Nissan Qashqai (2007-2010). Manual — part 641

DIFFERENTIAL ASSEMBLY

DLN-137

< DISASSEMBLY AND ASSEMBLY >

[REAR FINAL DRIVE: R145]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

8.

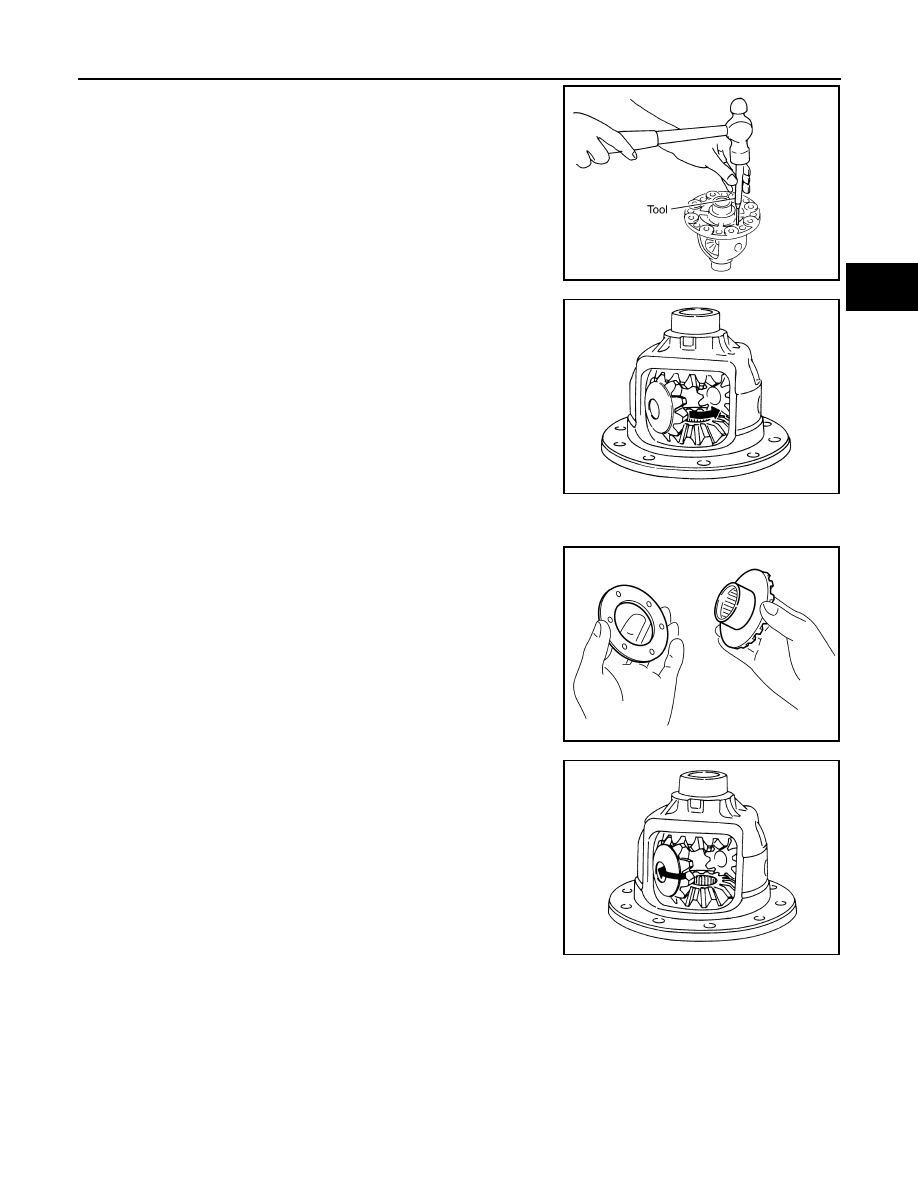

Pull the lock pin out of pinion mate shaft, using the pin punch

(commercial service tool).

9.

Remove pinion mate shaft, pinion mate gears, pinion mate

thrust washers, side gears, side gear thrust washers from differ-

ential case.

Assembly

INFOID:0000000000972186

1.

Install side gear thrust washers with the same thickness as the

ones installed prior to disassembly or reinstall the old ones on

the side gears.

2.

Install side gears and side gear thrust washers into differential

case.

3.

Align 2 pinion mate gears in diagonally opposite positions, then

rotate and install them into differential case after installing pinion

mate thrust washer to pinion mate gear.

PDIA0062E

SDIA0032J

SDIA0193J

SDIA0036J

DLN-138

< DISASSEMBLY AND ASSEMBLY >

[REAR FINAL DRIVE: R145]

DIFFERENTIAL ASSEMBLY

4.

Align the lock pin holes on differential case with shaft, and install

pinion mate shaft.

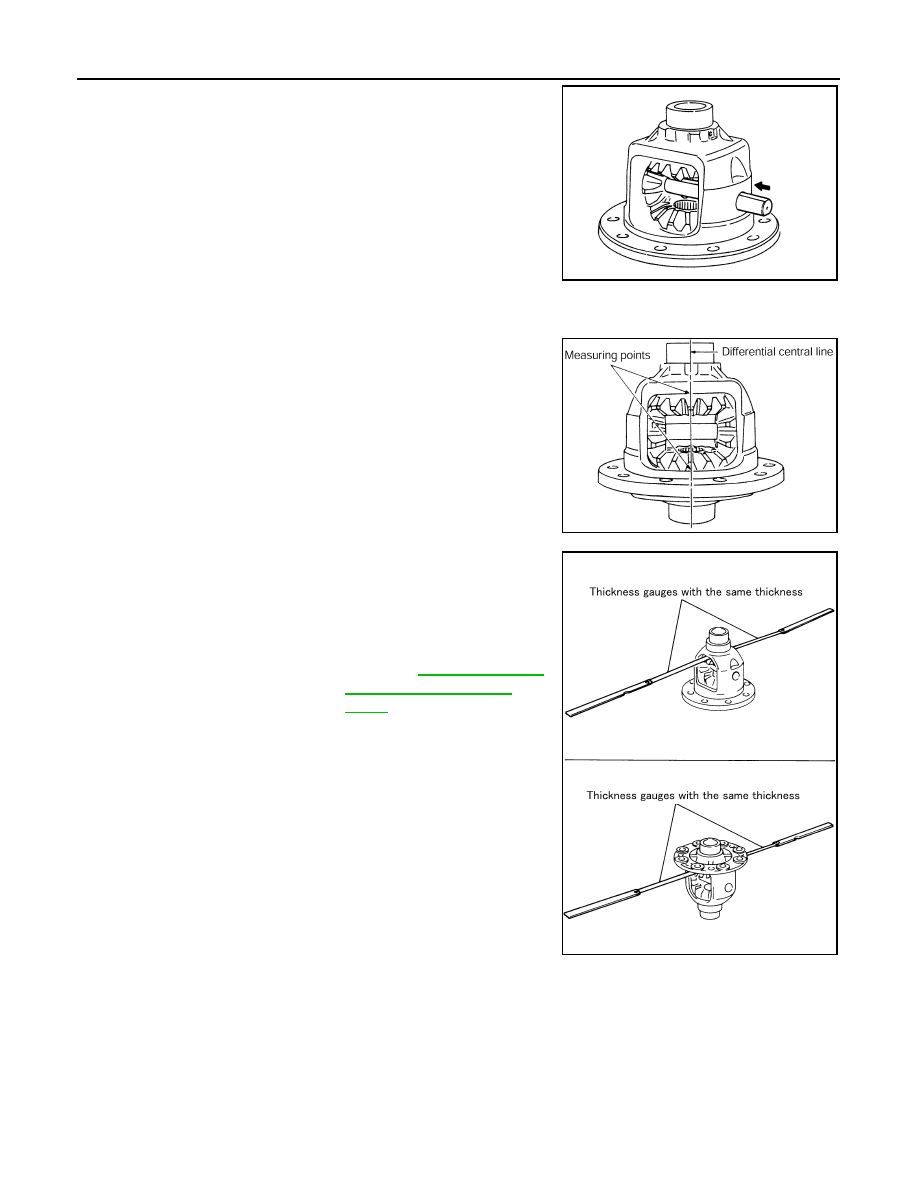

5.

Measure side gear end play following the procedure below, and select the appropriate side gear thrust

washers.

a.

Place differential case straight up so that side gear to be mea-

sured comes upward.

b.

Using thickness gauges, measure the clearance between side

gear back and differential case at 3 different positions, while

rotating side gear. Average the 3 readings, and then measure

the clearance. (Measure the clearance of the other side as well.)

CAUTION:

To prevent side gear from tilting, insert thickness gauges

with the same thickness from both sides.

c.

If the back clearance is outside the specification, use a thicker/

thinner side gear thrust washer to adjust.

CAUTION:

Select a side gear thrust washer for right and left individu-

ally.

SDIA0037J

PDIA0460E

Standard

Side gear back clearance

: Refer to

When the back clearance is large:

Use a thicker thrust washer.

When the back clearance is small:

Use a thinner thrust washer.

SDIA0583E

DIFFERENTIAL ASSEMBLY

DLN-139

< DISASSEMBLY AND ASSEMBLY >

[REAR FINAL DRIVE: R145]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

6.

Drive a lock pin into pinion mate shaft, using the pin punch

(commercial service tool).

CAUTION:

Never reuse lock pin.

7.

Press side bearing inner races to differential case, using the drift

(commercial service tool).

CAUTION:

Never reuse side bearing inner races.

8.

Apply locking sealant into the thread hole of drive gear.

CAUTION:

The drive gear back and threaded holes shall be cleaned

and decreased sufficiently.

9.

Install drive gear to the differential case, and apply anti-corrosive

oil onto threads and seats on the mounting bolts, and then

tighten to the specified torque.

10. Apply gear oil to side bearings, and install new side bearing

adjusting shims (2 pieces for one side) with the same thickness

as the ones installed prior to disassembly or re-install the old

ones, with side bearing outer race to differential case.

If side bearing adjusting shims have been already selected, use

them.

CAUTION:

Never reuse side bearing outer race.

11. Set the drifts (commercial service tool) to the right and left side

bearing adjusting shims individually. Compress differential case

assembly and side bearing to install gear carrier assembly to dif-

ferential case assembly.

CAUTION:

• The drift shall be placed on the center of the adjusting

shims.

• The pressure shall be as low as possible to install differ-

ential assembly into gear carrier assembly. The maximum

pressure shall be 10 kN (1 ton, 1.0 Imp ton).

• If the adjusting shims are installed by tapping, the gear

carrier may be damaged. Avoid tapping.

PDIA0062E

PDIA0052E

SPD554

PDIA0466E

PDIA0064E

DLN-140

< DISASSEMBLY AND ASSEMBLY >

[REAR FINAL DRIVE: R145]

DIFFERENTIAL ASSEMBLY

12. Install dummy cover set, check and adjust drive gear runout, tooth contact, backlash, and total preload

13. Remove dummy cover set.

14. Apply liquid gasket to mating surface of rear cover. Overlap both

ends of the bead for at least 3 mm (0.12 in).

CAUTION:

Remove old gasket adhering to the mounting surfaces.

Also remove any moisture, oil, or foreign material adhering

to the mounting surfaces.

15. Set the drifts (commercial service tool) to the right and left side

bearing adjusting shims individually. Compress differential case

assembly and side bearing to install rear cover.

CAUTION:

• The drift shall be placed on the center of the adjusting

shims.

• The pressure shall be as low as possible to install the rear

cover. The maximum pressure shall be 10 kN (1 ton, 1.0

Imp ton).

• If rear cover is forced in by tapping, rear cover may be

damaged by adjusting shims. Avoid tapping.

16. Tighten rear cover mounting bolts to the specified torque.

17. Using the drift (SST: KV38100200), drive side oil seals until it

becomes flush with the carrier end.

CAUTION:

• Never reuse oil seals.

• When installing, do not incline oil seals.

• Apply multi-purpose grease onto oil seal lips, and gear oil

onto the circumference of oil seal.

18. Check total preload torque. Refer to

.

Inspection After Disassembly

INFOID:0000000001078623

Clean up the disassembled parts. Then, inspect if the parts are worn or damaged. If so, follow the measures

below.

PDIA0447E

PDIA0065E

PDIA0448E

Content

Conditions and Measures

Hypoid gear

• If the gear teeth do not mesh or line-up correctly, determine the cause and adjust or replace as nec-

essary.

• If the gears are worn, cracked, damaged, pitted or chipped (by friction) noticeably, replace with new

drive gear and drive pinion as a set.

Bearing

If any chipped (by friction), pitted, worn, rusted or scratched mark, or unusual noise from the bearing is

observed, replace as a bearing assembly (as a new set).

Side gear and Pinion mate

gear

• If any cracks or damage on the surface of the tooth is found, replace.

• If any worn or chipped mark on the contact sides of the thrust washer is found, replace.

Side gear thrust washer and

pinion mate thrust washer

If it is chipped (by friction), damaged, or unusually worn, replace.

Differential case

If any wear or crack on the contact sides of the differential case is found, replace.

Companion flange

If any chipped mark (about 0.1 mm, 0.004 in) or other damage on the contact sides of the lips of the com-

panion flange is found, replace.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст