Mitsubishi Eclipse / Eclipse Spyder (2000-2002). Service and repair manual — part 357

CHARGING SYSTEM

TSB Revision

ENGINE ELECTRICAL

16-5

STEP 3.

Q: Does the charging warning light brightly when the

ignition switch is turned on?

YES : Go to Step 4.

NO :

•

Check the ignition switch. (Refer to GROUP 54A,

Ignition switch

•

Check for burnt-out charging warning light.

•

Check the generator. (Refer to Generator

−

Disassembly and assembly

−

Inspection

•

Check the charging warning light-related circuits.

STEP 4.

Q: Does the charging warning light go out after starting the

engine?

YES : Go to Step 5.

NO : Check the generator (Refer to Generator

−

Disassembly and assembly

−

Inspection

STEP 5.

Q: Is an oscilloscope available?

YES : Go to Step 6.

NO : Go to Step 7.

STEP 6.

Q: Dose the oscilloscope show a normal wave pattern?

(Refer to Charging system

−

Wave pattern check using a

oscilloscope

YES : Go to Step 7.

NO : Check the generator. (Refer to Generator

−

Disassembly and assembly

−

Inspection

STEP 7.

•

Engine: 2,500 r/min

•

Headlight: ON (high beam)

•

Voltage between generator terminal B and the positive

battery terminal

OK: 0.5V or less

•

Voltage between the negative battery terminal and

generator body

OK: 0.5V or less

Q: Are the generator output line and ground line in good

condition?

YES : Go to Step 8.

NO : Check the generator output line and ground line.

CHARGING SYSTEM

TSB Revision

ENGINE ELECTRICAL

16-6

STEP 8.

Q: Is the output current normal? (Refer to Charging system

−

On vehicle service

−

Output current test

.)

YES : Go to Step 9.

NO : Check the generator (Refer to Generator

−

Disassembly and assembly

−

Inspection

STEP 9.

Q: Is the regulated voltage normal? (Refer to Charging

system

−

On vehicle service - Regulated voltage test

.)

YES : Go to Step 10.

NO : Check the generator (Refer to Generator

−

Disassembly and assembly

−

Inspection

STEP 10.

Q: Is the voltage drops in the generator output line

normal?

YES : Generator is normal. Check other systems.

NO : Check the output line.

ON-VEHICLE SERVICE

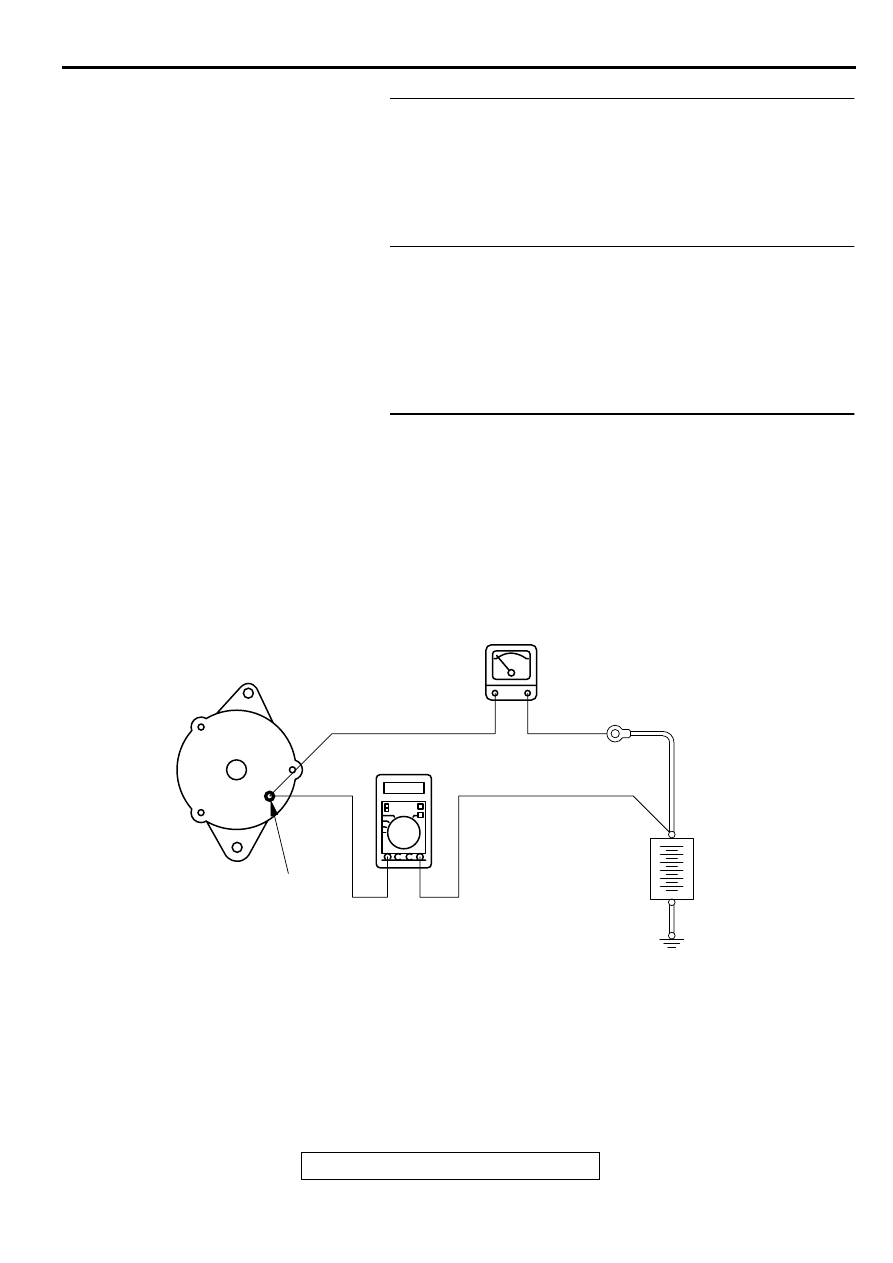

GENERATOR OUTPUT LINE VOLTAGE DROP TEST

M1161000900067

Required Special Tool:

MB991502: Scan Tool (MUT-II)

This test determines whether the wiring from the

generator "B" terminal to the positive battery terminal

(including the fusible link) is in good condition or not:

1. Always be sure to check the following before the

test.

•

Generator installation

•

Generator drive belt tension (Refer to GROUP

00, Maintenance Service

−

Drive Belts

•

Fusible link

•

Abnormal noise from the generator while the

engine is running

AKX00185

GENERATOR

AMMETER

VOLTMETER

(DIGITAL-TYPE)

BATTERY

+

-

"B"TERMINAL

AB

CHARGING SYSTEM

TSB Revision

ENGINE ELECTRICAL

16-7

2. Turn the ignition switch to the "LOCK" (OFF)

position.

WARNING

Battery posts, terminals and related

accessories contain lead and lead

compounds. WASH HANDS AFTER

HANDLING.

3. Disconnect the negative battery cable.

4. Disconnect the generator output wire from the

generator "B" terminal and connect a DC test

ammeter with a range of 0

−

100 A in series

between the "B" terminal and the disconnected

output wire. (Connect the positive lead of the

ammeter to the "B" terminal, and then connect the

negative lead of the ammeter to the disconnected

output wire.)

NOTE: A clamp-type ammeter which enables

measurements to be taken without disconnecting

the generator output wire is recommended. If the

voltage may have dropped due to a bad

connection at generator "B" terminal and the

generator "B" terminal is loosened when the test

ammeter is connected, the connection will be

completed at this time and the possibility of

finding the problems will be reduced.

5. Connect a digital-type voltmeter between the

generator "B" terminal and the positive battery

terminal. (Connect the positive lead of the

voltmeter to the "B" terminal, and then connect the

negative lead of the voltmeter to the positive

battery cable.)

WARNING

Battery posts, terminals and related

accessories contain lead and lead

compounds. WASH HANDS AFTER

HANDLING.

6. Reconnect the negative battery cable.

7. Connect a tachometer or scan tool MB991502.

8. Leave the hood open.

9. Start the engine.

10.With the engine running at 2,500 r/min, turn the

headlights and other lights on and off to adjust the

generator load so that the value displayed on the

ammeter is slightly above 30 A.

Limit value: maximum 0.3 V

NOTE: When the generator output is high and the

value displayed on the ammeter does not

decrease to 30A, set the value to 40A. Read the

value displayed on the voltmeter at this time.

In this case the limit value becomes maximum

0.4V.

Adjust the engine speed by gradually decreasing

it until the value displayed on the ammeter is 30

A. Take a reading of the value displayed on the

voltmeter at this time.

11.If the value displayed on the voltmeter is above

the limit value, there is probably a malfunction in

the generator output wire. Check the wiring

between the generator "B" terminal and the

positive battery terminal (including fusible link).

If a terminal is not sufficiently tight or if the

harness has become discolored due to

overheating, repair and then test again.

12.After the test, run the engine at idle.

13.Turn off all lights and turn the ignition switch to the

"LOCK" (OFF) position.

14.Disconnect the tachometer or scan tool

MB991502.

WARNING

Battery posts, terminals and related

accessories contain lead and lead

compounds. WASH HANDS AFTER

HANDLING.

15.Disconnect the negative battery cable.

16.Disconnect the ammeter and voltmeter and

tachometer.

17.Connect the generator output wire to the

generator "B" terminal.

WARNING

Battery posts, terminals and related

accessories contain lead and lead

compounds. WASH HANDS AFTER

HANDLING.

18.Connect the negative battery cable.

CHARGING SYSTEM

TSB Revision

ENGINE ELECTRICAL

16-8

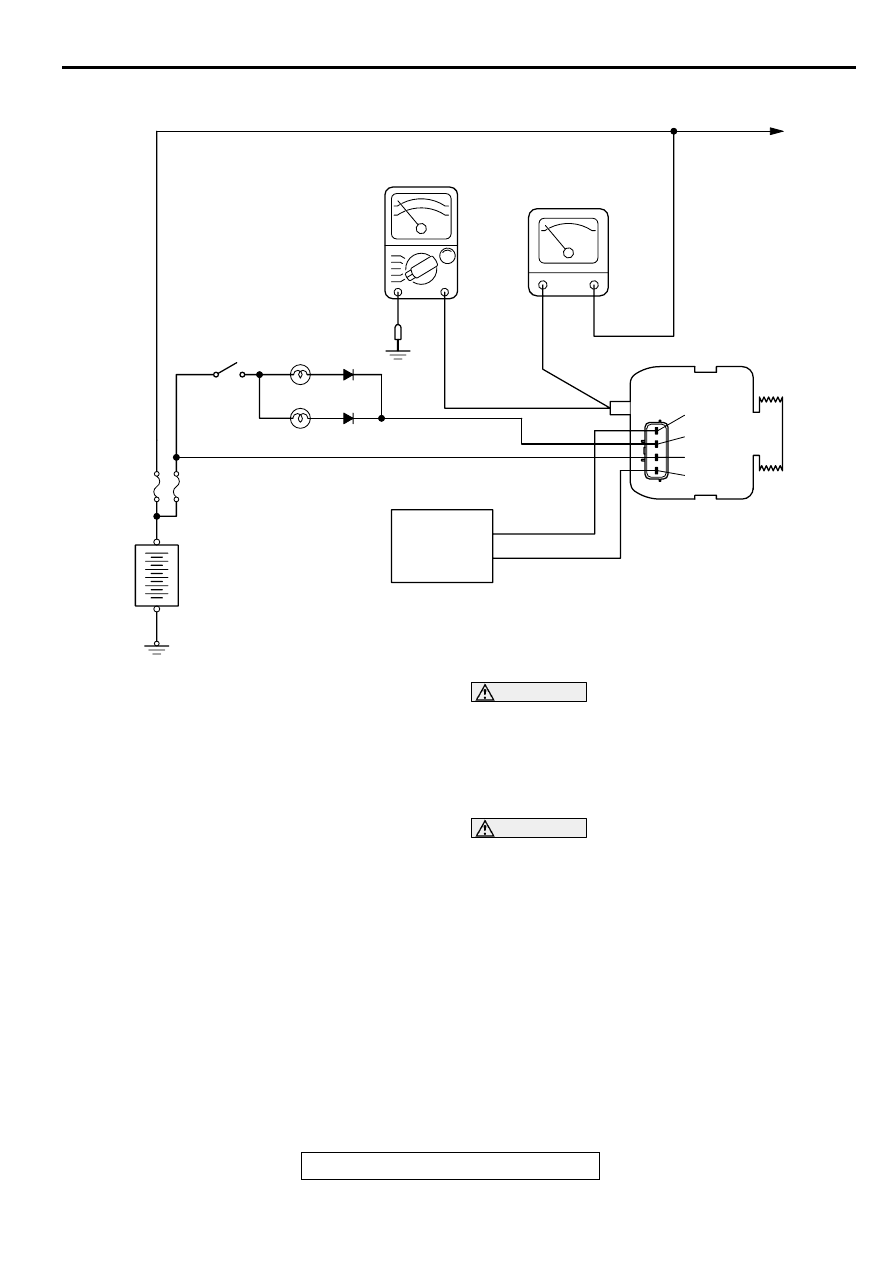

OUTPUT CURRENT TEST

M1161001000067

Required Special Tool:

MB991502: Scan Tool (MUT-II)

This test determines whether the generator outputs

normal current.

1. Before the test, always be sure to check the

following.

•

Generator installation

•

Battery (Refer to GROUP 54A, Battery

−

On-

vehicle Service

−

Battery Check

NOTE: The battery to be used should be slightly

discharged. The load in a fully-charged battery

will be insufficient and the test may not be able to

be carried out correctly.

•

Generator drive belt tension (Refer to GROUP

00, Maintenance Service

−

Drive Belts

•

Fusible link

•

Abnormal noise from the generator while the

engine is running

2. Turn the ignition switch to the "LOCK" (OFF)

position.

WARNING

Battery posts, terminals and related

accessories contain lead and lead

compounds. WASH HANDS AFTER

HANDLING.

3. Disconnect the negative battery cable.

WARNING

Never use clips to connect the line. Loose

connections (e.g. using clips) will lead to a

serious accident because of high current.

4. Disconnect the generator output wire from the

generator "B" terminal and connect a DC test

ammeter with a range of 0

−

100 A in series

between the "B" terminal and the disconnected

output wire. (Connect the positive lead of the

ammeter to the "B" terminal, and then connect the

negative lead of the ammeter to the disconnected

output wire.)

NOTE: A clamp-type ammeter which enables

measurements to be taken without disconnecting

the generator output wire is recommended.

AKX01214

VOLTMETER

AMMETER

LOAD

CHARGING

WARNING LIGHT

IGNITION

SWITCH

INDICATOR LAMP

(BRAKE WARNING LIGHT, etc.)

BATTERY

+

-

PCM<A/T>

GENERATOR

FR

L

S

G

AC

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст