Mitsubishi Colt Ralliart. Manual — part 757

TROUBLESHOOTING

MULTIPORT FUEL INJECTION (MPI) <4G1>

13B-353

Standard Wave Pattern

Observation condition

Description of Wave Pattern

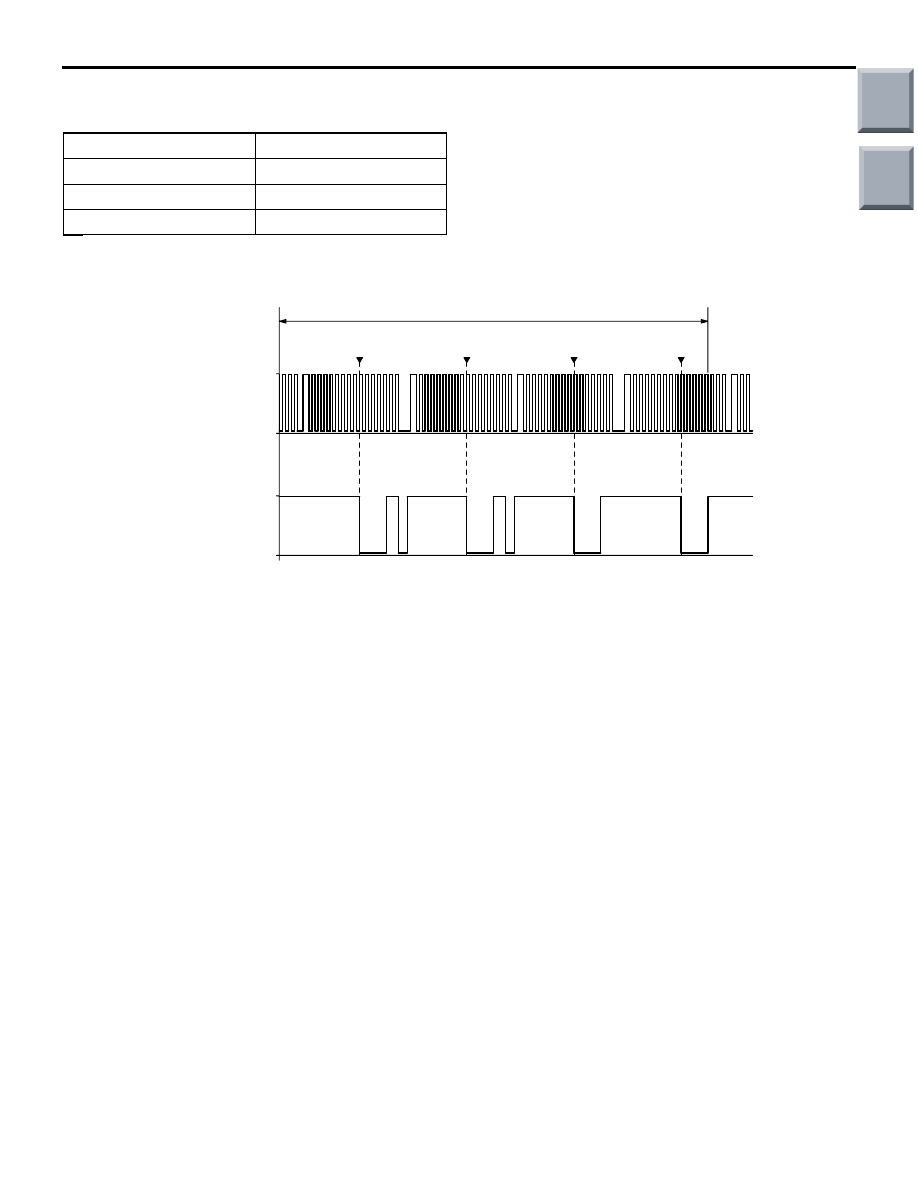

• The camshaft position sensor detects the com-

pression top dead center of each cylinder.

Observing this signal as well as other control sig-

nals simultaneously allows cylinder identification

to be achieved.

• The crank angle sensor detects the crank angle

of each cylinder. 72 crank angle sensor high sig-

nals (including missing tooth) are output at equal

spaces per two revolutions of the engine.

Wave Pattern Observation Points

• Check that the wave pattern becomes shorter

when the engine speed increases.

Function

Special patterns

Pattern height

Low

Pattern selector

Display

Engine

Idle

AK204111AC

(V)

5

0

5

0

No. 1TDC

No. 3TDC

No. 4TDC

No. 2TDC

time

Standard wave pattern

Crank angle

sensor output

wave pattern

Camshaft position

sensor output

wave pattern

2 engine revolutions

(1 camshaft revolution)

TDC: Top dead centre

Main

Index

Group

TOC

TROUBLESHOOTING

MULTIPORT FUEL INJECTION (MPI) <4G1>

13B-354

Examples of Abnormal Wave Patterns

•

Example 1

Wave pattern characteristics

Rectangular wave pattern is output even when the

engine is not started.

Cause of problem

Sensor interface malfunction

•

Example 2

Wave pattern characteristics

Wave pattern shifts left and right frequently.

Cause of problem

Loose timing belt

Abnormality in sensor disk

INJECTOR

Measurement Method

1. Disconnect the injector connector and connect the

special tool test harness (MB991658) in between

(All terminals should be connected).

2. Connect the probe of the oscilloscope to injector

connector terminal No. 2.

Alternate Method (Test harness not

available)

1. Disconnect the engine-ECU connector and

connect the special tool Power plant ECU check

harness (MB991987) in between.

2. Connect the oscilloscope special patterns pickup

to engine-ECU terminal No. 8 (When checking the

No. 1 cylinder).

3. Connect the oscilloscope special patterns pickup

to engine-ECU terminal No. 9 (When checking the

No. 2 cylinder).

4. Connect the oscilloscope special patterns pickup

to engine-ECU terminal No. 23 (When checking

the No. 3 cylinder).

5. Connect the oscilloscope special patterns pickup

to engine-ECU terminal No. 24 (When checking

the No. 4 cylinder).

AK304525

AK203244

AK101807

1

2

AC

Special

patterns

pickup

Oscilloscope

Main

Index

Group

TOC

TROUBLESHOOTING

MULTIPORT FUEL INJECTION (MPI) <4G1>

13B-355

Standard Wave Pattern

Observation conditions

Description of Wave Pattern

• Normally the power voltage is applied, and when

there is a signal from the engine-ECU, the volt-

age drops to near 0 V only for the drive signal

time.

• When the signal from the engine-ECU is turned

off, the peak of the voltage appears by the back

electromotive force of the coil, and the voltage

returns to the power voltage.

• Injector drive time: Fuel injection time determined

by the engine-ECU according to output values of

various sensors. Injector drive time = effective

injection time + ineffective injection time (ineffec-

tive injection time: Corrects operation delay

caused by a drop in the power voltage)

• Back electromotive force of solenoid coil: When

the signal from the engine-ECU is turned off, a

back electromotive force is generated in the

injector coil (approximately 65

− 75 V).

• Power voltage: When there is no signal from the

engine-ECU, the power voltage is applied. When

this power voltage is low, the ineffective injection

time becomes long, and the drive time also

becomes long.

Wave Pattern Observation Points

Point A: Height of solenoid back electromotive force

Point B: Injector drive time

• The injector drive time will be synchronized with

the M.U.T.-III tester display.

• When the engine is suddenly raced, the drive

time will be greatly extended at first, but the drive

time will soon match the engine speed.

Function

Special patterns

Pattern height

Variable

Variable knob

Adjust while viewing the

wave pattern

Pattern selector

Display

Engine

Idle

AK305803

(V)

50

0

Power

voltage

Solenoid back

electromotive force

(Approximately 7×10V)

Drive signal: ON

Drive signal: OFF

Point B

Injector drive

time

Point A.

Standard wave pattern

Time

AB

Contrast with standard wave

pattern

Probable

cause

Solenoid coil back electromotive

force is low or does not appear at

all.

Short in the

injector solenoid

AKX01605AE

When idling

When racing

Main

Index

Group

TOC

TROUBLESHOOTING

MULTIPORT FUEL INJECTION (MPI) <4G1>

13B-356

IGNITION COIL AND POWER TRANSIS-

TOR

Measurement Method

1. Disconnect the ignition coil connector, and

connect the special tool test harness (MB991658)

in between (All terminals should be connected).

2. Connect the probe of the oscilloscope to ignition

coil connector terminal No. 3.

3. To check the ignition advance condition, observe

the crank angle sensor output signal

simultaneously.

Alternate Method (Test harness not

available)

1. Disconnect the engine-ECU connector and

connect the special tool Power plant ECU check

harness (MB991987) in between.

2. Connect the oscilloscope probe to engine-ECU

terminal No. 10 (When checking the number 1

cylinder.)

3. Connect the oscilloscope probe to engine-ECU

terminal No. 25 (When checking the number 2

cylinder.)

4. Connect the oscilloscope probe to engine-ECU

terminal No. 40 (When checking the number 3

cylinder.)

5. Connect the oscilloscope probe to engine-ECU

terminal No. 55 (When checking the number 4

cylinder.)

Standard Wave Pattern

Observation condition

AK000845

1 2 3

AC

Ignition coil

connector

Oscilloscope

Function

Special patterns

Pattern height

Low

Pattern selector

Display

Engine

Idle

AK204112

Standard wave pattern

Crank angle

sensor output

wave pattern

Power transistor

control signal

wave pattern

TDC: Top dead centre

AC

2 engine revolutions

(1 camshaft revolution)

Ignition timing

Dwell section

0

10

OFF

ON

5˚ BTDC

(V)

TDC

0

5

Main

Index

Group

TOC

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст