Nissan Qashqai (2007-2010). Manual — part 642

DRIVE PINION

DLN-141

< DISASSEMBLY AND ASSEMBLY >

[REAR FINAL DRIVE: R145]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

DRIVE PINION

Exploded View

INFOID:0000000001077005

Disassembly

INFOID:0000000000972195

1.

Filler plug

2.

Gasket

3.

Drain plug

4.

Rear cover

5.

Side oil seal

6.

Side bearing adjusting shim

7.

Side bearing

8.

Drive gear

9.

Differential case

10. Pinion mate thrust washer

11.

Pinion mate gear

12. Pinion mate shaft

13. Lock pin

14. Side gear thrust washer

15. Side gear

16. Drive pinion

17. Pinion rear bearing

18. Drive pinion adjusting shim

19. Collapsible spacer

20. Gear carrier

21. Pinion front bearing

22. Drive pinion nut

23. Center oil seal

24. 4WD solenoid harness

25. Electric controlled coupling

26. Bearing shim

27. Coupling front bearing

28. Reamer bolt

29. Connector bracket

30. Coupling cover

31. Front oil seal

32. Companion flange

33. Companion flange lock nut

A: Oil seal lip

B: Screw hole

: Apply gear oil.

: Apply anti-corrosive oil.

: Apply Genuine Liquid Gasket, Three Bond TB1217 or equivalent.

: Apply Genuine Medium Strength Thread Locking Sealant, Three Bond TB1322B or equivalent.

Refer to

for symbols not described on the above.

JSDIA0234GB

DLN-142

< DISASSEMBLY AND ASSEMBLY >

[REAR FINAL DRIVE: R145]

DRIVE PINION

1.

Remove electric controlled coupling assembly. Refer to

2.

Remove differential case assembly. Refer to

3.

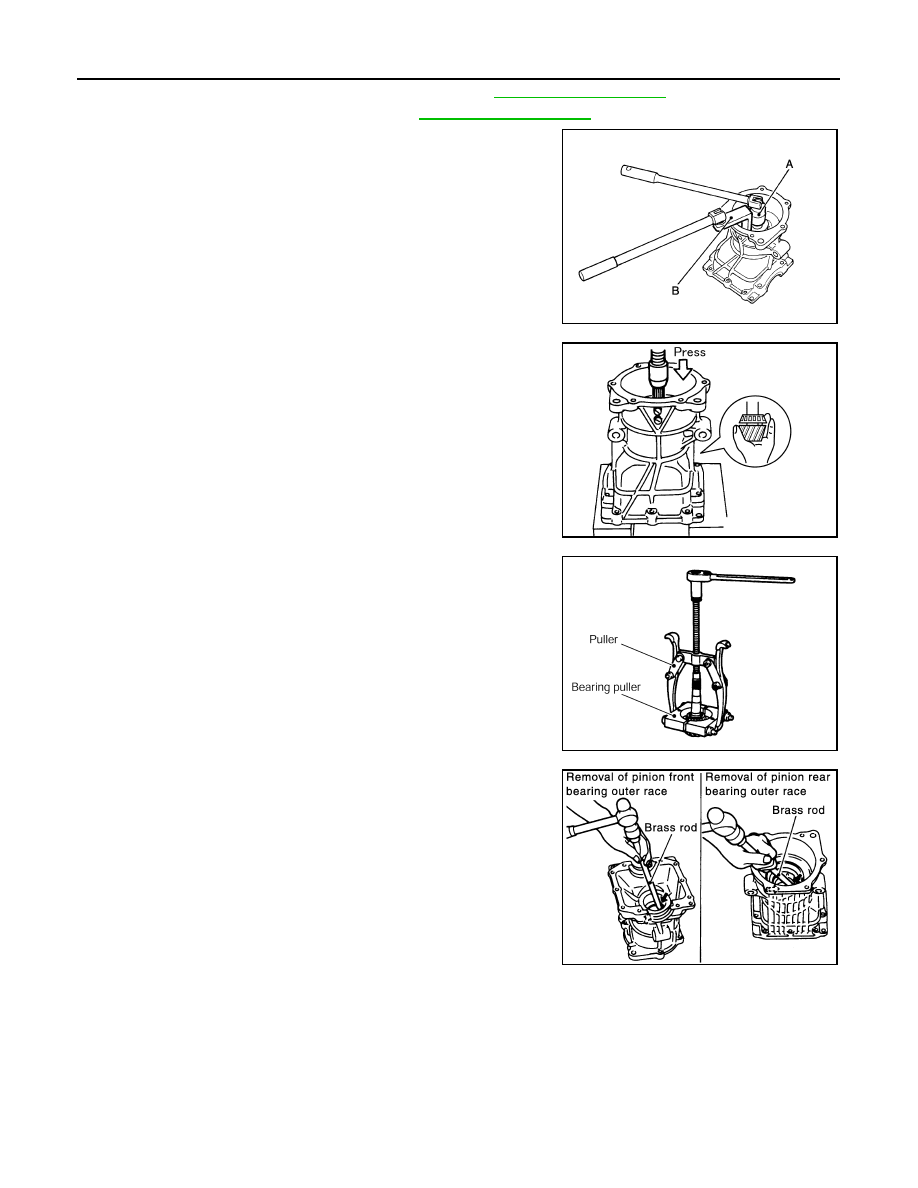

Fit drive pinion socket (A) (SST: KV38108500) onto drive pinion

spline. Remove drive pinion nut, using the pinion nut wrench (B)

(SST: KV38108400).

4.

Press drive pinion assembly out of gear carrier.

CAUTION:

Never drop drive pinion assembly.

5.

Remove pinion front bearing inner race.

6.

Remove collapsible spacer.

7.

Remove pinion rear bearing inner race from drive pinion, using

puller and bearing puller.

8.

Using a brass rod, tap pinion front bearing outer race evenly

from the 2 cutouts on gear carrier and remove pinion front bear-

ing outer race.

CAUTION:

Be careful not to damage gear carrier.

9.

Using a brass rod, tap drive pinion adjusting shim evenly from

the 2 cutouts on gear carrier and remove drive pinion adjusting

shim and pinion rear bearing outer race.

CAUTION:

Be careful not to damage the gear carrier.

Assembly

INFOID:0000000000972196

JSDIA0265ZZ

PDIA0445E

PDIA0179E

SDIA0564E

DRIVE PINION

DLN-143

< DISASSEMBLY AND ASSEMBLY >

[REAR FINAL DRIVE: R145]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

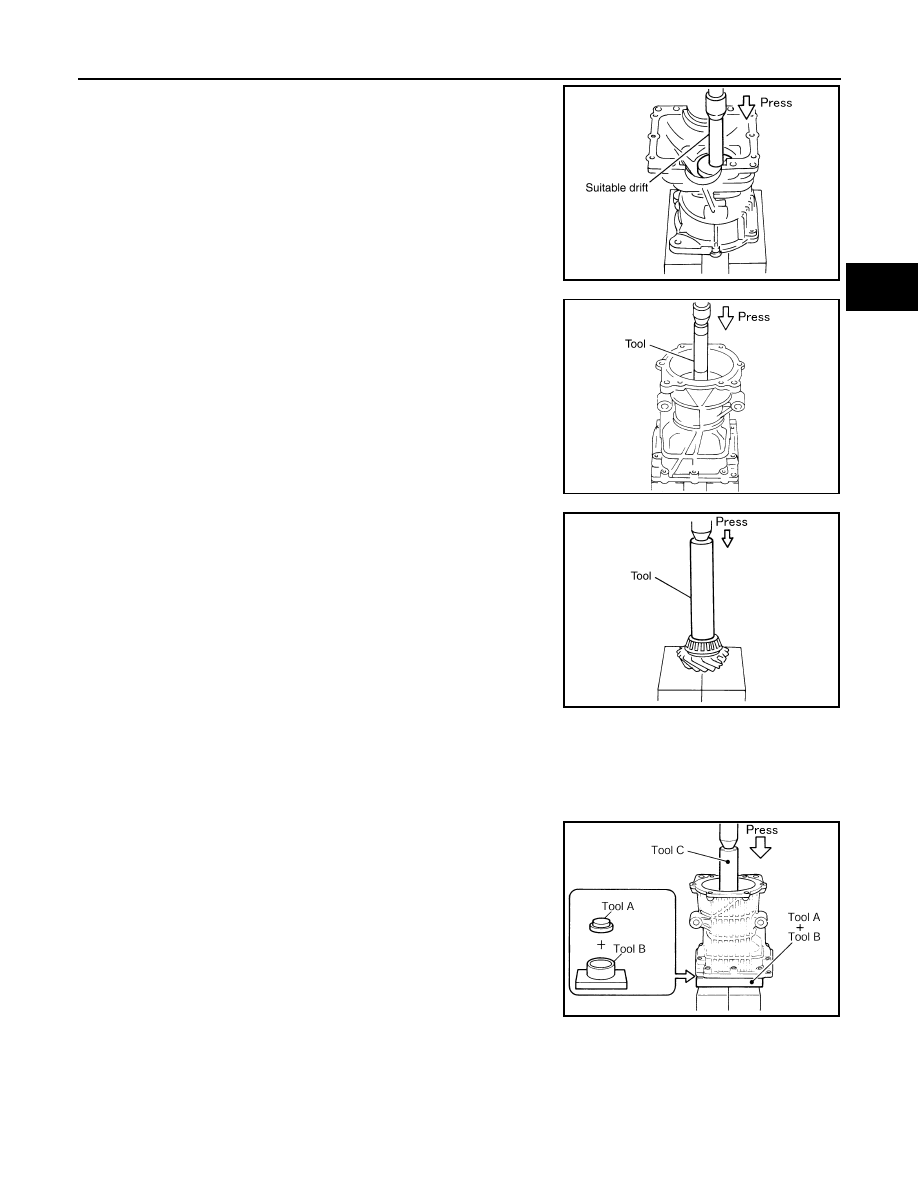

1.

Install a drive pinion adjusting shim of the same thickness as

was installed prior to disassembly. Press pinion rear bearing

outer race into gear carrier, using the suitable drift.

CAUTION:

• At first, using a hammer, tap bearing outer race until it

becomes flush to gear carrier.

• Never reuse pinion rear bearing outer race.

2.

Press pinion front bearing outer race into gear carrier, using the

drift (SST: 33230000).

CAUTION:

• At first, using a hammer, tap bearing outer race until it

becomes flush to gear carrier.

• Never reuse pinion front bearing outer race.

3.

Press pinion rear bearing inner race to drive pinion, using the

drift (SST: ST23860000).

CAUTION:

Never reuse pinion rear bearing inner race.

4.

After checking and adjusting the tooth contact and backlash of the hypoid gear following the procedure

below.

a.

Apply gear oil to the pinion rear bearing, and assemble the drive pinion to the gear carrier.

CAUTION:

Never assemble a collapsible spacer.

b.

Apply gear oil to pinion front bearing, and assemble pinion front

bearing inner race to drive pinion. Using the drifts and stand,

press pinion front bearing inner race to drive pinion as far as

drive pinion nut can be tightened.

CAUTION:

Never reuse pinion front bearing inner race.

c.

Temporarily tighten removed drive pinion nut to drive pinion.

NOTE:

Use removed drive pinion nut only for the preload measurement.

PDIA0898E

PDIA0067E

PDIA0068E

A

: Drift (commercial service tool)

B

: Stand (commercial service tool)

C

: Drift (SST: ST23860000)

PDIA0057E

DLN-144

< DISASSEMBLY AND ASSEMBLY >

[REAR FINAL DRIVE: R145]

DRIVE PINION

d.

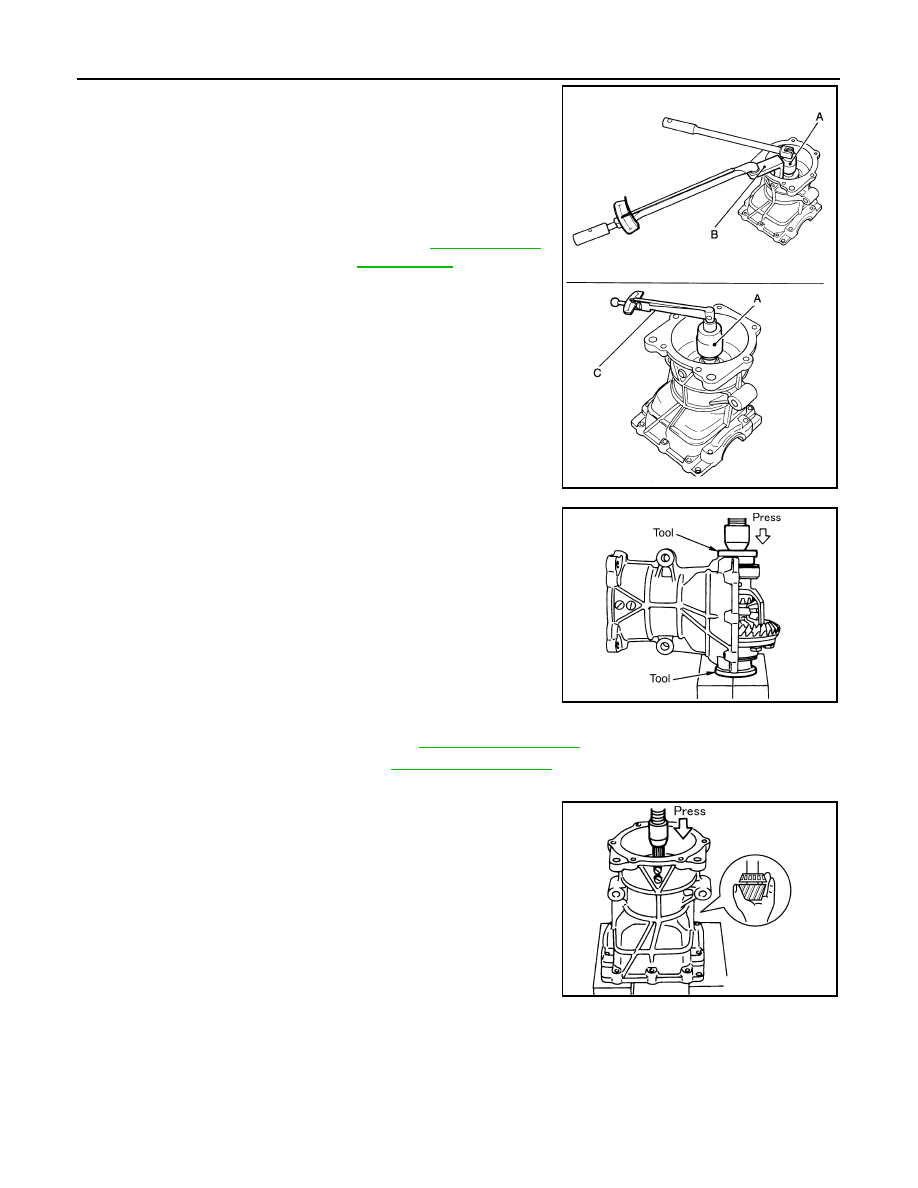

Fit the drive pinion socket (A) (SST: KV38108500) onto the drive

pinion spline. Using the pinion nut wrench (B) (SST:

KV38108400), tighten drive pinion nut to the specified preload

torque.

CAUTION:

Drive pinion nut is tightened with no collapsible spacer. Be

careful not to overtighten it. While measuring the preload,

tighten it by 5

°

to 10

°

.

e.

Apply gear oil to side bearings, and install new side bearing

adjusting shims with the same thickness or re-install the old

ones to the same mounting position they were in prior to disas-

sembly. Set the drifts (commercial service tool) to the right and

left. Install differential case assembly to gear carrier.

CAUTION:

• The drifts shall be placed on the center of the adjusting

shims.

• The pressure shall be as low as possible to install gear

carrier assembly to differential assembly. The maximum

pressure shall be 10 kN (1 ton, 1.0 Imp ton).

• If adjusting shims are installed by tapping, gear carrier

may be damaged. Avoid tapping.

f.

Check and adjust the tooth contact. Refer to

g.

Check and adjust the backlash. Refer to

h.

Remove dummy cover set, and remove differential case assembly.

i.

Remove drive pinion nut and press drive pinion assembly out of

gear carrier.

CAUTION:

Never drop drive pinion assembly.

j.

Remove pinion front bearing inner race.

C

: Preload gauge (SST: ST3127S000)

Standard

Pinion bearing preload

: Refer to

.

JSDIA0266ZZ

PDIA0064E

PDIA0445E

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст