Nissan Qashqai (2007-2010). Manual — part 626

DRIVE PINION

DLN-77

< DISASSEMBLY AND ASSEMBLY >

[TRANSFER: TY30A]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

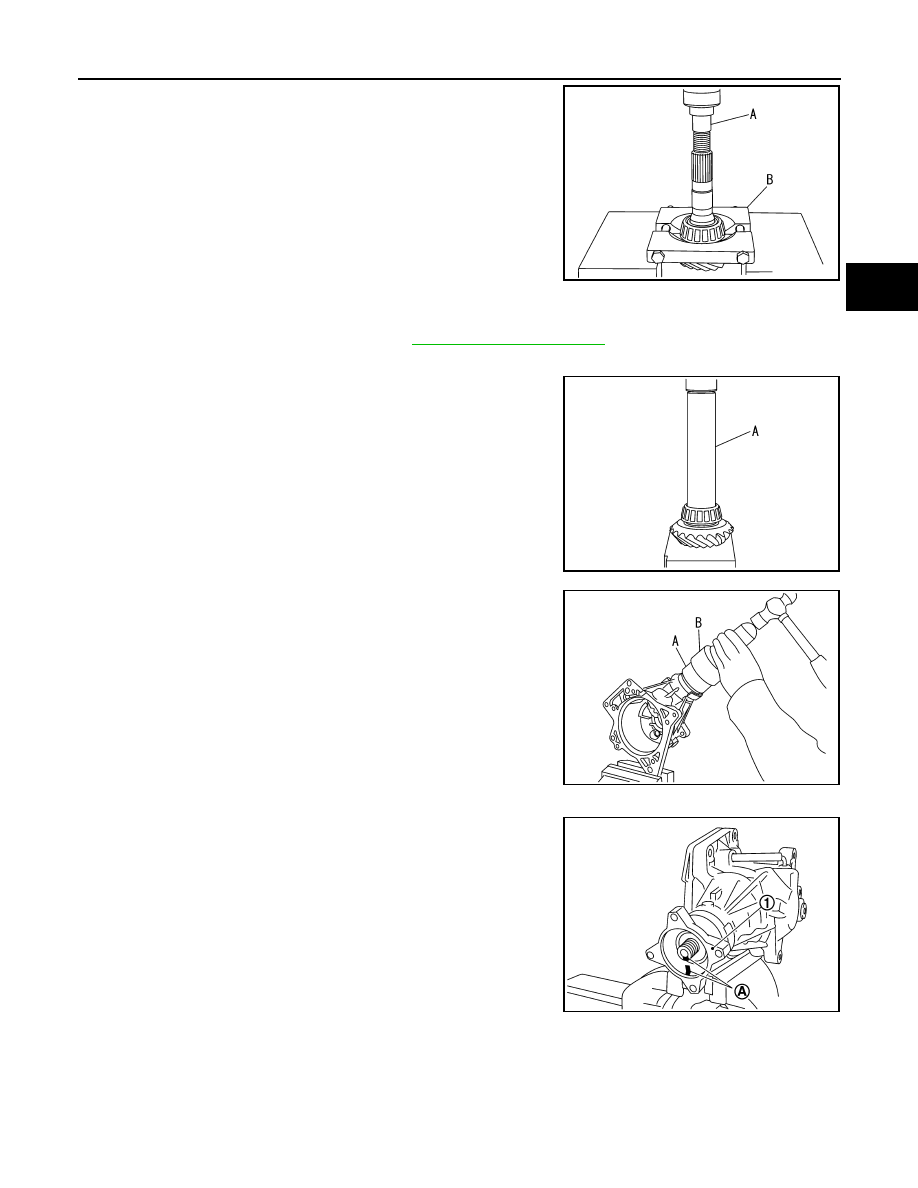

10. Remove inner race of drive pinion bearing (front side) from drive

pinion with a drift (A) (SST: ST33052000) and replacer (B) (SST:

ST22730000).

11. Remove drive pinion adjusting shim from the drive pinion.

M/T : Assembly

INFOID:0000000000972147

1.

Select drive pinion adjusting shim. Refer to

2.

Install selected drive pinion adjusting shim to drive pinion.

3.

Install inner race of drive pinion bearing (front side) to drive pin-

ion with a drift (A) (SST: ST23860000).

CAUTION:

• Never reuse drive pinion bearing (front side).

• Apply gear oil to the drive pinion bearing (front side).

4.

Assemble the inner race of drive pinion bearing (rear side) into

the transfer case.

CAUTION:

• Never reuse drive pinion bearing (rear side).

• Apply gear oil to the drive pinion bearing (rear side).

5.

Install drive pinion oil seal to transfer case with drifts so that it

becomes flush with case end surface.

CAUTION:

• Never reuse oil seal.

• Apply multi-purpose grease onto oil seal lips, and gear oil

onto the circumference.

6.

Assemble a collapsible spacer onto the drive pinion.

CAUTION:

Never reuse the collapsible spacer.

7.

Assemble drive pinion assembly into the transfer case, and then

install companion flange (1) to drive pinion.

NOTE:

Align matching marks (A) on the thread edge of companion

flange and drive pinion and install companion flange if drive pin-

ion is reused.

SDIA3087J

SDIA3094J

A

: Drift (SST: ST27861000)

B

: Drift (SST: ST30720000)

SDIA3093J

SDIA3084J

DLN-78

< DISASSEMBLY AND ASSEMBLY >

[TRANSFER: TY30A]

DRIVE PINION

8.

Tap the companion flange with a plastic hammer as far as the

lock nut can be tightened.

CAUTION:

Never damage drive pinion oil seal.

9.

Apply anti-corrosive oil to the thread and seat of the lock nut,

and temporarily tighten lock nut to the drive pinion.

CAUTION:

Never reuse lock nut.

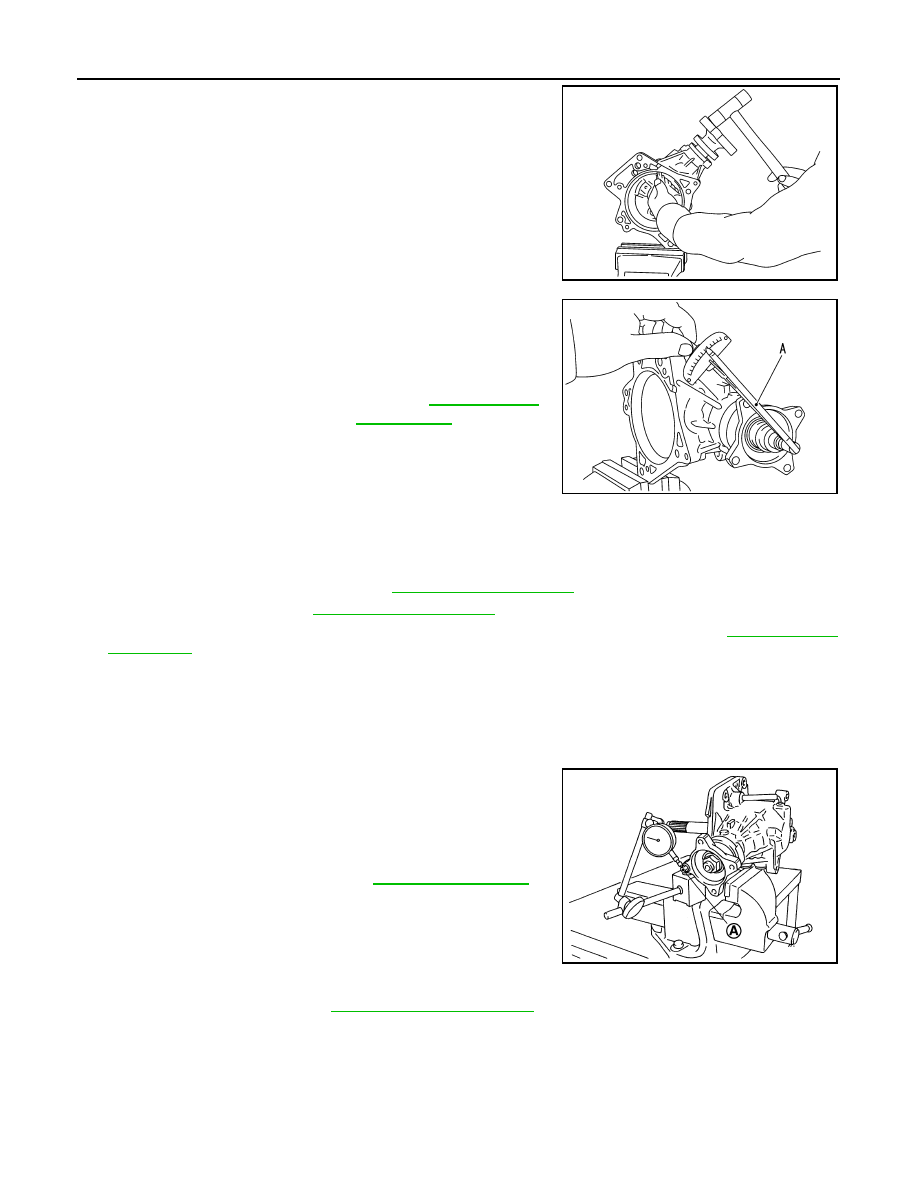

10. Tighten lock nut within the specified torque range with a preload

gauge (A) (SST: ST3127S000) so that the drive pinion bearing

preload is within standard.

CAUTION:

• Start the tightening of lock nut from lower limit of the

specified torque. Check the preload every 5

°

to 10

°

while

tightening the lock nut.

• Replace the collapsible spacer and tighten it again to adjust if preload exceeds the specified

value. Never loosen lock nut to adjust preload.

• After adjustment, rotate the drive pinion back and forth from 2 to 3 times to check for unusual

noise, sticking, binding, and so on.

11. Install ring gear shaft assembly. Refer to

12. Install adapter case. Refer to

.

13. Check backlash, tooth contact, total preload and companion flange runout. Refer to

.

CAUTION:

Measure the total preload without the adapter case oil seal.

M/T : Adjustment

INFOID:0000000001056555

BACKLASH

1.

Install the bolt (A) to the companion flange.

2.

Fit a dial indicator onto the bolt.

3.

Measure the circumference backlash of the companion flange.

Disassemble the transfer assembly to check and adjust each

part if outside the standard.

TOOTH CONTACT

1.

Remove adapter case. Refer to

SDIA3095J

Standard

Drive pinion bearing preload

: Refer to

SDIA3072J

Standard

Backlash

: Refer to

.

SDIA3065J

DRIVE PINION

DLN-79

< DISASSEMBLY AND ASSEMBLY >

[TRANSFER: TY30A]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

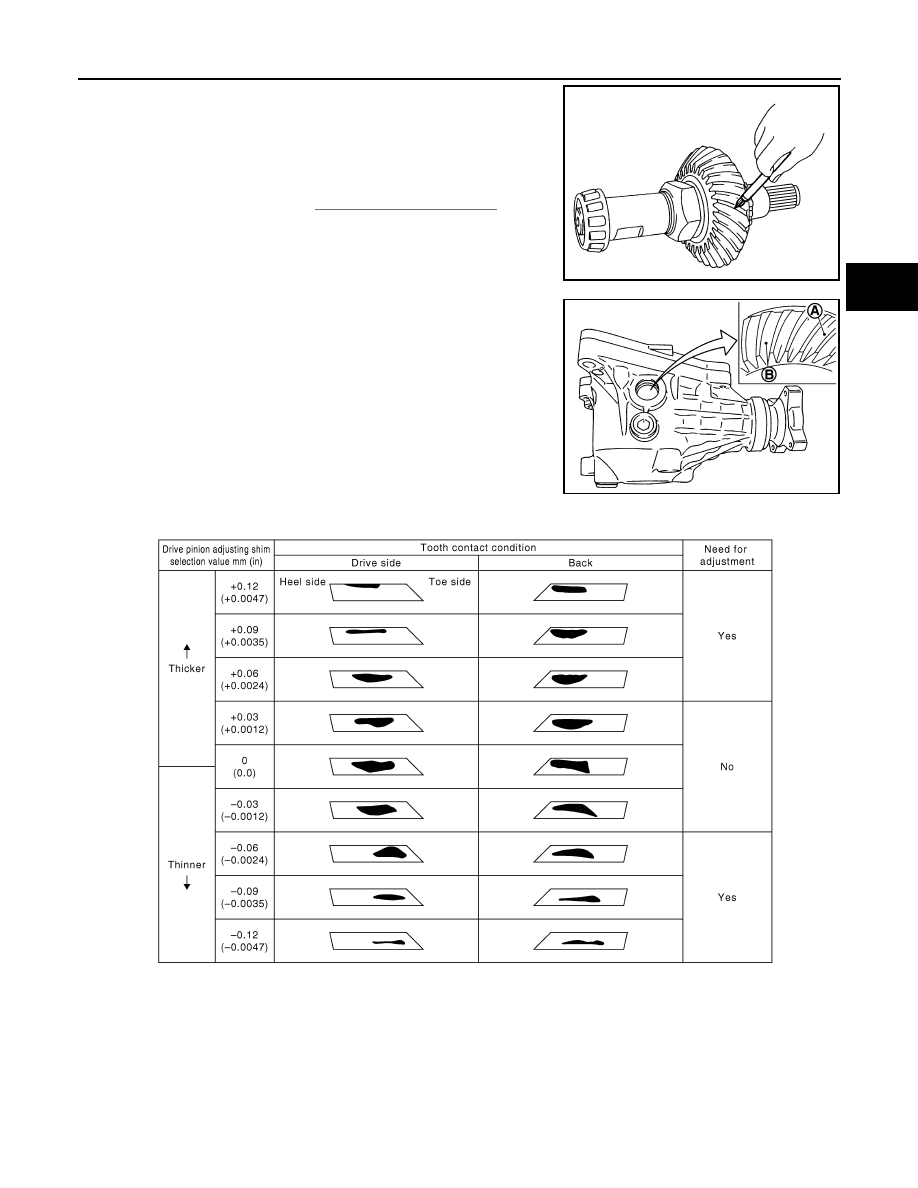

2.

Remove ring gear shaft assembly from transfer case. Then

apply red lead onto the ring gear.

CAUTION:

Apply red lead to both faces of 3 to 4 gears at 4 locations

evenly spaced on the ring gear.

3.

Assemble the ring gear shaft assembly to the transfer case.

4.

Install adapter case. Refer to

5.

Remove plug on the lower side of the transfer case.

6.

Rotate the companion flange back and forth several times. Then

check drive pinion to ring gear tooth contact by viewing from the

tooth contact test hole. (A: Drive side, B: Reverse side)

Tooth Contact Judgment Guide

JSDIA0255ZZ

SDIA3067J

JSDIA0213GB

DLN-80

< DISASSEMBLY AND ASSEMBLY >

[TRANSFER: TY30A]

DRIVE PINION

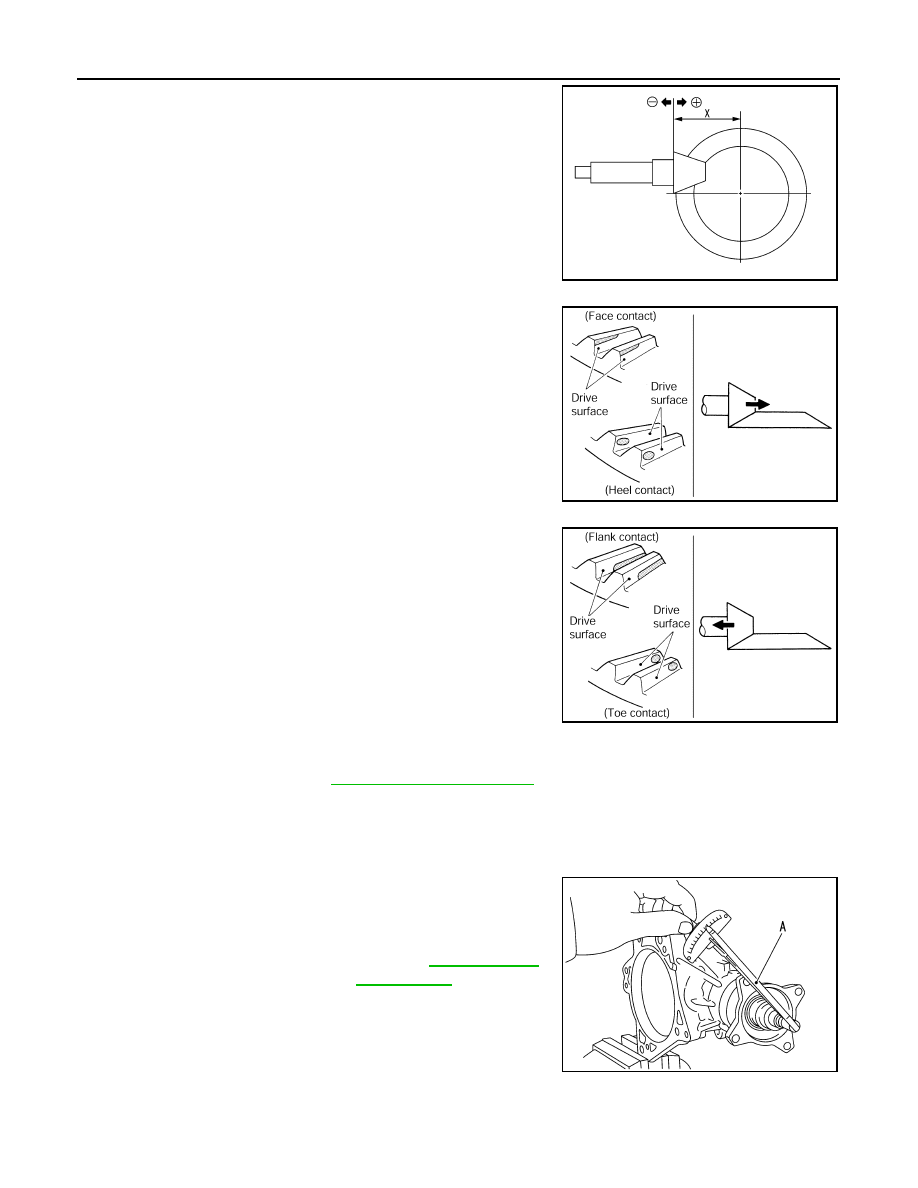

7.

Follow the procedure below to adjust pinion height (dimension

X) if tooth contact is improper.

CAUTION:

If no adjusting shim with the calculated value is available,

select the thicker and closest one.

• Thicken the drive pinion adjusting shim to move the drive pin-

ion closer to the ring gear in case of face contact or heel con-

tact.

CAUTION:

Only one adjusting shim can be selected.

• Thin the drive pinion adjusting shim to move the drive pinion

farther from the ring gear in case of flank contact or toe con-

tact.

CAUTION:

Only one adjusting shim can be selected.

8.

Assemble the plug to the transfer case.

CAUTION:

• Remove old gasket on mounting surface, then remove

any moisture, oil, and foreign material on the application

and mounting surfaces.

• Apply liquid gasket to the thread, and tighten to the speci-

fied torque when installing plug.

DRIVE PINION BEARING PRELOAD

1.

Remove adapter case. Refer to

2.

Remove ring gear shaft assembly from the transfer case.

3.

Rotate the companion flange back and forth from 2 to 3 times to check for unusual noise, binding, sticking,

and so on.

4.

Rotate the companion flange at least 20 times to check for smooth operation of the bearing.

5.

Measure the drive pinion bearing preload with a preload gauge

(A) (SST: ST3127S000).

CAUTION:

Each rotational part should rotate smoothly with the speci-

fied gear oil.

• Disassemble the drive pinion assembly to check and adjust

each part if outside the standard.

TOTAL PRELOAD

1.

Measure drive pinion bearing preload (P

1

). Refer to “DRIVE PINION BEARING PRELOAD”.

SDIA3158J

PDIA0440E

PDIA0441E

Standard

Drive pinion bearing preload

: Refer to

SDIA3072J

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст