Chrysler 300M, Dodge Interpid. Manual — part 93

(4) Check for B+ power at the spot lamp bulb with

switch turned ON (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING

-

EXTERIOR/SPOT

LAMP -

REMOVAL). If there is B+ power at the spot lamp

bulb connector, replace bulb. If there is not B+ power

present, refer to Step 5.

(5) If there is not B+ power present at the spot

lamp with the switch turned on, check circuit for an

open. Possibly the connector in the A-pillar. Refer to

Wiring Diagrams for circuit information.

(6) If there is B+ power at the spot lamp connec-

tor, and no B+ power at the spot lamp bulb, then the

switch is defective within the spot lamp assembly

and the entire unit must be replaced. (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING

-

EXTERIOR/

SPOT LAMP - REMOVAL).

(7) If lamp still does not light, remove the handle

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

EXTERIOR/SPOT LAMP - REMOVAL), and check

the contact on the shaft end of the head assembly

into the handle to make sure the contact is not dam-

aged.

IF SPOT LAMP IS HARD TO TURN

(1) Check that the head housing clamping screw

creates just enough drag to hold the spot lamp head

in position in windy conditions. Extreme drag will

require more force on the handle to move the spot

lamp head and cause damage.

REMOVAL

CAUTION: Make sure that fuse F (master spot lamp

feed) or either fuse X or Y (left or right spot lamp

feed) are removed from the Power Distribution Cen-

ter (PDC) before performing service on the spot

lamps.

(1) Remove the fuse cover and pull either the X or

Y fuse, depending on which spot lamp is being ser-

viced.

(2) Raise the spot lamp from the stowed to the

operating position.

(3) Using a trim stick (special tool #C-4755) or

equivalent, gently pry out on the A-pillar trim to

release it. This will allow access to the spot lamp

electrical connector.

(4) Remove the instrument panel end cap.

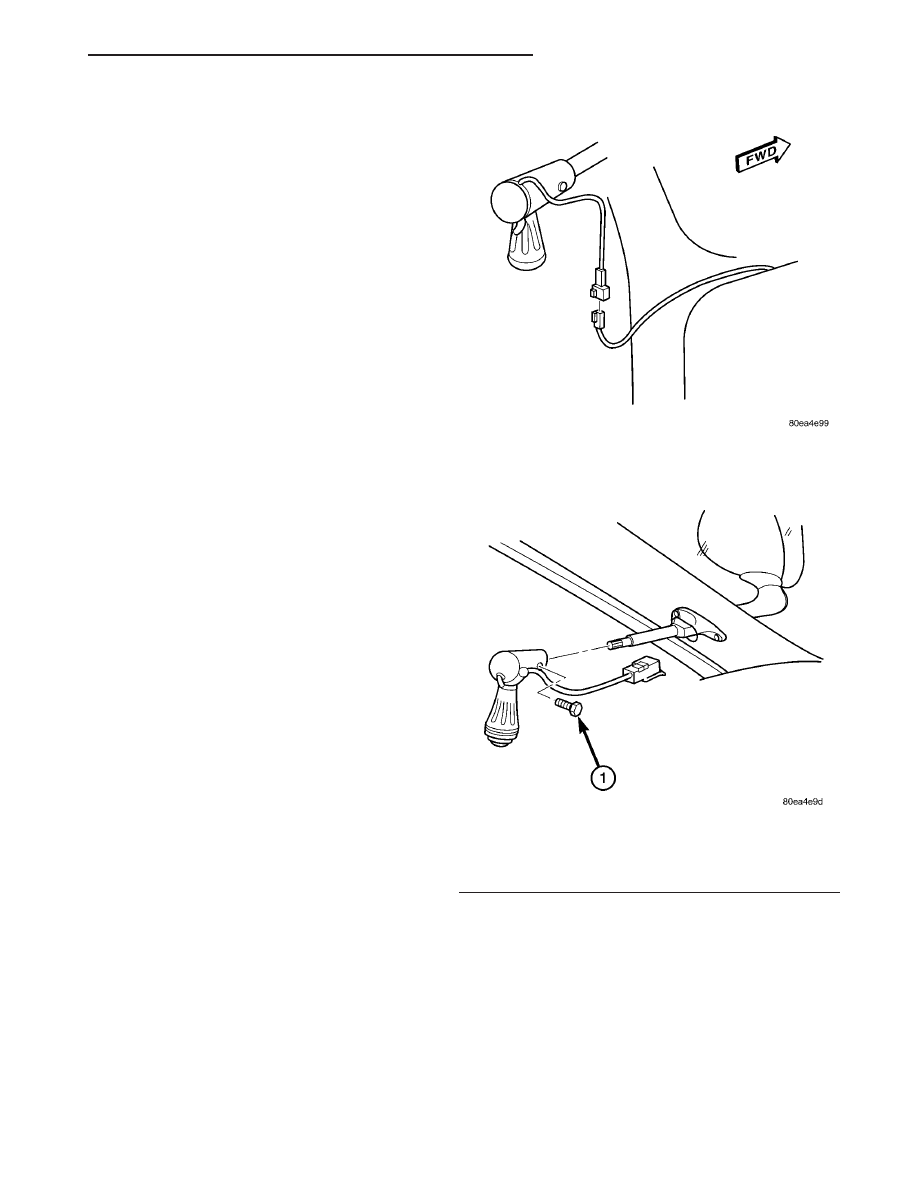

(5) Disconnect the spot lamp electrical connector

(located behind the instrument panel endcap) (Fig.

53).

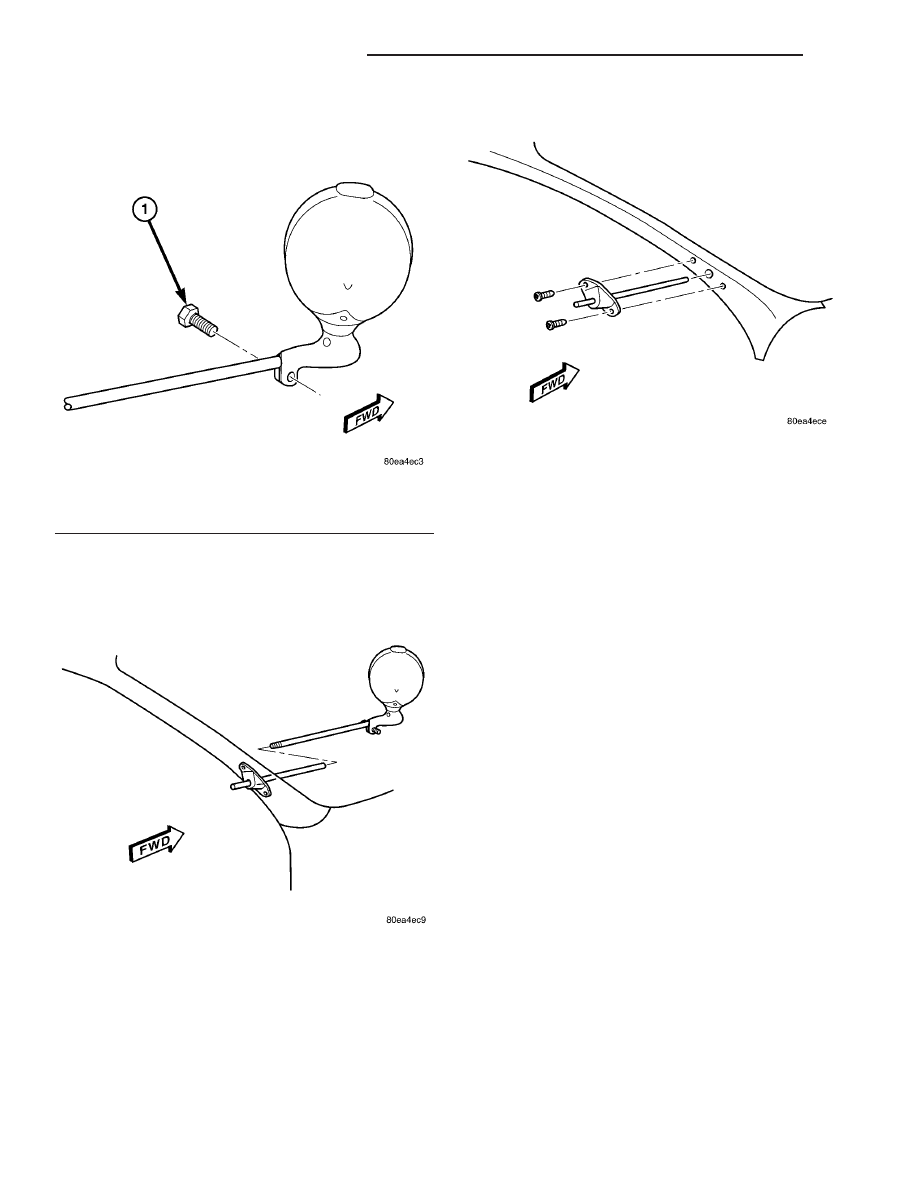

(6) Loosen, but do not remove the bolt retaining

the handle to the outer tube (Fig. 54).

NOTE: Do not remove the bolt all the way.

(7) Using a plastic tipped hammer, gently tap the

head of the handle retaining bolt (Fig. 54) and the

opposing wedge nut.

(8) Remove the handle from the outer tube.

(9) Remove the A-pillar trim from the spot lamp

outer tube.

CAUTION: Support the head of the spot lamp while

loosening the head assembly clamp screw.

Fig. 53 SPOT LAMP ASSEMBLY ELECTRICAL

CONNECTOR

Fig. 54 SPOT LAMP ASSEMBLY HANDLE

RETAINING BOLT - LOOSEN/TIGHTEN

1 - SPOT LAMP HANDLE RETAINING BOLT

LH

LAMPS/LIGHTING - EXTERIOR

8L - 41

SPOT LAMP ASSEMBLY - POLICE (Continued)

(10) Loosen the clamp screw at the base of the

spot lamp head assembly (Fig. 55).

(11) Carefully remove the spot lamp head with the

intermediate and inner shafts from the outer tube

and mounting bracket (Fig. 56).

(12) Remove the screws retaining the spot lamp

mounting bracket to the A-pillar (Fig. 57).

(13) Remove the spot lamp outer tube and mount-

ing bracket from the A-pillar (Fig. 57).

INSTALLATION

CAUTION: Make sure that fuse F (master spot lamp

feed) or either fuse X or Y (left or right spot lamp

feed) are removed from the Power Distribution Cen-

ter (PDC) before performing service on the spot

lamps.

(1) Install the spot lamp outer tube and mounting

bracket to the A-pillar (Fig. 57).

(2) Install the screws retaining the spot lamp

mounting bracket to the A-pillar (Fig. 57) and tighten

to 33 N·m (29 in. lbs.).

(3) Carefully lift the edge of the secondary door

seal along the windshield pillar to expose the spot

lamp outer tube and apply a small amount of clear

silicone sealer to the base of the outer tube.

(4) Carefully install the spot lamp head with the

intermediate and inner shafts to the outer tube and

mounting bracket until the head assembly bottoms

out on the outer tube (Fig. 56).

(5) Tighten the clamp screw at the base of the spot

lamp head assembly in small incriments while test-

ing the effort required to rotate the spot lamp

between the stowed and operating positions. Stop

tightening the clamp screw when the spot lamp can

maintain any desired position (Fig. 55).

(6) Position the A-pillar trim to the spot lamp

outer tube.

CAUTION: Support the head of the spot lamp while

tightening the head assembly clamp screw. Main-

tain an operating or vertical position.

(7) Install the handle to the outer tube.

Fig. 55 SPOT LAMP HEAD ASSEMBLY

1 - SPOT LAMP HEAD CLAMP SCREW

Fig. 56 SPOT LAMP HEAD ASSEMBLY - REMOVE/

INSTALL

Fig. 57 SPOT LAMP MOUNTING BRACKET -

REMOVE/INSTALL

8L - 42

LAMPS/LIGHTING - EXTERIOR

LH

SPOT LAMP ASSEMBLY - POLICE (Continued)

(a) Position the spot lamp handle in the operat-

ing (downward close to vertical) position to the

outer tube.

(b) There are two detent positions to which the

handle must line up and engage. Rotate the knob

of the handle and the handle base to aid in engag-

ing each of the detents. Using the wedge nut open-

ing on the handle for visual aid, rotate the handle

as necessary while installing, in order to bring the

flat detent on the intermediate shaft into view

along the bottom of the opening.

(8) Tighten the bolt retaining the handle to the

outer tube (Fig. 54) and tighten to 6.5 N·m (58 in.

lbs.).

(9) Connect the spot lamp electrical connector (Fig.

53).

(10) Install the instrument panel endcap.

(11) Install the A-pillar trim.

(12) Install the X or Y fuse, depending on which

spot lamp is being serviced.

(13) Inspect the operation of the spot lamp to

ensure that the range of movement is correct.

• Using the handle, rotate the spot lamp from the

operating position to the stowed position and back.

Ensure that the lamp will maintain the desired posi-

tion. The stowed position should be just above the

windshield and the operating position should be ver-

tical to slightly outboard.

• Using the knob of the handle, rotate the head of

the spot lamp around on its axis. The spot lamp must

rotate 360 degrees on its axis.

(14) If the spot lamp head does not rotate 360

degrees on its axis, or if excessive effort is required

to rotate the lamp head on its axis, perform the fol-

lowing:

(a) Remove the handle and inspect for damage

to the inner shaft and the gears in the handle.

Repair or replace as necessary.

(b) If no damage is present to the inner shaft or

the gears in the handle, reinstall the handle and

reinspect the operation of the lamp.

(c) If the spot lamp head still does not properly

rotate 360 degrees on its axis, remove the cover

from the end of the spot lamp head assembly and

inspect for damage to the gears in the head assem-

bly. Repair or replace as necessary.

(15) Lower the spot lamp to the stowed position.

TAIL LAMP

REMOVAL

(1) Release decklid latch and open decklid.

(2) Remove trunk lining from rear closure panel as

necessary to gain access to tail lamp fasteners.

(3) Remove nuts attaching tail lamp to rear clo-

sure panel.

(4) Remove tail lamp from rear closure panel.

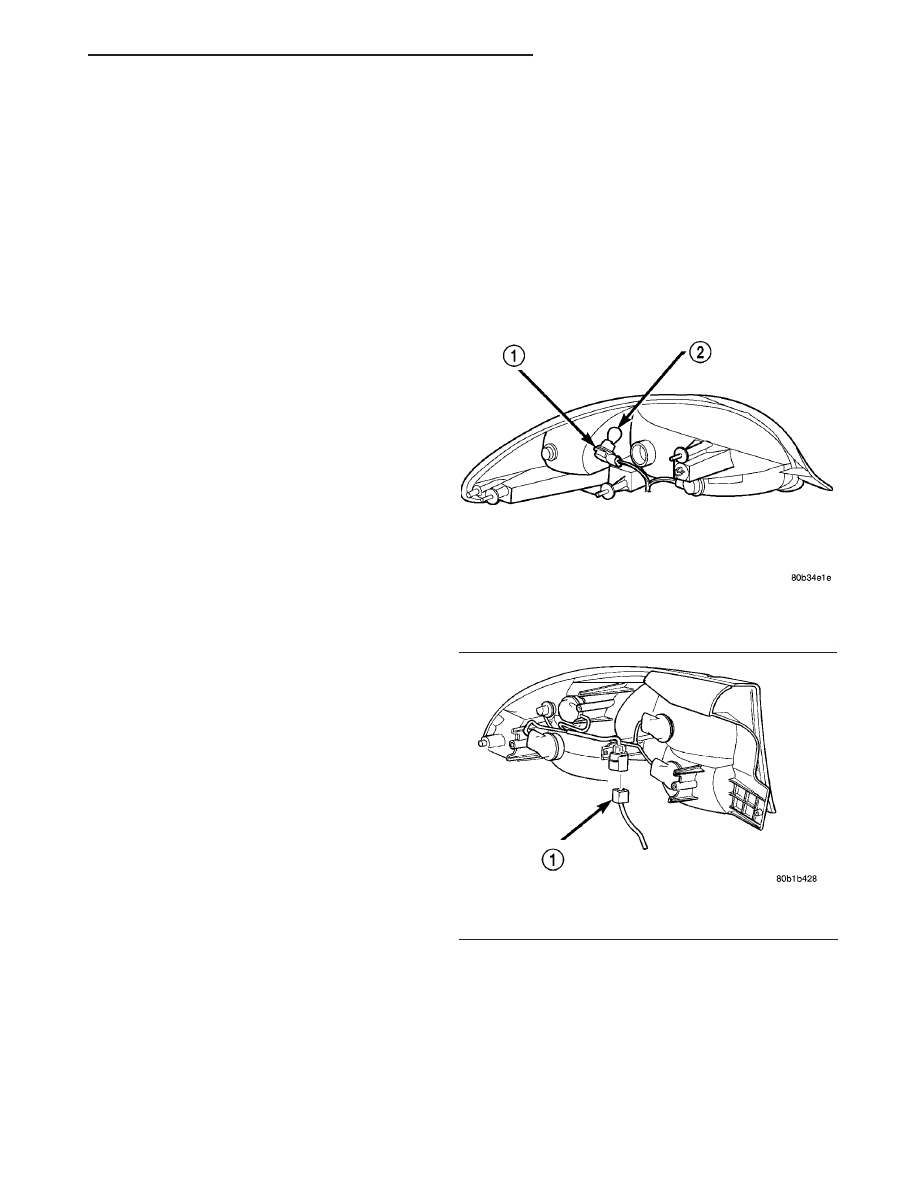

(5) Remove socket(s) from tail lamp unit (Fig. 58),

(Fig. 59), and (Fig. 60).

(6) Pull lamp from socket.

INSTALLATION

(1) Push lamp into socket.

(2) Install socket(s) in tail lamp unit.

(3) Place tail lamp unit in position on rear closure

panel.

(4) Install nuts attaching tail lamp unit to rear

closure panel.

(5) Install trunk lining.

Fig. 58 TAIL LAMP - CONCORDE

1 - SOCKET

2 - BULB

Fig. 59 TAIL LAMP - INTREPID

1 - BODY WIRE HARNESS CONNECTOR

LH

LAMPS/LIGHTING - EXTERIOR

8L - 43

SPOT LAMP ASSEMBLY - POLICE (Continued)

(6) Connect the battery negative cable and close

hood.

(7) Verify lamp operation.

TAIL LAMP UNIT

REMOVAL

(1) Release decklid latch and open decklid.

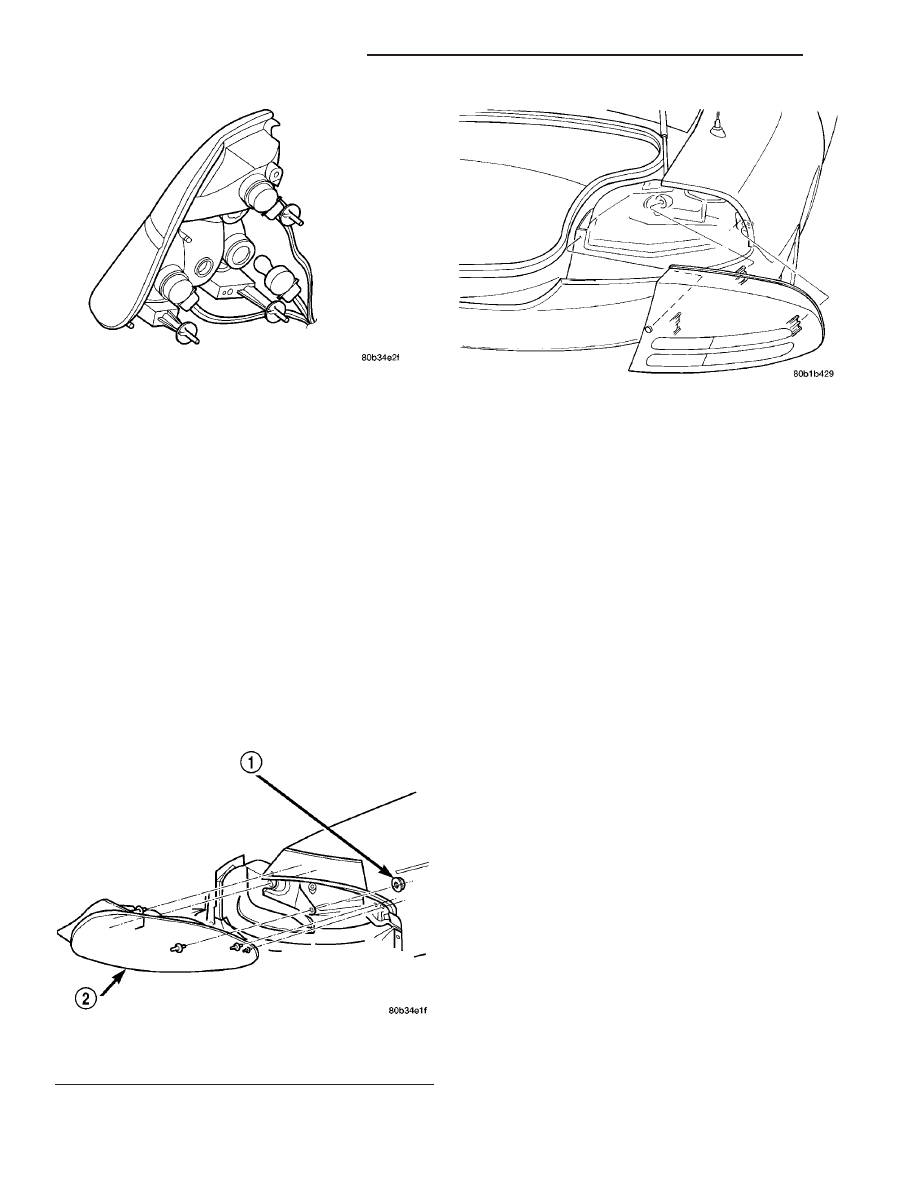

(2) Remove fasteners attaching trunk lining to

lower rear trunk panel.

(3) Move the trunk lining to access the tail lamp

unit fasteners.

(4) Remove nuts attaching tail lamp unit to lower

trunk and quarter panel (Fig. 61), (Fig. 62) and (Fig.

60).

(5) Remove tail lamp unit from vehicle.

(6) Disconnect tail lamp unit wire connector from

body wire harness.

INSTALLATION

(1) Connect tail lamp unit wire connector to body

wire harness.

(2) Place tail lamp unit in position on vehicle.

(3) Install nuts to attach tail lamp unit to lower

trunk and quarter panel.

(4) Place trunk lining in position on lower trunk

panel.

(5) Install fasteners to attach trunk lining to lower

rear trunk panel.

(6) Verify lamp operation.

TURN SIGNAL LAMP UNIT -

CONCORDE/300M

REMOVAL

(1) Open hood, disconnect and isolate the battery

negative cable.

(2) Remove headlamp unit to access lamp housing.

(3) Rotate and pull socket from lamp unit.

(4) Disconnect fastener attaching lamp unit to fas-

cia (Fig. 63).

(5) Remove lamp unit from vehicle.

INSTALLATION

(1) Place lamp unit in position on fascia.

(2) Install lamp unit fastener.

(3) Install bulb socket in lamp unit.

(4) Connect the battery negative cable.

(5) Verify lamp operation.

(6) Install headlamp unit.

(7) Close hood.

Fig. 60 TAIL LAMP - 300M

Fig. 61 TAIL LAMP - CONCORDE

1 - PLASTIC HEX NUT (4)

2 - TAIL LAMP UNIT

Fig. 62 TAIL LAMP - INTREPID

8L - 44

LAMPS/LIGHTING - EXTERIOR

LH

TAIL LAMP (Continued)

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст