Nissan Qashqai (2007-2010). Manual — part 451

P0045 TC BOOST CONTROL SOLENOID VALVE

EC-1323

< COMPONENT DIAGNOSIS >

[K9K]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

P0045 TC BOOST CONTROL SOLENOID VALVE

DTC Logic

INFOID:0000000001115054

DTC DETECTION LOGIC

NOTE:

• If the DTC is present:

- Malfunction indicator (Red) lights up.

Diagnosis Procedure

INFOID:0000000001088004

1.

CHECK TURBOCHARGER BOOST CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT

1.

Turn ignition switch OFF.

2.

Disconnect turbocharger boost control solenoid valve harness connector.

3.

Turn ignition switch ON.

4.

Check the voltage between turbocharger boost control solenoid valve harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> GO TO 2.

2.

DETECT MALFUNCTIONING PART

Check the following.

• Harness for open or short between IPDM E/R and turbocharger boost control solenoid valve

• Harness for open or short between ECM and turbocharger boost control solenoid valve

>> Repair open circuit or short to ground or short to power in harness or connectors.

3.

CHECK TURBOCHARGER BOOST CONTROL SOLENOID VALVE OUTPUT SIGNAL CIRCUIT FOR

OPEN AND SHORT

1.

Turn ignition switch OFF.

2.

Disconnect ECM harness connector.

3.

Check the continuity between turbocharger boost control solenoid valve harness connector and ECM har-

ness connector.

4.

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> GO TO 4.

4.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connector E7, F121

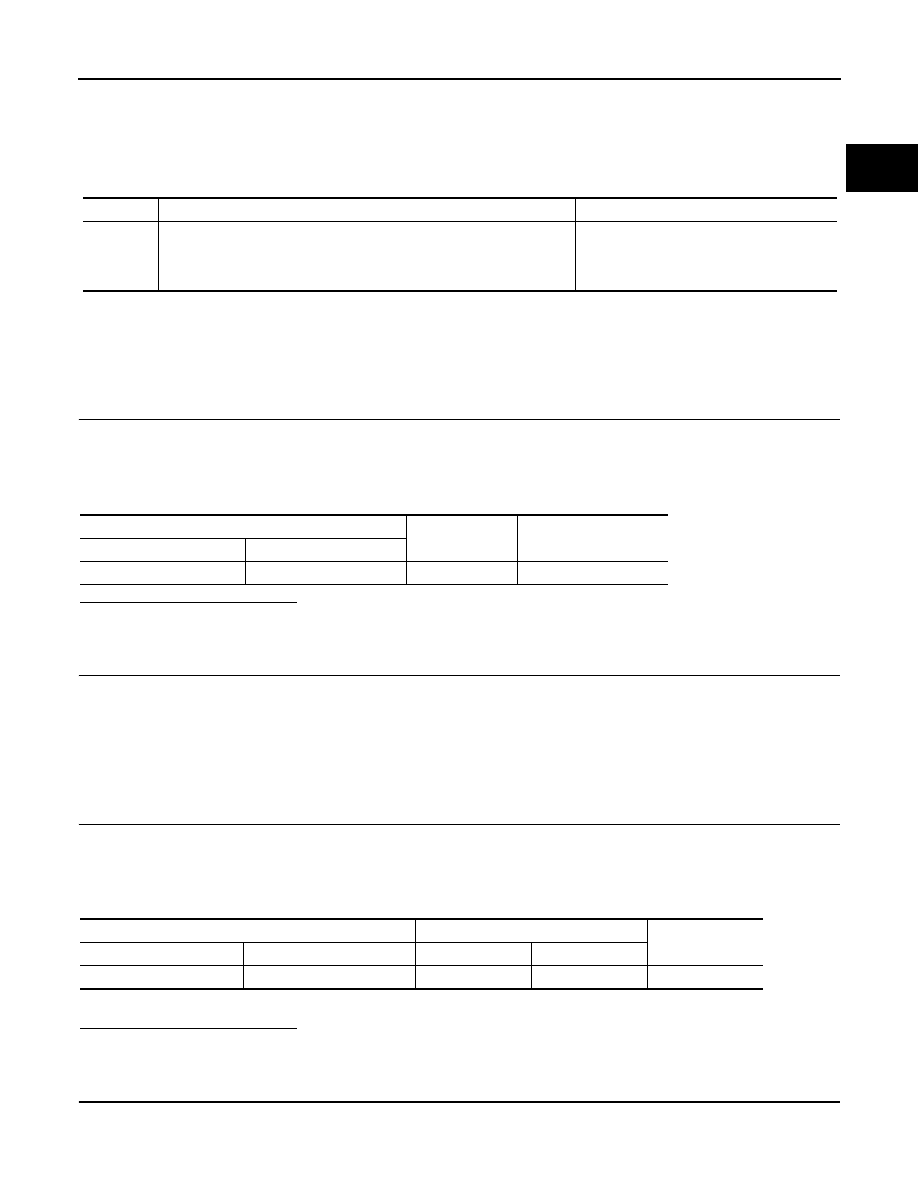

DTC No.

Trouble diagnosis name

Possible cause

P0045

TURBOCHARGER BOOST CONTROL SOLENOID VALVE CIRCUIT

• CO: Open circuit

• CO.0: Open circuit or short circuit to ground

• CC.1: Short circuit to +12V

• Harness or connectors

(The solenoid valve circuit is open or short-

ed.)

• Turbocharger boost control solenoid valve

Turbocharger boost control solenoid valve

Ground

Voltage

Connector

Terminal

E55

2

Ground

Battery voltage

Turbocharger boost control solenoid valve

ECM

Continuity

Connector

Terminal

Connector

Terminal

E55

1

F68

52

Existed

EC-1324

< COMPONENT DIAGNOSIS >

[K9K]

P0045 TC BOOST CONTROL SOLENOID VALVE

• Harness for open or short between ECM and turbocharger boost control solenoid valve

>> Repair open circuit or short to ground or short to power in harness or connectors.

5.

CHECK TURBOCHARGER BOOST CONTROL SOLENOID VALVE

EC-1328, "Component Inspection"

.

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> Replace turbocharger boost control solenoid valve.

6.

CHECK INTERMITTENT INCIDENT

GI-39, "Intermittent Incident"

>> INSPECTION END

Component Inspection

INFOID:0000000001088005

1.

CHECK TURBOCHARGER BOOST CONTROL SOLENOID VALVE

1.

Turn ignition switch OFF.

2.

Disconnect turbocharger boost control solenoid valve harness connector.

3.

Check resistance between turbocharger boost control solenoid valve terminals as follows.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace high pressure supply pump.

Terminals

Resistance

1 and 2

18.9 - 23.1

Ω

[at 23

°

C (73

°

F)]

P0069 TC BOOST SENSOR, BARO SENSOR CORRELATION

EC-1325

< COMPONENT DIAGNOSIS >

[K9K]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

P0069 TC BOOST SENSOR, BARO SENSOR CORRELATION

DTC Logic

INFOID:0000000001115055

DTC DETECTION LOGIC

NOTE:

• Conditions for applying the diagnostic procedure to the stored DTCs:

The DTC becomes present after the engine is started.

• If the DTC is present:

- Malfunction indicator (Red) lights up.

Diagnosis Procedure

INFOID:0000000000953026

1.

CHECK GROUND CONNECTIONS

1.

Turn ignition switch OFF.

2.

Check ground connection E17. Refer to Ground inspection in

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace ground connection.

2.

CHECK TUBOCHARGER BOOST SENSOR SUPPLY CIRCUIT

1.

Disconnect turbocharger boost sensor harness connector.

2.

Turn ignition switch ON.

3.

Check the voltage between turbocharger boost sensor connector and ground.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

3.

CHECK TUBOCHARGER BOOST SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1.

Check the continuity between turbocharger boost sensor harness connector and ECM harness connector.

2.

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

4.

CHECK TUBOCHARGER BOOST SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1.

Check the continuity between turbocharger boost sensor harness connector and ECM harness connector.

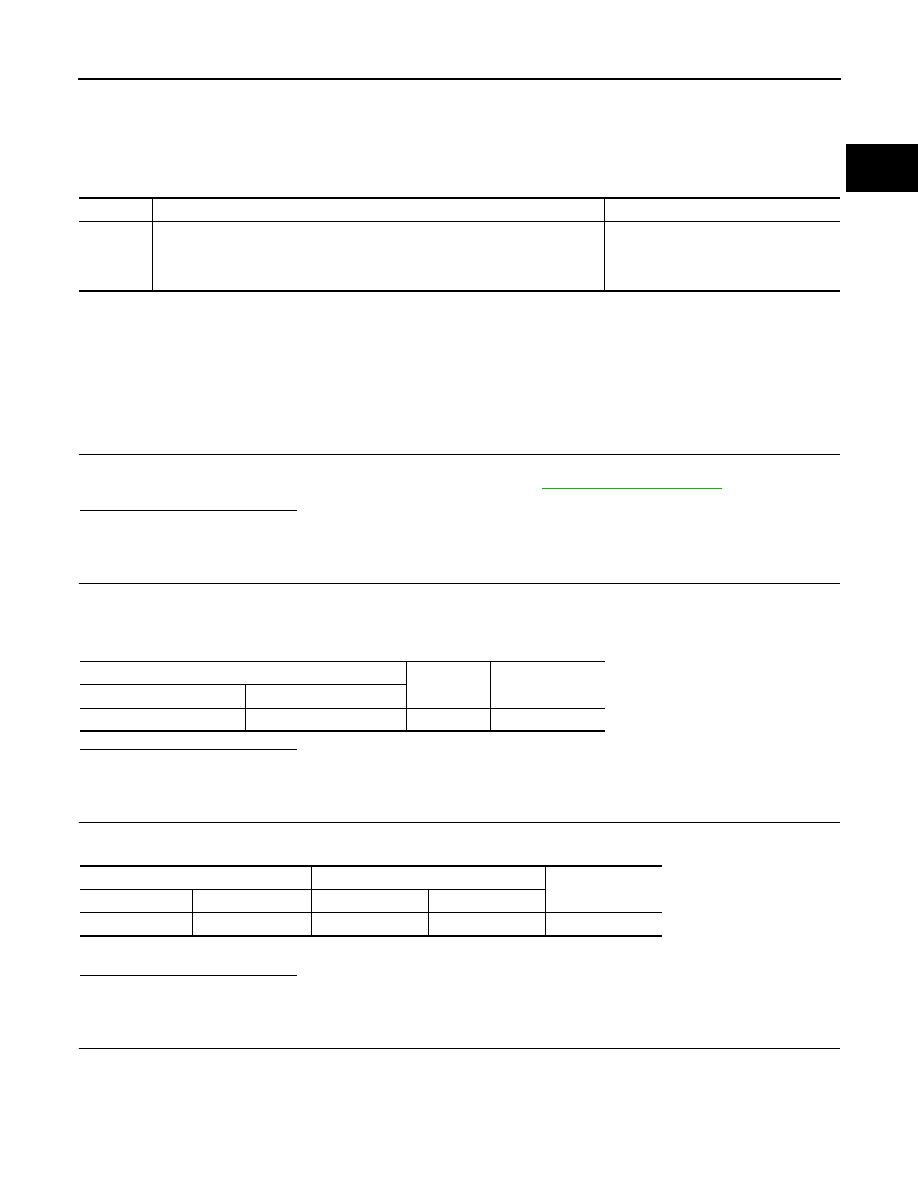

DTC No.

Trouble diagnosis name

Possible cause

P0069

TURBOCHARGER BOOST SENSOR - BAROMETRIC PRESSURE SENSOR

CORRELATION

• 1.DEF: Signal outside lower level

• 2.DED: Signal outside upper level

• Harness or connectors

(Turbocharger boost sensor)

• Turbocharger boost sensor

• Barometric pressure sensor

Turbocharger boost sensor

Ground

Voltage

Connector

Terminal

F91

1

Ground

Approx. 5V

Turbocharger boost sensor

ECM

Continuity

Connector

Terminal

Connector

Terminal

F91

2

F85

43

Existed

EC-1326

< COMPONENT DIAGNOSIS >

[K9K]

P0069 TC BOOST SENSOR, BARO SENSOR CORRELATION

2.

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

5.

CHECK TUBOCHARGER BOOST SENSOR

EC-1364, "Component Inspection"

.

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> Replace turbocharger boost sensor.

6.

REPLACE ECM

1.

Perform

EC-1273, "ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Special Repair

.

2.

Perform EGR volume control valve closed position learning. Refer to

TROL VALVE CLOSED POSITION LEARNING : Special Repair Requirement"

>> INSPECTION END

Component Inspection

INFOID:0000000001088007

1.

CHECK TURBOCHARGER BOOST SENSOR-I

1.

Turn ignition switch OFF.

2.

Remove turbocharger boost sensor with its harness connected.

3.

Turn ignition switch ON.

4.

Select “DATA MONITOR” mode with CONSULT-III.

5.

Check “BOOST_PRESS” and “ATOMOS_PRESS” indication.

If the value is not very close to “ATOMOS_PRESS”, maximum pressure difference between

“ATOMOS_PRESS” and “BOOST_PRESS” with the ignition switch ON (engine stop) =

±

50 mbar?

YES

>> GO TO 2.

NO

>> Replace turbocharger boost sensor.

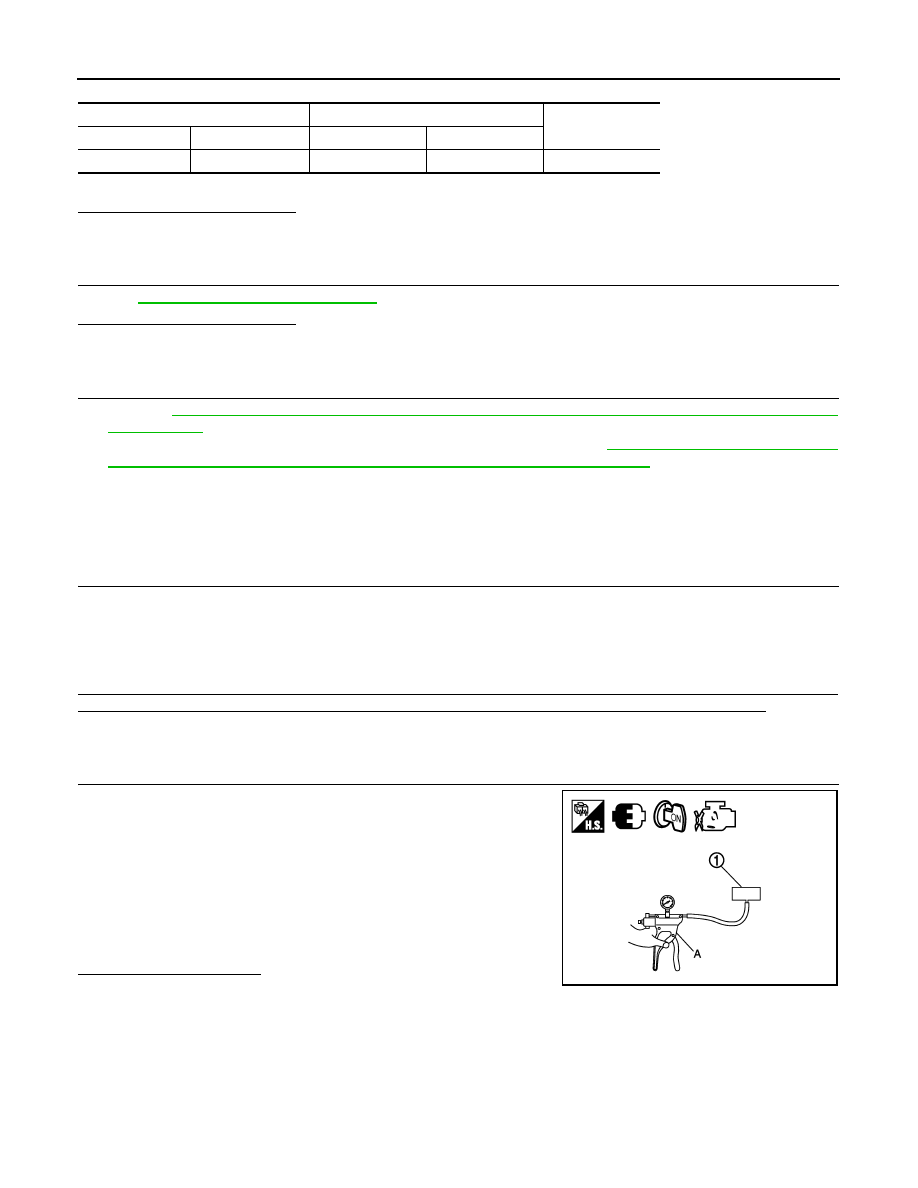

2.

CHECK TURBOCHARGER BOOST SENSOR-II

1.

Use pump to apply turbocharger boost sensor as shown in the

figure.

2.

Apply a pressure of between 10kPa(0.100 bar, 0.102 kg/cm

2

,

1.5 psi) - 13kPa(0.130 bar, 0.133 kg/cm

2

, 1.9 psi) [maximum

pressure to be applied: 13kPa(0.130 bar, 0.133 kg/cm

2

, 1.9

psi)].

3.

Select “DATA MONITOR” mode with CONSULT-III.

4.

Check “BOOST_PRESS” indication with that given by the vac-

uum pump.

If there is no discrepancy?

YES

>> INSPECTION END

NO

>> Replace turbocharger boost sensor.

Turbocharger boost sensor

ECM

Continuity

Connector

Terminal

Connector

Terminal

F91

3

F85

44

Existed

JMBIA0433ZZ

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст