Acura TL (1995-1998) body repair. Manual — part 18

Rear Floor

Replacement

1. Remove the related parts.

• Rear seat

• Trim and other luggage compartment fittings

• Left and right rear suspension assembly

• Parking brake parts

• Muffler

• Wire harness

• Other parts as necessary

• Fuel tank and fuel pipes

Do not smoke while working near

the fuel system. Keep open flame away from the fuel

system. If necessary, remove the fuel tank and/or

lines before welding nearby. Drain fuel into an

approved container.

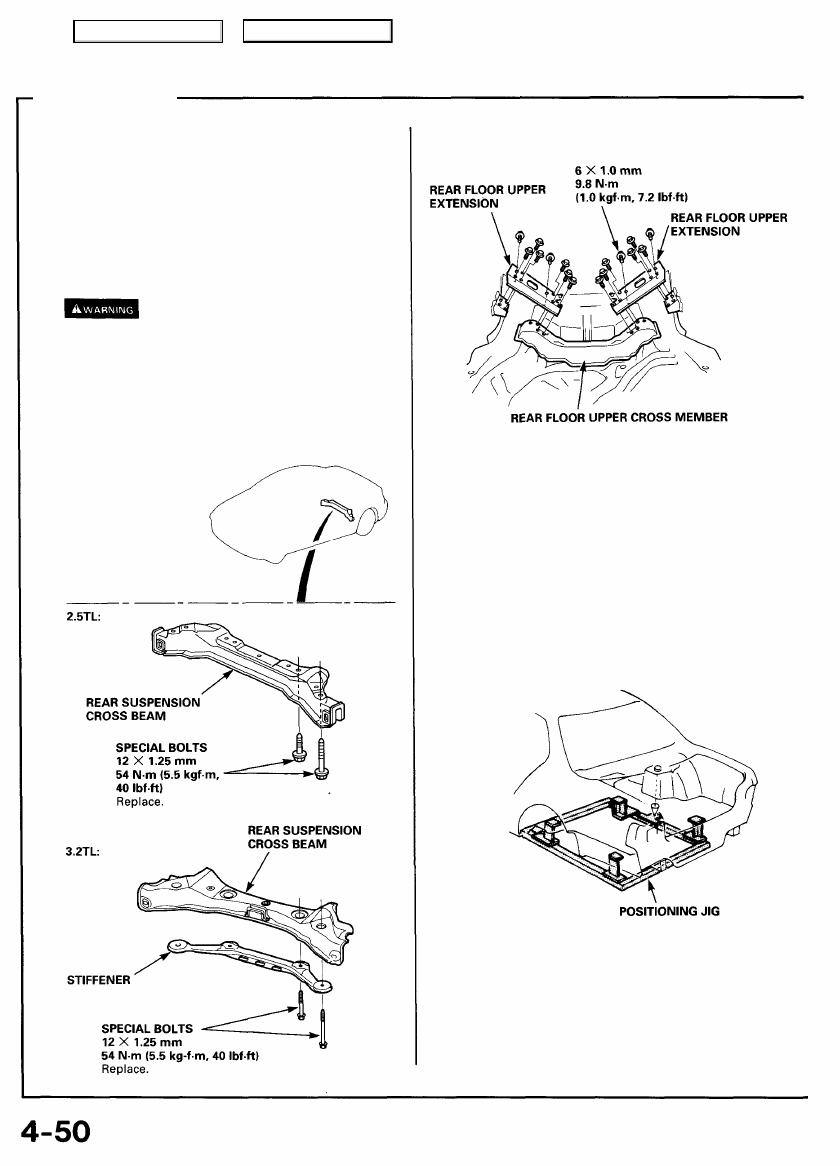

2. Remove the rear suspension cross beam.

3. Remove the rear floor upper extensions.

4. Pull out and straighten the damaged area.

• Check whether the damage extended to the rear

floor cross member, rear wheelhouse and the pas-

senger compartment, and pull out the damaged

parts using the frame corrector.

• Impact damage to the rear floor spreads to related

parts such as the rear frame, rear floor cross member

and rear wheelhouse.

• Therefore, pull out the damaged areas with the

frame straightener and measure in reference to body

dimensional drawing.

NOTE: Use of a positioning jig is recommended (see

page

).

5. Peel off the undercoat.

Heat the undercoat at the weld areas of the lower rear

floor with a gas torch and peel off the undercoat with a

metal spatula.

CAUTION: Be careful not to burn the fittings inside the

trunk compartment while heating.

6. Cut and pry off the rear panel (see page

).

Main Menu

Table of Contents

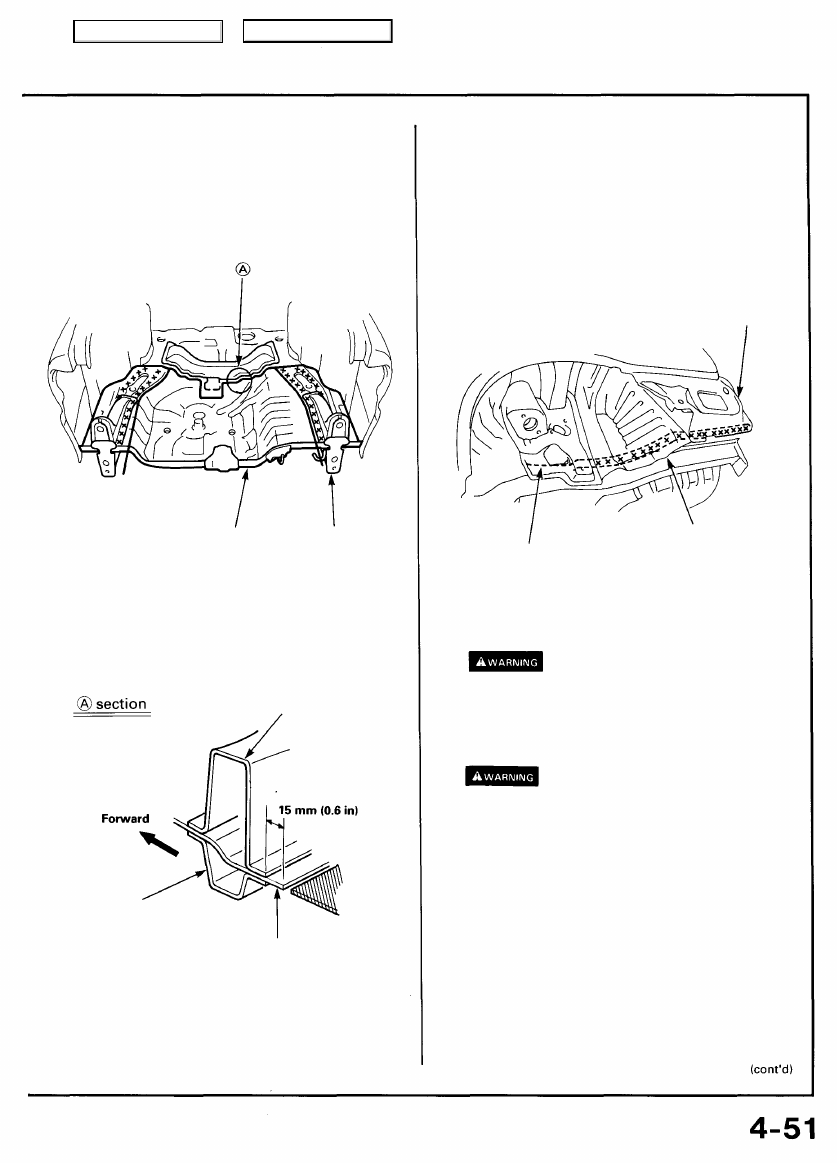

7. Cut and pry off the rear floor.

• Cut off the rear floor with a gas cutter or air chisel.

Level the spot welded flanges of the rear side frame

and rear floor cross member, as shown by the bold

line in the figure below.

REAR FLOOR

REAR FRAME

NOTE: Cut the rear floor 15 mm (0.6 in) from the welded

flange of the rear floor upper cross member.

REAR FLOOR UPPER

CROSS MEMBER

REAR FLOOR

CROSS MEMBER

REAR FLOOR

• Center punch around the spot weld imprints on the

remaining welded flanges. Do the same with the rear

wheelhouse and the side of the rear end inner panel.

• Drill holes with a spot cutter.

NOTE: When drilling holes, be careful not to drill down

to the rear frame.

• Pry off the flanges using a chisel.

OUTER PANEL

REAR INNER PANEL

REAR WHEELHOUSE

8. Mold the related parts.

• Remove the burrs from the spot weld or MIG weld

using a sander.

To prevent eye injury, wear goggles

or safety glasses whenever sanding, cutting or

grinding.

• Fill any holes made in the spot welded areas of the

flange by MIG or gas welding.

To prevent eye injury and burns

when welding, wear an approved welding helmet,

gloves and safety shoes.

Main Menu

Table of Contents

Rear Floor

Replacement (cont'd)

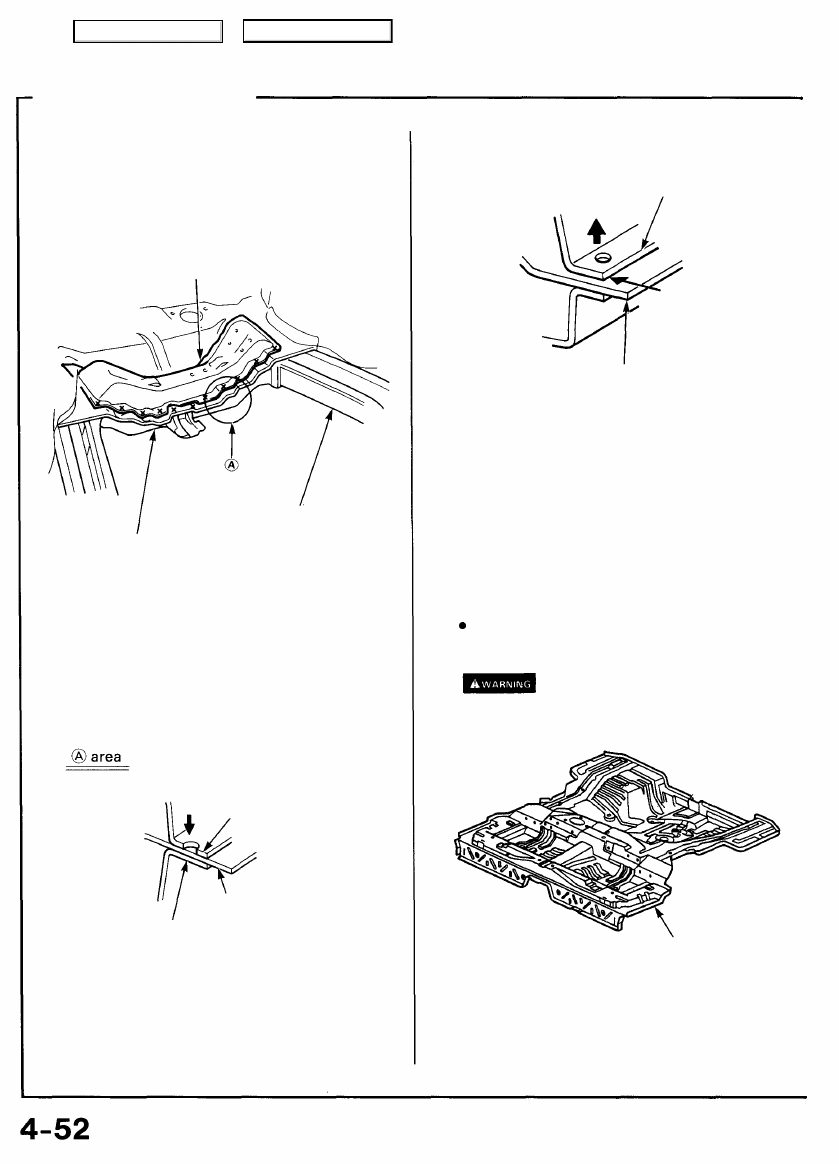

• Smooth the welding flanges of the rear frame with a

hammer and dolly.

NOTE: Check that the rear frame is parallel at the right

and left.

REAR FLOOR UPPER

CROSS MEMBER

REAR FRAME

REAR FLOOR

CROSS MEMBER

• Center punch the spot weld imprints on the rear floor

upper cross member welded flange.

• Drill holes with a spot cutter at the areas joined to the

rear floor upper cross member and rear floor.

NOTE: When drilling holes be careful not to drill down to

the rear floor.

REAR FLOOR

UPPER CROSS

MEMBER

REAR FLOOR

REAR FLOOR

CROSS MEMBER

• Pry off the welded flange sections using a chisel.

REAR FLOOR UPPER

CROSS MEMBER

REAR FLOOR

9. Keep the body level.

Jack-up the body at the front and back. Place safety

stands at the four designated places of the side sill.

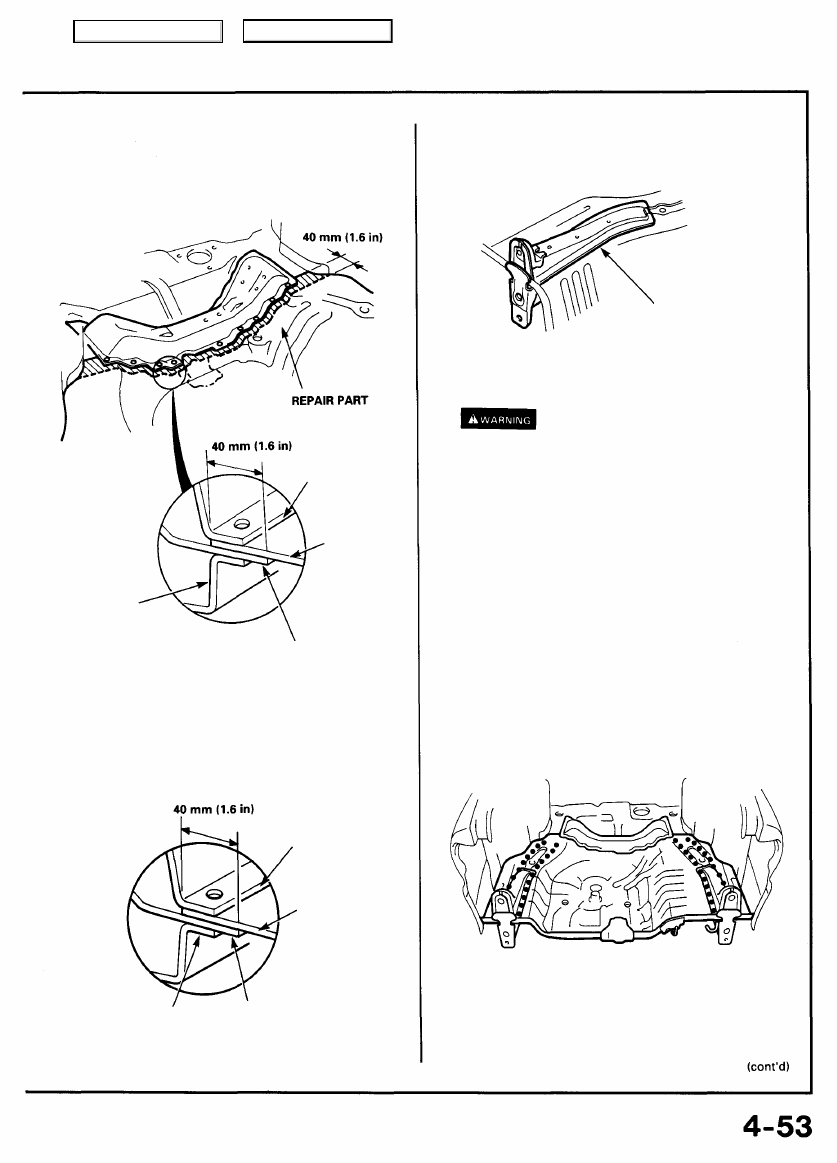

10. Set the repair part.

• Cut the new rear floor to align it with the body.

NOTE: Cut the new part so it overlaps the body side floor

by approximately 40 mm (1.6 in).

Remove the undercoat from both sides of the areas

to be welded with a sander to expose the steel plate.

To prevent eye injury, wear goggles

or safety glasses whenever sanding, cutting or

grinding.

REPAIR PART

Main Menu

Table of Contents

• Insert the repair part between the rear floor and rear

floor upper cross member.

• Check that the weld flange surfaces fit closely.

REAR FLOOR

UPPER CROSS

MEMBER

REPAIR

PART

REAR FLOOR

CROSS MEMBER

REAR

FLOOR

• Check the position of the rear floor and rear frames using

the body dimensional drawings (see

) and the

positioning jig.

REAR FLOOR

UPPER CROSS

MEMBER

REPAIR

PART

REAR FLOOR REAR FLOOR

CROSS MEMBER

11. Set the rear floor upper stiffener, and check the rear panel

position.

REAR FLOOR

UPPER

STIFFENER

12. Perform the main welding.

To prevent eye injury and burns

when welding, wear an approved welding helmet,

gloves and safety shoes.

Spot welding:

NOTE: Apply the spot sealer to the welding surface when

spot welding.

• Recheck the position of the rear frames and rear floor,

then weld the repair part and rear frames.

• Make 20% to 30% more spot welds than there were

holes drilled.

MIG welding:

• Drill the holes for welding the repair part.

• Check the rear frame position and weld the repair part

to the rear frames.

Main Menu

Table of Contents

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст