Infiniti M35/M45 Y50. Manual — part 360

COMBINATION METERS

DI-23

C

D

E

F

G

H

I

J

L

M

A

B

DI

1.

CHECK UNIFIED METER AND A/C AMP. INPUT SIGNAL

1.

Select “METER A/C AMP” on CONSULT-II.

2.

Using “FUEL METER” on “DATA MONITOR”, compare the value

of “DATA MONITOR” to the indication of fuel gauge of combina-

tion meter.

OK or NG

OK

>> GO TO 2.

NG

>> Replace combination meter.

2.

CHECK FUEL LEVEL SENSOR

1.

Turn ignition switch OFF.

2.

DI-26, "CHECK FUEL LEVEL SENSOR UNIT"

OK or NG

OK

>> GO TO 3.

NG

>> Replace fuel level sensor unit.

3.

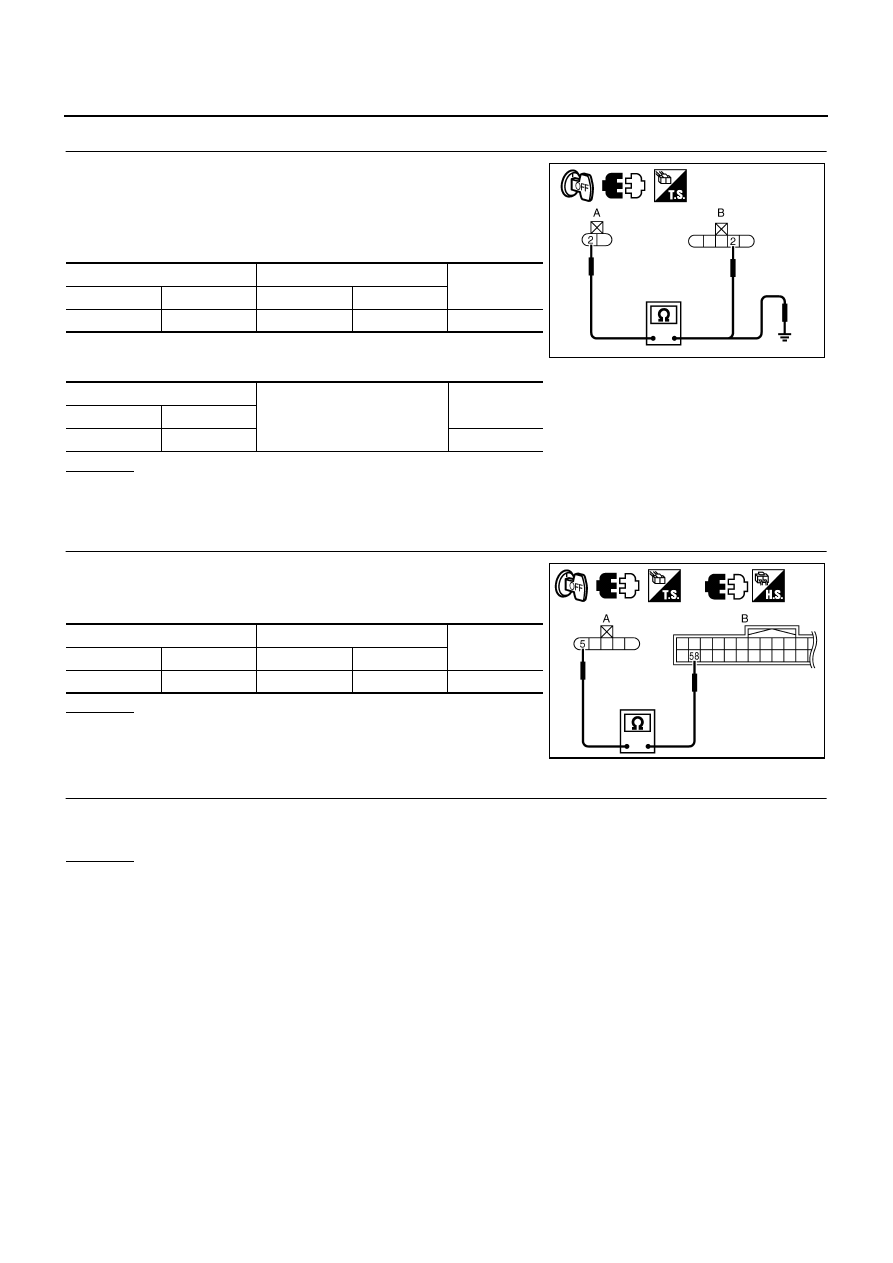

CHECK FUEL LEVEL SENSOR (SUB) CIRCUIT

1.

Disconnect unified meter and A/C amp. connector and fuel level

sensor unit (sub) connector.

2.

Check continuity between unified meter and A/C amp. harness

connector (A) and fuel level sensor unit (sub) harness connector

(B).

3.

Check continuity between unified meter and A/C amp. harness

connector (A) and ground.

OK or NG

OK

>> GO TO 4.

NG

>> Repair harness or connector.

Fuel gauge pointer

Reference value of data monitor [lit.]

Full

Approx. 74

Three quarters

Approx. 61

Half

Approx. 42

A quarter

Approx. 22

Empty

Approx. 8

PKIA2088E

A

B

Continuity

Connector

Terminal

Connector

Terminal

M65

42

B52

1

Yes

A

Ground

Continuity

Connector

Terminal

M65

42

No

PKIB7642E

DI-24

COMBINATION METERS

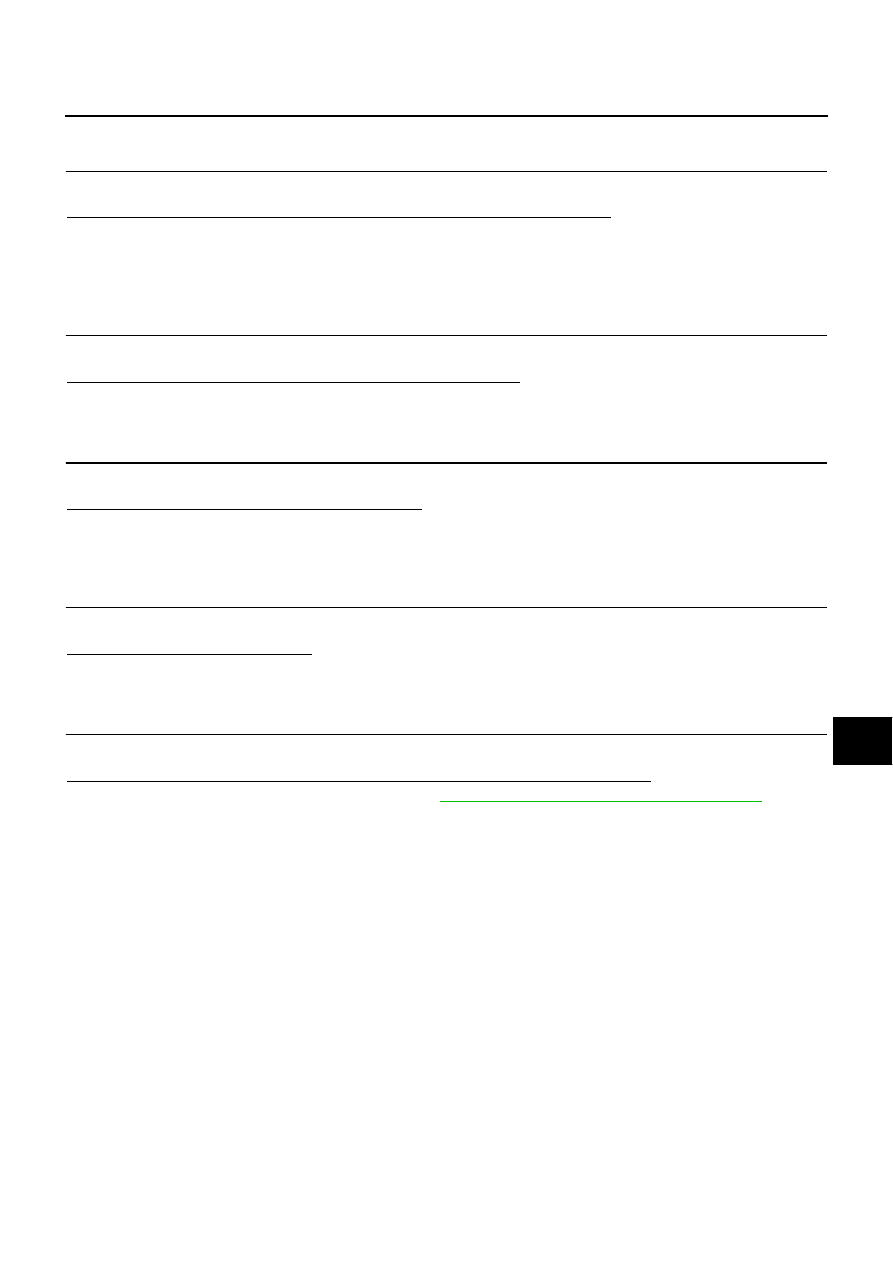

4.

CHECK FUEL LEVEL SENSOR (MAIN-SUB) CIRCUIT

1.

Disconnect fuel level sensor unit and fuel pump (main) connec-

tor.

2.

Check continuity between fuel level sensor unit (sub) harness

connector (A) and fuel level sensor unit and fuel pump (main)

harness connector (B).

3.

Check continuity between fuel level sensor unit (sub) harness

connector (A) and ground.

OK or NG

OK

>> GO TO 5.

NG

>> Repair harness or connector.

5.

CHECK FUEL LEVEL SENSOR (MAIN) CIRCUIT

Check continuity between fuel level sensor unit and fuel pump

(main) harness connector (A) and unified meter and A/C amp. har-

ness connector (B).

OK or NG

OK

>> GO TO 6.

NG

>> Repair harness or connector.

6.

CHECK INSTALLATION CONDITION

Check fuel level sensor unit installation, and check whether the float arm interferes or binds with any of the

internal components in the fuel tank.

OK or NG

OK

>> Replace unified meter and A/C amp.

NG

>> Install the fuel level sensor unit properly.

A

B

Continuity

Connector

Terminal

Connector

Terminal

B52

2

B433

2

Yes

A

Ground

Continuity

Connector

Terminal

B52

2 No

PKIB7643E

A

B

Continuity

Connector

Terminal

Connector

Terminal

B433

5

M65

58

Yes

PKIB7644E

COMBINATION METERS

DI-25

C

D

E

F

G

H

I

J

L

M

A

B

DI

Fuel Gauge Pointer Fluctuates, Indicator Wrong Value or Varies

NKS003UB

1.

CHECK FUEL GAUGE FLUCTUATION

Test drive vehicle to see if gauge fluctuates only during driving or at the instant of stopping.

Does the indication value vary only during driving or at the instant of stopping?

YES

>> The pointer fluctuation may be caused by fuel level change in the fuel tank. Condition is normal.

NO

>> Ask the customer about the situation when the symptom occurs in detail, and perform the trouble

diagnosis.

Fuel Gauge Does Not Move to FULL Position

NKS003UC

1.

QUESTION 1

Does it take a long time for the pointer to move to FULL position?

YES

>> GO TO 2.

NO

>> GO TO 3.

2.

QUESTION 2

Was the vehicle fueled with the ignition switch ON?

YES

>> Be sure to fuel the vehicle with the ignition switch OFF. Otherwise, it will take a long time to move

to FULL position because of the characteristic of the fuel gauge.

NO

>> GO TO 3.

3.

QUESTION 3

Is the vehicle parked on an incline?

YES

>> Check the fuel level indication with vehicle on a level surface.

NO

>> GO TO 4.

4.

QUESTION 4

During driving, does the fuel gauge pointer move gradually toward EMPTY position?

YES

>> Check the fuel level sensor unit. Refer to

DI-26, "CHECK FUEL LEVEL SENSOR UNIT"

.

NO

>> The float arm may interfere or bind with any of the components in the fuel tank.

DI-26

COMBINATION METERS

Electrical Components Inspection

NKS003UD

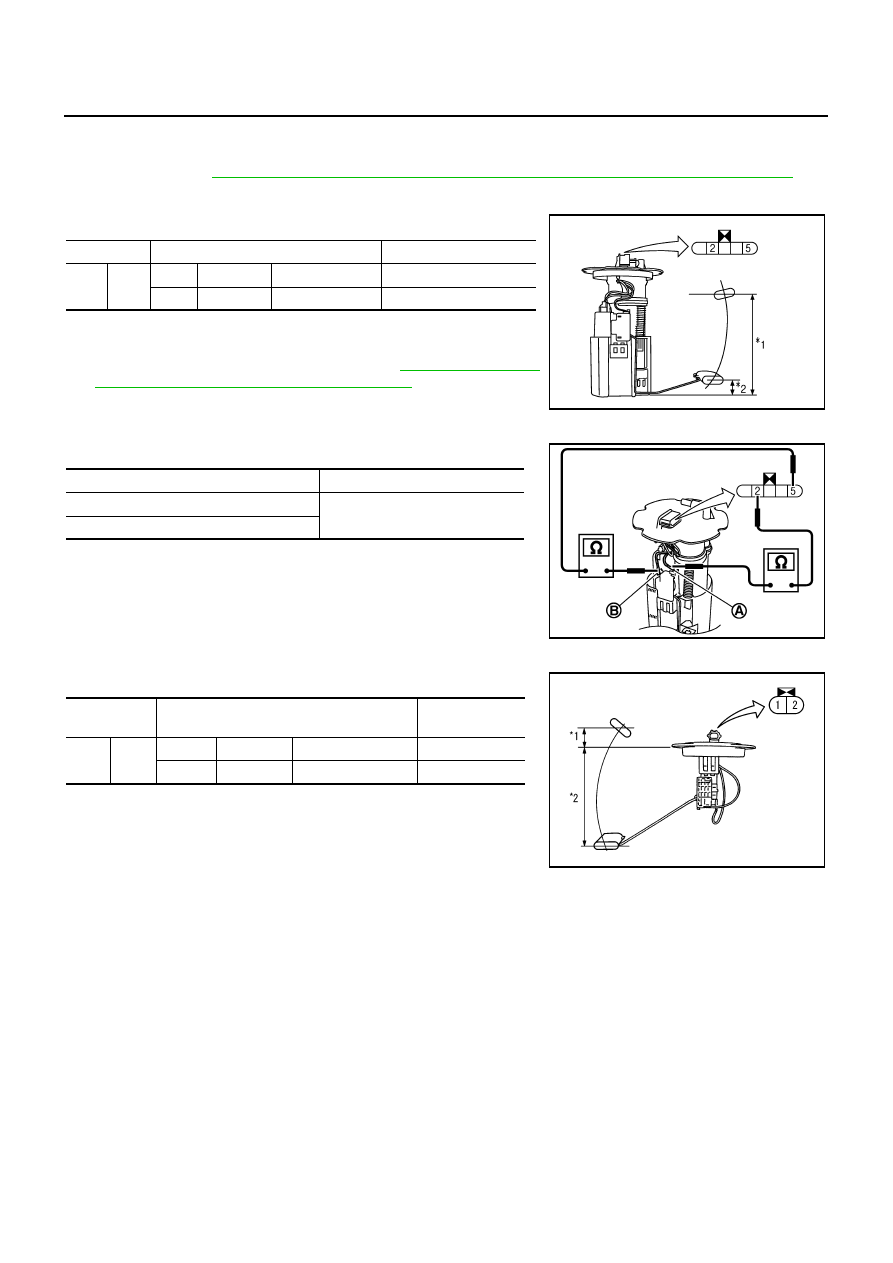

CHECK FUEL LEVEL SENSOR UNIT

FL-4, "FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY"

Check Fuel Level Sensor Unit and Fuel Pump (Main)

Check resistance between terminals 2 and 5.

*1 and *2: When float rod is in contact with stopper.

●

If the results of check are NG, check the fuel level sensor unit

and fuel pump (main) harness. Refer to

Level Sensor Unit and Pump (Main) Harness"

Check Fuel Level Sensor Unit and Pump (Main) Harness

Check continuity at following terminals.

●

If the results of check are NG, replace fuel pump assembly. If the

results of check are OK, replace fuel level sensor unit.

Check Fuel Level Sensor Unit (Sub)

Check resistance between terminals 1 and 2.

*1 and *2: When float rod is in contact with stopper.

Terminal

Float position

[mm (in)]

Resistance value [

Ω

]

2

5

*1

Full

210 (8.27)

Approx. 3

*2

Empty

30 (1.18)

Approx. 80

SKIB3550J

Terminal

Continuity

2 - Signal terminal (A)

Yes

5 - Ground terminal (B)

SKIB3551J

Terminal

Float position

[mm (in)]

Resistance

value [

Ω

]

1

2

*1

Full

9 (0.35)

Approx. 3

*2

Empty

179 (7.05)

Approx. 43

SKIB2678J

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст