Nissan Qashqai (2007-2010). Manual — part 550

TRANSAXLE ASSEMBLY

TM-135

< DISASSEMBLY AND ASSEMBLY >

[6MT: RS6F52A]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

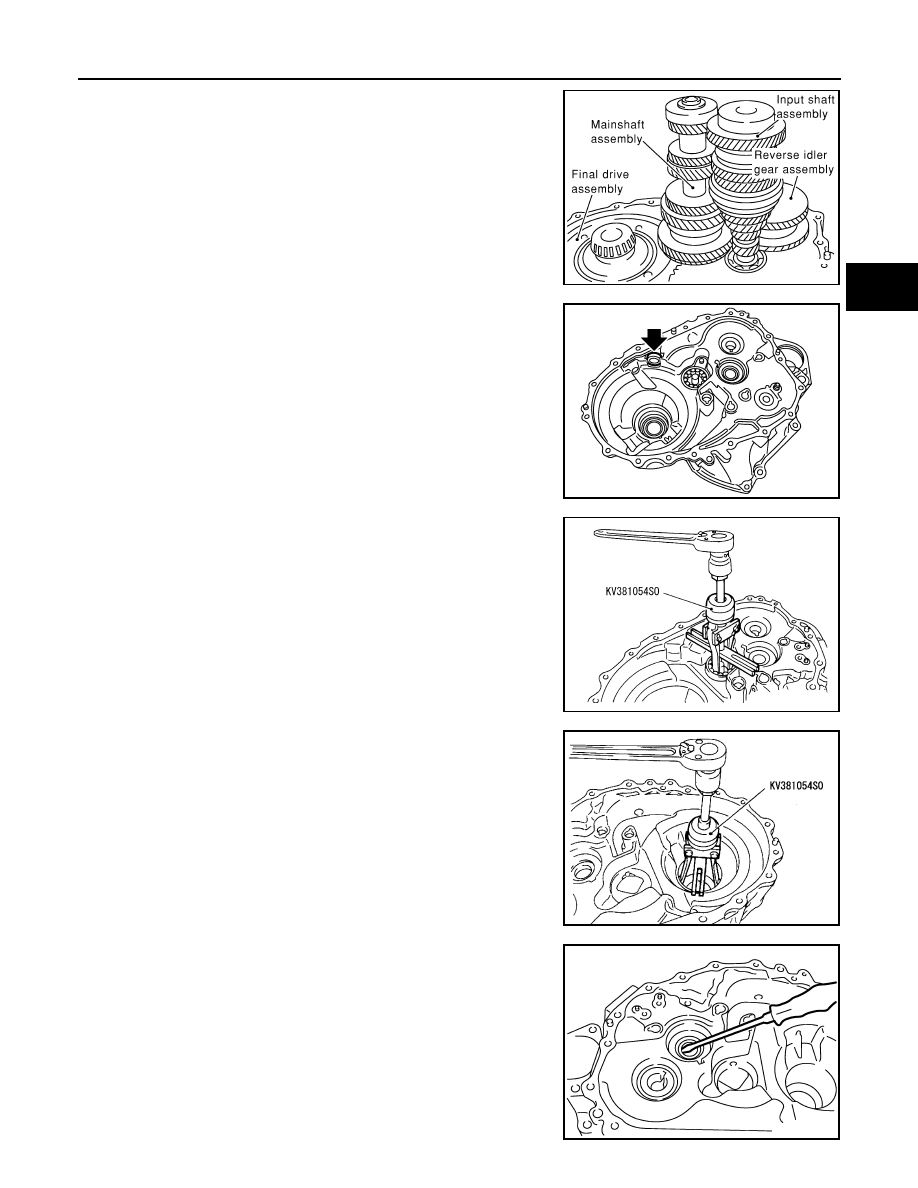

30. Remove gear components from clutch housing in the following

procedure.

a.

Remove a set of input shaft assembly, mainshaft assembly, and

reverse idler gear assembly by tapping the tip of input shaft from

the back of the clutch housing with a plastic hammer.

CAUTION:

Always withdraw mainshaft straight out. Failure to do so

can damage resin oil channel on clutch housing side.

b.

Remove final drive assembly.

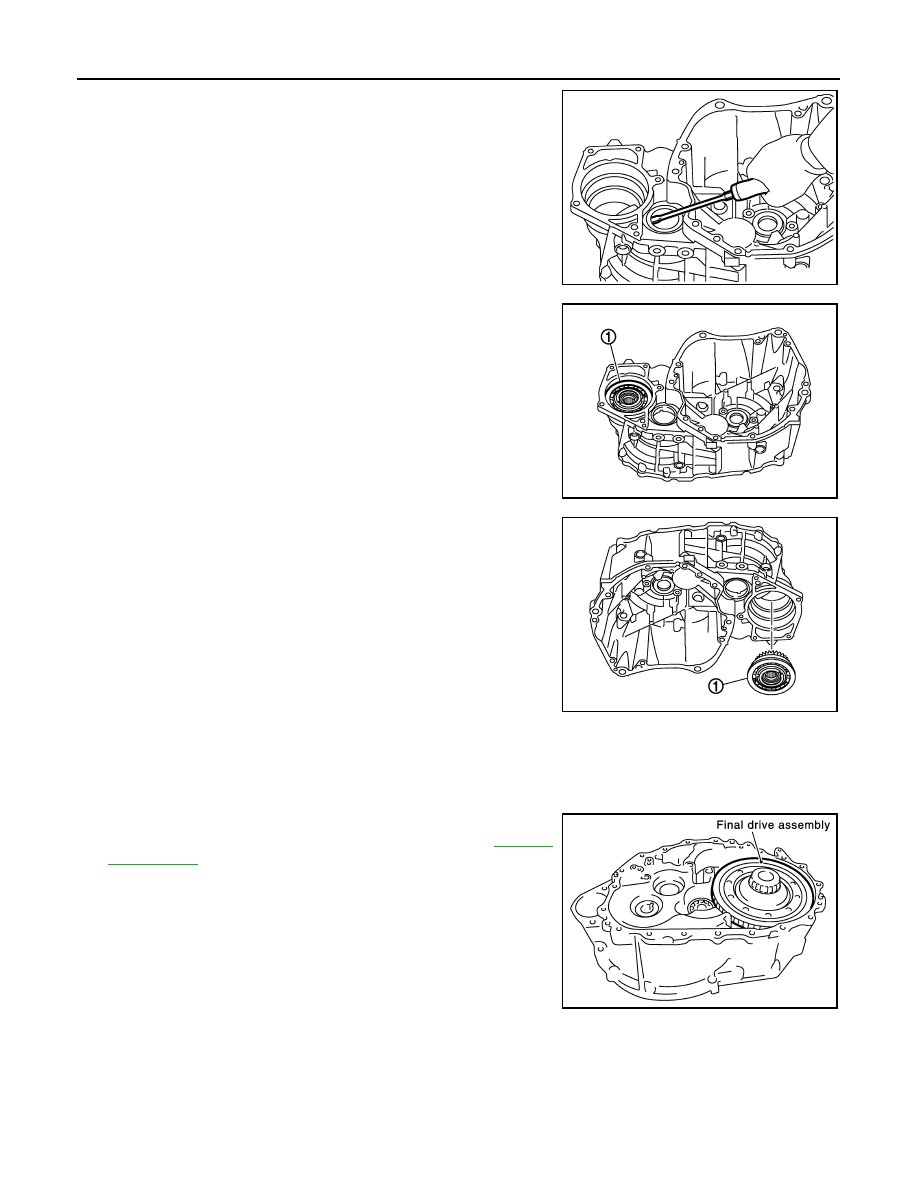

31. Remove magnet from clutch housing.

32. Remove mainshaft bearing retainer and then mainshaft front

bearing from clutch housing using the puller.

CAUTION:

Never damage clutch housing, mainshaft front bearing, and

oil channel.

33. Remove oil channel from clutch housing.

34. Remove differential side bearing outer race (clutch housing

side) from clutch housing using the puller.

CAUTION:

Never damage clutch housing and differential side bearing

outer race.

35. Remove input shaft oil seal from clutch housing.

CAUTION:

Never damage clutch housing.

SCIA0964E

PCIB1859E

SCIA1077J

SCIA1069J

SCIA0398E

TM-136

< DISASSEMBLY AND ASSEMBLY >

[6MT: RS6F52A]

TRANSAXLE ASSEMBLY

36. Remove differential side oil seal from clutch housing.

CAUTION:

Never damage clutch housing.

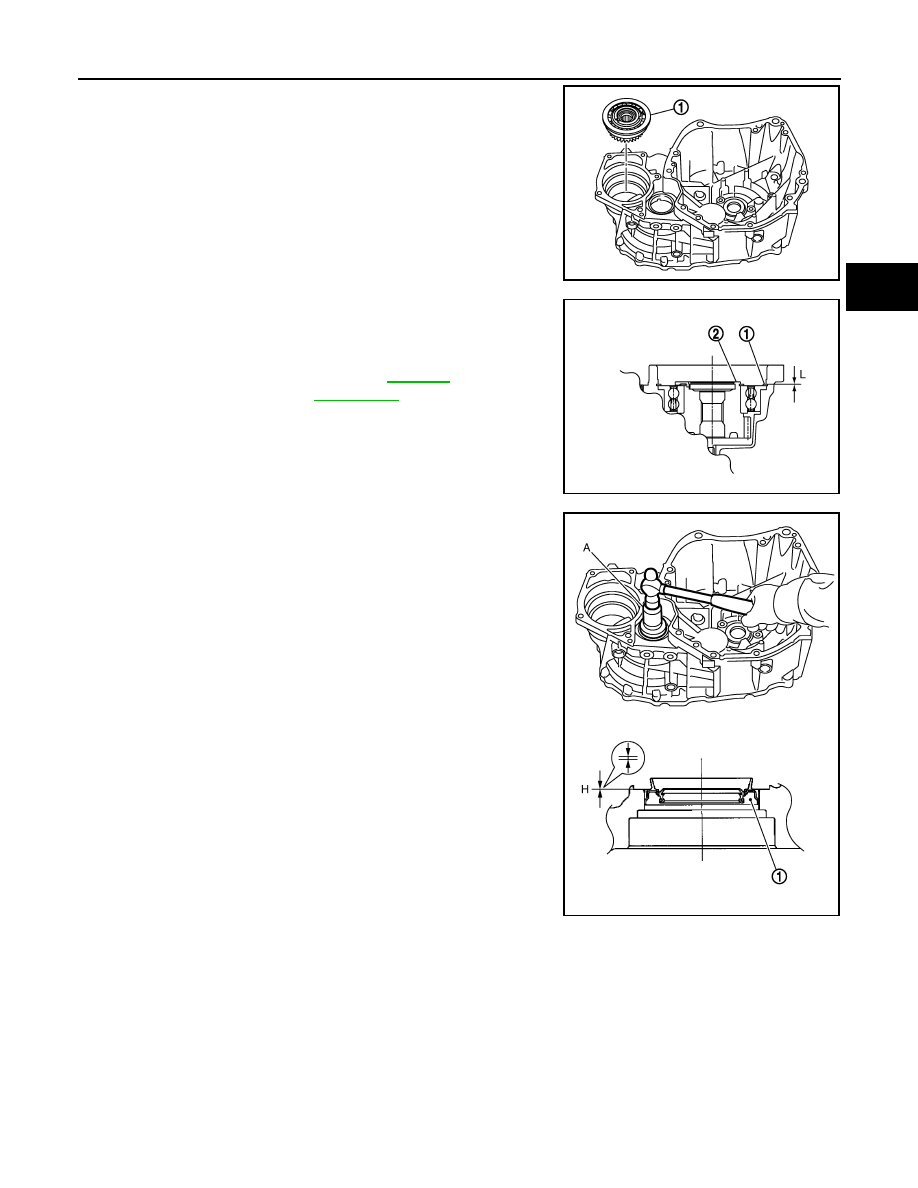

37. Remove snap ring (1) from clutch housing.

CAUTION:

Never damage clutch housing.

38. With output gear assembly (1) held by hand, turn clutch housing

upside down as shown in the figure.

CAUTION:

• When turning clutch housing upside down, hold output

gear assembly by hand so that it will not become

detached.

• Never damage clutch housing.

NOTE:

Output gear assembly spontaneously falls when changing the

clutch housing direction as shown in the figure.

39. With output gear assembly held by hand, slowly remove output

gear assembly from clutch housing. If output gear assembly can

not be removed, tap it with a plastic hammer from the transaxle case contact surface side of clutch hous-

ing for removal.

Assembly

INFOID:0000000001034953

1.

Install final drive assembly into clutch housing.

2.

Select differential side bearing adjusting shim. Refer to

CAUTION:

Never select differential side bearing adjusting shim with

output gear assembly installed on clutch housing.

3.

Remove final drive assembly.

JPDIC0076ZZ

JPDIC0044ZZ

JPDIC0075ZZ

SCIA0888E

TRANSAXLE ASSEMBLY

TM-137

< DISASSEMBLY AND ASSEMBLY >

[6MT: RS6F52A]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

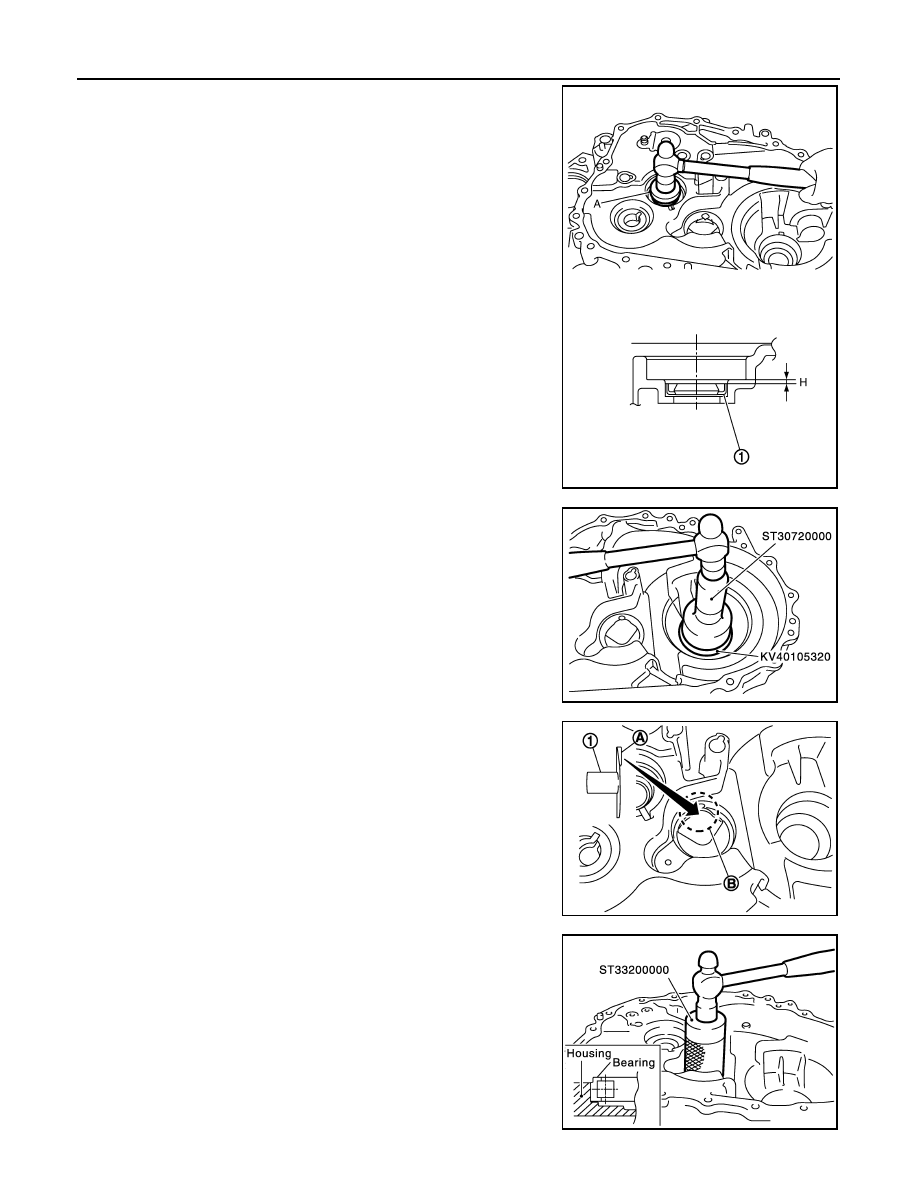

4.

Turn clutch housing upside down as shown in the figure. And

then install output gear assembly (1) into clutch housing.

CAUTION:

• Gently install it, aligning the clutch housing hole with the

center of output gear assembly.

• Install output gear assembly, straightening it with a mag-

net.

• Never damage clutch housing and output gear assembly.

5.

Install snap ring (1) onto clutch housing and make sure that end

play (gap between snap ring and groove) of output gear assem-

bly (2) satisfies the standard value.

CAUTION:

• Only one snap ring can be selected.

• Never reuse snap ring.

• Never damage clutch housing.

6.

Install differential side oil seal (1) to clutch housing using the drift

(A) [SST: ST33400001].

CAUTION:

• Never reuse differential side oil seal.

• When installing, never incline differential side oil seal.

• Never damage clutch housing.

JPDIC0074ZZ

End play standard val-

ue “L”

: Refer to

JPDIC0043ZZ

Dimension “H”

: -0.5 - 0.5 mm (-0.020 - 0.020 in)

JPDIC0077ZZ

TM-138

< DISASSEMBLY AND ASSEMBLY >

[6MT: RS6F52A]

TRANSAXLE ASSEMBLY

7.

Install input shaft oil seal (1) to clutch housing using the drift (A)

[SST: ST35321000].

CAUTION:

• Never reuse input shaft oil seal.

• When installing, never incline input shaft oil seal.

• Never damage clutch housing.

8.

Install differential side bearing outer race (clutch housing side) to

clutch housing using the drifts.

CAUTION:

Replace differential side bearing and differential side bear-

ing outer race as a set.

9.

Install oil channel (1) on mainshaft side.

CAUTION:

When installing oil channel, fit the rib (A) of oil channel into

the processed area of the spot facing (B).

10. Install mainshaft front bearing to clutch housing using the drift.

CAUTION:

Be careful with the orientation of mainshaft front bearing.

Dimension “H”

: 1.1 - 2.1 mm (0.043 - 0.083 in)

PCIB1814E

SCIA0987E

PCIB1921E

SCIA0401E

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст