Mitsubishi Colt Ralliart. Manual — part 6

CAMSHAFT

ENGINE MECHANICAL <4A9>

11A-21

INSTALLATION SERVICE POINTS

>>A<< OIL CONTROL VALVE FILTER

INSTALLATION

CAUTION

When installing the oil control valve filter, exer-

cise special care to avoid adhesion of foreign

objects and damage/deformation of the filter.

>>B<< O-RING/OIL CONTROL VALVE

INSTALLATION

1. Cover the oil groove of the oil control valve with a

cardboard.

CAUTION

When installing the O-ring to the oil control

valve, take care not to damage the O-ring.

2. Apply the engine oil to the O-ring and install it to

the oil control valve.

CAUTION

When installing the oil control valve to the cylin-

der head, take care not to damage the O-ring.

3. Apply the engine oil to the O-ring and install the oil

control valve to the cylinder head.

>>C<< CAMSHAFT/CAMSHAFT BEARING

CAP/FRONT CAMSHAFT BEARING CAP/

V.V.T. SPROCKT ASSEMBLY/CAMSHAFT

SPROCKET INSTALLATION

AC312251

AC

V.V.T. sprocket assembly

Camshaft sprocket

Inlet camshaft

Exhaust camshaft

Dowel pin

Dowel pin

Hole

Groove

1. First, lift the V.V.T. sprocket assembly side of the

camshaft sprocket, V.V.T. sprocket assembly and

the timing chain assembly. Then align the dowel

pin of the inlet camshaft with the V.V.T. sprocket

assembly hole, and assemble the inlet camshaft

and the V.V.T. sprocket assembly. Temporarily

tighten the mounting bolt.

2. Next, lift the camshaft sprocket side of the

camshaft sprocket, V.V.T. sprocket assembly and

the timing chain assembly. Then align the dowel

pin of the exhaust camshaft with the camshaft

sprocket groove, and assemble the exhaust

camshaft and the camshaft sprocket. Temporarily

tighten the mounting bolt.

3. Place the inlet camshaft and exhaust camshaft on

the installing location of the cylinder head.

AC403719

AE

3

8

8

2

7

7

1

6

6

5

5

4

4

3

3

2

2

1

1

Engine front

Front camshaft

bearing cap

Camshaft bearing cap

Camshaft bearing cap

CAMSHAFT

ENGINE MECHANICAL <4A9>

11A-22

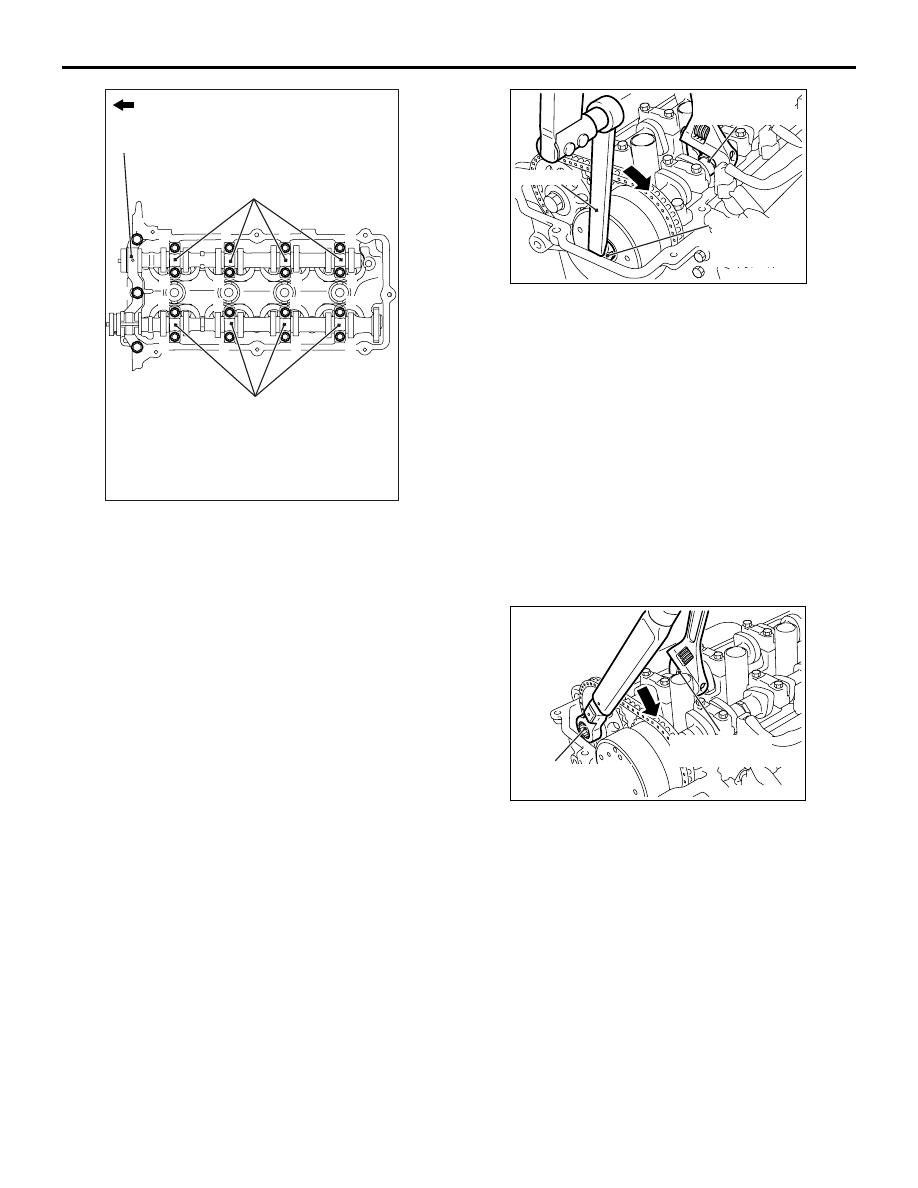

4. Tighten each camshaft bearing cap mounting

bolts to the specified torque in the order shown,

and then tighten the front camshaft bearing cap

mounting bolts as well.

Tightening torque:

11

± 1 N⋅m (Camshaft bearing cap mounting

bolts)

20

± 1 N⋅m (Front camshaft bearing cap

mounting bolts)

AC311267

AC

Hexagon part of

the inlet camshaft

V.V.T. sprocket

assembly

mounting bolt

MB991992

5. While holding the inlet camshaft hexagonal area

using a wrench or a similar tool, use special tool

torque wrench adapter (MB991992) to tighten the

V.V.T. sprocket assembly mounting bolt to the

specified torque. Since the V.V.T. sprocket

assembly mounting bolt is tightened by special

tool (MB991992), calculate the tightening torque

by the following formula.

Tightening torque: (65

± 5) × {L ÷ (L + 150)}

N

⋅m

65

± 5: Tightening torque of the V.V.T. sprocket

assembly mounting bolt (unit: N

⋅m)

L: Distance between the centre of a torque

wrench drive and of its handle (unit: mm)

150: Length of special tool (unit: mm)

AC311268

AB

Hexagon part of

the exhaust camshaft

Camshaft sprocket

mounting bolt

6. While holding the exhaust camshaft hexagonal

area using a wrench or similar tool, tighten the

camshaft sprocket mounting bolt to the specified

torque.

Tightening torque: 88

± 10 N⋅m

CAMSHAFT

ENGINE MECHANICAL <4A9>

11A-23

>>D<< TIMING CHAIN TENSIONER

INSTALLATION

AC311263

AB

Timing chain tensioner

Pin

1. Install the timing chain tensioner with the pin or

the similar tool to the cylinder block through the

timing chain case hole, and tighten the timing

chain tensioner mounting bolts to the specified

torque.

Tightening torque: 8.4

± 0.6 N⋅m

2. Pull out the pin or the similar tool of the timing

chain tensioner.

>>E<< TIMING CHAIN TENSIONER

COVER INSTALLATION

1. Remove the sealant from the installation face of

the timing chain tensioner cover and the timing

chain case assembly.

AC311269

3 mm

Timing chain case

assembly

AC

φ 2 mm

2. Apply a bead of the specified sealant to the

mating surface of the timing chain case assembly.

Then, install the timing chain tensioner cover to

the timing chain case assembly within 3 minutes.

Specified sealant: LOCTITE 5971 or exact

equivalent

>>F<< CYLINDER HEAD COVER

ASSEMBLY INSTALLATION

1. Remove the sealant from the cylinder head cover

assembly and the matching area of the cylinder

head assembly and the timing chain case

assembly.

AC311270

Timing

chain

case

assembly

Cylinder head assembly

Section A - A

A A

A A

AC

φ 4 mm

2. Apply specified sealant to the matching area of

the cylinder head assembly and the timing chain

case assembly as shown, and install the cylinder

head cover assembly to the cylinder head

assembly within 3 minutes.

Specified sealant: LOCTITE 5971 or exact

equivalent

AC405036

AC

4

8

5

10

2

6

9

1

7

3

Engine front

3. Tighten the cylinder head cover assembly

mounting bolts to the specified torque in the order

of the numbers shown in the illustration.

Tightening torque: 9.0

± 1.0 N⋅m

OIL PAN

ENGINE MECHANICAL <4A9>

11A-24

OIL PAN

REMOVAL AND INSTALLATION

M1112002801443

Pre-removal Operation

• Front Under Cover Panel Assembly Removal (Refer to

GROUP 51, Front Bumper Assembly and Radiator Grille

).

• Engine Room Side Under Cover (RH) Removal

• Engine Oil Draining (Refer to GROUP 12, On-vehicle

Service

− Engine Oil Replacement

).

• Crankshaft Damper Pulley Removal (Refer to

Post-installation Operation

• Crankshaft Damper Pulley Installation (Refer to

• Engine Oil Refilling (Refer to GROUP 12, On-vehicle

Service

− Engine Oil Replacement

).

• Engine Room Side Under Cover (RH) Installation

• Front Under Cover Panel Assembly Installation (Refer to

GROUP 51, Front Bumper Assembly and Radiator Grille

).

AC403072

N

7.6 ± 0.6 N·m

39 ± 5 N·m

2

3

5

4

AB

1

7.6 ± 0.6 N·m

7.6 ± 0.6 N·m

N

6

11.5 ± 0.5 N·m

11.5 ± 0.5 N·m

Removal steps

•

Engine oil level gauge

1.

Bell housing cover

2.

Engine oil pan drain plug

3.

Engine oil pan drain plug gasket

<<

A

>> >>

B

<< 4.

Engine oil pan

>>

A

<< 5.

Engine oil screen assembly

>>

A

<< 6.

O-ring

Removal steps (Continued)

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст