Acura RL (1996-2004 year). Manual — part 463

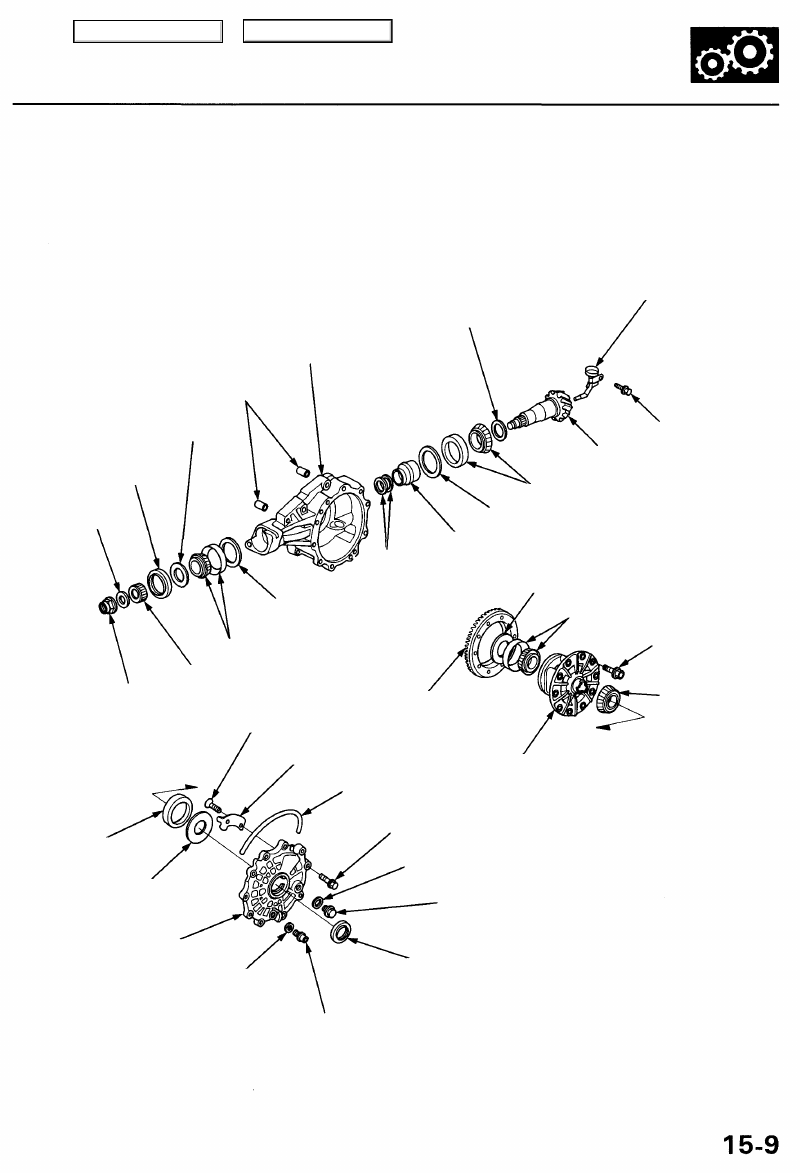

Illustrated Index

OIL GUIDE PIPE

43 mm THRUST SHIM

Selection, page

DIFFERENTIAL

CASE

DOWEL

PINS

THRUST

WASHER

OIL SEAL

Replace.

DRIVE PINION

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)

THRUST

WASHER

THRUST

WASHERS

LOCKNUT

Replace.

THRUST

WASHER

TAPERED ROLLER BEARING

PINION HUB

SCREW Replace.

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)

BREATHER PLATE

TAPERED ROLLER BEARING

THRUST WASHER

PINION SPACER Replace.

79.5 mm THRUST SHIM(S) (1 or 2 shims)

Adjustment, page

TAPERED ROLLER BEARING

11 x 1.0 mm

118 N-m (12 kgf-m,

87 Ibf-ft)

TAPERED ROLLER

BEARING

BREATHER

TUBE

BEARING OUTER RACE

RING GEAR

DIFFERENTIAL

CARRIER

10 x 1.25 mm

44 N-m (4.5 kgf-m, 33 Ibf-ft)

79.5 mm THRUST SHIM(S)

(1 or 2 shims)

Adjustment, page

DIFFERENTIAL

CASE COVER

WASHER

Replace.

OIL FILLER PLUG

44 N-m (4.5 kgf-m, 33 Ibf-ft)

WASHER

Replace.

OIL SEAL

Replace.

DRAIN PLUG

39 N-m (4.0 kgf-m, 29 Ibf-ft)

Main Menu

Table of Contents

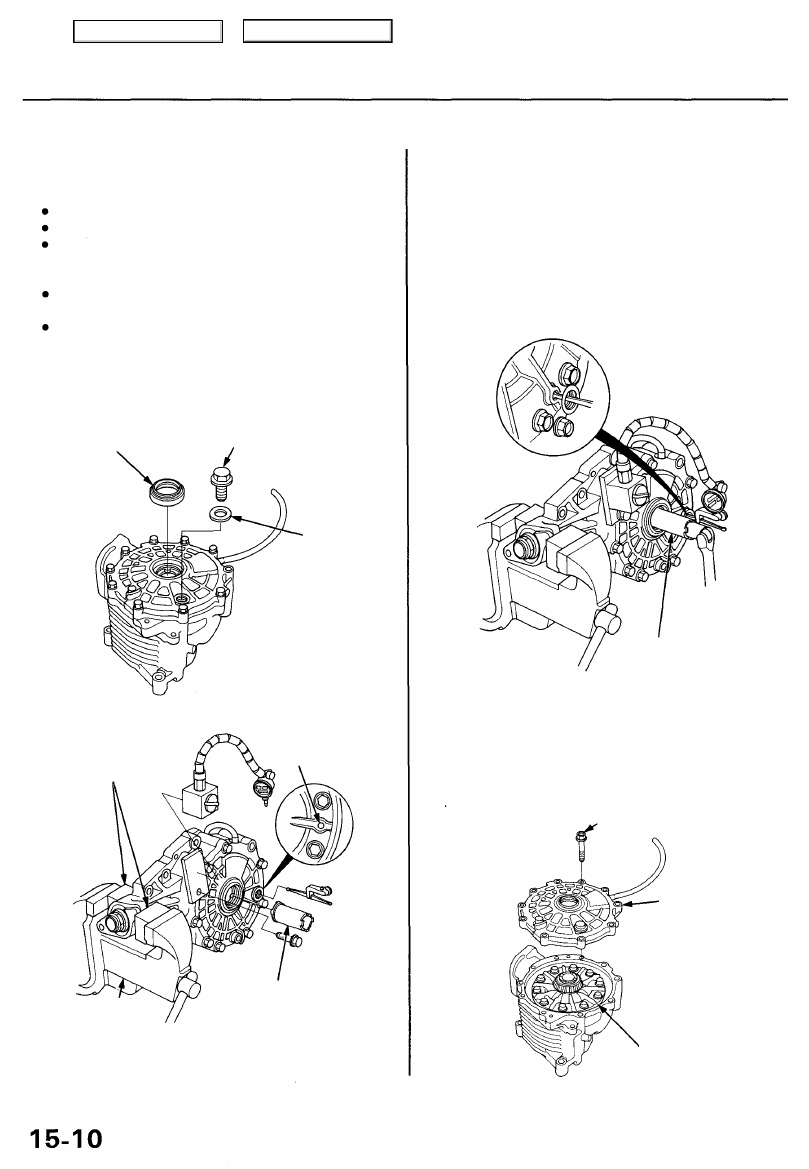

Differential Assembly

Inspection

To establish a starting point before disassembly, inspect

the following:

Ring gear backlash

Total bearing preload

Gear tooth contact

NOTE:

Be sure the differential is at room temperature before

inspecting.

Record the results of the preliminary inspections.

This information will be helpful during reassembly.

Ring gear backlash

1. Remove the oil filler plug and the oil seal.

OIL SEAL

Replace.

OIL FILLER PLUG

44 N-m (4.5 kgf-m, 33 Ibf-ft)

WASHER

Replace.

BENCH

VISE

LOCKNUT SOCKET,

36 x 41 mm

3. Align the differential gear inspection hole with the

oil filler plug hole.

4. Measure the backlash of the ring gear on the differ-

ential carrier using the special tools as shown. After

measuring, remove the dial gauge and turn the dif-

ferential carrier one full turn, then remeasure the

backlash.

Standard: 0.06 - 0.14 mm (0.002 - 0.006 in)

The difference between the two measurements taken

must not exceed 0.06 mm (0.002 in).

LOCKNUT SOCKET,

36 x 41 mm

Total bearing preload

5. Remove the differential case cover and the differen-

tial carrier.

NOTE: Loosen the bolts in a crisscross pattern, in

several steps.

10 x 1.25 mm

44 N-m (4.5 kgf-m, 33 Ibf-ft)

DIFFERENTIAL

CASE COVER

DIFFERENTIAL

CARRIER

2. Secure the differential assembly in a vise with soft

jaws.

SOFT JAWS

INSPECTION

HOLE

Main Menu

Table of Contents

Use a dial-type torque wrench on the drive pinion to

measure the drive pinion bearing preload (Tp).

Standard: 1.42 - 1.91 N-m

(14.5 - 19.5 kgf-cm, 12.6 - 16.9 Ibf-in)

7. Reinstall the differential carrier and the differential

case cover, then measure the total bearing preload.

The total bearing preload should exceed the drive

pinion bearing preload (Tp) by:

Standard:

0.94 - 1.07 N-m (9.6 - 10.9 kgf-cm, 8.33 - 9.46 Ibf-in)

Example:

Total bearing preload (from step 7)

- Tp (from step 6)

Gear tooth contact

8. Remove the differential case cover and differential

carrier. Clean and paint the ring gear teeth lightly and

evenly with Prussian Blue (on both sides of each

tooth).

9. Reinstall the differential carrier and the differential

case cover, then torque the bolts in a crisscross pat-

tern in several steps.

10. Install the special tool as shown, then rotate the

drive pinion in both directions so that the ring gear

rotate one full turn in both directions. During this

operation resistance should be applied to the ring

gear.

LOCKNUT SOCKET,

36 x 41 mm

DRIVE

PINION

11. Remove the differential case cover and the differen-

tial carrier, then check the tooth contact pattern.

CORRECT TOOTH CONTACT

TOE

CONTACT

HEEL

CONTACT

FLANK

CONTACT

FACE

CONTACT

= 0.94 - 1.07 N-m (9.6 - 10.9 kgf-cm, 8.33 - 9.46 Ibf-in)

Main Menu

Table of Contents

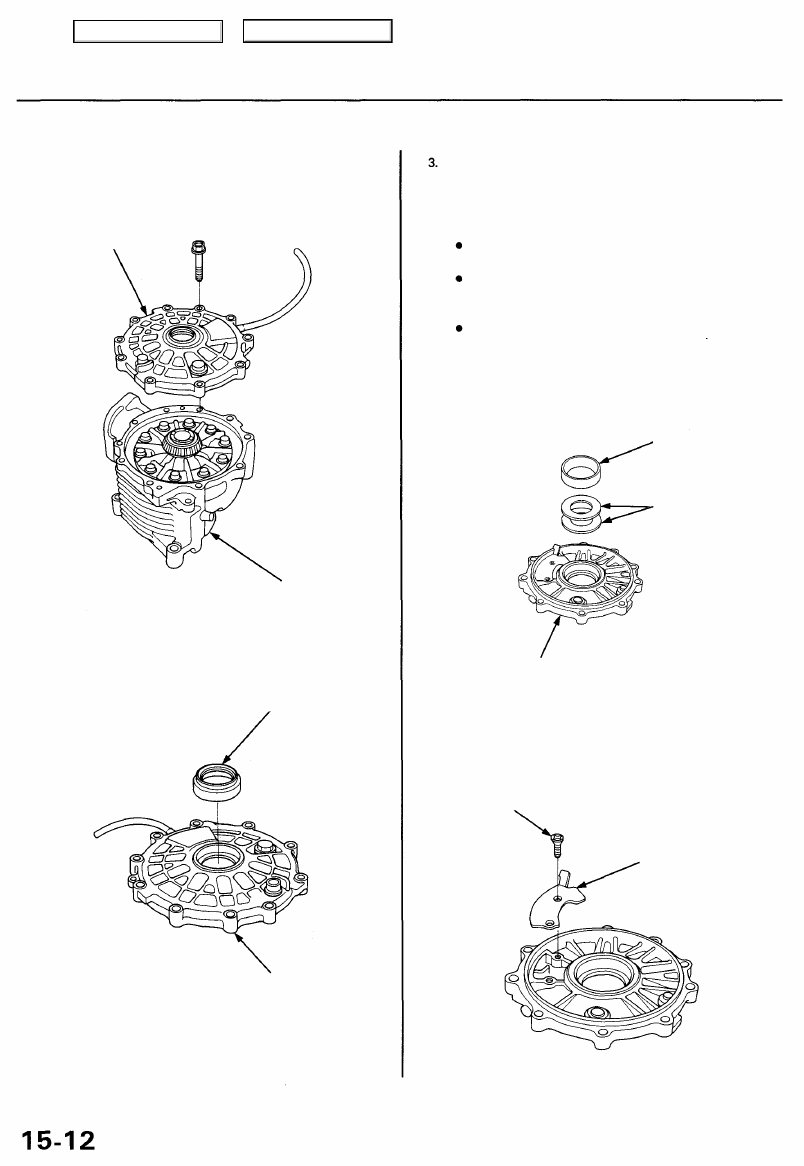

Differential Assembly

Disassembly

1. Remove the bolts in a crisscross pattern, in several

steps, then remove the differential case cover.

DIFFERENTIAL

CASE COVER

DIFFERENTIAL CASE

2. Remove the oil seal from the differential case cover.

OIL SEAL

Replace.

DIFFERENTIAL

CASE COVER

Remove the bearing outer race and the 79.5 mm

thrust shim(s) from the differential case cover by heat-

ing the differential case cover to about 212°F (100°C).

NOTE:

Do not heat the differential case cover in excess

of 212°F (100°C).

If the bearing outer race was removed by heat-

ing, allow the differential case cover to cool to

room temperature.

Replace the tapered roller bearing with a new

one whenever the bearing outer race is replaced.

BEARING OUTER

RACE

79.5 mm

THRUST SHIM

(1 or 2 shims)

DIFFERENTIAL CASE COVER

4. Remove the breather plate.

SCREW

Replace.

BREATHER PLATE

Main Menu

Table of Contents

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст