Defender (1993+). Manual — part 32

FUEL SYSTEM

REMOVING

THROTTLE

POSITION SENSOR

To Remove

To Remove

REMOVING IDLE AIR CONTROL VALVE

1.

Disconnect battery ground terminal.

1.

Disconnect battery ground terminal.

2.

Disconnect electrical plug.

2. Remove multi-plug.

3.

Remove

two

screws securing throttle position

3.

Unscrew idle air control valve from rear

sensor to plenum chamber and carefully pull

plenum chamber.

throttle position sensor

off throttle shaft.

4.

Remove washer.

4.

Remove old gasket.

To Refit

5.

Fit new gasket.

6.

Align throttle position sensor and shaft fiats,

slide switch

on

to

throttle shaft. Secure throttle

position sensor to plenum chamber.

To Refit

5. Fit

NEW sealing washer.

CAUTION: D O NOT operate throttle mechanism

while throttle position sensor is loosely fitted,

NOTE: If same idle air control valve is being

damage may be caused to throttle position

refitted clean sealing compounds from threads.

sensor wiper track.

Apply Loctite 241 to threads of idle air control

valve before reassembly.

6. Tighten idle air control valve to 20 Nm.

7. Reverse removal instructions.

REISSUED:

FEB

1993

9

FUEL

SYSTEM

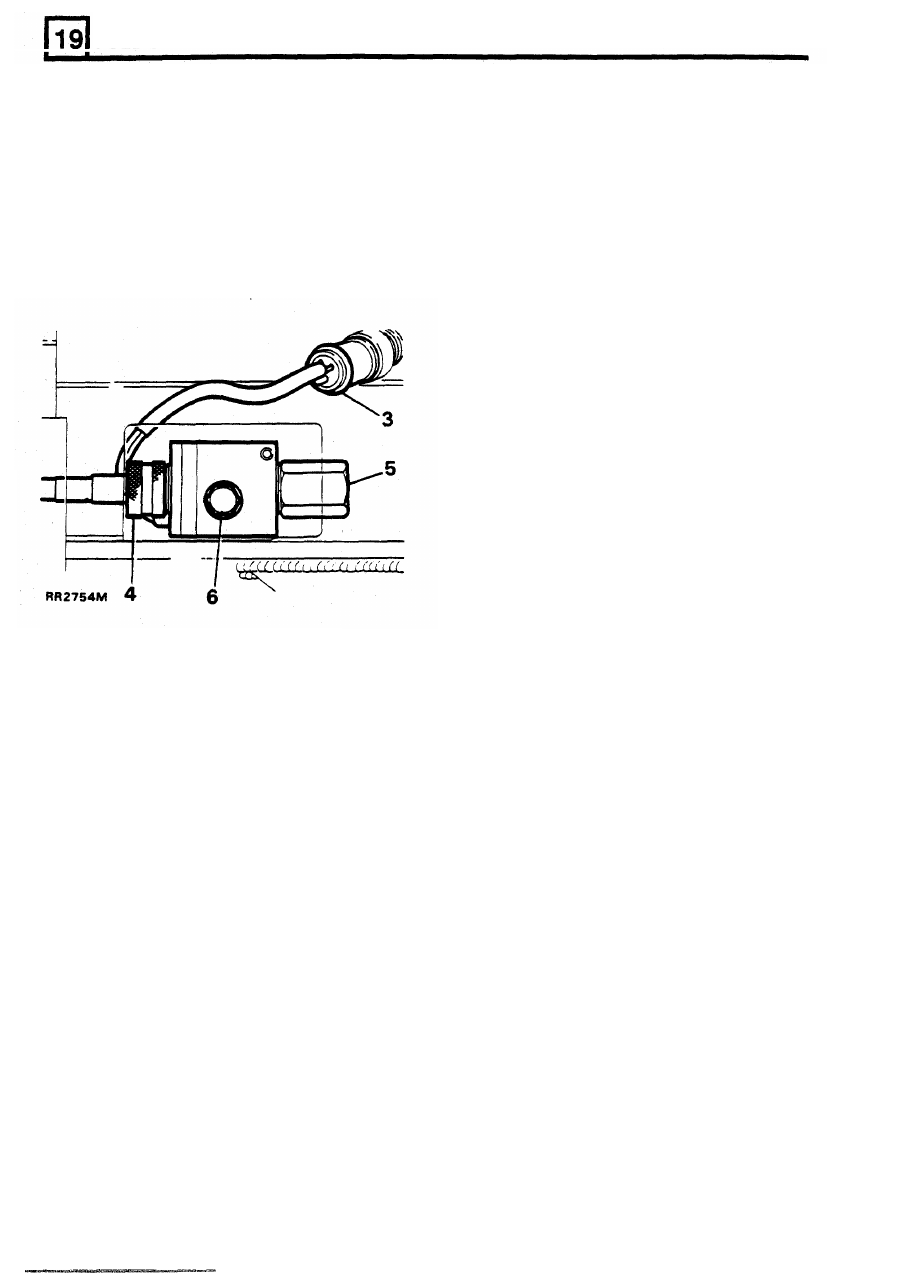

REMOVING VEHICLE SPEED SENSOR

REMOVING FUEL INJECTION-RELAY MODULES

To Remove

Incorporated in fuel injection electrical system are

two

relays modules and a diagnostic plug. Access

to

the modules and plug is gained by removing the toe

board from the front passenger’s footwell. For exact

location, refer to illustration ST 3362M in Electrical

1.

Place vehicle on ramp, apply parking brake.

2.

Disconnect battery ground terminal

.

3.

Raise ramp, disconnect electrical plug.

4.

Disconnect speedometer cable.

Section 86.

5.

Do not remove blanking cap.

6.

Remove single bolt. Remove vehicle speed

REMOVING ELECTRONIC CONTROL MODULE

NOTE: The ECM is not serviceable, in event of

module failure

it

must be replaced.

To Remove

sensor from mounting bracket.

(ECM)

-

14

CUX

1.

Disconnect battery ground terminal.

2.

Remove toe board from front passenger’s

footwell.

3.

Release ECM plug retaining clip.

4.

Detach plug from ECM.

5.

Remove securing screws and withdraw

ECM.

To Refit

6.

Refit ECM by reversing the removal

procedure.

To Refit

7. Reverse the removal instructions.

10

REISSUED:

FEB

1993

FUEL SYSTEM

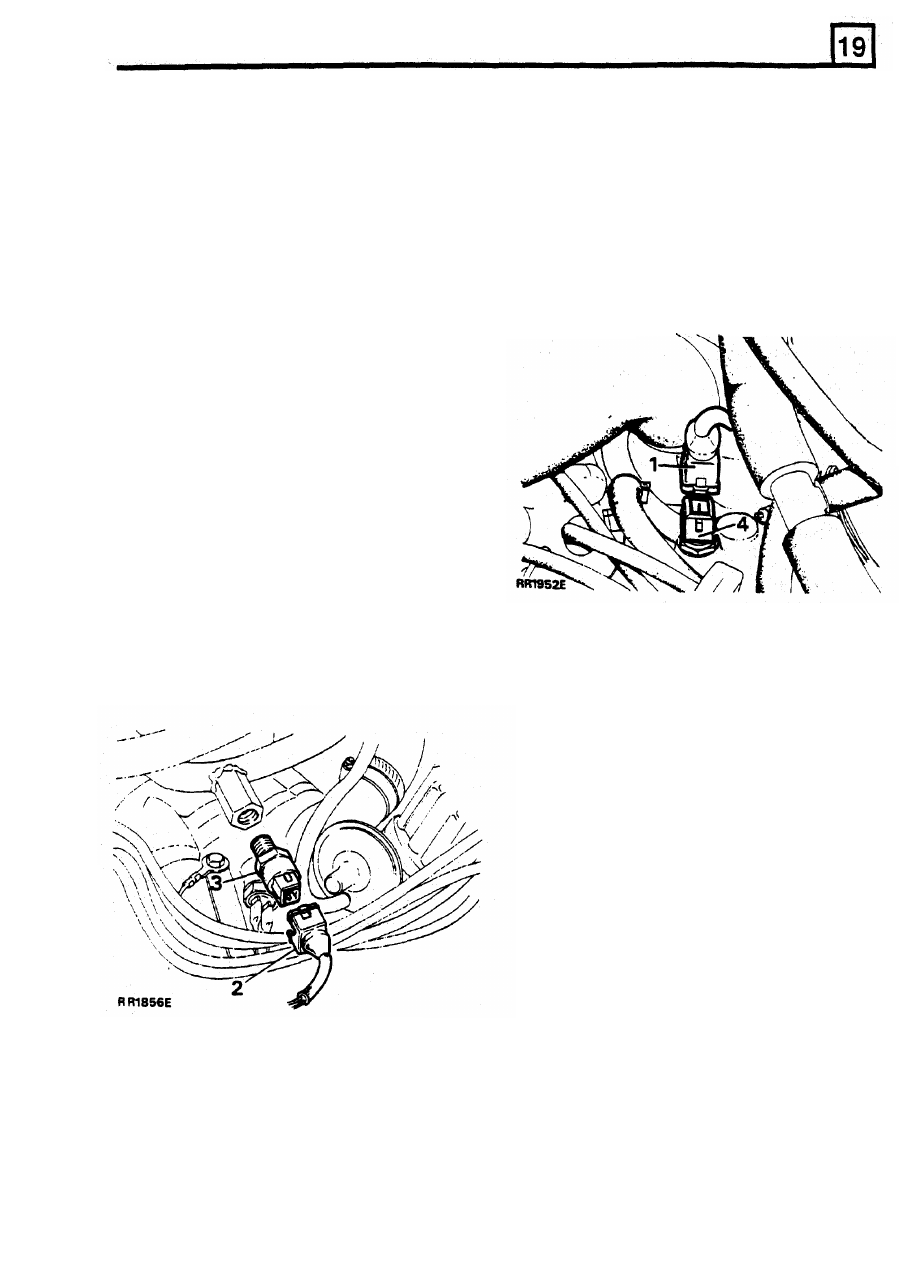

REMOVING INERTIA FUEL SHUT-OFF SWITCH

REMOVING ENGINE COOLANT TEMPERATURE

The inertia fuel shut

off switch is located

adjacent to the auxiliary fuse panel. Access

is

gained by removing the fuse panel cover.

To Remove

multi-plug.

SENSOR

To Remove

1.

Disconnect engine coolant temperature sensor

1.

Disconnect battery ground terminal

.

2.

Release radiator bottom hose, partially drain

2.

Remove

two

screws securing inertia fuel

cooling system.

3.

Withdraw inertia fuel shut-off switch and

4.

Remove engine coolant temperature sensor

shut-off switch.

3. Refit hose and tighten clamp.

disconnect multi-plug.

from left hand front branch of intake manifold.

5. Remove copper washer.

To Refit

4.

Reverse removal procedure. Ensure that

switch is reset (plunger in lowest position).

REMOVlNG

ENGINE

FUEL

TEMPERATURE

SENSOR

To Remove

NOTE: Fuel leakage will not occur when engine

fuel temperature sensor is removed from fuel rail,

therefore

it

is

not necessary

to depressurise the

fuel system.

1.

Disconnect battery ground terminal

.

To Refit

2. Remove multi-plug from engine fuel

temperature sensor

.

3.

Release engine fuel temperature sensor from

fuel feed rail.

tighten securely.

6.

Fit a NEW copper washer.

7.

Fit engine coolant temperature sensor and

8.

Refill cooling system.

9.

Run engine, check for water leaks around

engine coolant temperature sensor

.

To Refit

4.

Reverse removal procedure. Ensure engine

fuel temperature sensor is tightened securely

in

fuel rail.

REISSUED: FEB

1993

11

FUEL SYSTEM

DEPRESSURISING FUEL SYSTEM

WARNING: Under normal operating conditions

To Remove

the fuel injection system is pressurised by a high

pressure fuel pump, operating

at

up to

2.3

to 2.5

bar When

engine is stationary pressure

is

2. Disconnect battery ground terminal.

maintained

within

system.

To

prevent

3.

Release hose clamp securing fuel return hose

pressurised fuel escaping and to avoid personal

to

fuel pressure regulator. Remove the hose.

injury it i s necessary to depressurise fuel

4.

Pull vacuum hose from rear of fuel pressure

injection system before any service operations

regulator.

are carried out.

5. Remove

two

nuts and bolts securing fuel

pressure regulator to fuel rail, ease regulator

If

vehicle has not been run there will

be a small

fuel inlet pipe

out

of fuel rail.

amount of residual pressure in fuel line. The

6.

Withdraw fuel pressure regulator from engine

depressurising procedure must still

be carried

compartment.

out before disconnecting any component within

the fuel system.

The spilling of fuel is unavoidable during this

operation. Ensure that all necessary precautions

are taken to prevent fire and explosion.

REMOVING FUEL PRESSURE REGULATOR

1.

Depressurise fuel system.

1.

Remove fuel pump relay module.

2.

Start and run engine.

3.

When sufficient fuel has been used to cause

fuel line pressure to drop, injectors

will

become inoperative, resulting

in engine stall.

Switch

off ignition.

4.

Disconnect battery ground terminal

.

NOTE: Fuel at low pressure will remain in

system. To remove

low pressure fuel, place

absorbent cloth around fuel feed hose at fuel rail.

5. Disconnect either:

a) Nut and olive at fuel rail

OR

b) Hose at inlet end of fuel filter.

NOTE: Fit a

NEW ’0’ ring to fuel inlet pipe if

original fuel pressure regulator is refitted.

To

Refit

6.

Refit fuel feed hose.

7.

Refit fuel pump relay module, reconnect

7.

Lightly coat

‘0’

ring with silicon grease 300

before fitting fuel pressure regulator.

8. Crank engine (engine will fire

in approximately

8. Reverse removal procedure.

9.

Reconnect battery and pressurise fuel system.

Check there are no fuel leaks around fuel

pressure regulator connections.

battery.

6

to

8

seconds).

12

REISSUED:

FEB

1993

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст