Defender (1993+). Manual — part 33

FUEL SYSTEM

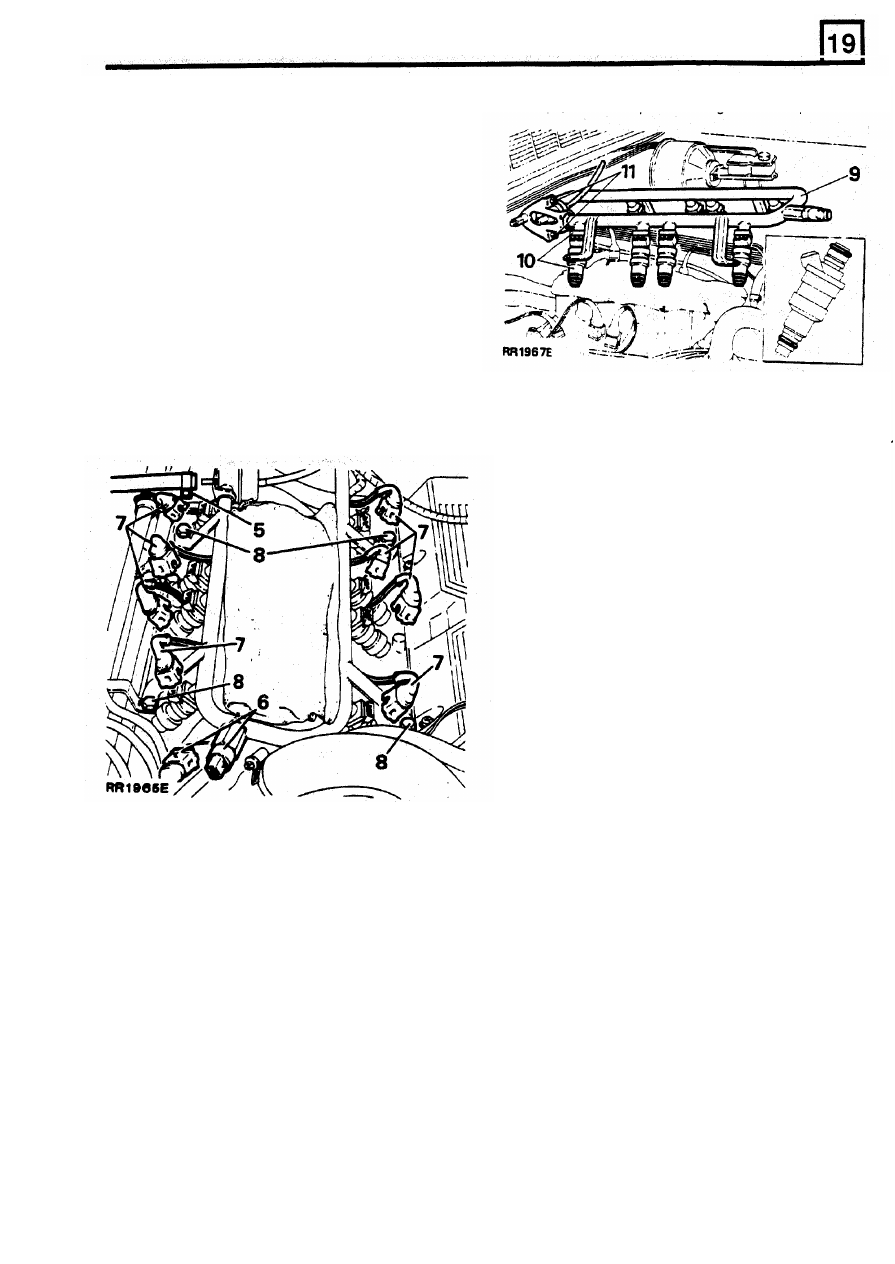

REMOVING FUEL RAIL-INJECTORS R/H AND L/H

To Remove

11. Remove fuel pressure regulator

if

required.

1.

Depressurise fuel system.

2.

Disconnect battery ground terminal.

3. Remove plenum chamber.

4. Remove ram housing.

NOTE: Place cloth over ram tube openings to

prevent ingress of

dirt.

5.

Release hose clamp and remove fuel return

hose from fuel pressure regulator.

6.

Disconnect multi-plug from engine fuel

temperature sensor.

7.

Disconnect multi-plugs from injectors.

To Refit

8.

Remove

five

bolts securing fuel rail support

brackets to intake manifold. Lay heater pipes

to one side.

12.

Fit

NEW

'0' rings, to injectors. Lightly coat

‘O’

rings with silicon grease 300. Insert injectors

into fuel rail, multi-plug connections facing

outwards.

13. Refit retaining clips.

CAUTION: Care must

be

taken when refitting the

fuel rail and injectors to intake manifold to

prevent damage to

'0' rings.

14. Fit a NEW

'O'

ring to fuel pressure regulator

lightly coat

'0' ring with silicon grease 300

and secure regulator to the fuel rail.

15.

Fit fuel rail and heater pipe assemblies to

intake manifold. Secure rail and pipes in

position

with

five bolts.

16. Reverse

removal

instructions

2 to

7.

17. Pressurise

fuel

system and check for fuel

leaks around injectors and fuel pressure

regulator.

9.

Remove fuel rail and injectors.

from rail.

10. Remove injector retaining clips, ease injectors

REISSUED FEB

1993

13

FUEL SYSTEM

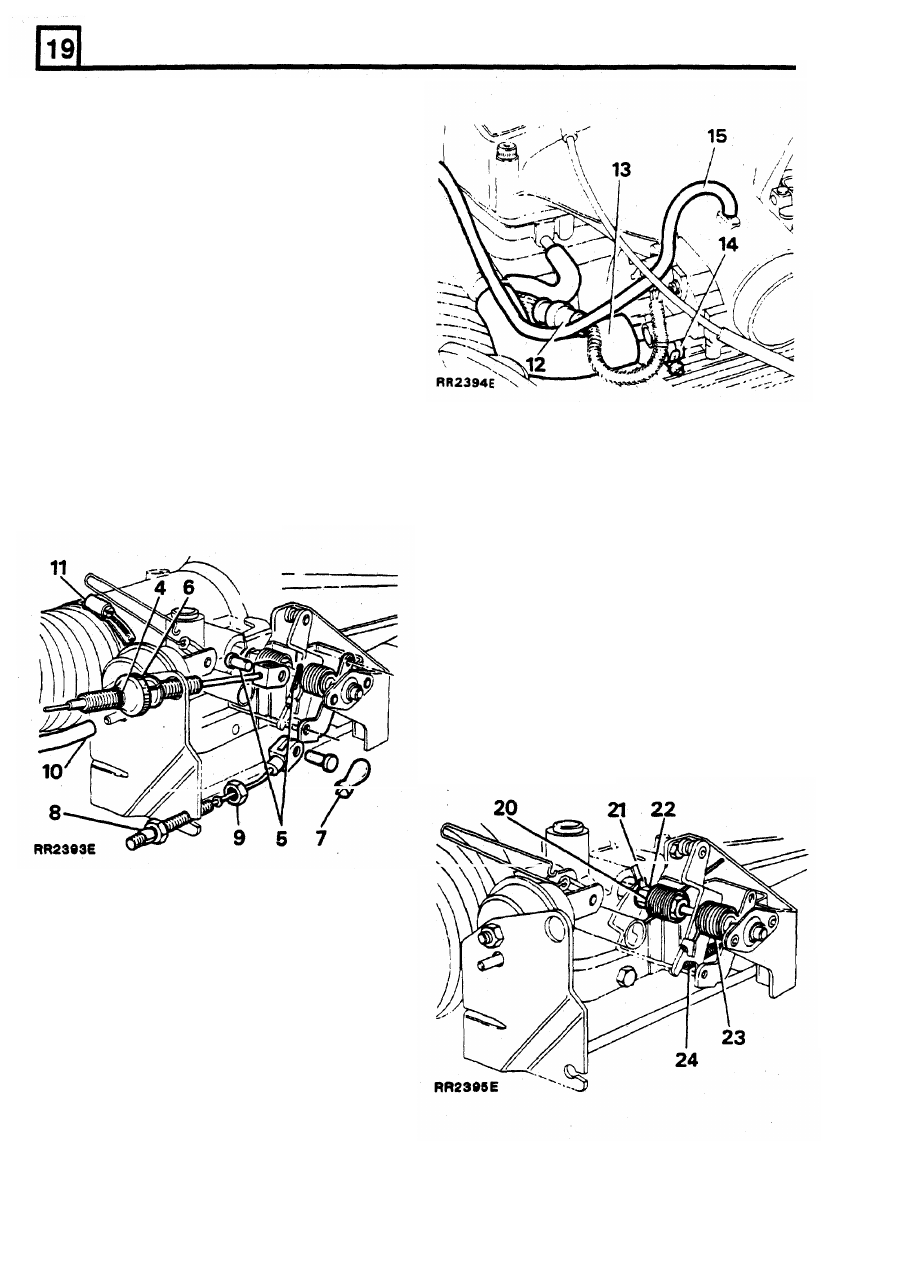

REMOVING PLENUM CHAMBER

Includes throttle levers and throttle disc

To Remove

1. Disconnect battery ground terminal.

2. Disconnect electrical multi-plug from idle

air

control valve.

3. Disconnect vacuum hose adjacent to idle air

control valve.

4.

Mark an identification line

on throttle cable

outer to assist re-assembly.

5.

Remove clevis pin from throttle cable.

6. Pry adjustment thumb wheel from throttle

bracket. Lay cable aside.

7.

Remove retaining clip and clevis bin from kick

down cable (automatic vehicles).

8. Apply adhesive tape behind rear adjustment

15. Remove distributor vacuum hose.

nut on kick down cable to prevent nut moving.

16. Release

two screws and remove throttle

9.

Remove front lock nut. Remove cable and lay

aside.

17. Remove six screws securing plenum chamber.

fitted).

18.

Remove

idle air control

valve

hose.

position sensor.

10. Remove cruise control vacuum hose (where

Remove plenum chamber.

Removing throttle lever assembly

19.

If

fitted

-

unclip cruise control actuator link.

Hold throttle fully open, release link from

countershaft assembly. Carefully return lever

assembly to close throttle.

20. Release tension on inboard throttle spring.

21. Bend back lock washer tabs.

22. Hold throttle stop lever

in closed position,

release nut from throttle shaft.

23. Release tension on outboard throttle spring.

24.

Remove overtravel spring.

11. Remove intake hose

from

neck

of plenum

chamber.

12. Disconnect throttle

position sensor multi-plug.

13. Remove PCV breather hose.

14.

Disconnect two coolant hoses and plug each

hose

to

prevent excessive loss of coolant.

Identify each hose for re-assembly.

14

REISSUED:

FEB 1993

FUEL

SYSTEM

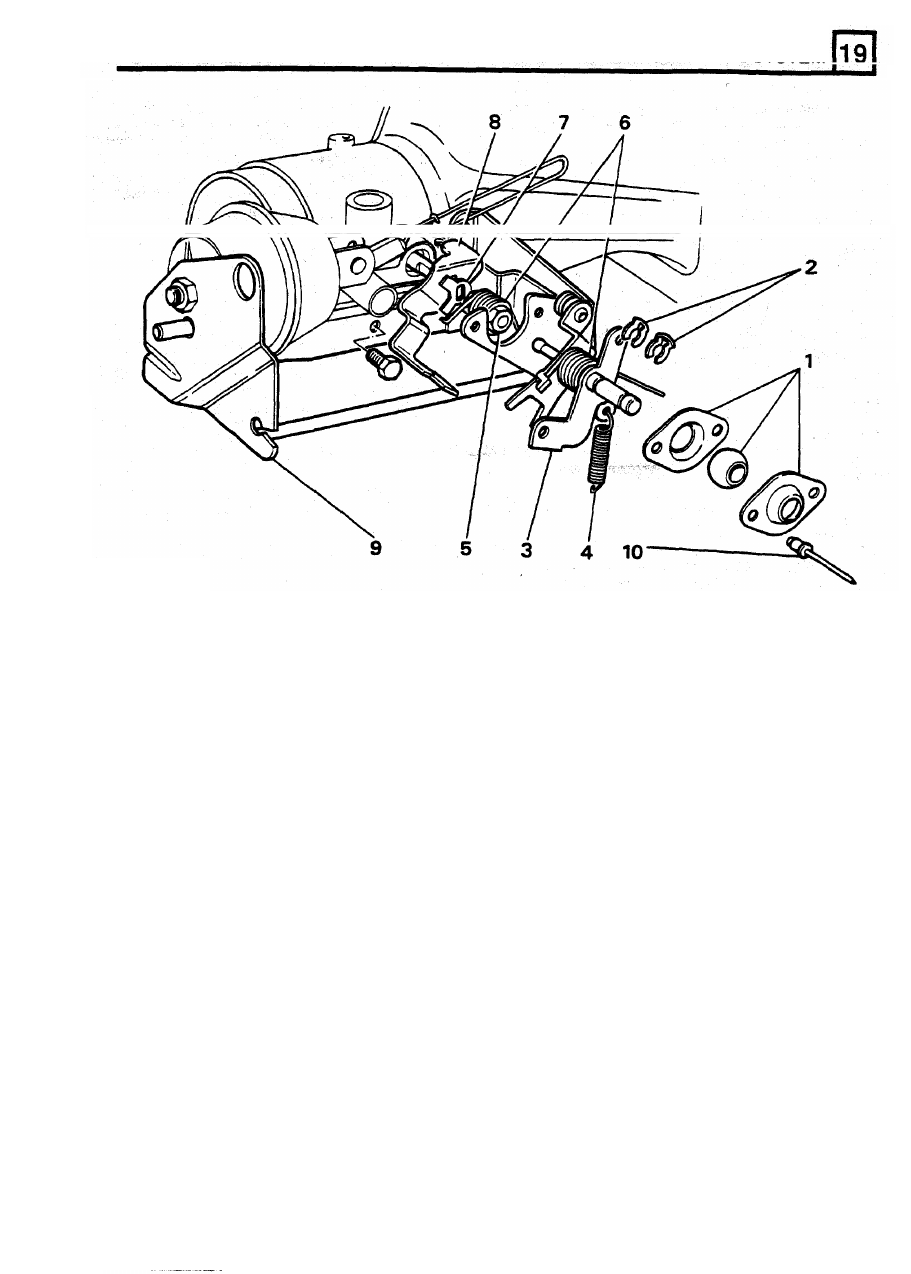

RR2406E

KEY

1.

Spherical bush/housing

2.

Retaining clips (2)

3.

Countershaft assembly

4.

Overtravel spring

5.

Throttle spindle nut

6.

Throttle return spring (2)

7.

Tab washer

8.

Throttle stop lever

9.

Throttle bracket assembly

10.

Pop rivets (2)

REISSUED:

FEB 1993

15

FUEL

SYSTEM

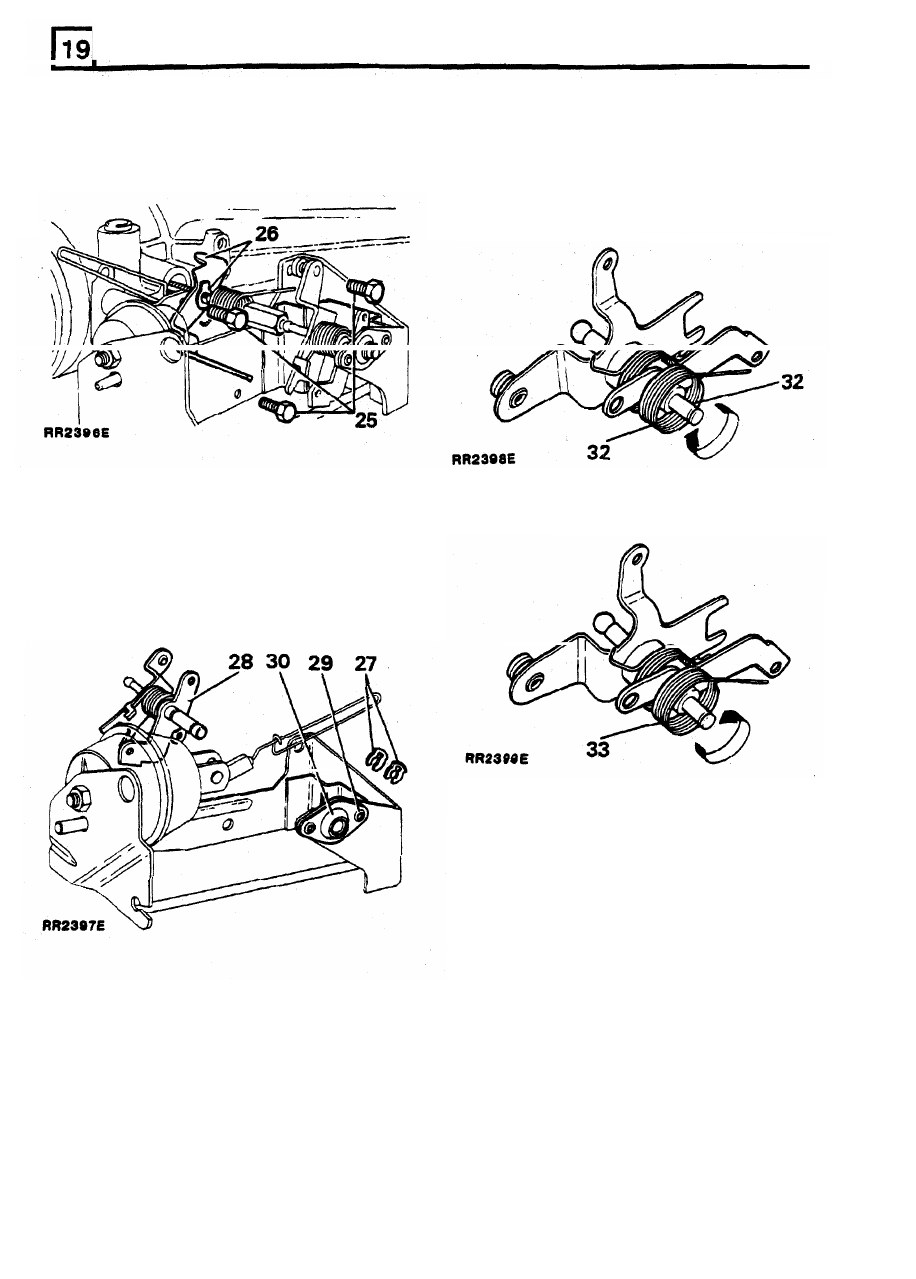

25.

Remove three

bolts

securing throttle bracket

31.

Grease new bush with Admax

L3

or

to

plenum chamber,

withdraw

bracket

Energrease

LS3.

Assemble bush into housing.

assembly

.

Assemble to throttle bracket using

two 4.7

mm

(3/16 in) diameter domed head rivets.

from throttle shaft.

32. Examine bearing surface of countershaft

assembly.

If

worn fit new assembly, otherwise

wind throttle return spring

off levers.

26. Remove tab washer and throttle stop lever

inspect

and

overhaul throttle lever assembly

33. Wind new spring onto countershaft assembly,

small hooked end

of spring is wound on first.

27.

Remove two retaining clips from spherical

bush.

28. Remove the countershaft assembly.

29.

If

spherical bush

is

worn, drill out

two

securing

rivets (4,7 mm, (3/16 in) diameter drill).

30.

Split assembly, discard worn bush.

34.

Grease shaft with

Admax L3 or Energrease

LS3,

fit

countershaft assembly

to

spherical

bearing, secure with

two

clips.

35. Examine throttle

stop lever for wear,

fit

a new

lever if necessary.

16

REISSUED: FEB 1993

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст