Mitsubishi Colt Ralliart. Manual — part 756

TROUBLESHOOTING

MULTIPORT FUEL INJECTION (MPI) <4G1>

13B-349

65

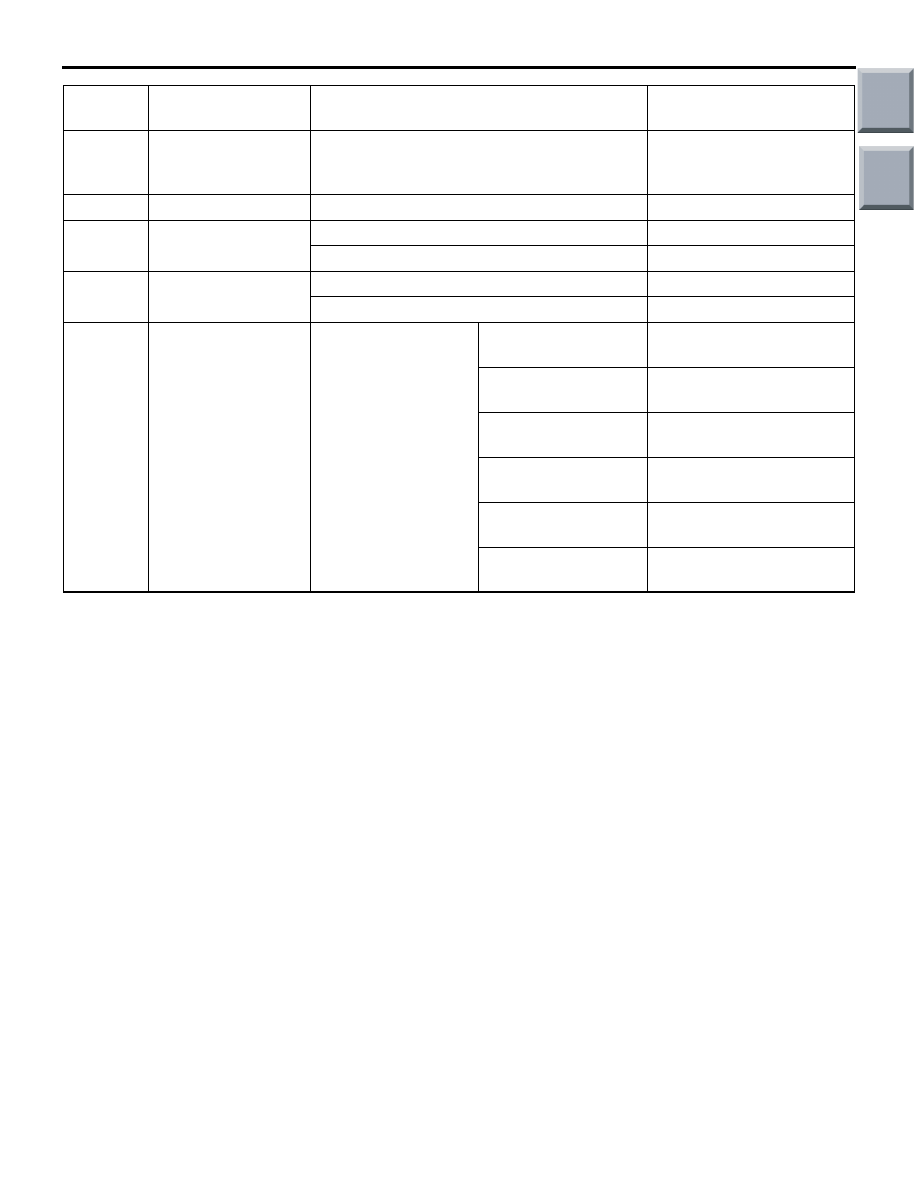

Alternator FR

terminal

• Engine: Idling after warm-up

• Radiator fan: Inoperative

• Headlamp switch: OFF → ON

• Stop lamp: OFF → ON

• Rear defogger switch: OFF → ON

Voltage decreases

77

Power supply

Ignition switch: ON

System voltage

92

78

Power supply for

throttle valve control

servo

Ignition switch: ON

System voltage

79

Oxygen sensor

(rear) heater

Engine: Idling

1 V or less

Engine: 5,000 r/min

System voltage

81

Fuel pump relay

Ignition switch: ON

System voltage

Engine: Idling

1 V or less

82

Backup power

supply

Ignition switch: "LOCK" (OFF)

System voltage

83

Accelerator pedal

position sensor

(main)

Ignition switch: ON

Release the

accelerator pedal

0.8

− 1.2 V

Depress the

accelerator pedal

fully

4.0 V or more

85

Power supply

voltage applied to

accelerator pedal

position sensor

(main)

Ignition switch: ON

4.9

− 5.1 V

86

Power supply

voltage applied to

accelerator pedal

position sensor (sub)

Ignition switch: ON

4.9

− 5.1 V

88

Accelerator pedal

position sensor (sub)

Ignition switch: ON

Release the

accelerator pedal

0.3

− 0.7 V

Depress the

accelerator pedal

fully

2.0 V or more

90

Airflow sensor

Raise engine speed gradually

Voltage rises with engine

speed

95

Cooling fan control

relay (Lo)

Fan inactive state

System voltage

Fan low-speed rotation state

1 V or less

96

Cooling fan control

relay (Hi)

Fan inactive state

System voltage

Fan high-speed rotation state

1 V or less

97

Oxygen sensor

(rear)

Engine: Running at 2,500 r/min after warmed

up

0.2

− 0.8 V (After several

seconds have elapsed)

107

Engine control relay Ignition switch: "LOCK" (OFF)

System voltage

Ignition switch: ON

1 V or less

Terminal

No.

Check item

Check condition (Engine condition)

Normal condition

Main

Index

Group

TOC

TROUBLESHOOTING

MULTIPORT FUEL INJECTION (MPI) <4G1>

13B-350

110

A/C relay

• Engine: Idling

• A/C switch: OFF → ON

(A/C compressor is operating)

System voltage

122

Ignition switch - IG

Ignition switch: ON

System voltage

123

Throttle valve control

servo relay

Ignition switch: "LOCK" (OFF)

0

− 0.1 V

Ignition switch: ON

1 V or less

128

Stop lamp switch

Depress the brake pedal

System voltage

Release the brake pedal

1 V or less

129

Intake air

temperature sensor

Ignition switch: ON

When intake air

temperature is

−20°C

3.8

− 4.4 V

When intake air

temperature is 0

°C

3.2

− 3.8 V

When intake air

temperature is 20

°C

2.3

− 2.9 V

When intake air

temperature is 40

°C

1.5

− 2.1 V

When intake air

temperature is 60

°C

0.8

− 1.4 V

When intake air

temperature is 80

°C

0.4

− 1.0 V

Terminal

No.

Check item

Check condition (Engine condition)

Normal condition

Main

Index

Group

TOC

TROUBLESHOOTING

MULTIPORT FUEL INJECTION (MPI) <4G1>

13B-351

CHECK CHART FOR RESISTANCE AND

CONTINUITY BETWEEN TERMINALS

1. Turn the ignition switch to "LOCK" (OFF) position.

2. Disconnect the engine-ECU connector.

3. Measure the resistance and check for continuity

between the terminals of the engine-ECU

harness-side connector while referring to the

check chart.

NOTE:

.

1. When measuring resistance and checking

continuity, a harness for checking contact pin

pressure should be used instead of inserting a

test probe.

2. Checking need not be carried out in the order

given in the chart.

CAUTION

If the terminals that should be checked are mis-

taken, or if connector terminals are not correctly

shorted to earth, damage may be caused to the

vehicle wiring, sensors, engine-ECU and/or ohm-

meter. Be careful to prevent this!

4. If the ohmmeter shows any deviation from the

standard value, check the corresponding sensor,

actuator and related electrical wiring, and the

repair or replace.

5. After repair or replacement, recheck with the

ohmmeter to confirm that the repair or

replacement has corrected the problem.

Engine-ECU Harness Side Connector

AK402726

61

46

31

64

49

19

34

50

51

6665

36

21

35

20

47

48

6362

33

18

32

17

58

43

28

44

45

6059

30

1615

29

14

41

42

5756

27

12

13

26

11

53

38

23

8

39

40

54

55

24

9

L

25

10

37

52

22

7

5

3

1

6

4

2

93

71

72

75

73

76

74

92

77

98

83

95 94

R

96

97

80

78

79

81

82

99

86

84

85

107

122

108

123

109

124

110

125

111

126

112

127

113

128

114

129

115

130

116

131

117

132

118

133

119

134

120

135

121

136

101100

102

103

104

105

106

87

88

919089

A-114

A-08

AC

Engine-CVT-ECU Harness Side Connector

Terminal

No.

Inspection item

Normal condition (check condition)

7

− 22

Throttle valve control servo

0.3

− 100 Ω (at 20°C)

8

− 92

No. 1 injector

10.5

− 13.5 Ω (at 20°C)

9

− 92

No. 2 injector

23

− 92

No. 3 injector

24

− 92

No. 4 injector

14

− 29

Engine coolant temperature sensor

14

− 17 kΩ (When engine coolant temperature is

−20°C)

5.1

− 6.5 kΩ (When engine coolant temperature is 0°C)

2.1

− 2.7 kΩ (When engine coolant temperature is

20

°C)

0.9

− 1.3 kΩ (When engine coolant temperature is

40

°C)

0.48

− 0.68 kΩ (When engine coolant temperature is

60

°C)

0.26

− 0.36 kΩ (When engine coolant temperature is

80

°C)

36

− 92

Waste gate solenoid valve

29

− 35 Ω (at 20°C)

38

− 92

Purge control solenoid valve

30

− 34 Ω (at 20°C)

Main

Index

Group

TOC

TROUBLESHOOTING

MULTIPORT FUEL INJECTION (MPI) <4G1>

13B-352

INSPECTION PROCEDURE USING

OSCILLOSCOPE

M1131154501739

The output signals of the sensors and the conditions

of the actuation signals of the actuators can be

inspected visually by observing the waveforms on

the oscilloscope.

CAMSHAFT POSITION SENSOR AND

CRANK ANGLE SENSOR

Measurement Method

1. Disconnect the camshaft position sensor

connector and connect the special tool test

harness (MB991709) in between (All terminals

should be connected).

2. Disconnect the crank angle sensor intermediate

connector and connect the special tool test

harness (MB991658) in between.

3. Connect the probe of each channel of the

oscilloscope to camshaft position sensor

connector terminal No. 2 and crank angle sensor

intermediate connector terminal No. 2.

Alternate Method (Test harness not

available)

1. Disconnect the engine-ECU connector and

connect the special tool Power plant ECU check

harness (MB991987) in between.

2. Connect the oscilloscope special patterns pickup

to engine-ECU terminal No. 12 (When checking

the camshaft position sensor signal wave pattern).

3. Connect the oscilloscope special patterns pickup

to engine-ECU terminal No. 13 (When checking

the crank angle sensor signal wave pattern).

51

− 92

Oxygen sensor heater (front)

5

− 30 Ω (at 20°C)

52

− 92

Oil feeder control valve

6.9

− 7.9 Ω (at 20°C)

57

− 92

Fuel pressure solenoid valve

29

− 35 Ω (at 20°C)

75

− Body

earth

ECU earth

Continuity (2

Ω or less)

76

− Body

earth

93

− Body

earth

108

−

Body

earth

129

− 102 Intake air temperature sensor

13

− 17 kΩ (When intake air temperature is −20°C)

5.4

− 6.6 kΩ (When intake air temperature is 0°C)

2.3

− 3.0 kΩ (When intake air temperature is 20°C)

1.0

− 1.5 kΩ (When intake air temperature is 40°C)

0.56

− 0.76 kΩ (When intake air temperature is 60°C)

0.31

− 0.43 kΩ (When intake air temperature is 80°C)

79

− 92

Oxygen sensor heater (rear)

5

− 30 Ω (at 20°C)

Terminal

No.

Inspection item

Normal condition (check condition)

2 3

3

2

1

1

AK203241

Crank angle sensor

intermediate

connector

Oscilloscope

Camshaft position

sensor connector

AD

Main

Index

Group

TOC

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст