Mitsubishi Colt Ralliart. Manual — part 608

ROCKER ARMS AND CAMSHAFT

ENGINE OVERHAUL <4G1>

11D-32

NOTE: If the lash adjuster contracts, perform the

operations 7 through 9 again. Replace the lash

adjuster if it still contracts even after the pressure

chamber has completely been filled with diesel

fuel (air has been bled).

10.Keep the serviced lash adjusters in their upright

positions to prevent diesel fuel from spilling out.

Protect them from dust or other foreign matter.

Install the lash adjusters onto the engine as soon

as possible.

Main

Index

Group

TOC

CYLINDER HEAD AND VALVES

ENGINE OVERHAUL <4G1>

11D-33

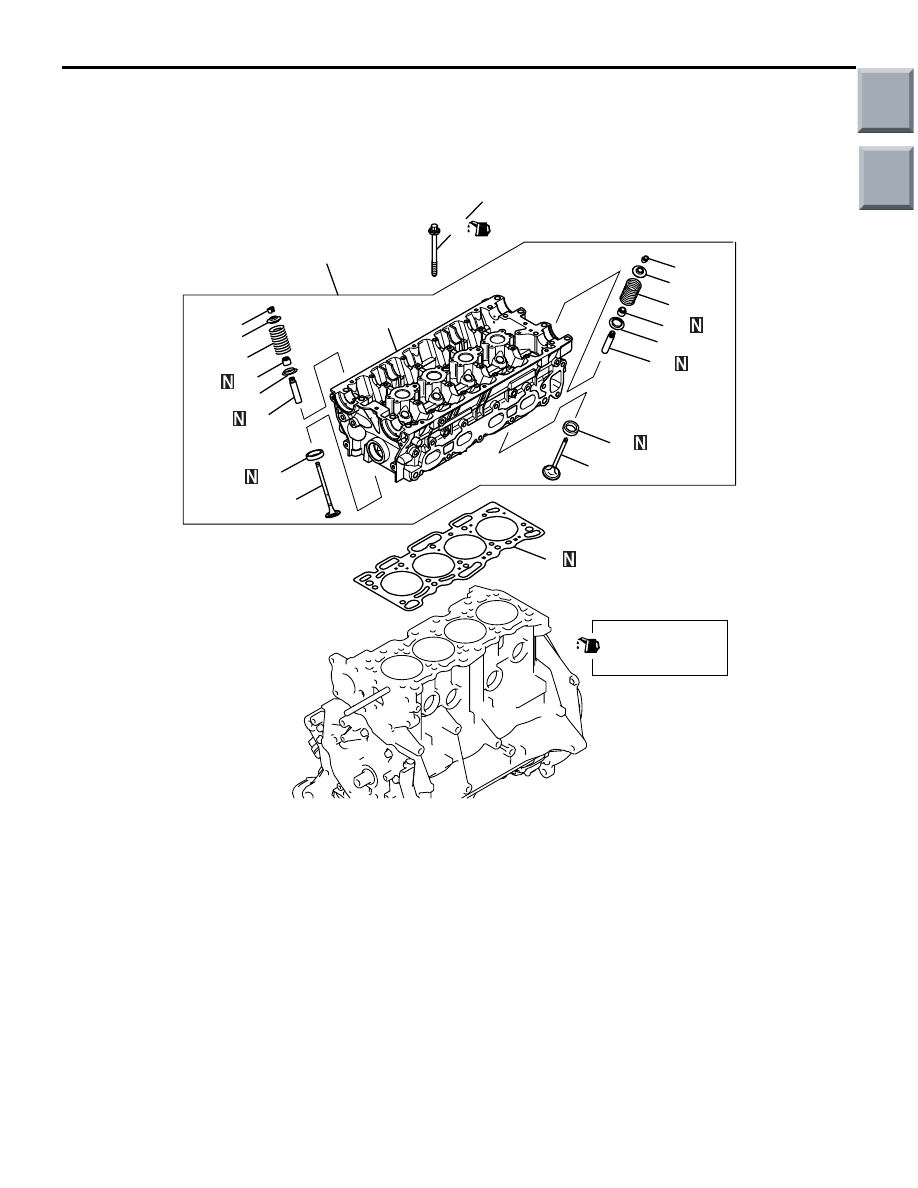

CYLINDER HEAD AND VALVES

REMOVAL AND INSTALLATION

M1113006901003

AK202373

49 ± 2 N·m

→ 0 N·m → 20 ± 2 N·m → 90˚ + 90˚

1

2

15

16

14

9

11

19

12

13

10

20

18

7

17

8

4

5

6

3

AD

Apply engine oil to

all moving parts

before installation.

Removal steps

<<

A

>> >>

D

<< 1. Cylinder head bolt

2. Cylinder head assembly

3. Cylinder head gasket

<<

B

>> >>

C

<< 4. Retainer lock

5. Valve spring retainer

>>

B

<< 6. Valve spring

7. Intake valve

<<

B

>> >>

C

<< 8. Retainer lock

9. Valve spring retainer

>>

B

<< 10. Valve spring

11. Exhaust valve

>>

A

<< 12. Valve stem seal

13. Valve spring seat

>>

A

<< 14. Valve stem seal

15. Valve spring seat

16. Intake valve guide

17. Exhaust valve guide

18. Intake valve seat

19. Exhaust valve seat

20. Cylinder head

Removal steps (Continued)

Main

Index

Group

TOC

CYLINDER HEAD AND VALVES

ENGINE OVERHAUL <4G1>

11D-34

REMOVAL SERVICE POINTS

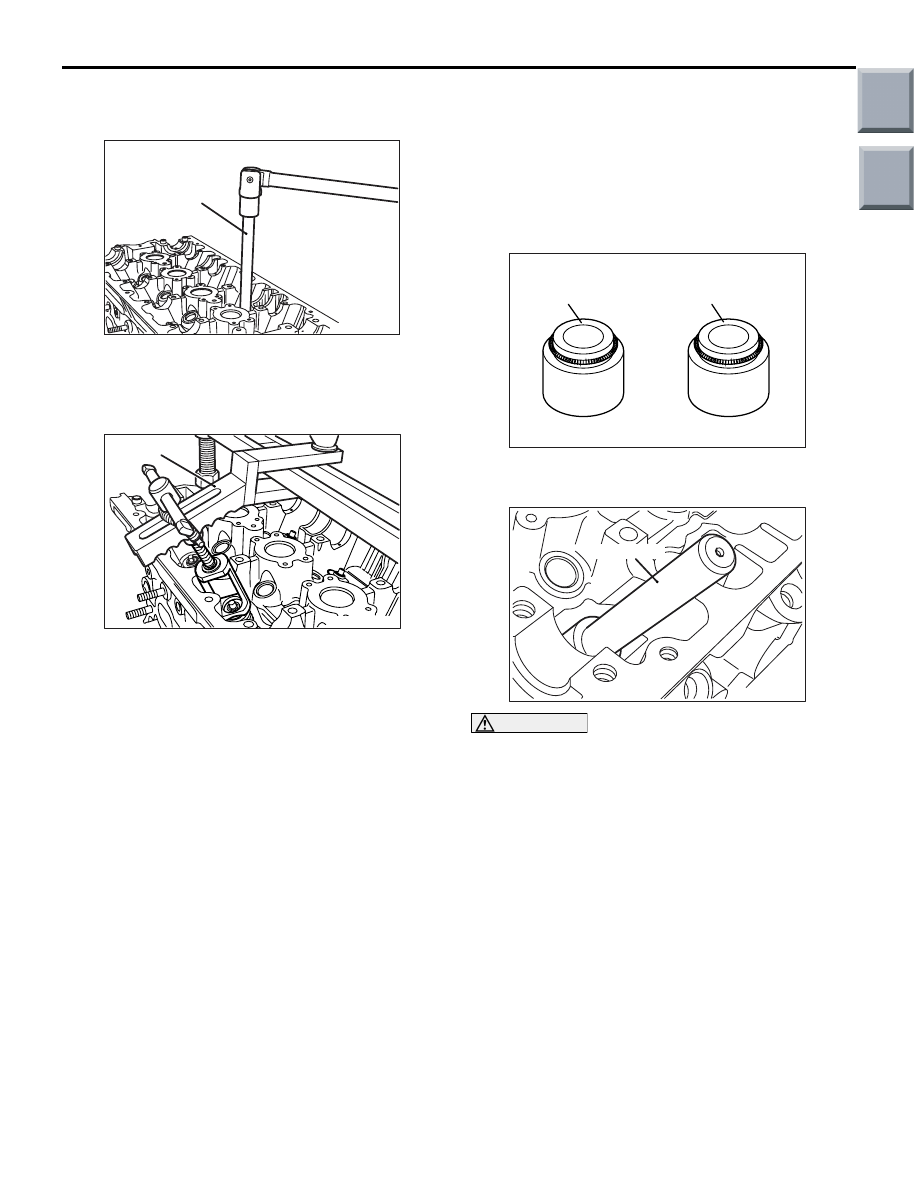

<<A>> CYLINDER HEAD BOLT REMOVAL

AK201787

MB991653

AC

Use the special tool Cylinder head bolt wrench

(MB991653) to loosen the cylinder head bolts.

<<B>> RETAINER LOCK REMOVAL

AK201789

MD998772

AC

Compress the valve spring using the special tool

Valve spring compressor (MD998772), then remove

the retainer lock.

NOTE: Store removed valves, springs and other

parts, after putting to each of them a tag that identi-

fies its cylinder No. or installation location.

INSTALLATION SERVICE POINTS

>>A<< VALVE STEM SEAL INSTALLA-

TION

1. Install the valve spring seat.

2. Install the valve.

3. Apply a thin coat of engine oil to a new valve stem

seal.

AK302994AC

Exhaust valve stem seal

Colour: Grayish green

Intake valve stem seal

Colour: Gray

NOTE: Do not confuse the stem seals for intake

valves with those for exhaust valves.

AK201791AC

MB991671

CAUTION

• Do not reuse the valve stem seal.

• The special tool must always be used when

installing the valve stem seal. Improper instal-

lation could result in oil leaks past the valve

guide.

4. Use the special tool Valve seal installer

(MB991671) to install the stem seal on the valve

guide. Use the stem of the valve to guide the stem

seal.

Main

Index

Group

TOC

CYLINDER HEAD AND VALVES

ENGINE OVERHAUL <4G1>

11D-35

>>B<< VALVE SPRING INSTALLATION

AK300590AB

Spring

retainer

Stem

seal

Spring

seat

Painted

end

Install each valve spring with the painted end toward

the rocker arm.

>>C<< RETAINER LOCK INSTALLATION

AK201789

MD998772

AC

Compress the valve spring using the special tool

Valve spring compressor (MD998772), then install

the retainer lock.

>>D<< CYLINDER HEAD BOLT

INSTALLATION

AK300591AB

Shank length

1. When reusing a cylinder head bolt, check that its

nominal length (shank length) is not greater than

the limit. If the limit is exceeded, replace the bolt.

Limit: 103.2 mm

2. Apply engine oil to the threads and washer of the

bolt.

AK201788

MB991653

AC

NOTE: Use the special tool Cylinder head bolt

wrench (MB991653) to tighten the bolts.

AK304398

1

3

9

6

8

2

5

7

4

10

Timing belt side

AB

3. Tighten the bolts to 49

± 2 N⋅m in the indicated

sequence.

4. Loosen all the bolts completely.

5. Tighten the bolts again to a torque of 20

± 2 N⋅m

in the indicated sequence.

AK202720

Paint marks

90˚

90˚

AB

CAUTION

• If the tightening angle is smaller than 90°,

proper fastening performance could not be

assured. Be sure to respect that angle.

• If the bolt is tightened to an angle greater than

the specified angle, loosen the bolt com-

pletely and then retighten it beginning with

the first step.

6. Make paint marks on each bolt’s head and on the

cylinder head.

7. Turn the bolts 90

° in the tightening direction and

in the indicated sequence.

Main

Index

Group

TOC

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст