Discovery 2. Manual — part 420

ENGINE - TD5

OVERHAUL 12-1-77

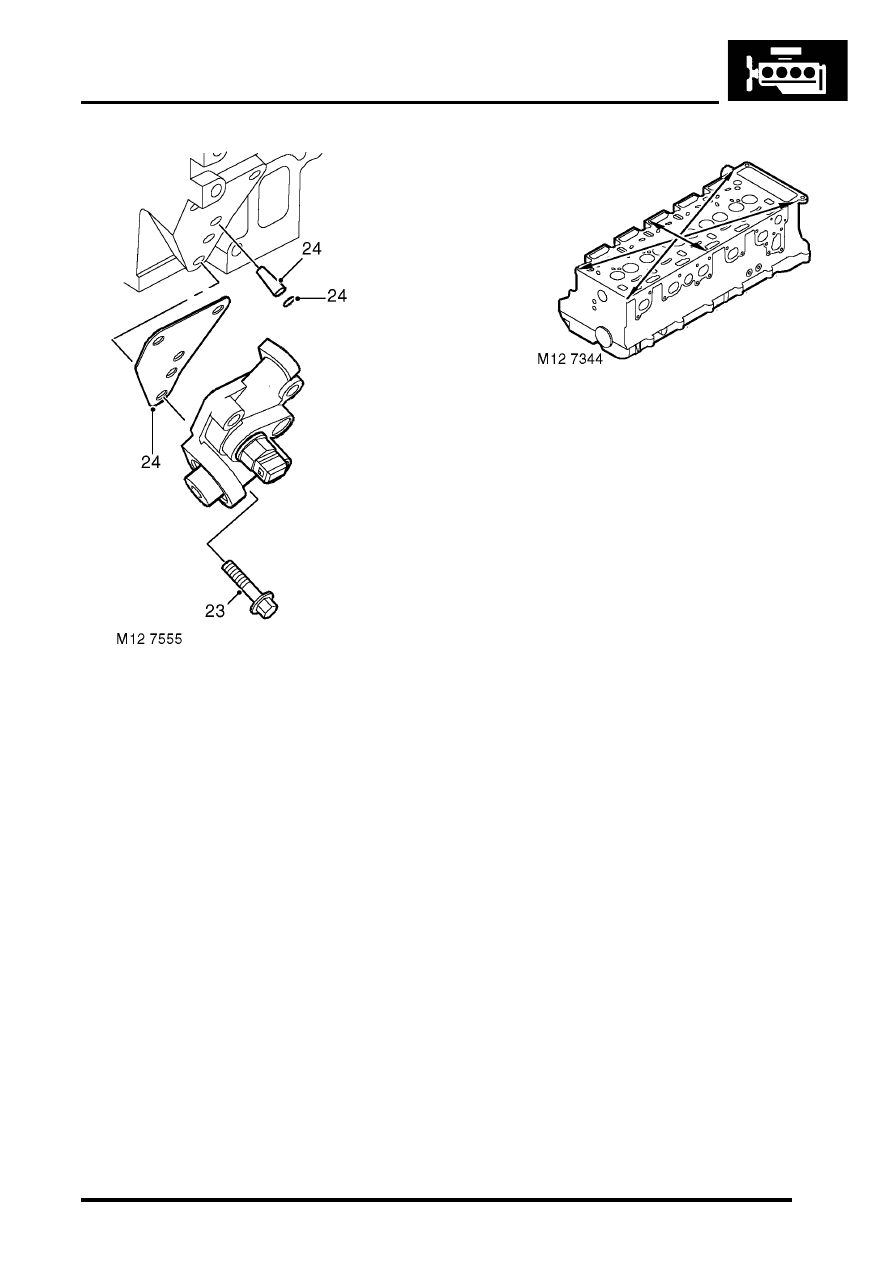

23. Remove 3 bolts and remove fuel connector

block from cylinder head.

24. Remove gasket, discard 'O' ring and fuel filter.

25. If fitted: Remove spacer block and gasket.

Inspect

1. Thoroughly clean cylinder head mating faces,

ensure that EUI drillings, oil and coolant

passages are clear and bolt holes are clean

and dry.

2. Using suitable solvent, remove all traces of

sealant and gasket material.

CAUTION: Do not use metal scrapers.

3. Remove all traces of oil from camshaft bearings

and journals.

4. Clean glow plug threads.

5. Check core plugs for signs of leakage and

corrosion, seal replacement plugs with Loctite

243.

6. Check cylinder head for warping across centre

and from corner to corner:

l

Maximum cylinder head warp = 0.1 mm

(0.004 in)

Cylinder heads must not be refaced.

Replace the head assembly if warping

exceeds the limit.

7. Check lash adjuster bores for scoring and signs

of wear or damage.

8. Check lash adjusters for signs of wear, scoring

and overheating, replace as necessary.

Ensure oil hole in each lash adjuster is clear.

Store lash adjusters upright and in their

fitted order.

9. Check finger followers for wear and that rollers

are free to rotate. Store finger followers in

their fitted order.

10. Check camshaft lobes and bearing journals for

signs of scoring and wear.

11. Check bearing surfaces in cylinder head and

camshaft carrier for signs of scoring and wear.

Cylinder head and camshaft carrier are

machined together as an assembly. If

bearing surfaces in either component are

damaged, both components must be

replaced as an assembly.

12. Check camshaft end-float using following

procedures.

13. Position camshaft in camshaft carrier.

ENGINE - TD5

12-1-78 OVERHAUL

14. Check end-float of camshaft using a DTI:

l

Camshaft end-float = 0.06 to 0.16 mm

(0.002 to 0.006 in)

15. Renew components as necessary to achieve

correct end-float.

16. Check camshaft bearing clearances using the

following procedures.

17. Position camshaft in cylinder head.

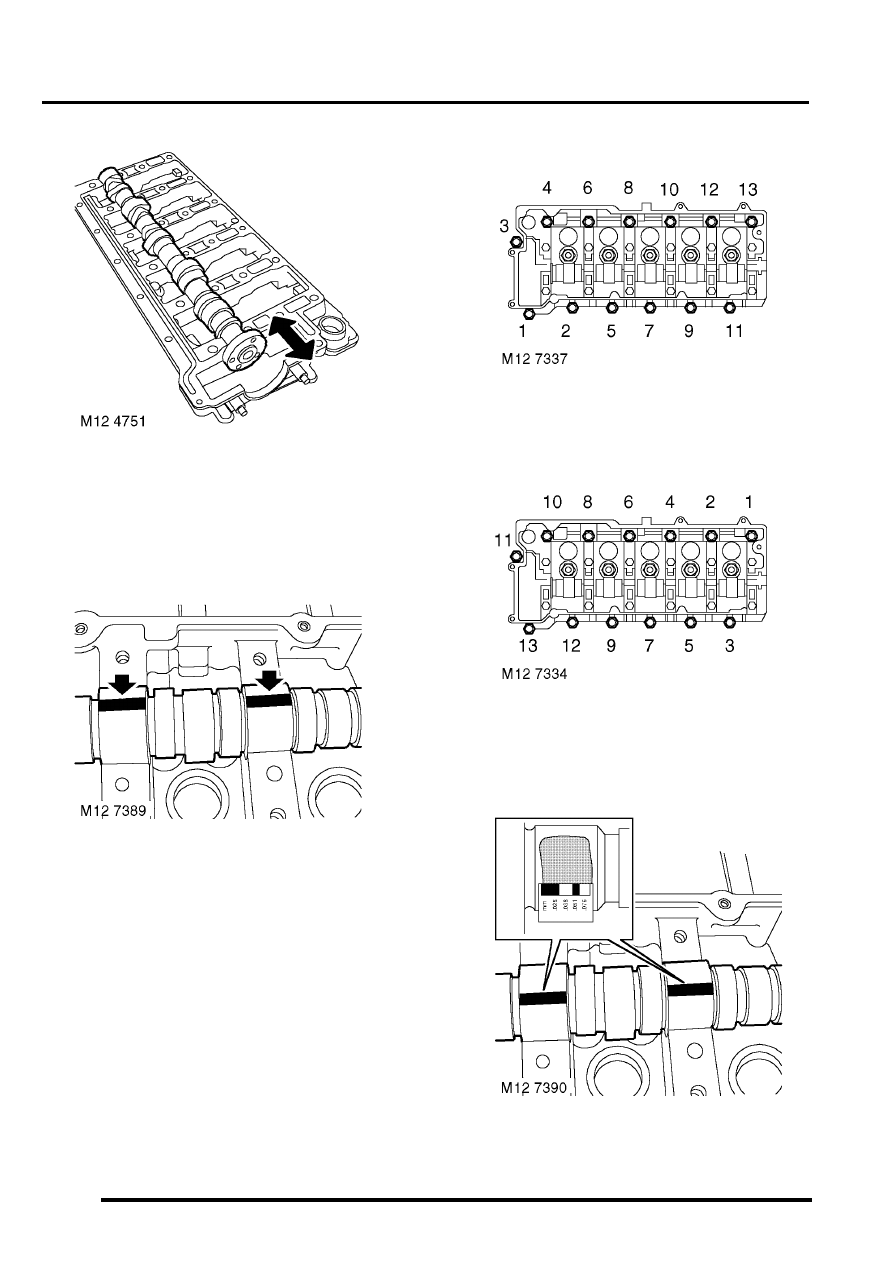

18. Place a piece of Plastigage along centre line of

each camshaft bearing journal.

19. Carefully fit the camshaft carrier ensuring it is

located on dowels. Do not rotate camshaft.

20. Fit original camshaft carrier bolts and tighten in

sequence shown to 25 Nm (18 lbf.ft).

21. Using sequence shown, loosen then remove

camshaft carrier retaining bolts. Do not

discard bolts at this stage.

22. Carefully remove camshaft carrier.

23. Measure and record widest portion of

Plastigage on each camshaft bearing journal.

ENGINE - TD5

OVERHAUL 12-1-79

24. Compare figures obtained with camshaft

bearing clearance:

l

Camshaft bearing clearance = 0.04 to 0.10

mm (0.002 to 0.004 in)

25. If any bearing clearance is found to exceed

figures given, repeat the above procedures

using a new camshaft. If, after repeating the

clearance check using a new camshaft the

clearances are still excessive, a new cylinder

head and camshaft carrier assembly must be

fitted.

26. Remove all traces of Plastigage using an oily

cloth, do not use a scraper.

27. On completion, discard camshaft carrier bolts.

28. Check free length of valve springs:

l

Free length = 46.75 to 47.25 mm (1.84 to

1.86 in)

29. Replace valve springs as a set, if springs

are to be refitted, keep them in their fitted

order.

30. Clean carbon from valves, check valves for

burning, pitting or cracking; replace as

necessary.

31. Clean carbon from valve seat inserts, remove

all loose particles on completion.

32. Check valve seat inserts for pitting and burning.

It is not permissible to recut or replace valve

seat inserts.

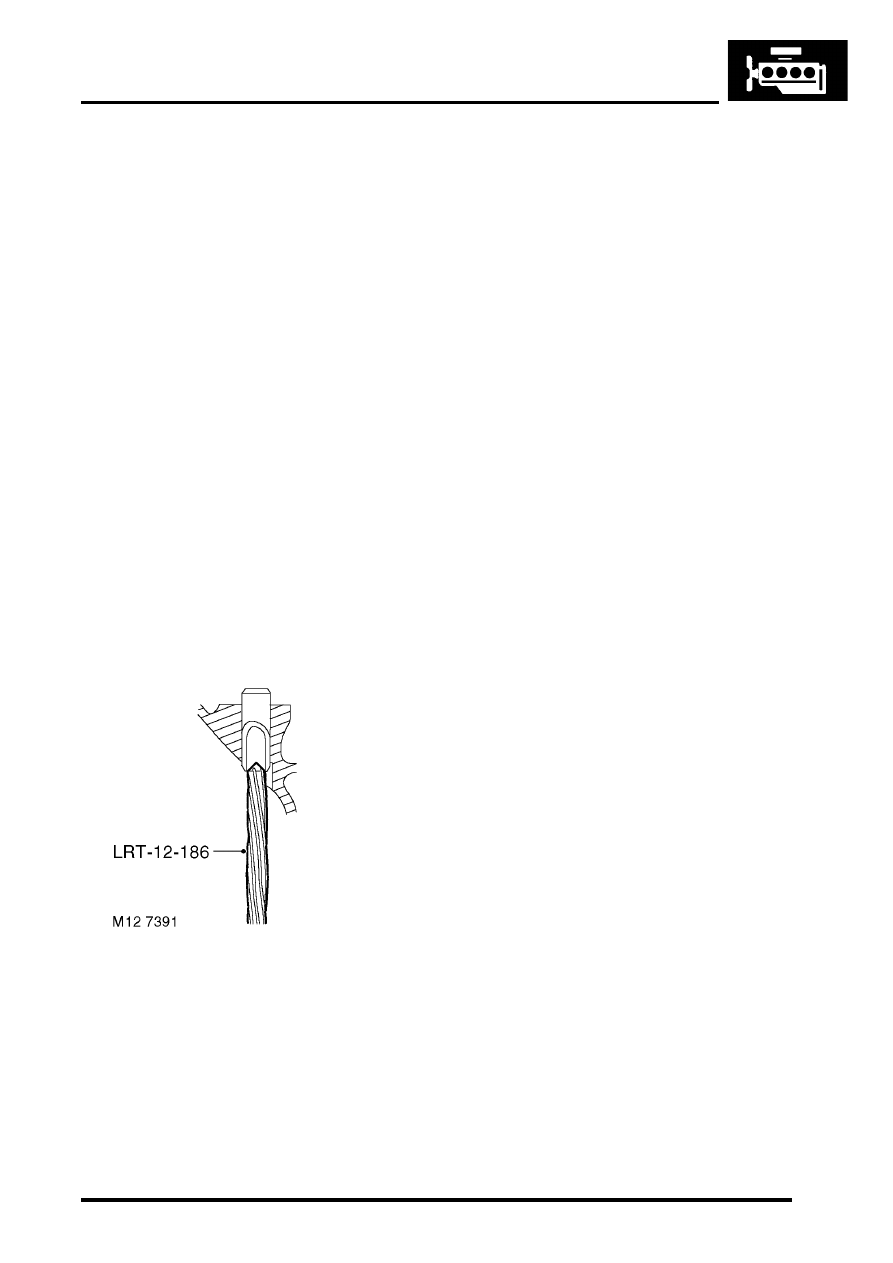

33. Remove carbon deposits from valve guides

using tool LRT-12-186 inserted from the

combustion chamber face side of cylinder

head. Ensure all loose particles of carbon are

removed on completion.

34. Check and record diameter of each valve stem:

l

Valve stem diameter - Inlet = 6.907 to 6.923

mm (0.2719 to 0.2725 in)

l

Valve stem diameter - Exhaust = 6.897 to

6.913 mm (0.2715 to 0.2721 in)

35. Renew any valve if stem diameter is less than

specified.

36. Check and record valve stem to guide

clearance using the following procedures.

37. Insert each valve into its respective guide.

38. Extend valve head 10 mm (0.375 in) out of

valve seat and position a DTI gauge to rear of

valve head.

39. Move valve towards front of cylinder head and

zero DTI gauge ensuring that stylus of gauge

remains in contact with valve head.

40. Move valve towards rear of cylinder head,

record gauge reading to give valve stem to

guide clearance:

l

Inlet valve = 0.025 to 0.059 mm (0.0009 to

0.0023 in)

l

Exhaust valve = 0.035 to 0.069 mm (0.0013

to 0.0027 in)

41. If stem to guide clearance exceeds figures

given and valve stem diameters were as

specified, cylinder head assembly must be

replaced; it is not possible to replace valve

guides.

42. Repeat above procedures for remaining valves.

Keep valves in their fitted order.

43. Check face angle of each valve, renew any

valve with incorrect face angles, do not attempt

to recut.

l

Valve face angle - inlet = 29

°

48'

±

12'

l

Valve face angle - exhaust = 44

°

48'

±

12'

44. Lap each valve to its seat using grinding paste.

45. Apply Prussion Blue to valve seat, insert valve

into guide and press it firmly, without rotating

on to seat.

46. Remove valve and check that a continuous,

even line of Prussian Blue has been

transferred on to valve face. Note that line

does not have to be across whole width of

valve face.

47. Remove all traces of grinding paste on

completion.

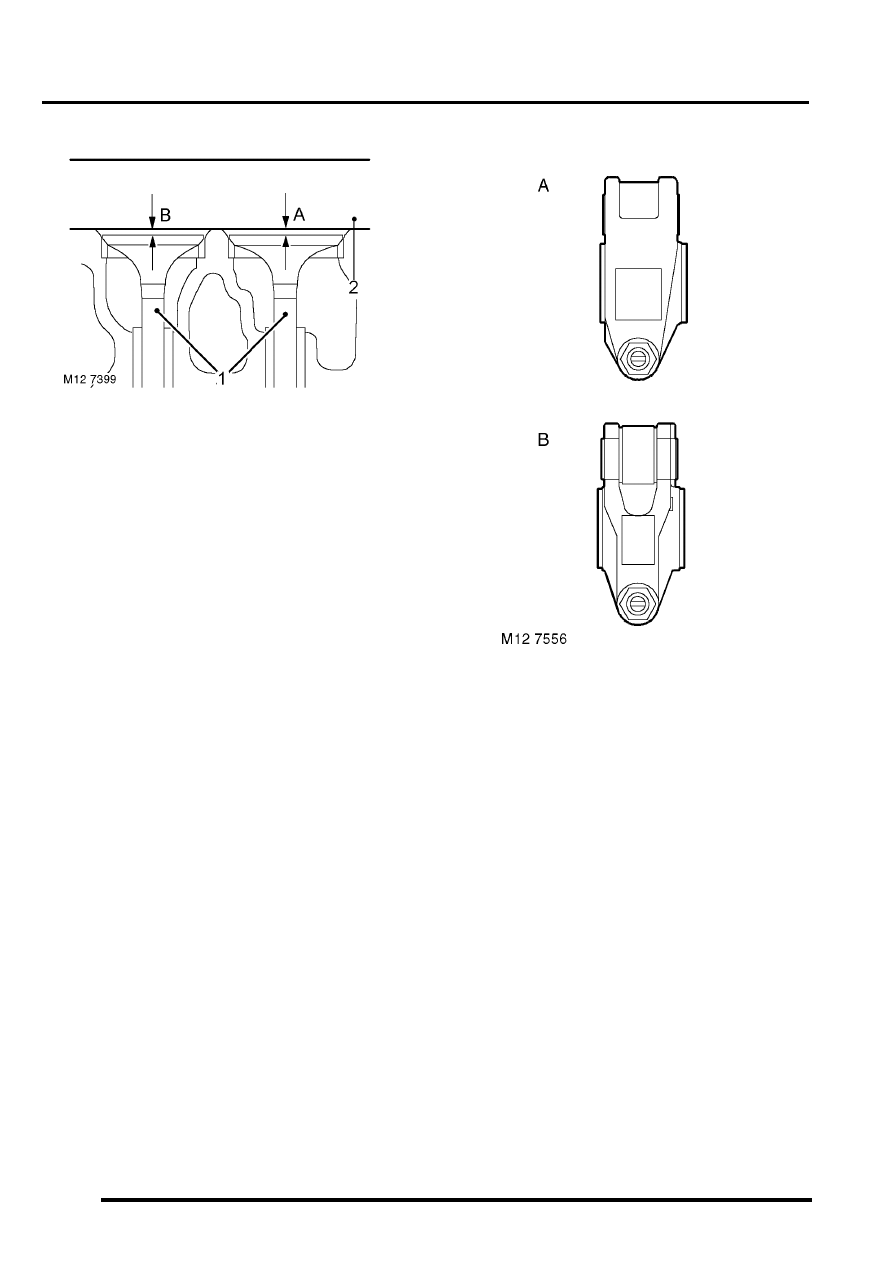

48. Check valve head stand down using the

following procedures.

ENGINE - TD5

12-1-80 OVERHAUL

49. Insert each valve into its respective guide.

50. Using a straight edge and feeler gauges, check

and record stand down of each valve head.

51. Compare figures obtained with those given

below:

l

Valve head stand down - Inlet valve A =

0.555 to 0.825 mm (0.022 to 0.032 in)

l

Valve head stand down - Exhaust valve B =

0.545 to 1.35 mm (0.021 to 0.053 in)

52. If any valve has a stand down greater than

specified, repeat check using a new valve.

If, after checking with a new valve, stand

down is still excessive, cylinder head

assembly must be replaced. It is not

possible to replace valve seat inserts.

53. Suitably identify each rocker arm to its fitted

position and type of rocker arm fitted.

NOTE:

l

Engine Serial No. Prefixes 10P to 14P -

Type A rocker arms

l

Engine Serial No. Prefixes 15P to 19P -

Type B rocker arms.

Type B rocker arms and shafts may be fitted to

Engine Serial No. Prefixes 10P to 14P as an

assembly.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст