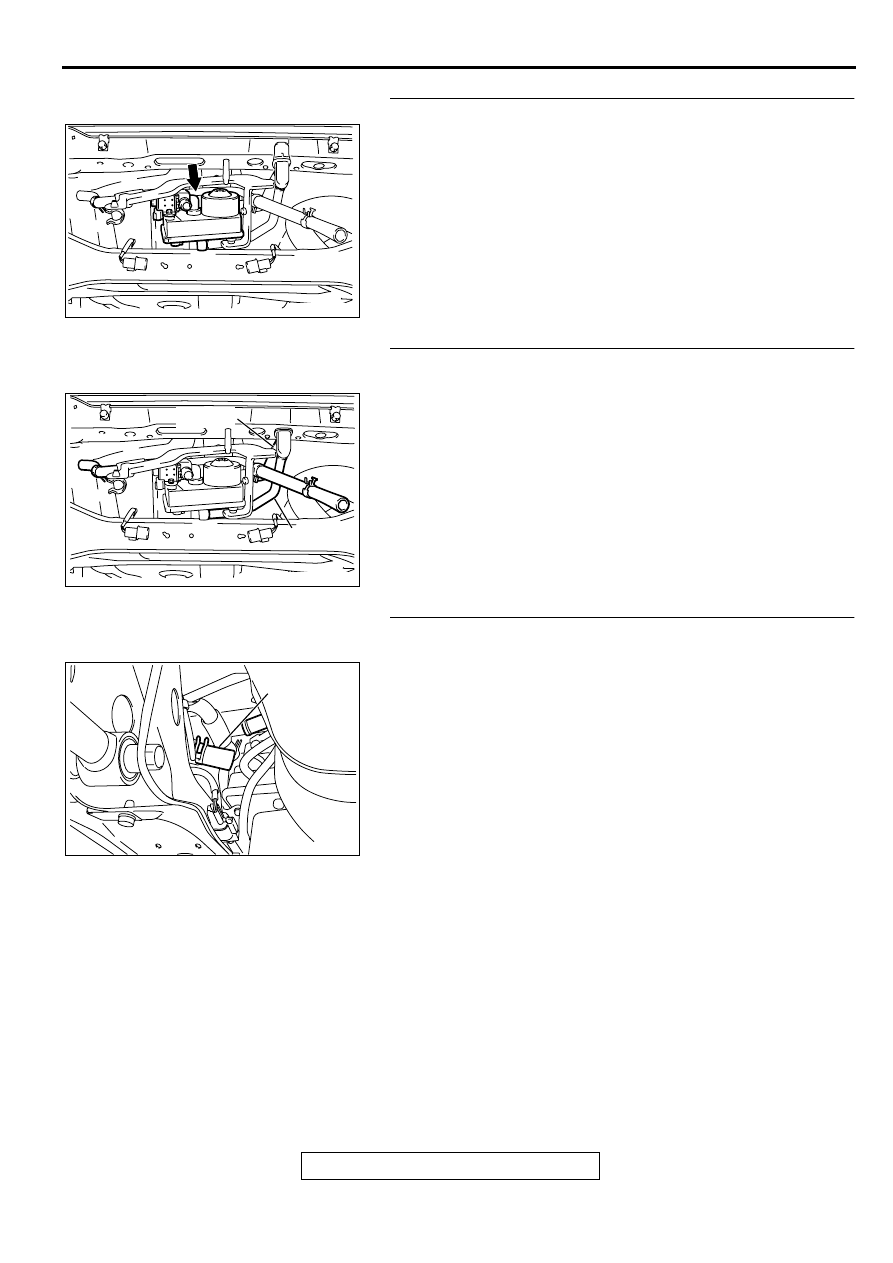

STEP 20. Check for clogging in the evaporator line from

hose E to hose G.

(1) Remove the module bracket mounting bolts, and

disconnect hose E from the evaporative emission

ventilation solenoid side, and plug the hoses from which the

hoses have been disconnected.

(2) Install the EVAP pressure pump outlet hose to the fuel tank

filler neck as described in the pump manufacturer's

instructions.

(3) On the EVAP pressure pump, set the pressure/hold valve to

OPEN, and set the vent valve to CLOSED.

(4) Turn the pump timer to ON. You can reset the timer as

required. (These settings are listed under "Leak Test" in the

pump instructions.)

(5) When the hose E is unplugged, the air passes through the

hose E.

Q: Does air pass through the hose E?

YES : Go to Step 21.

NO : Go to Step 23.

AC001252

MB991502

16 PIN

AB

AC000186

AC002028

HOSE E

AC

OPEN

OPEN

CLOSED

CLOSED

Pressure

Hold

Vent

ACX01806

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <2.4L ENGINE>

13A-248

STEP 21. Check the vent valve module for clogging.

(1) Check the vent valve module for clogging. (Refer to

GROUP 17

−

Vent Valve

.)

Q: Air there any clogs?

YES : Replace the vent valve module. Then go to Step 26.

NO : Go to Step 22.

STEP 22. Check for clogging in the evaporator lines O and

hose P.

(1) Apply vacuum with a hand vacuum pump connected to

hose O and hose P.

Q: Are there any clogs?

YES : Replace that hose. Then go to Step 26.

NO : Go to Step 26.

STEP 23. Check for clogging in the evaporator line from

hose G.

(1) Carry out the clogging test with a hand vacuum pump on

each hose from hose G.

Q: Are there any clogs?

YES : Replace that hose. Then go to Step 26.

NO : Go to Step 24.

AC002034 AB

AC002033 AE

HOSE P

HOSE O

AC002072

HOSE G

AD

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <2.4L ENGINE>

13A-249

STEP 24. Check for clogging in the evaporator line from

hose E and hose F.

(1) Remove the fuel tank. (Refer to GROUP 13C, Fuel Tank

(2) Carry out the clogging test with a hand vacuum pump on

each hose from hose E and hose F.

Q: Are there any clogs?

YES : Replace that hose, reinstall the fuel tank. Then go to

Step 26.

NO : Go to Step25.

STEP 25. Check for clogging in the evaporative emission

canister.

(1) Connect a hand vacuum pump to the vent nipple of the

evaporative emission canister.

(2) Plug the other two nipples or loop a hose between the other

nipples.

(3) Apply vacuum. When each nipple is unplugged, the vacuum

should fluctuate.

Q: Does the vacuum pump gauge reading fluctuate?

YES : Reinstall the fuel tank. Then go to Step 26.

NO : Replace the evaporative emission canister, reinstall

the fuel tank. Then go to Step 26.

STEP 26. Test the OBD-II drive cycle.

(1) Carry out a test drive with the drive cycle pattern. (Refer to

, Procedure 1

−

Evaporative Emission Control

system Leak Monitor.)

(2) Read the diagnostic trouble code P0450 does not reset.

Q: Are the DTCs reset?

YES : This diagnosis is complete. (If no malfunctions are not

found in all steps, an intermittent malfunction is

suspected.) Refer to GROUP INTRODUCTION, How

to Use Troubleshooting/Inspection Service Points

−

How to Cope with Intermittent Malfunction

NO : Replace the ECM or PCM.

AC002037

HOSE E

HOSE F

AF

AC000191AB

VENT

NIPPLE

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <2.4L ENGINE>

13A-250

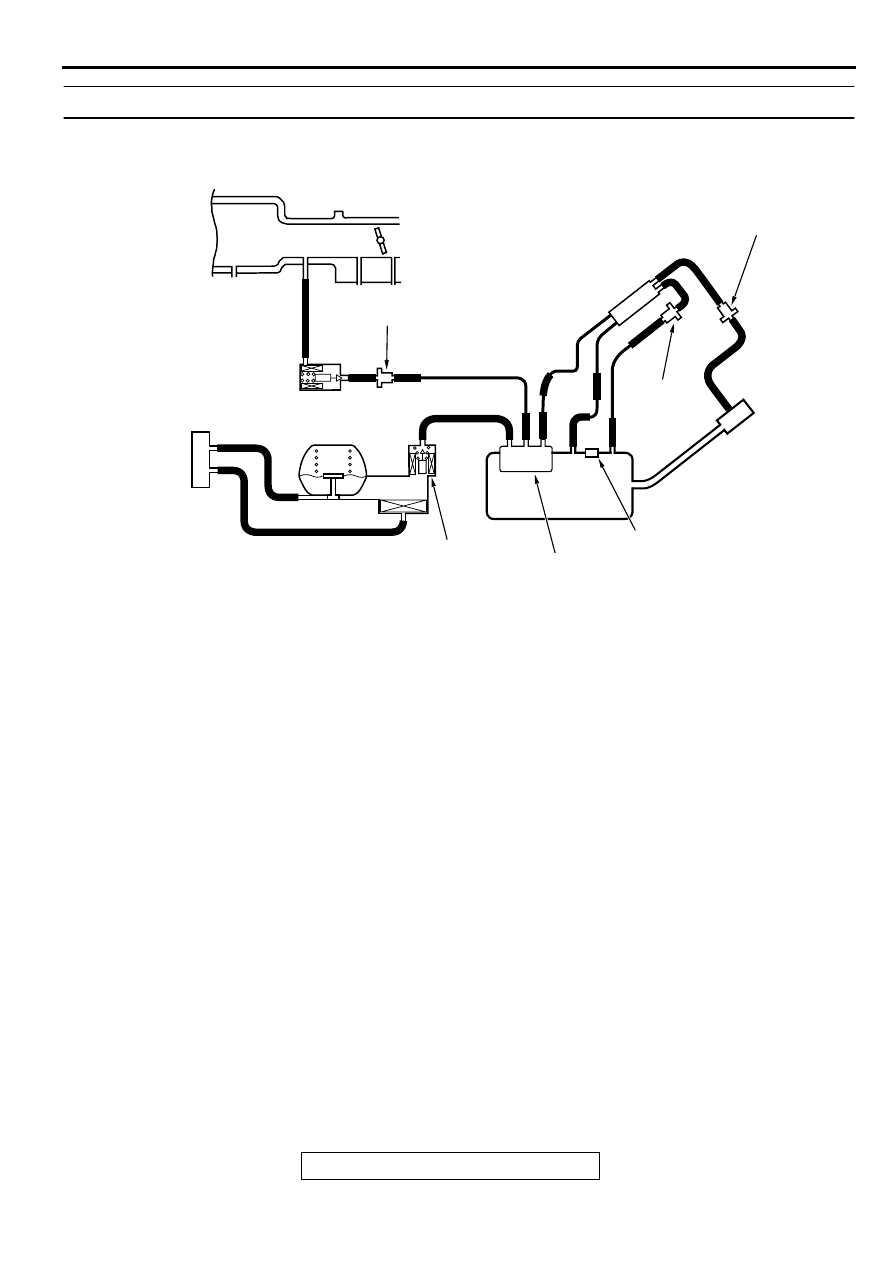

DTC P0451: Evaporative Emission Control System Pressure Sensor Range/Performance

AC001943

A

B

C

EVAPORATIVE EMISSION

PURGE SOLENOID

EVAPORATIVE

EMISSION CANISTER

EVAPORATIVE

EMISSION

VENTILATION

SOLENOID

FUEL TANK

CHECK VALVE A

CHECK

VALVE B

INTAKE MANIFOLD

SYSTEM DIAGRAM

D

E

F

G

I

H

L

N

M

K

J

O

P

CHAMBER

AC

FUEL TANK DIFFRENTIAL

PRESSURE SENSOR

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст