Subaru Impreza 3 / Impreza WRX / Impreza WRX STI. Service manual — part 502

DI-53

Rear Differential (T-type)

DIFFERENTIALS

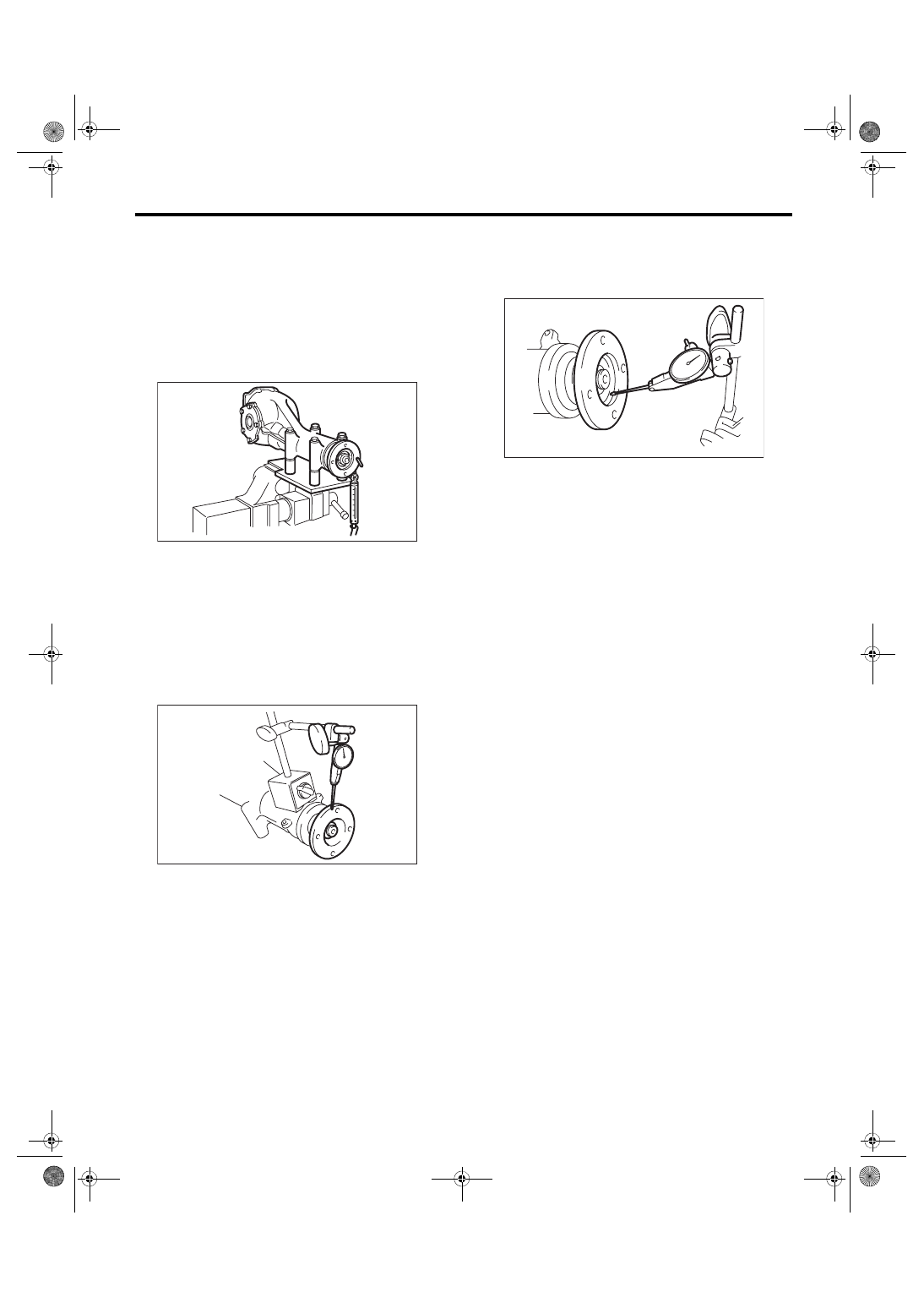

5. TOTAL PRELOAD

Using a spring scale, check the total preload.

Total preload:

T-type (B2):

20.7 — 54.4 N (2.1 — 5.5 kgf, 4.7 — 12.2 lbf)

T-type (H3):

26.5 — 53 N (2.7 — 5.4 kgf, 6.0 — 11.9 lbf)

If the total preload is not within the specification,

adjust the side retainer shim.

6. COMPANION FLANGE

1) If rust or dirt is attached to the companion flange,

remove them.

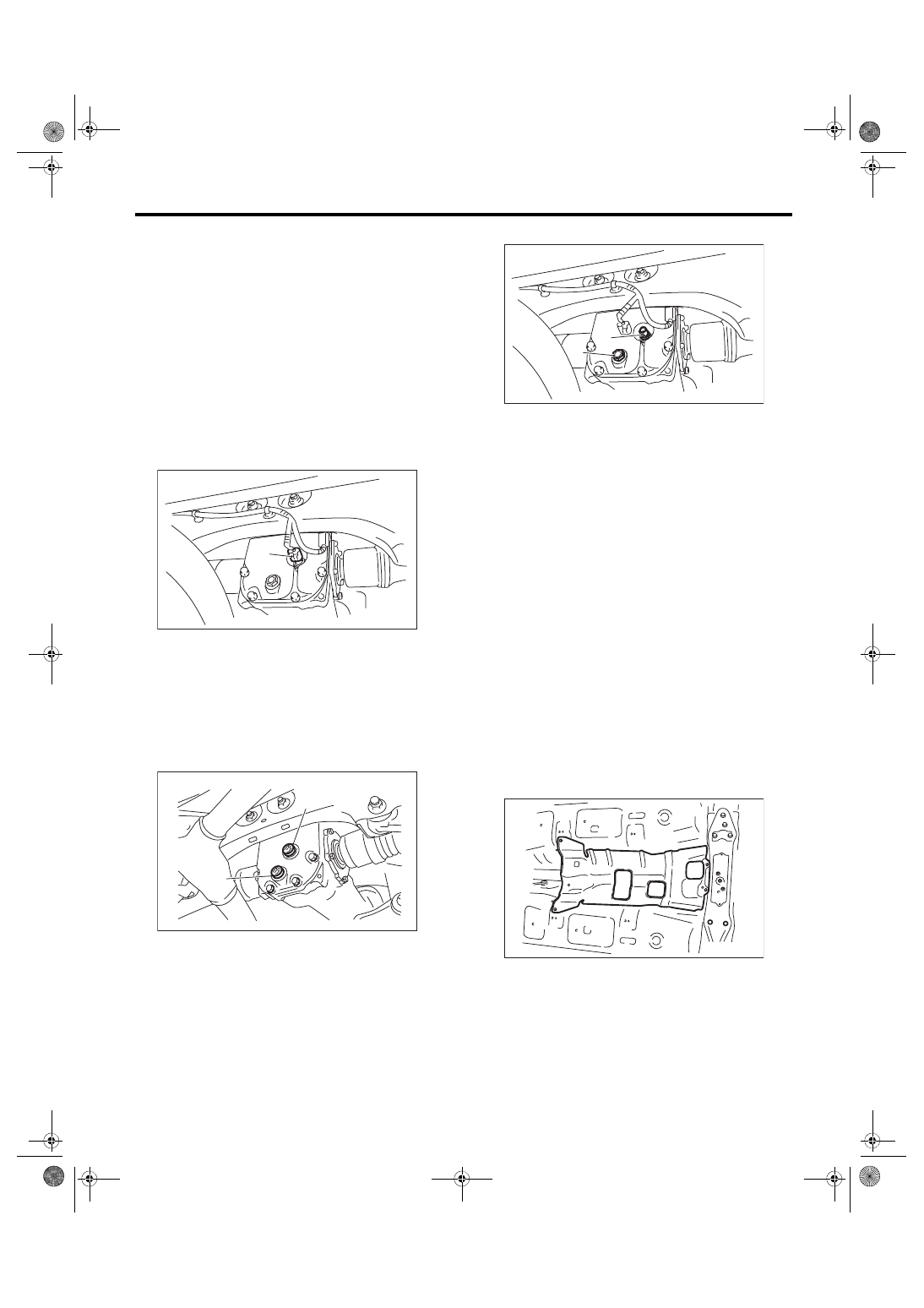

2) Set a dial gauge at a companion flange surface

(mating surface of propeller shaft and companion

flange), and then measure the companion flange

runout.

Limit of runout:

0.08 mm (0.003 in)

3) Set the gauge inside of the companion flange,

and measure the runout.

Limit of runout:

0.08 mm (0.003 in)

4) If either runout exceeds the limit, move the

phase of companion flange and drive pinion 90°

each, and find the point where the runout is within

the limit.

5) If the runout exceeds the limit after changing the

phase, replace the companion flange and recheck

the runout.

6) If the runout exceeds the limit after replacing the

companion flange, the drive pinion may be assem-

bled incorrectly or bearing is faulty.

F: ADJUSTMENT

1. SIDE GEAR BACKLASH (T-TYPE (B2))

Adjust the side gear backlash. <Ref. to DI-31, AS-

SEMBLY, Rear Differential (T-type).>

2. HYPOID DRIVEN GEAR BACKLASH

Adjust hypoid driven gear backlash. <Ref. to DI-31,

ASSEMBLY, Rear Differential (T-type).>

3. TOOTH CONTACT BETWEEN HYPOID

DRIVEN GEAR AND DRIVE PINION

Adjust the tooth contact between hypoid driven

gear and drive pinion gear. <Ref. to DI-31, ASSEM-

BLY, Rear Differential (T-type).>

4. TOTAL PRELOAD

Adjust the side retainer shim. <Ref. to DI-31, AS-

SEMBLY, Rear Differential (T-type).>

DI-00117

DI-00360

DI-00361

DI-54

Rear Differential Front Oil Seal

DIFFERENTIALS

5. Rear Differential Front Oil

Seal

A: INSPECTION

Check that there is no leakage from front oil seal

portion. If there is any leakage replace the oil seal

and inspect the propeller shaft.

B: REPLACEMENT

1) Disconnect the ground cable from battery.

2) Shift the select lever or gear shift lever to neutral.

3) Release the parking brake.

4) Lift up the vehicle.

5) Disconnect the oil temperature switch connec-

tor. (T-type (H3))

6) Remove the drain plug and filler plug or the oil

temperature switch, and drain the gear oil.

NOTE:

Remove the oil temperature switch and adapter as

a unit.

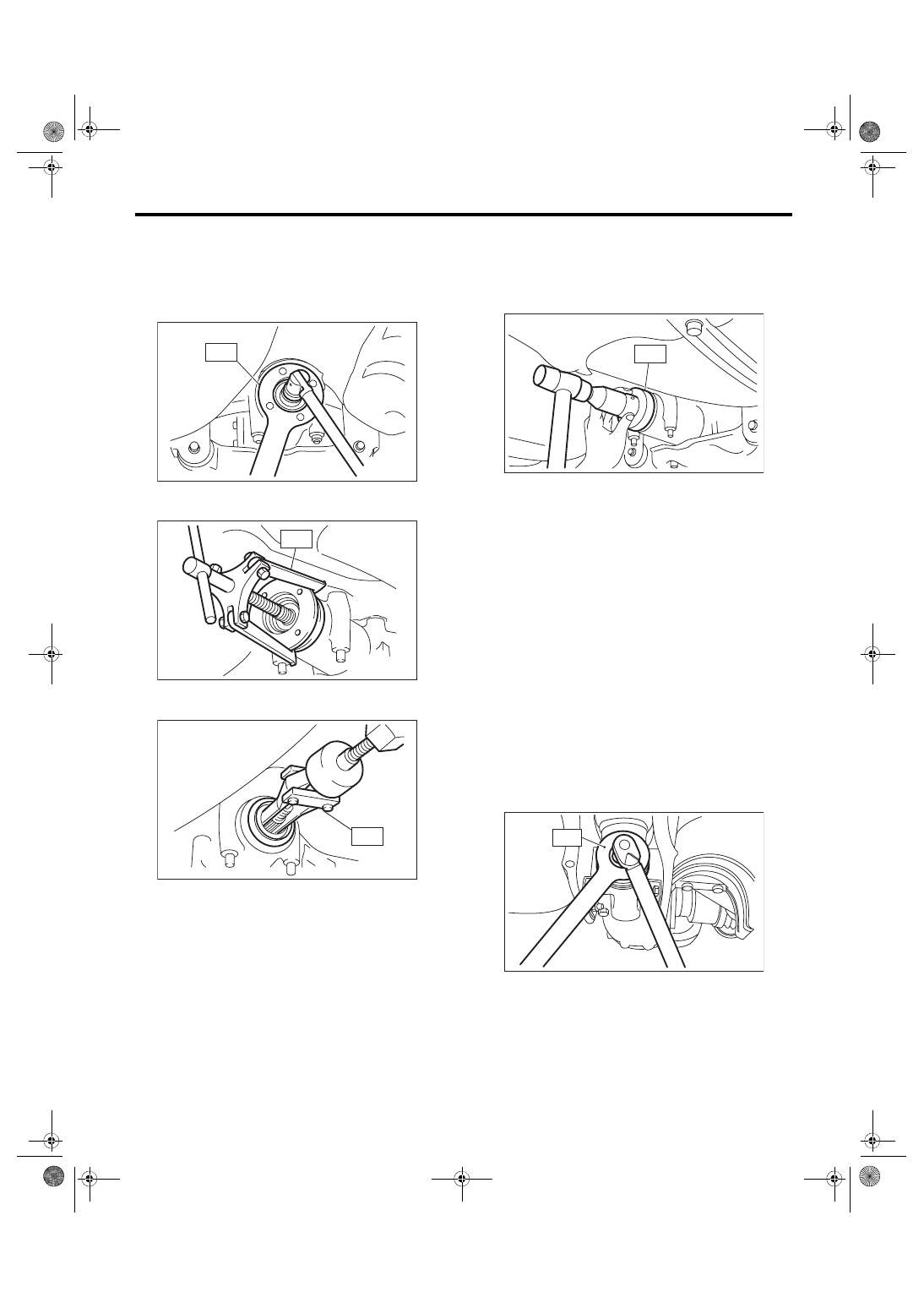

• T-type (B2)

• T-type (H3)

7) Install the drain plug.

NOTE:

• For the T-type (B2), apply liquid gasket to the

drain plug.

• For T-type (H3), use a new gasket.

Liquid gasket:

THREE BOND 1105 (Part No. 004403010) or

equivalent

Tightening torque:

T-type (B2);

49 N·m (5.0 kgf-m, 36.1 ft-lb)

T-type (H3);

60 N·m (6.1 kgf-m, 44.3 ft-lb)

8) Remove the rear exhaust pipe and muffler.

• 6MT model

<Ref. to EX(STI)-13, REMOVAL, Rear Exhaust

Pipe.> <Ref. to EX(STI)-15, REMOVAL, Muffler.>

• 5MT model

<Ref. to EX(w/o STI)-2, General Description.>

9) Remove the heat shield cover.

10) Remove the propeller shaft. <Ref. to DS-11,

11) Check the initial torque and write it down.

(A) Oil temperature switch connector

(A) Filler plug

(B) Drain plug

DI-00749

(A)

DI-00522

(A)

(B)

(A) Oil temperature switch

(B) Drain plug

DI-00593

(A)

(B)

AT-04522

DI-55

Rear Differential Front Oil Seal

DIFFERENTIALS

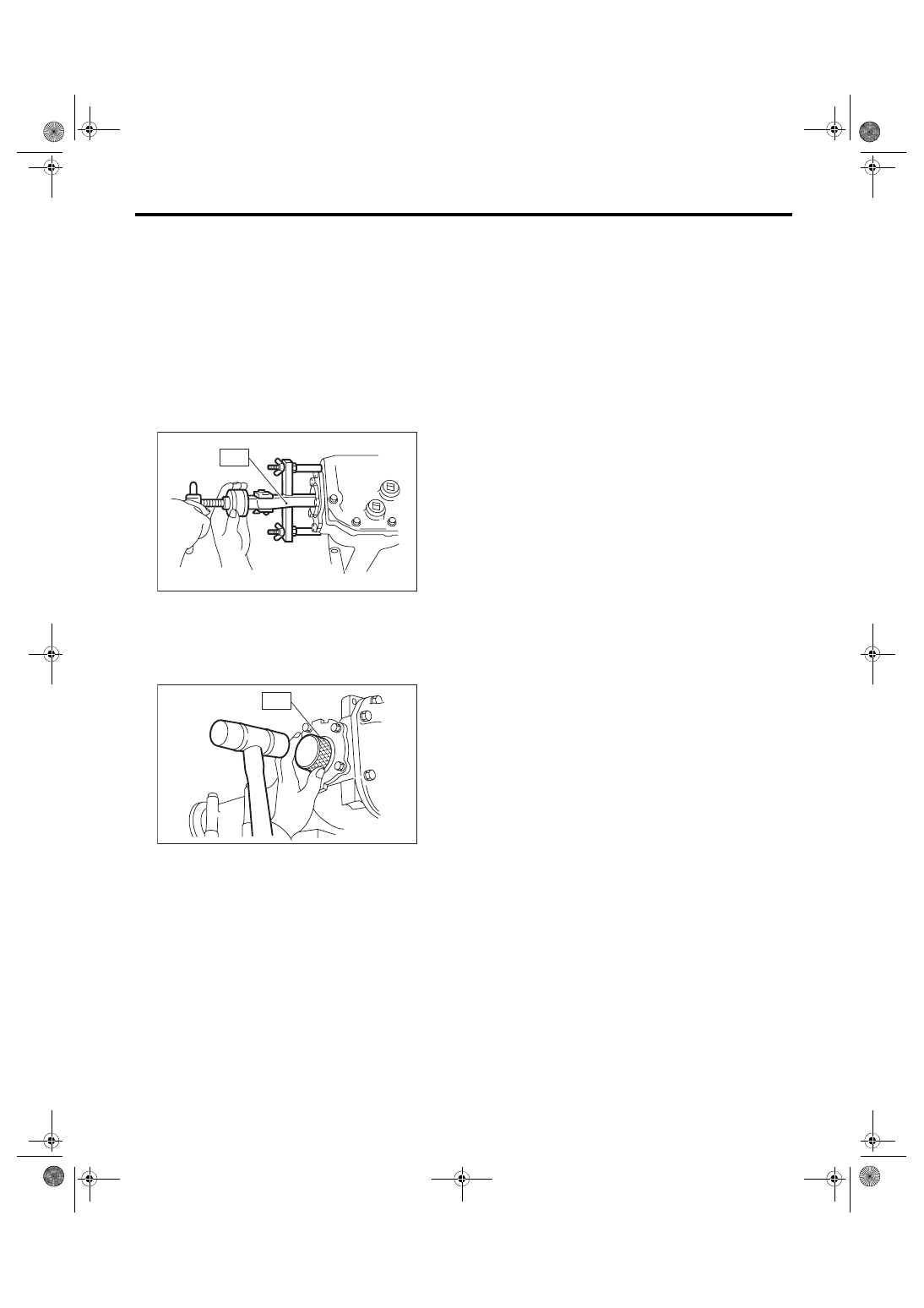

12) Remove the self-locking nut while holding the

companion flange with ST.

ST 18633AA000 WRENCH COMPL (T-TYPE

(H3))

ST 498427200

FLANGE WRENCH (T-TYPE

(B2))

13) Remove the companion flange using ST.

ST 399703600

PULLER ASSY

14) Remove the oil seal using ST or screwdriver.

ST 398527700

PULLER ASSY

15) Using the ST, install the oil seal.

NOTE:

• Use a new oil seal.

• Apply differential gear oil to the oil seal lips.

ST 498447120

INSTALLER

16) Use a plastic hammer to install companion

flange.

17) Tighten the self-locking nut to the specified

torque so that the rotating resistance of the com-

panion flange is the same value as that before re-

placing the oil seal.

NOTE:

• Use a new self-locking nut.

• Before installing the self-locking nut, apply seal

material to self-locking nut threads.

Seal material:

THREE BOND 1324 (Part No. 004403042) or

equivalent

Tightening torque:

167 — 196 N·m (17.0 — 20.0 kgf-m, 123.2 —

144.6 ft-lb)

ST 18633AA000 WRENCH COMPL (T-TYPE

(H3))

ST 498427200

FLANGE WRENCH (T-TYPE

(B2))

18) Hereafter, reassemble in the reverse order of

disassembly.

19) After installing, fill the differential carrier with

gear oil up to the bottom of the filler plug hole or the

oil temperature switch hole. <Ref. to DI-19, RE-

PLACEMENT, Differential Gear Oil.>

DI-00194

ST

DI-00196

ST

DI-00197

ST

DI-00292

ST

ST

DI-00199

DI-56

Rear Differential Side Oil Seal

DIFFERENTIALS

6. Rear Differential Side Oil Seal

A: INSPECTION

Check that there is no oil leakage from the side oil

seal. If there is any leakage, replace the oil seal.

B: REPLACEMENT

1) Remove the rear differential. <Ref. to DI-22, RE-

MOVAL, Rear Differential (T-type).>

2) Remove the rear differential side oil seal using a

ST or screwdriver wrapped with vinyl tape to pre-

vent the side retainer from scratching.

ST 398527700

PULLER ASSY

3) Using the ST, install the side oil seal.

NOTE:

• Use a new oil seal.

• Apply differential gear oil to the oil seal lips.

ST 398437700

DRIFT

4) Install the rear differential. <Ref. to DI-24, IN-

STALLATION, Rear Differential (T-type).>

ST

DI-00208

DI-00209

ST

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст