Defender (1993+). Manual — part 30

FUEL SYSTEM

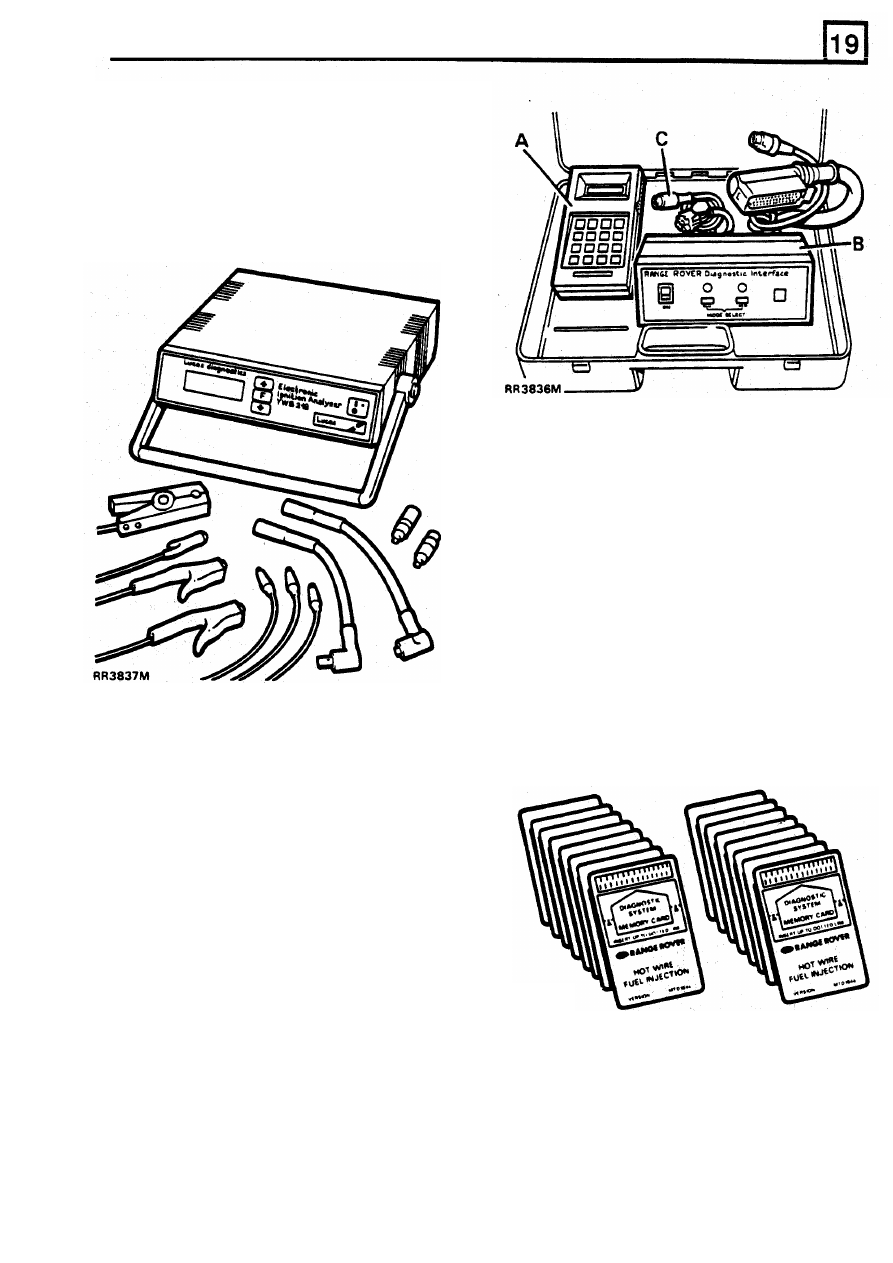

DIAGNOSTIC EQUIPMENT

IGNITION

Electronic Ignition Analsyer

Lucas Part No.

-

YWB 119

Supplied by Lucas Complete with instruction manual.

MEMORY CARDS

Land Rover Part Numbers include

two

memory

card and instruction manual in appropriate

language

Suitable for 14CUX ECU

ENGLISH

. . . . . .

RTC 6835

USA

. . . . . . . ..

RTC 6836

FRENCH

. . . . . ..

RTC 6837

GERMANY

. . . . ...

RTC 6838

ITALIAN

. . . . . ...

RTC 6839'

SPANISH

. . . . . .

RTC 6840

DUTCH

. . . . . .

RTC 6842

JAPANESE

. . . . ..

STC 127

LUCAS MFI DIAGNOSTIC EQUIPMENT

Complete kit Land Rover Part No. RTC 6834

Kit Comprises:-

A

Hand held tester

B

Interface unit

C

Foam lined carrying case

Serial link cable (Spare part Lucas

No. 54744753).

Memory cards are supplied separately

see

below

RR3838M

REISSUED: FEB

1993

1

FUEL SYSTEM

HOT WIRE MULTIPORT FUEL INJECTION

Engine fuel temperature sensor

Description

The engine fuel temperature sensor is located in the

fuel rail forward

of the ram housing. The engine fuel

The ’Hot Wire’ Multiport Fuel Injection system

temperature sensor sends fuel temperature data to

derives

its

name from the air flow meter which uses

the ECM, the ECM on receiving the data

will adjust

one cold wire and one electrically heated wire

to

the injector open time accordingly to produce good

measure the volume

of air entering the engine.

hot starting in high ambient temperatures.

The function of the system is to supply the exact

Idle air control valve

amount

of fuel directly into the inlet manifold

according

to the prevailing engine operating

The idle air control valve is screwed into a housing

conditions.

attached

to the rear of the plenum chamber, between

the plenum chamber and bulkhead. The idle air

To monitor these conditions, various sensors are

control valve has two windings which enable the

fitted

to

the engine to measure engine parameters.

motor to be energised

in

both directions thus

Data from the sensors is received by the Electronic

opening

or closing the idle air control valve as

Control Module (ECM), the ECM

will

then determine

required by the ECM.

the exact amount

of

fuel required at any condition.

The bypass valve will open and allow extra air into

the plenum chamber

to

maintain engine idle speed

The ECM having received data from the sensors

when the engine is under increased (Electrical and

produces pulses, the length

of which will determine

Mechanical) loads.

the simultaneous open time of each bank of injectors

The idle air control valve will control engine idle

in turn, which will govern the amount

of fuel injected.

speed when the vehicle

I

S

stationary.

Electronic control module - ECM

Heated oxygen sensors

The Multiport Fuel Injection system is controlled by

The two heated oxygen sensors are located forward

the ECM which is located behind the front

of the catalysts mounted

in the exhaust downpipes.

passenger’s toe board. The control unit is a

The sensors monitor the oxygen content of the

microprocessor

with

integrated

circuits

and

exhaust gases and provide feedback information

of

components mounted on printed circuit boards. The

the air/fuel ratio

to the ECM. Each heated oxygen

ECM is connected to the main harness by a

40

pin

sensor is heated by an electrical element

to

improve

plug.

its response time when the ignition is switched on.

Injectors

Fuel pressure regulator

The eight fuel injectors are fitted between the

The fuel pressure regulator is mounted in the fuel rail

pressurized fuel rail and inlet manifold. Each injector

at the rear of the plenum chamber. The regulator

is

comprises a solenoid operated needle valve with a

a mechanical device controlled by plenum chamber

movable plunger rigidly attached

to

the

nozzle valve.

vacuum,

it

ensures that fuel rail pressure is

When the solenoid is energized the plunger is

maintained at a constant pressure difference of

2.5

attracted off its seat and allows pressurized fuel into

bar above that of the manifold.

the intake manifold.

When pressure exceeds the regulator setting excess

fuel is returned to the fuel tank.

Engine coolant temperature sensor

Fuel pump

The engine coolant temperature sensor is located by

the front left hand branch

of the intake manifold. The

The electric fuel pump is located

in the fuel tank,

engine coolant temperature sensor provides engine

and is a self priming ‘wet’ pump, the motor is

coolant information to the ECM. The ECM on

immersed in the fuel

within

the tank.

receiving the signal from the engine coolant

temperature sensor

will

lengthen slightly the time that

the injectors are open, and reducing this time as the

engine reaches normal operating temperature.

2

REISSUED: FEB

1993

FUEL

SYSTEM

Mass air flow sensor

The hot-wire mass air flow sensor is mounted on a

It

should be noted that under high coolant

bracket attached

to

the left hand valance, rigidly

temperatures, when the engine is switched

off,

the

connected to the air cleaner and by hose

to the

condenser fans will be activated and will run for

plenum chamber inlet neck.

approximately ten minutes.

The mass air flow sensor consists of a cast alloy

body through which air flows. A proportion

of

this air

Vehicle speed sensor

flows through

a bypass

in

which

two

wire elements

are situated: one is a sensing wire and the other is a

The vehicle speed sensor is mounted on a bracket

Compensating wire. Under the control of an

located on the left hand chassis side member

electronic module which is mounted on the air flow

adjacent

to

the rear engine mounting. The vehicle

sensor body, a small current is passed through the

speed sensor provides road speed data

to

the ECM.

sensing wire

to

produce a heating effect. The

The ECM in turn detects vehicle movement from the

compensating wire is also connected to the module

road speed input and ensures that idle speed control

but is not heated, but reacts

to

the temperature of

mode is disengaged. Should the vehicle speed

the air taken in, as engine intake air passes over the

sensor fail in service the ECM idle speed control

wires

a cooling effect takes place.

would become erratic.

The electronic module monitors the reaction of the

The vehicle speed sensor also provides road speed

wires in proportion to the air stream and provides

data

to

the electric speedometer.

output signals in proportion

to

the air mass flow rate

which are compatible with the requirements of the

Inertia fuel shut off switch

ECM.

The inertia fuel shut off switch is

a

mechanically

Throttle

position

sensor

operated switch that is normally closed and is

connected to the fuel pump circuit. In the event of a

The throttle position sensor is mounted on the side

sudden impact the inertia fuel shut off switch opens,

of the plenum chamber inlet neck and is directly

and disconnects the electrical feed to the fuel pump.

coupled to the throttle butterfly shaft.

The inertia fuel shut off switch is reset by pressing

The throttle position sensor is a resistive device

down the button.

supplied with a voltage from the ECM. Movement of

the throttle pedal causes the throttle butterfly to

Relay modules

open, thus rotating the wiper arm within the throttle

position sensor which in turn varies the resistance in

Two multiport fuel injection relay modules are

proportion to the valve position. The ECM lengthens

located behind the front passenger toe board. The

the injector open time when it detects a change in

main relay module is energized via the ECM when

output voltage (rising) from the throttle position

the ignition is switched on and supplies current to

sensor.

the multiport fuel injection system. The fuel pump

In addition the ECM will weaken the mixture when it

relay module is energized by the ECM which in turn

detects the throttle position sensor output voltage is

operates the fuel pump to pressurize the fuel

decreasing under deceleration and will shorten the

system.

length of time the injectors are open.

When the throttle is fully open, the ECM will detect

the corresponding throttle position sensor voltage

and will apply full load enrichment. This is a fixed

percentage and is independent of temperature. Full

load enrichment is also achieved by adjusting the

length of the injector open time.

When the throttle is closed, overrun fuel cut off or

idle speed control may be facilitated dependant on

other inputs to the ECM.

The throttle position sensor is 'self adaptive', which

means that adjustment is not possible. It also means

the the throttle position sensor setting is not lost, for

example, when throttle stop wear occurs.

CAUTION: D o not attempt t o adjust throttle

position sensor.

Condenser fans

REISSUED:

FEB

1993

3

FUEL SYSTEM

ENGINE TUNING

MULTI METER CHECKS

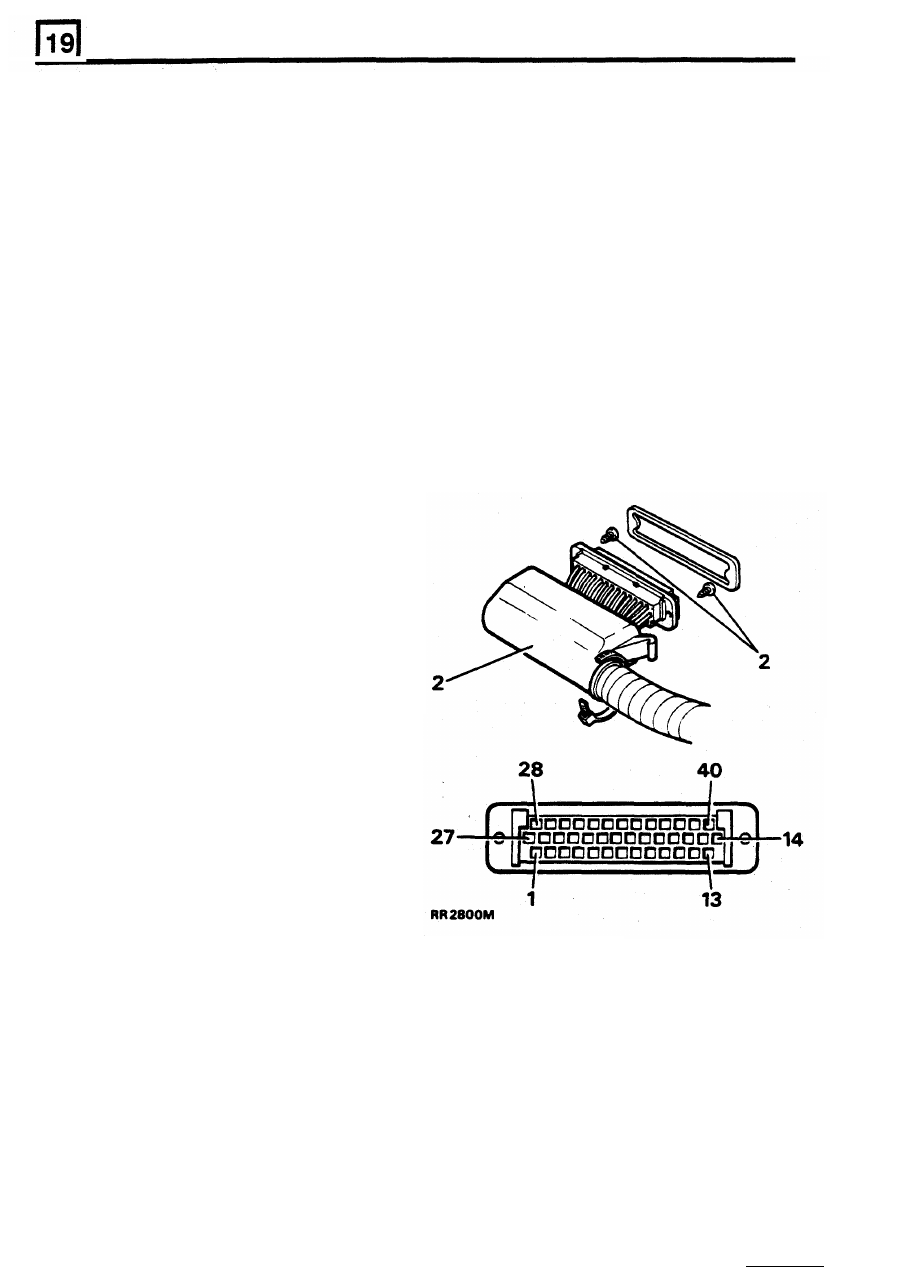

ECM - MFI circuit diagnosis

To carry out tests when 40 way multi-plug is

connected to the ECM,

it

is necessary to remove the

Circuit fault diagnosis may be carried out on all

MFI

two

screws securing the shroud to the plug to enable

vehicles, using a good quality Multi Meter or the

the multi-meter probes

to

be inserted into the back

of

hand held tester RTC6834. The tester displays the

the appropriate pin.

fault code and guides the operator by visual

prompts, through a series of diagnostic checks. Full

CAUTION: Tests requiring plug to be removed

operational and diagnosis instructions are provided

from ECM, must have meter probes inserted into

with the unit memory card.

back of plug. I f probes are inserted into plug

sockets, damage will occur to sockets resulting

Which ever instrument is used to diagnose the

i n poor connections when plug i s reconnected.

problem, the following Preliminary Checks must be

carried out first.

Testing

Preliminary checks

1.

Release harness plug from ECM.

CAUTION:

If

engine is misfiring or fails to start

within

12

seconds the cause must

be rectified.

Failure to do

so will result

in

irreparable damage

to the catalysts. After rectification the engine

are moulded onto rear of plug.

must

be run

at 1500

rev/min

(no

load) for 3

minutes to purge any accumulation of fuel

in

the

system.

1.

Check that the inertia fuel shut

off switch

is

not tripped.

2. Check fuse

D

in main fuse panel and the fuel

pump fuse in the auxiliary fusebox.

3.

Check

for ample fuel in tank.

4. Check air inlet system for possible leaks into

the inlet manifold.

5. Check

HT cables

for correct firing order and

routing.

2.

Remove plug shroud and manoeuvre

it

along

harness to enable meter probes to be inserted

into back

of plug.

3.

Only pin numbers

1,

13,

14,

27,

28

and 40

6.

Check ignition timing.

ETM A1.

Only when the above checks have been carried out,

should circuit diagnosis begin.

For diagnosis procedure using

a

Multi Meter

see

The diagnosis procedure using Hand Held Tester is

contained in the hand held tester manual.

View of plug - cover removed.

Pins 1 to 13 bottom row.

Pins 14 to 27 centre row.

Pins 28 to 40 top row. For clarity electrical leads

omitted.

For diagnostics using a multi meter, see ETM A1

.

4

REISSUED:

FEB

1993

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст