Subaru Legacy (2005 year). Service manual — part 690

6MT-107

MANUAL TRANSMISSION AND DIFFERENTIAL

Front Differential Assembly

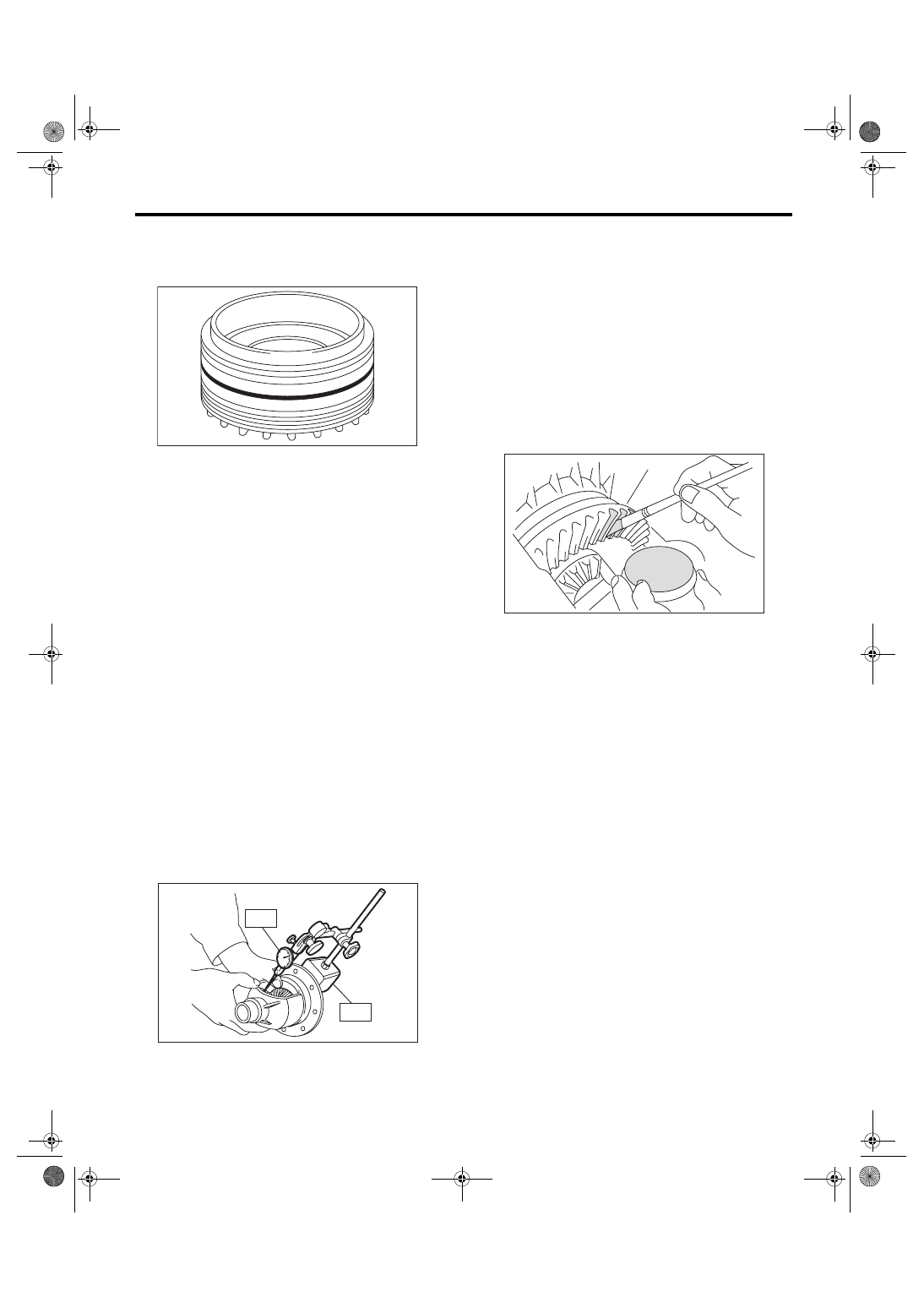

3) Install the O-ring.

NOTE:

Use a new O-ring.

E: INSPECTION

Repair or replace the front differential in following

cases.

• When each gear is damaged, seized, or exces-

sively worn.

• When sliding surfaces of the differential case is

damaged, seized or excessively worn.

• When bearings and bearings part is damaged,

rusted or worn.

• When bearing that fails to turn smoothly or

makes noise when turned.

1. BEVEL PINION GEAR BACKLASH

Measure the bevel pinion gear backlash. If it is not

within specification, install a suitable washer to ad-

just. <Ref. to 6MT-108, ADJUSTMENT, Front Dif-

ferential Assembly.>

NOTE:

• Be sure the pinion gear teeth contact adjacent

gear teeth during measurement.

• Before measuring the backlash, rotate each gear

to get each part accustomed.

ST1

498247001

MAGNET BASE

ST2

498247100

DIAL GAUGE

Standard backlash:

0.13 — 0.18 mm (0.0051 — 0.0071 in)

2. HYPOID GEAR BACKLASH

Check the hypoid gear backlash. If it is not within

specification, adjust it. <Ref. to 6MT-108, HYPOID

GEAR BACKLASH, ADJUSTMENT, Front Differ-

ential Assembly.>

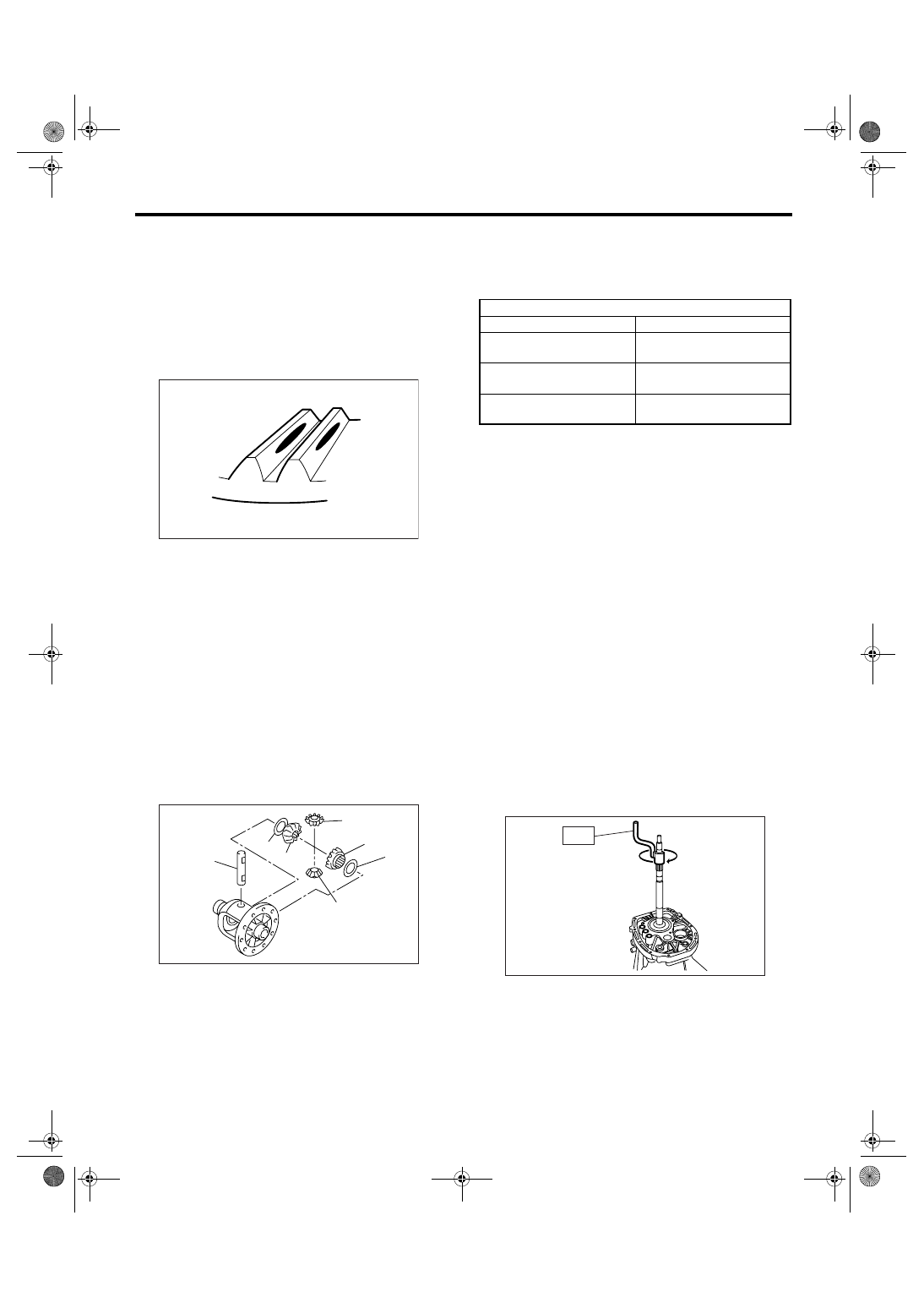

3. TOOTH CONTACT OF HYPOID GEAR

1) Be sure the hypoid gear backlash is within spec-

ification. If it is not within specification, adjust it.

<Ref. to 6MT-108, HYPOID GEAR BACKLASH,

ADJUSTMENT, Front Differential Assembly.>

2) Apply a uniform thin coat of red lead on both

tooth surfaces of three or four teeth of the hypoid

driven gear.

3) Install the drive pinion shaft assembly, and then

secure with four bolts.

NOTE:

Use the old gasket and washer to prevent the mat-

ing surface of housing from damaging.

Tightening torque:

50 N

⋅

m (5.1 kgf-m, 36.9 ft-lb)

4) Rotate the drive pinion shaft to right and left for

several times.

AT-00219

ST1

ST2

MT-00672

MT-00652

6MT-108

MANUAL TRANSMISSION AND DIFFERENTIAL

Front Differential Assembly

5) Remove the drive pinion shaft assembly, and

then check tooth contact. If tooth contact is inaccu-

rate, adjust it. <Ref. to 6MT-99, ADJUSTMENT,

Drive Pinion Shaft Assembly.>

• Correct tooth contact

NOTE:

Under no load, tooth contacts 50 — 60% from cen-

ter to toe side (tooth contact shifts to heel side

when driving).

F: ADJUSTMENT

1. BEVEL PINION GEAR BACKLASH

1) Measure the bevel pinion gear backlash. <Ref.

to 6MT-107, BEVEL PINION GEAR BACKLASH,

INSPECTION, Front Differential Assembly.>

2) Disassemble the differential case. <Ref. to 6MT-

104, DIFFERENTIAL CASE, DISASSEMBLY,

Front Differential Assembly.>

3) Select a washer from the following table, and

then assemble the differential case. <Ref. to 6MT-

106, DIFFERENTIAL CASE, ASSEMBLY, Front

Differential Assembly.>

NOTE:

If the backlash is excessive, select a thicker wash-

er. If the backlash is insufficient, select a thinner

new washer.

2. HYPOID GEAR BACKLASH

1) Install the side retainers of RH and LH side.

ST1

499787000

WRENCH ASSY (RH SIDE)

ST2

18630AA000 WRENCH ASSY (LH SIDE)

NOTE:

Screw in the side retainer of RH side a bit further

than LH side.

2) Install the drive pinion shaft assembly, and then

secure with four bolts.

NOTE:

Use the old gasket and washer to prevent the mat-

ing surface of housing from damaging.

Tightening torque:

50 N

⋅

m (5.1 kgf-m, 36.9 ft-lb)

3) Using the ST, screw in the side retainer LH until

the drive pinion and hypoid driven gear contacts

lightly. Loosen the side retainer RH.

ST1

499787000

WRENCH ASSY (RH SIDE)

ST2

18630AA000 WRENCH ASSY (LH SIDE)

4) Using the ST, rotate the drive pinion shaft sever-

al times.

ST

18631AA000

HANDLE

5) Repeat step 3) and 4) until the side retainer LH

can not be rotated. For the side retainer RH, screw

in until the inner race and outer race contacts light-

ly. This is “0” backlash condition.

(A) Toe side

(B) Heel side

(A) Pinion shaft

(B) Bevel pinion gear

(C) Bevel gear

(D) Washer

AT-00207

(A)

(B)

(A)

(B)

(B)

(C)

(C)

(D)

(D)

MT-00662

Washer

Part No.

Thickness mm (in)

803038021

0.925 — 0.950

(0.0364 — 0.0374)

803038022

0.975 — 1.000

(0.0384 — 0.0394)

803038023

1.025 — 1.050

(0.0404 — 0.0413)

MT-00653

ST

6MT-109

MANUAL TRANSMISSION AND DIFFERENTIAL

Front Differential Assembly

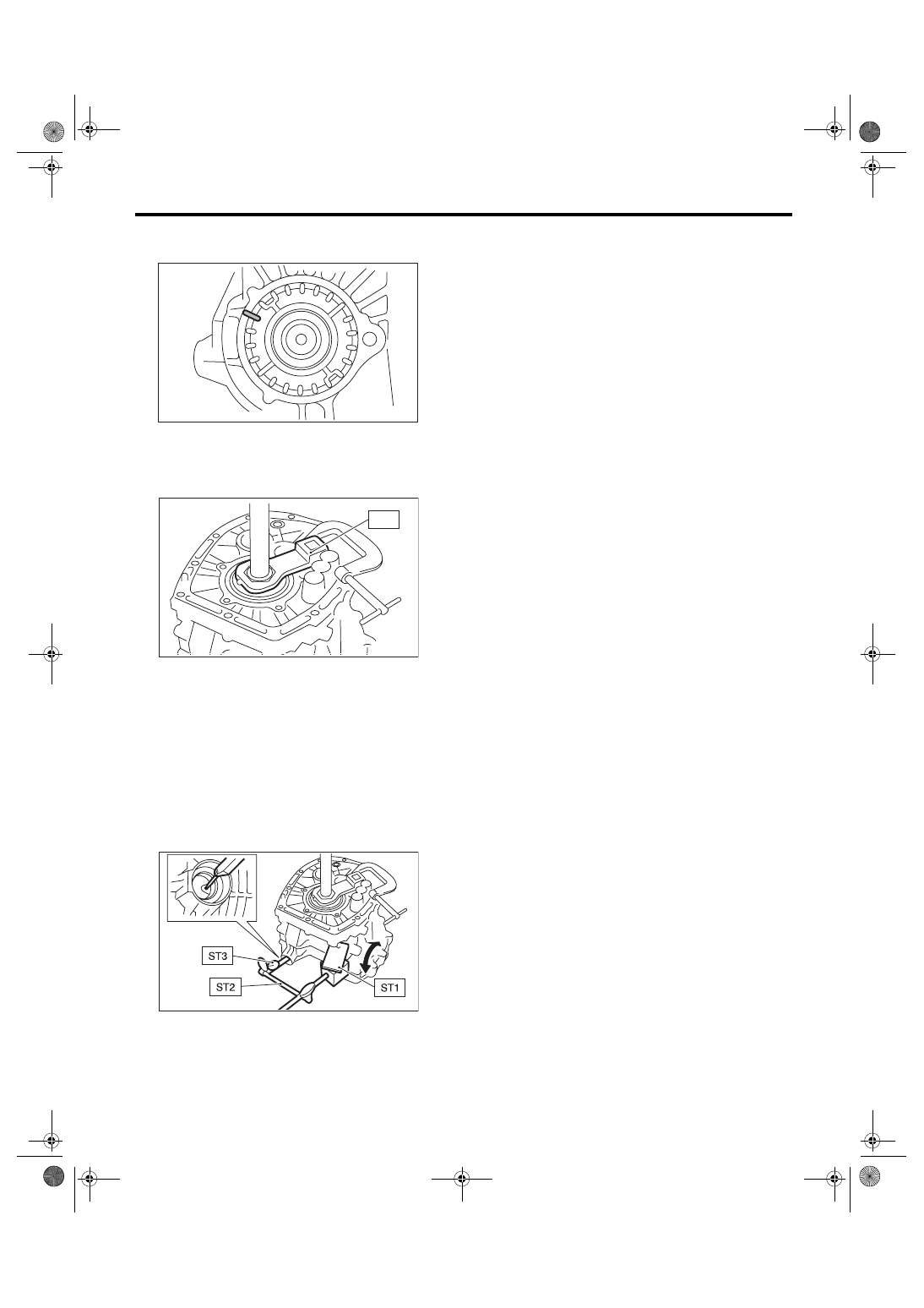

6) Put marks on the engagement position of the

right and left side retainer and clutch housing.

7) Return the side retainer LH for three teeth, and

screw in the side retainer RH for three teeth.

8) Using the ST, secure the drive pinion shaft.

ST

18621AA000

ADAPTER WRENCH

9) Install the SUBARU genuine axle shaft to front

differential LH and RH.

Parts No. 38415AA000 AXLE SHAFT

10) After rotating the drive pinion shaft several

times, measure the hypoid gear backlash using the

ST.

ST1

498255400

PLATE

ST2

498247001

MAGNET BASE

ST3

498247100

DIAL GAUGE

Hypoid gear backlash:

0.13 — 0.18 mm (0.0051 — 0.0071 in)

11) If the backlash is out of specification, adjust it

by turning the right and left side retainers.

12) Screw in the side retainer of RH side for more

than 1.75 teeth.

3. TOOTH CONTACT OF HYPOID GEAR

Refer to the section of drive pinion for checking of

tooth contact. <Ref. to 6MT-107, TOOTH CON-

TACT OF HYPOID GEAR, INSPECTION, Front

Differential Assembly.>

MT-00658

ST

MT-00674

MT-00675

6MT-110

MANUAL TRANSMISSION AND DIFFERENTIAL

Shifter Fork and Rod

24.Shifter Fork and Rod

A: REMOVAL

1) Remove the manual transmission assembly

from vehicle. <Ref. to 6MT-34, REMOVAL, Manual

Transmission Assembly.>

2) Prepare the transmission for overhaul. <Ref. to

6MT-40, Preparation for Overhaul.>

3) Remove the oil pipe, neutral position switch,

back-up light switch and harness. <Ref. to 6MT-42,

REMOVAL, Oil Pipe.> <Ref. to 6MT-45, REMOV-

AL, Neutral Position Switch.> <Ref. to 6MT-43, RE-

MOVAL, Back-up Light Switch.>

4) Remove the extension case. <Ref. to 6MT-47,

REMOVAL, Extension Case.>

5) Remove the transfer driven gear. <Ref. to 6MT-

58, REMOVAL, Transfer Driven Gear.>

6) Remove the center differential. <Ref. to 6MT-60,

REMOVAL, Center Differential.>

7) Remove the oil pump. <Ref. to 6MT-61, RE-

MOVAL, Oil Pump.>

8) Remove the transmission case. <Ref. to 6MT-

64, REMOVAL, Transmission Case.>

9) Remove each gear assembly. <Ref. to 6MT-69,

REMOVAL, Main Shaft Assembly.>

B: INSTALLATION

1) Install each gear assembly at a time. <Ref. to

6MT-70, INSTALLATION, Main Shaft Assembly.>

2) Install the transmission case. <Ref. to 6MT-65,

INSTALLATION, Transmission Case.>

3) Install the oil pump. <Ref. to 6MT-62, INSTAL-

LATION, Oil Pump.>

4) Install the center differential. <Ref. to 6MT-60,

INSTALLATION, Center Differential.>

5) Install the transfer driven gear. <Ref. to 6MT-58,

INSTALLATION, Transfer Driven Gear.>

6) Install the extension case. <Ref. to 6MT-47, IN-

STALLATION, Extension Case.>

7) Install the oil pipe, neutral position switch, back-

up light switch and harness. <Ref. to 6MT-42, IN-

STALLATION, Oil Pipe.> <Ref. to 6MT-45, IN-

STALLATION, Neutral Position Switch.> <Ref. to

6MT-43, INSTALLATION, Back-up Light Switch.>

8) Install the manual transmission assembly into

vehicle. <Ref. to 6MT-36, INSTALLATION, Manual

Transmission Assembly.>

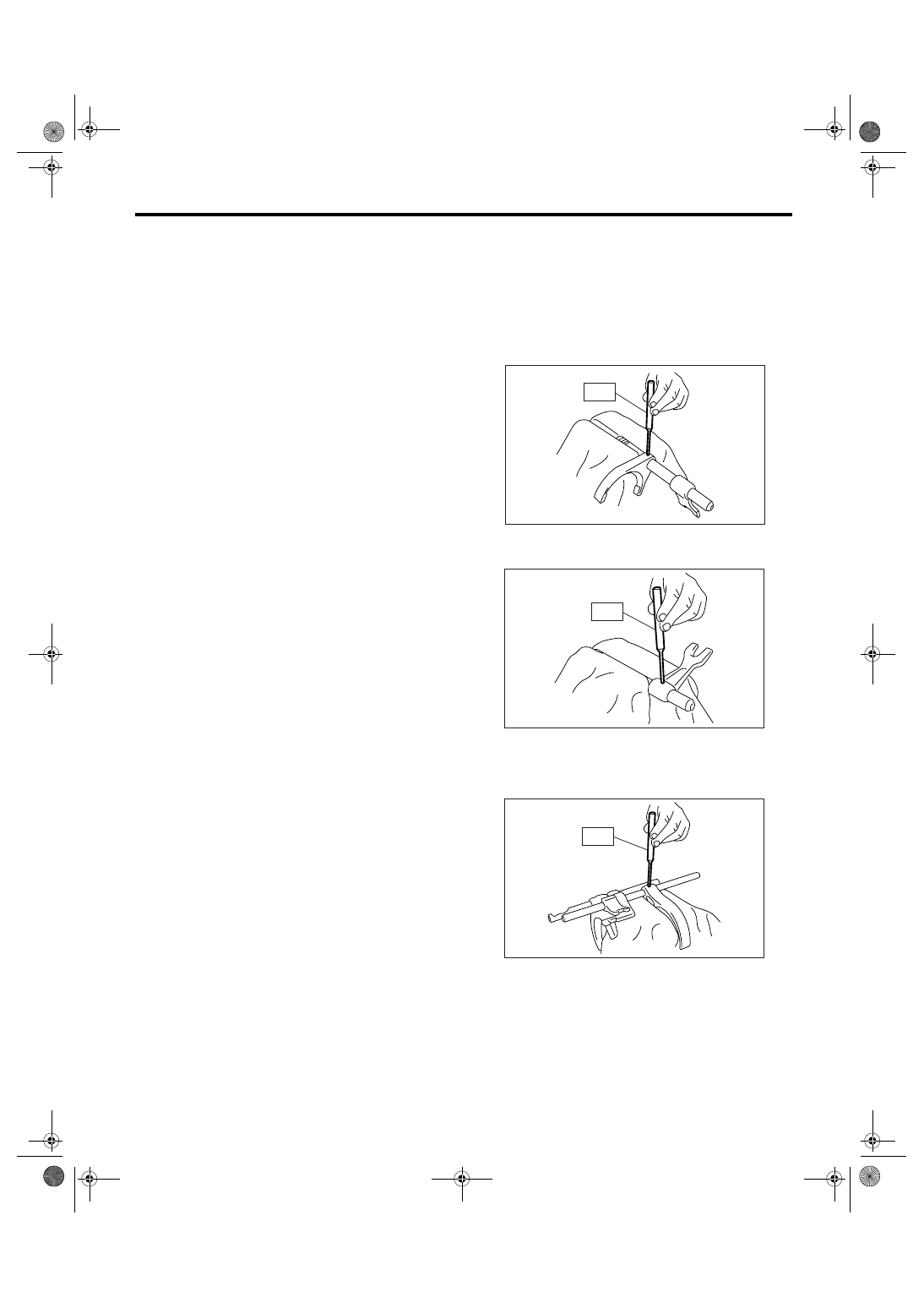

C: DISASSEMBLY

NOTE:

Discard the removed spring pin and replace with a

new one.

1. REVERSE SHIFTER FORK

1) Using the ST, remove the reverse fork.

ST

398791700

REMOVER

2) Using the ST, remove the reverse shifter arm.

ST

398791700

REMOVER

2. 1ST-2ND, 3RD-4TH SHIFTER FORK

1) Using the ST, remove the 3rd-4th shifter fork.

ST

398791700

REMOVER

MT-00680

ST

MT-00681

ST

MT-00682

ST

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст