Chrysler 300M, Dodge Interpid. Manual — part 92

300M

(1) Push bulb into socket (Fig. 44). Rotate socket.

(2) Reach under the fascia and place the socket

into the lamp housing and rotate to lock.

(3) Connect and the battery negative cable and

close hood.

CONCORDE

(1) Push bulb into lamp socket.

(2) Place lamp socket into headlamp housing and

rotate to the lock position.

(3) Connect wire connector to lamp socket(s).

(4) Verify headlamp operation.

(5) Install headlamp housing.

(6) Verify headlamp operation and alignment.

REAR FOG LAMP - EXPORT

DESCRIPTION

Some vehicles are equipped with rear fog lamps

(Fig. 45). The rear fog lamp is integrated into the tail

lamp assembly. If the rear fog lamp proves faulty the

entire tail lamp must be replaced. Rear fog lamps

utilize a red lens and clear bulb.

Rear fog lamps are standard equipment in certain

parts of the world where excessive fog is experienced

on a regular basis.

OPERATION

The rear fog lamps are turned ON and OFF with

the rear fog lamp switch. (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING

-

EXTERIOR/FOG

LAMP

SWITCH - OPERATION) and Wiring Diagrams.

DIAGNOSIS AND TESTING - REAR FOG LAMP

- EXPORT

NOTE: Battery must be completely charged (12v)

prior to testing. It may also be necessary to install

battery charger on the vehicles electrical system

when performing this test. Refer to the Battery sec-

tion of the service manual for detailed information.

(1) Remove the rear fog lamp bulb and check for

burned out condition, replace bulb if necessary.

(2) If bulb appears OK, reinstall the bulb in its

socket and turn fog lamps ON and check for proper

operation. If lamp is still inoperative proceed to Step

3.

(3) Remove lamp bulb and check for proper power

(12v) and ground connections in lamp socket. If

power and/or ground connections are not present,

trace wire until open or short is found.

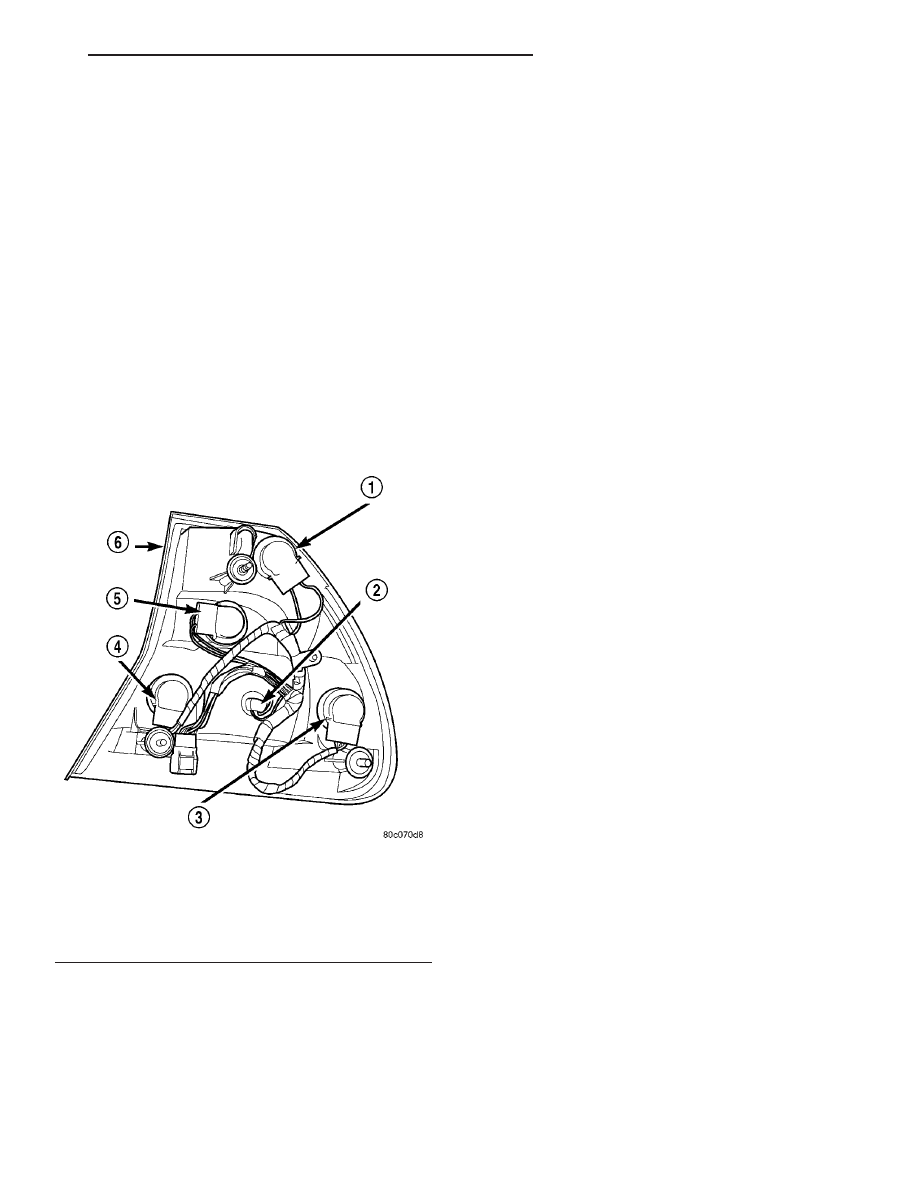

REMOVAL

(1) Remove the tail lamp from the vehicle.

(2) Rotate the rear fog lamp socket one-third turn

and pull from lamp housing (Fig. 45).

(3) Pull the rear fog lamp bulb straight from its

socket.

INSTALLATION

(1) Install the rear fog lamp bulb and socket in the

lamp housing (Fig. 45).

(2) Verify lamp operation.

(3) Install the tail lamp assembly in the vehicle.

REAR FOG LAMP SWITCH -

EXPORT

DESCRIPTION

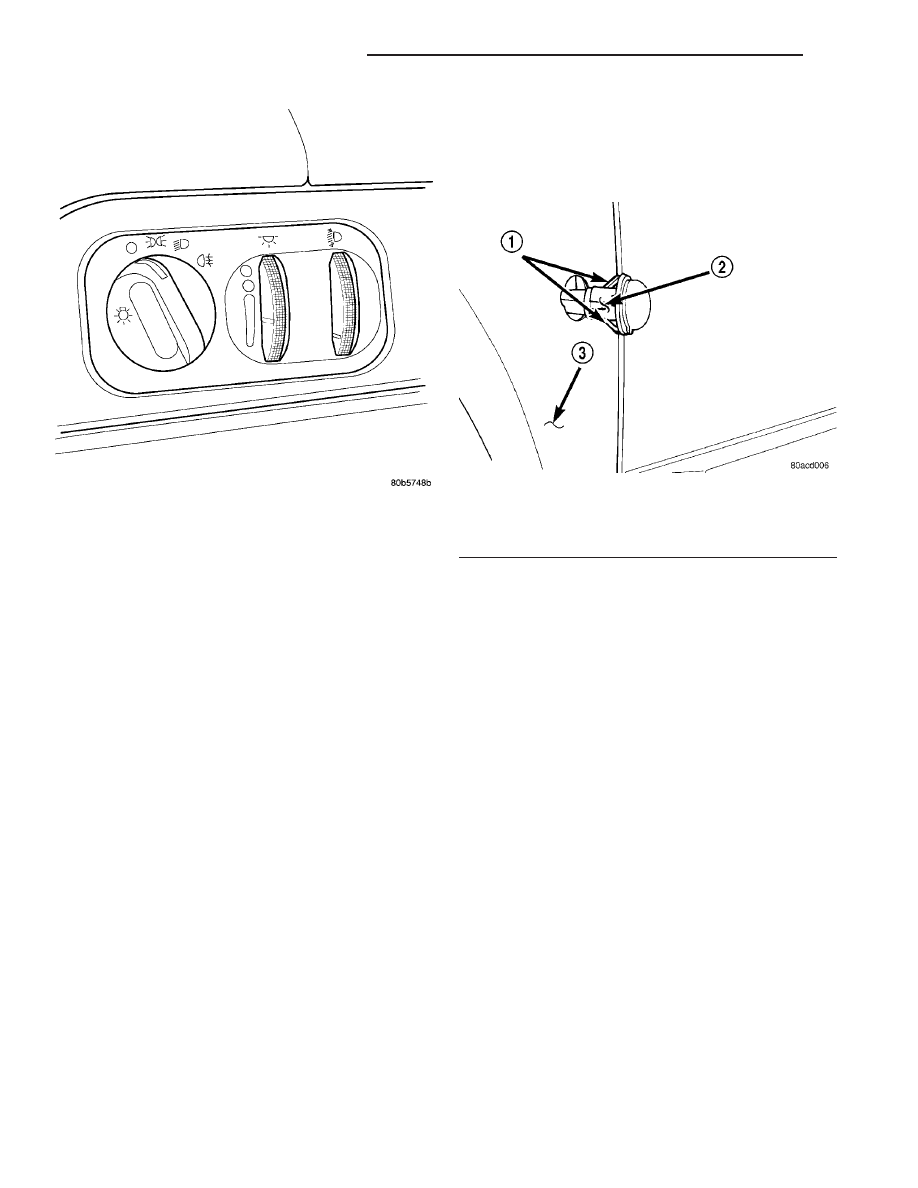

Vehicles equipped with rear fog lamps utilize a

rear fog lamp switch. This switch is located next to

the headlamp switch on (Fig. 46). The rear fog lamp

switch is the primary controller of the rear fog

lamps.

Fig. 45 TAIL LAMP BULBS

1 - REAR TURN SIGNAL LAMP

2 - REAR TAIL LAMP

3 - REAR STOP LAMP

4 - REAR FOG LAMP

5 - BACK-UP LAMP

6 - TAIL LAMP ASSEMBLY

LH

LAMPS/LIGHTING - EXTERIOR

8L - 37

PARK/TURN SIGNAL LAMP (Continued)

OPERATION

With the rotation of the rear fog lamp switch, volt-

age is sent through the rear fog lamp switch. This

illuminates the rear fog lamp or lamps. The head-

lamps must be “on” in order for the rear fog lamp/s to

function. Refer to the appropriate wiring information.

The wiring information includes wiring diagrams,

proper wire and connector repair procedures, details

of wire harness routing and retention, connector pin-

out information and location views for the various

wire harness connectors, splices and grounds.

REMOVAL

The rear fog lamp switch is integrated into the

headlamp switch on LH models. If the rear fog lamp

switch proves faulty the entire headlamp switch

must be replaced. (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING

-

EXTERIOR/HEADLAMP

SWITCH - REMOVAL).

INSTALLATION

The rear fog lamp switch is integrated into the

headlamp switch on LH models. If the rear fog lamp

switch proves faulty the entire headlamp switch

must be replaced. (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING

-

EXTERIOR/HEADLAMP

SWITCH - INSTALLATION).

SIDE REPEATER LAMP -

EXPORT

DESCRIPTION

One Side Repeater Lamp can be found on each side

of the vehicle just behind the front wheel (Fig. 47).

The side repeater lamp utilizes an amber colored

housing and clear bulb.

OPERATION

The side repeater lamps are turned ON or OFF

with the turn signal lamps. These lamps are con-

trolled by the steering column mounted multi-func-

tion switch.

DIAGNOSIS AND TESTING - SIDE REPEATER

LAMP - EXPORT

(1) Remove the suspect side repeater lamp bulb

and check for burned out condition. Replace bulb if

necessary.

(2) If the bulb appears to be OK, reinstall the bulb

in its socket and rotate the ignition switch to the ON

position. Turn the appropriate turn signal lamp ON

and check for lamp operation. If lamp is still inoper-

ative proceed to Step 3.

(3) Remove the suspect side repeater lamp bulb

and check for power (12v) and ground connections in

lamp socket. If either are not present, trace wire

until open or short is found.

REMOVAL

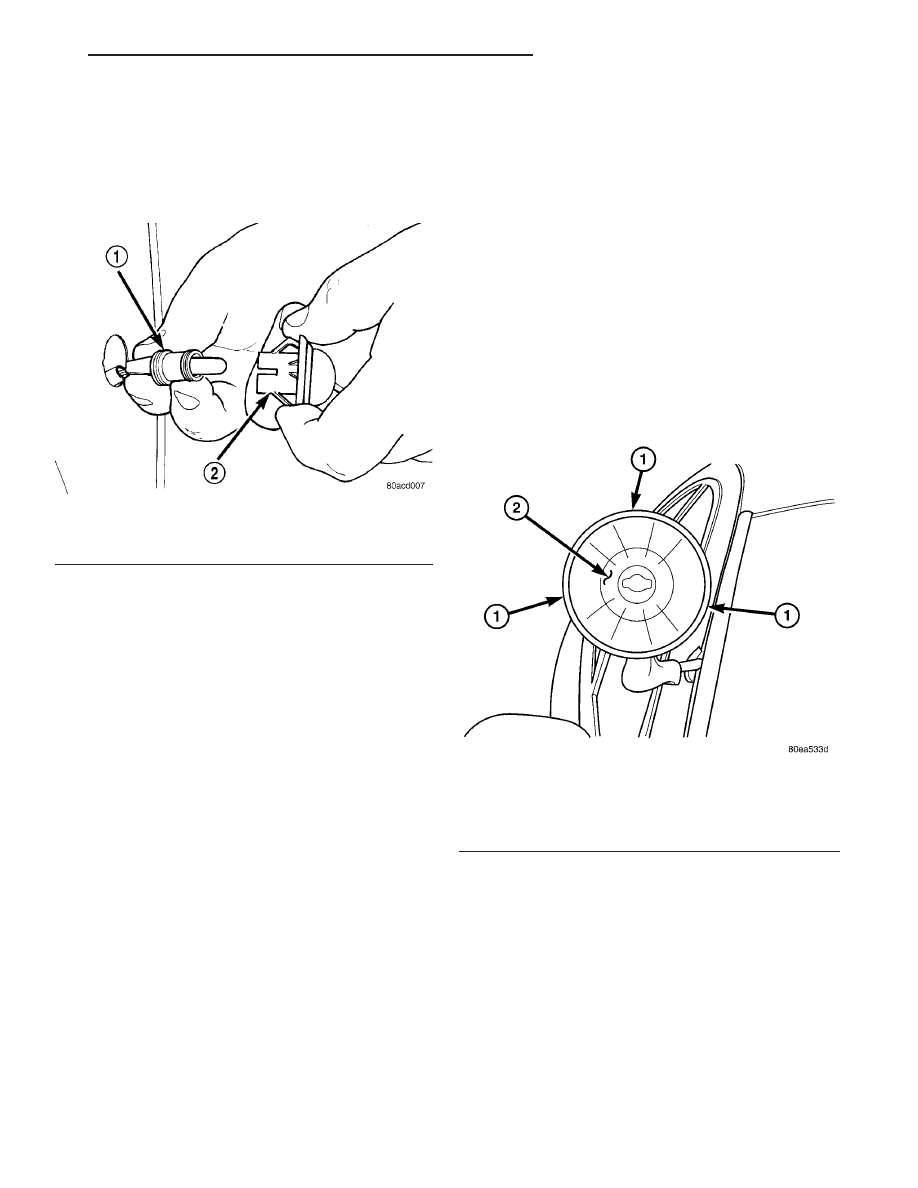

(1) Open front door.

Fig. 46 REAR FOG LAMP SWITCH

Fig. 47 SIDE REPEATER LAMP

1 - SIDE REPEATER LAMP RETAINING TABS

2 - SIDE REPEATER LAMP HOUSING

3 - FENDER

8L - 38

LAMPS/LIGHTING - EXTERIOR

LH

REAR FOG LAMP SWITCH - EXPORT (Continued)

(2) Reach up behind the side repeater lamp and

depress the two lamp unit retaining tabs. Remove

the lamp unit from the fender opening.

(3) Rotate the side repeater lamp unit counter-

clockwise and remove the lamp socket from the lamp

unit (Fig. 48).

(4) Pull the lamp bulb straight from its socket.

INSTALLATION

(1) Install the side repeater lamp bulb in the

socket.

(2) Verify lamp operation.

(3) Install the side repeater lamp socket into the

lamp unit.

(4) Install the side repeater lamp in the front

fender. Be certain lamp unit is secure in fender.

SIDE REPEATER LAMP UNIT -

EXPORT

REMOVAL

(1) Working in the appropriate front wheel well,

remove the rear most fasteners from the front wheel-

house liner.

(2) Reach up behind the side repeater lamp and

depress the two lamp housing retaining tabs (Fig.

48). Remove the side repeater lamp unit from the

fender opening.

(3) Rotate the side repeater lamp unit counter-

clockwise and remove the lamp socket from the lamp

unit (Fig. 48).

INSTALLATION

(1) Install the side repeater lamp socket into the

lamp unit.

(2) Install the side repeater lamp in the front

fender (Fig. 48). Be certain lamp is secure within the

fender.

(3) Install the front wheelhouse liner.

(4) Verify lamp operation.

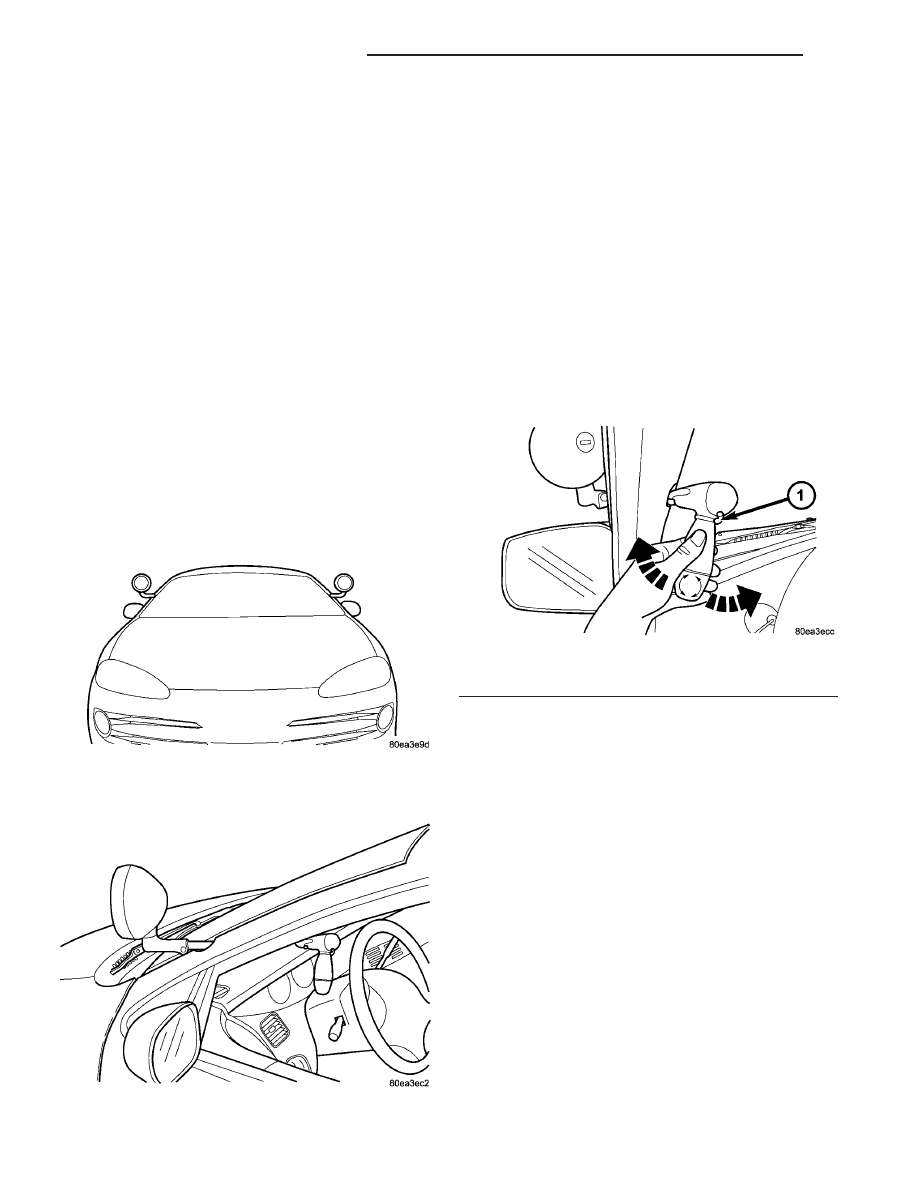

SPOT LAMP - POLICE

REMOVAL

(1) Remove the PDC cover and pull either the X or

Y fuse, depending on which spot lamp is being ser-

viced.

(2) Raise the spot lamp from the stowed to the

operating position.

(3) Support the spot lamp sealed beam in position.

(4) Remove the screws retaining the bezel to the

spot lamp head assembly (Fig. 49).

(5) Remove the bezel from the spot lamp head

assembly.

(6) Tilt the sealed beam away from the spot lamp

head assembly.

(7) Disconnect the electrical connector to the spot

lamp head assembly.

(8) Remove the bulb from the lamp housing by

moving the hold downs.

(9) Remove bulb from lamp.

INSTALLATION

(1) Position bulb into spot lamp assembly.

(2) Install the hold downs.

Fig. 48 SIDE REPEATER LAMP/HOUSING

1 - BULB SOCKET

2 - SIDE REPEATER LAMP UNIT

Fig. 49 SPOT LAMP RETAINING SCREWS -

REMOVE/INSTALL

1 - SPOT LAMP HEAD ASSEMBLY BEZEL RETAINING SCREWS

2 - SPOT LAMP

LH

LAMPS/LIGHTING - EXTERIOR

8L - 39

SIDE REPEATER LAMP - EXPORT (Continued)

(3) Connect the electrical connector to the spot

lamp head assembly.

(4) Tilt the sealed beam toward the spot lamp

head assembly.

(5) Install the bezel to the spot lamp head assem-

bly.

(6) Install the screws retaining the bezel to the

spot lamp head assembly (Fig. 49) and tighten to 2

N·m (18 in. lbs.).

(7) Lower the spot lamp from the operating to

stowed position.

(8) Install the fuse and PDC cover.

(9) Verify system and vehicle operation.

SPOT LAMP ASSEMBLY -

POLICE

DESCRIPTION

This vehicle may be equipped with up to two spot

lamp assemblies, attached to the A-Pillars (Fig. 50).

The spot lamp assembly switch is located on the han-

dle (Fig. 51), just above the rotating handle grip.

Each spot lamp assembly contains a 100 watt halo-

gen bulb. The spot lamp assemblies are fused indi-

vidually and powered hot at all times. There are

three fuses in the Power Distribution Center (PDC)

that control the spot lamp assemblies:

• Fuse F - IP ACC3/SPOT LPS - 50 amp

• Fuse X - SPOT LP LT - 20 amp

• Fuse Y - SPOT LP RT/UNDERHOOD - 20 amp

The parts available for service are:

• Complete spot lamp assembly.

• H3 100 watt halogen bulb.

• Inside control handle w/switch.

OPERATION

Use this switch to turn the spot lamp assembly ON

and OFF. Rotate and twist the handle to adjust the

position of the spot lamp assembly (Fig. 52).

DIAGNOSIS AND TESTING - SPOT LAMP

ASSEMBLY - POLICE

IF SPOT LAMP DOES NOT LIGHT

(1) If both spot lamps are inoperative, check fuse F

(spot lamp master). Refer to Wiring Diagrams for

fuse locations. If fuses are OK, refer to Step 4. If

fuse(s) are faulty, replace as necessary.

(2) If the left spot lamp is inoperative, check fuse

X. If fuse is OK, refer to Step 4. If fuse is faulty,

replace as necessary. If fuse blows again, find short

to ground. Refer to Wiring Diagrams for circuit infor-

mation.

(3) If the right spot lamp is inoperative, check fuse

Y. If fuse is OK, refer to Step 4. If fuse is faulty,

replace as necessary. If fuse blows again, find short

to ground. Refer to Wiring Diagrams for circuit infor-

mation.

Fig. 50 SPOT LAMP ASSEMBLY LOCATION

Fig. 51 SPOT LAMP ASSEMBLY

Fig. 52 SPOT LAMP ASSEMBLY OPERATION

1 - ON/OFF SWITCH

8L - 40

LAMPS/LIGHTING - EXTERIOR

LH

SPOT LAMP - POLICE (Continued)

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст