Mitsubishi Eclipse / Eclipse Spyder (2000-2002). Service and repair manual — part 363

STARTING SYSTEM

TSB Revision

ENGINE ELECTRICAL

16-29

DISASSEMBLY SERVICE POINTS

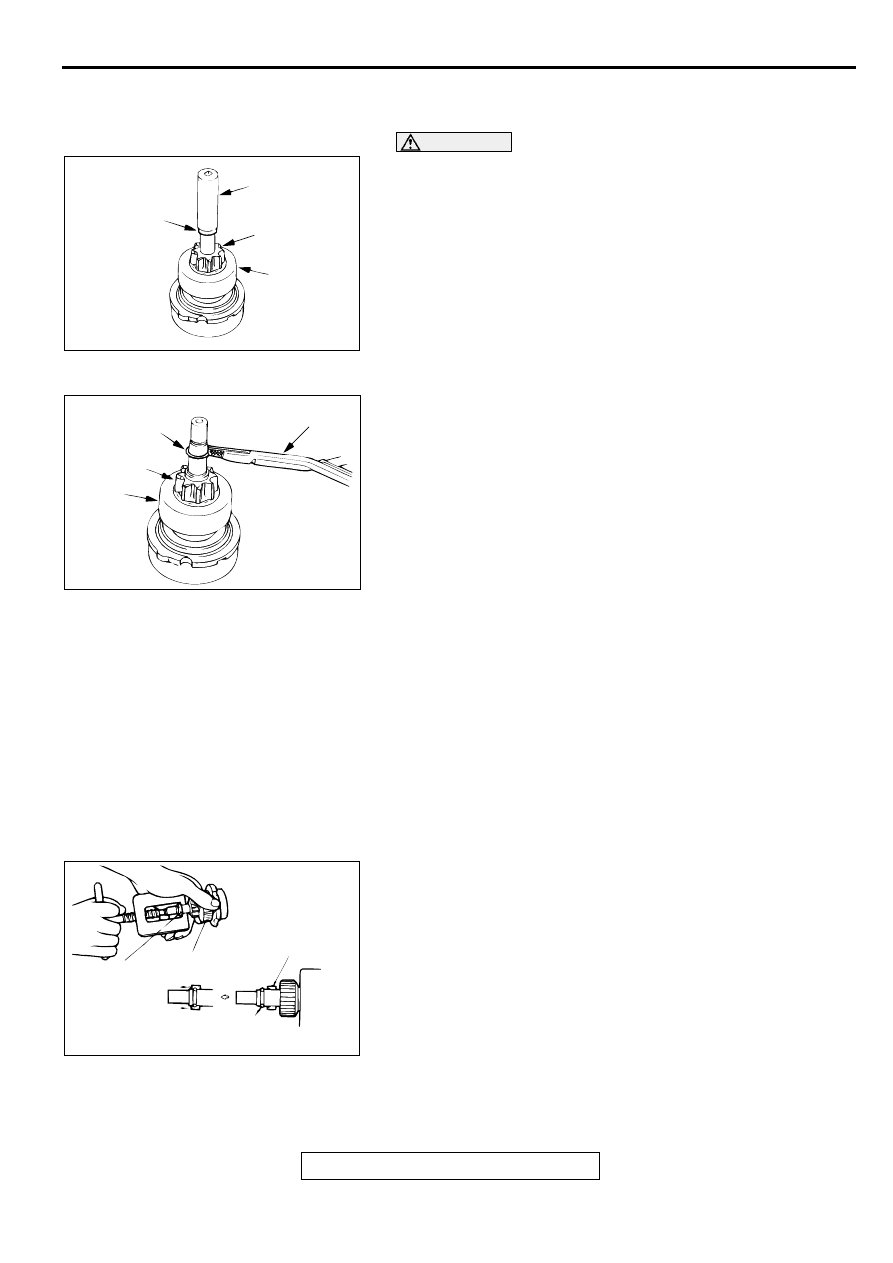

<<A>> ARMATURE AND BALL REMOVAL

CAUTION

When removing the armature, take care not to lose the ball

(which is used as a bearing) in the armature end.

<<B>> SNAP RING AND STOP RING REMOVAL

1. Press a long socket wrench of appropriate size to the stop

ring. Then tap the socket wrench to remove the stop ring to

the pinion gear side.

2. After removing the snap ring (by using snap-ring pliers),

remove the stop ring and the overrunning clutch.

STARTER MOTOR PART CLEANING

1. Do not immerse parts in cleaning solvent. Immersing the

yoke and field coil assembly and/or armature will damage

insulation. Wipe these parts with a shop towel only.

2. Do not immerse the drive unit in cleaning solvent.

Overrunning clutch is pre-lubricated at the factory and

solvent will wash lubrication from the clutch.

3. The drive unit may be cleaned with a brush moistened with

cleaning solvent and wiped dry with a shop towel.

ASSEMBLY SERVICE POINT

>>A<< STOP RING AND SNAP RING INSTALLATION

1. Using a suitable pulling tool, pull the overrunning clutch stop

ring over the snap ring.

AKX00370

SOCKET

STOP RING

PINION GEAR

OVERRUN-

NING

CLUTCH

AB

AKX00371

SNAP RING

PINION

GEAR

OVERRUN-

NING

CLUTCH

SNAP-RING

PLIERS

AB

AKX00372

STOP RING

OVERRUNNING

CLUTCH

SNAP RING

STOP

RING

AB

STARTING SYSTEM

TSB Revision

ENGINE ELECTRICAL

16-30

INSPECTION

M1162001300027

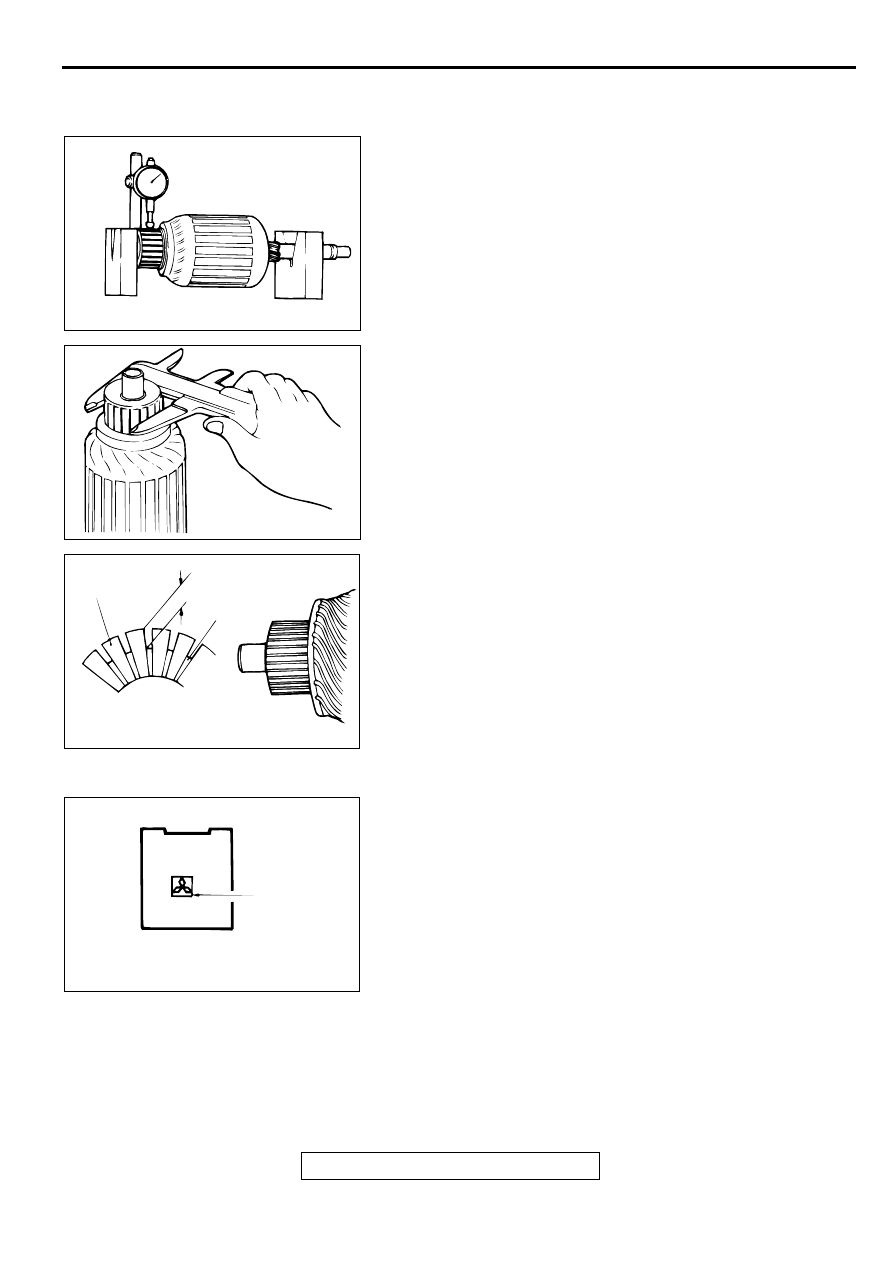

COMMUTATOR CHECK

1. Place the armature on a pair of V-blocks, and check the

deflection by using a dial gauge.

Standard value: 0.05 mm (0.002 inch)

Limit: 0.1 mm (0.004 inch)

2. Check the outer diameter of the commutator.

Standard value: 29.4 mm (1.16 inch)

Minimum limit: 28.8 mm (1.13 inch)

3. Check the depth of the undercut between segments.

Standard value: 0.5 mm (0.02 inch)

Minimum limit: 0.2 mm (0.008 inch)

BRUSH CHECK

1. Brushes that are worn beyond wear limit line, or oil-soaked,

should be replaced.

2. When replacing the ground brush, slide the brush from the

brush holder by prying the retaining spring back.

AKX00373

AKX00374

AKX00375

SEGMENT

UNDERCUT

MICA

AB

AKX00377

WEAR LIMIT

LINE

AB

STARTING SYSTEM

TSB Revision

ENGINE ELECTRICAL

16-31

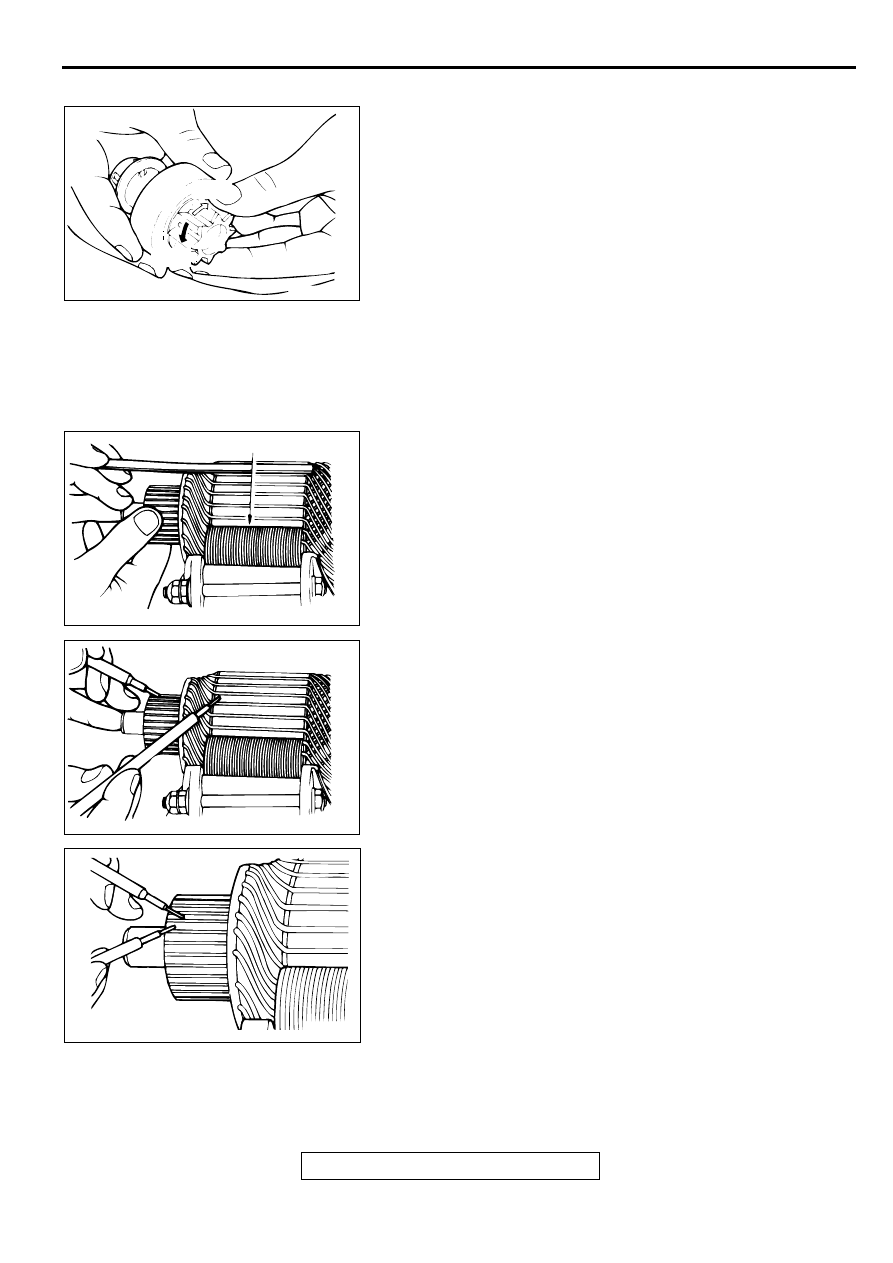

OVERRUNNING CLUTCH CHECK

1. While holding the clutch housing, rotate the pinion. The drive

pinion should rotate smoothly in one direction, but should

not rotate in opposite direction. If the clutch does not

function properly, replace the overrunning clutch assembly.

2. Inspect the pinion for wear or burrs. If the pinion is worn or

burred, replace the overrunning clutch assembly. If the

pinion is damaged, also inspect the ring gear for wear or

burrs.

FRONT AND REAR BRACKET BUSHING CHECK

Inspect the bushing for wear or burrs. If the bushing is worn or

burred, replace the front bracket assembly or rear bracket

assembly.

ARMATURE CHECK

1. Check that the armature coil is not grounded.

2. Place the armature in a growler.

3. Hold a thin steel blade parallel and just above while rotating

the armature slowly in the growler. A shorted armature will

cause a blade to vibrate and be attracted to the core.

Replace the shorted armature.

4. Check the insulation between the armature coil cores and

the commutator segments. They are normal if there is no

continuity.

5. Check for continuity between the segments. The condition is

normal if there is continuity.

AKX00378

FREE

LOCK

AB

AKX00379

GROWLER

AB

AKX00380

AKX00381

IGNITION SYSTEM

TSB Revision

ENGINE ELECTRICAL

16-32

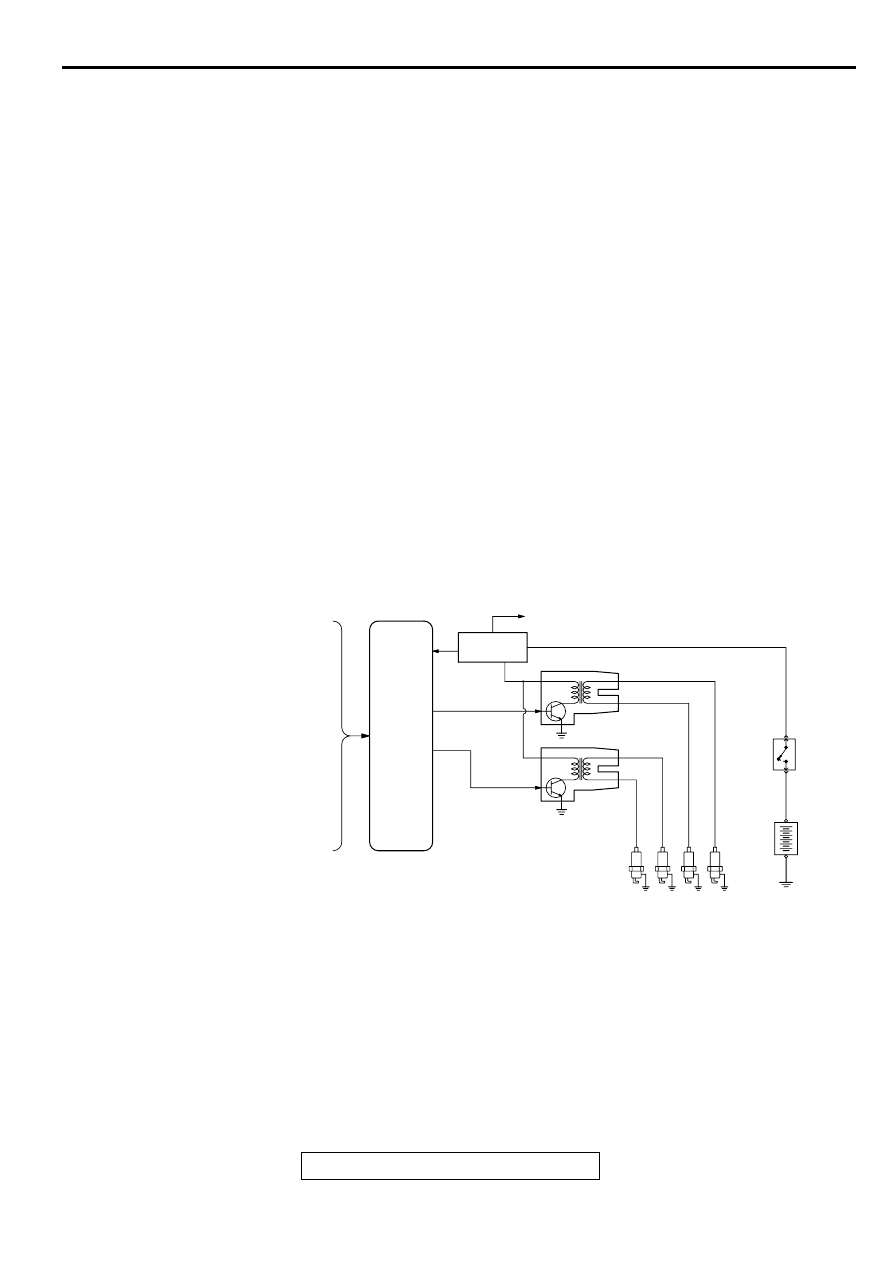

IG N ITIO N SYSTEM

GENERAL DESCRIPTION

M1163000100045

<2.4L Engine>

This system is provided with two ignition coils (A and

B) with built-in ignition power transistors for the

number 1 and number 4 cylinders, and number 2 and

number 3 cylinders respectively.

Interruption of the primary current flowing in the

primary side of ignition coil A generates a high

voltage in the secondary side of ignition coil A.

The high voltage thus generated is applied to the

spark plugs of number 1 and number 4 cylinders to

generate sparks. At the time that the sparks are

generated at both spark plugs, if one cylinder is at

the compression stroke, the other cylinder is at the

exhaust stroke, so that ignition of the compressed

air/fuel mixture occurs only for the cylinder which is

at the compression stroke.

In the same way, when the primary current flowing in

ignition coil B is interrupted, the high voltage thus

generated is applied to the spark plugs of number 2

and number 3 cylinders.

The engine control module controls the two ignition

power transistors to turn them alternately ON and

OFF. This causes the primary currents in the ignition

coils to be alternately interrupted and allowed to flow

to fire the cylinders in the order 1

−

3

−

4

−

2.

The engine control module determines which ignition

coil should be controlled by means of the signals

from the camshaft position sensor which is

incorporated in the camshaft and from the crankshaft

position sensor which is incorporated in the

crankshaft.

It also detects the crankshaft position in order to

provide ignition at the most appropriate timing in

response to the engine operation conditions.

When the engine is cold or operated at high

altitudes, the ignition timing is slightly advanced to

provide optimum performance.

<3.0L Engine>

Interruption of the primary current flowing in the

primary side of the ignition coil generates high

voltage in the secondary side of the ignition coil. The

high voltage thus generated is directed by the

distributor to the applicable spark plug. The engine

firing order is 1

−

2

−

3

−

4

−

5

−

6 cylinders.

On application of high voltage, the spark plug

generates a spark to ignite the compressed air fuel

mixture in the combustion chamber.

The engine control module makes and breaks the

primary current of the ignition coil to regulate the

ignition timing.

AKX01212

INTAKE AIR TEMPERATURE SENSOR

BAROMETRIC PRESSURE SENSOR

CAMSHAFT POSITION SENSOR

CRANKSHAFT POSITION SENSOR

VEHICLE SPEED SENSOR

PARK/NEUTRAL POSITION SWITCH <A/T>

IGNITION SWITCH-ST

KNOCK SENSOR <M/T>

CLOSED THROTTLE POSITION

SWITCH

ENGINE COOLANT TEMPERATURE

SENSOR

VOLUME AIR FLOW SENSOR

ECM

<M/T>,

PCM

<A/T>

IGNITION

FAILURE

SENSOR

TO TACHOMETER

IGNITION COIL A

IGNITION COIL B

IGNITION

SWITCH

BATTERY

SPARK PLUGS

CYLINDER NO.

3

2

4

1

AB

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст