Infiniti M35/M45 Y50. Manual — part 339

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

BRC-57

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

M

A

B

BRC

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

PFP:47660

Removal and Installation

NFS000RC

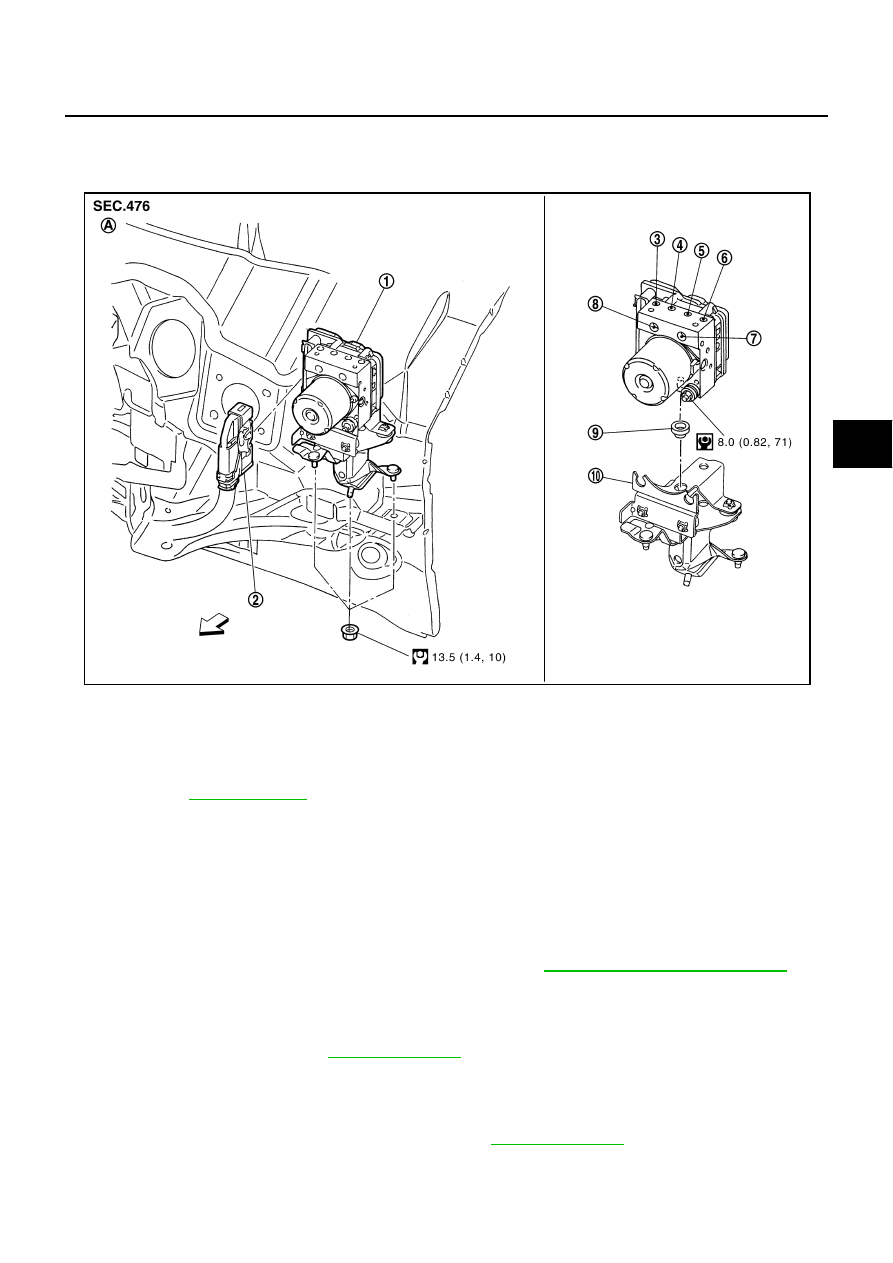

COMPONENT

CAUTION:

Be careful of the following.

●

Before servicing, disconnect the battery cable from negative terminal.

●

To remove brake tube, use a flare nut wrench to prevent flare nuts and brake tube from being dam-

aged. To install, use flare nut torque wrench.

●

Do not apply excessive impact to ABS actuator and electric unit (control unit), such as dropping it.

●

Do not remove and install actuator by holding harness.

●

After work is completed, bleed air from brake tube. Refer to

BR-10, "Bleeding Brake System"

●

After installing harness connector in the ABS actuator and electric unit (control unit), make sure

connector is securely locked.

REMOVAL

1.

Remove cowl top cover. Refer to

2.

Disconnect ABS actuator and electric unit (control unit) connector.

3.

Loosen brake tube flare nuts, then remove brake tubes from ABS actuator and electric unit (control unit).

4.

Remove tire.

5.

Remove fender protector (rear): (front LH side). Refer to

6.

Remove ABS actuator and electric unit (control unit) bracket mounting nut.

1.

ABS actuator and electric unit (con-

trol unit)

2.

Connector

3.

To front RH brake caliper

4.

To rear LH brake caliper

5.

To rear RH brake caliper

6.

To front LH brake caliper

7.

From master cylinder primary side

8.

From master cylinder secondary side 9.

Bushing

10.

Bracket

A.

Left side of dash panel

Refer to GI section

for symbol marks in the figure.

SFIA3018E

BRC-58

[VDC/TCS/ABS]

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

7.

Remove ABS actuator and electric unit (control unit) from vehicle.

INSTALLATION

Installation is the reverse order of removal.

CAUTION:

When replacing ABS actuator and electric unit (control unit), make sure to adjust neutral position of

steering angle sensor. Refer to

BRC-6, "Adjustment of Steering Angle Sensor Neutral Position"

G-SENSOR

BRC-59

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

M

A

B

BRC

G-SENSOR

PFP:47930

Removal and Installation

NFS000RD

CAUTION:

●

Do not drop or strike yaw rate/side G sensor, because it has little endurance to impact.

●

Do not use power tool etc., because yaw rate/side G sensor is sensitive for the impact.

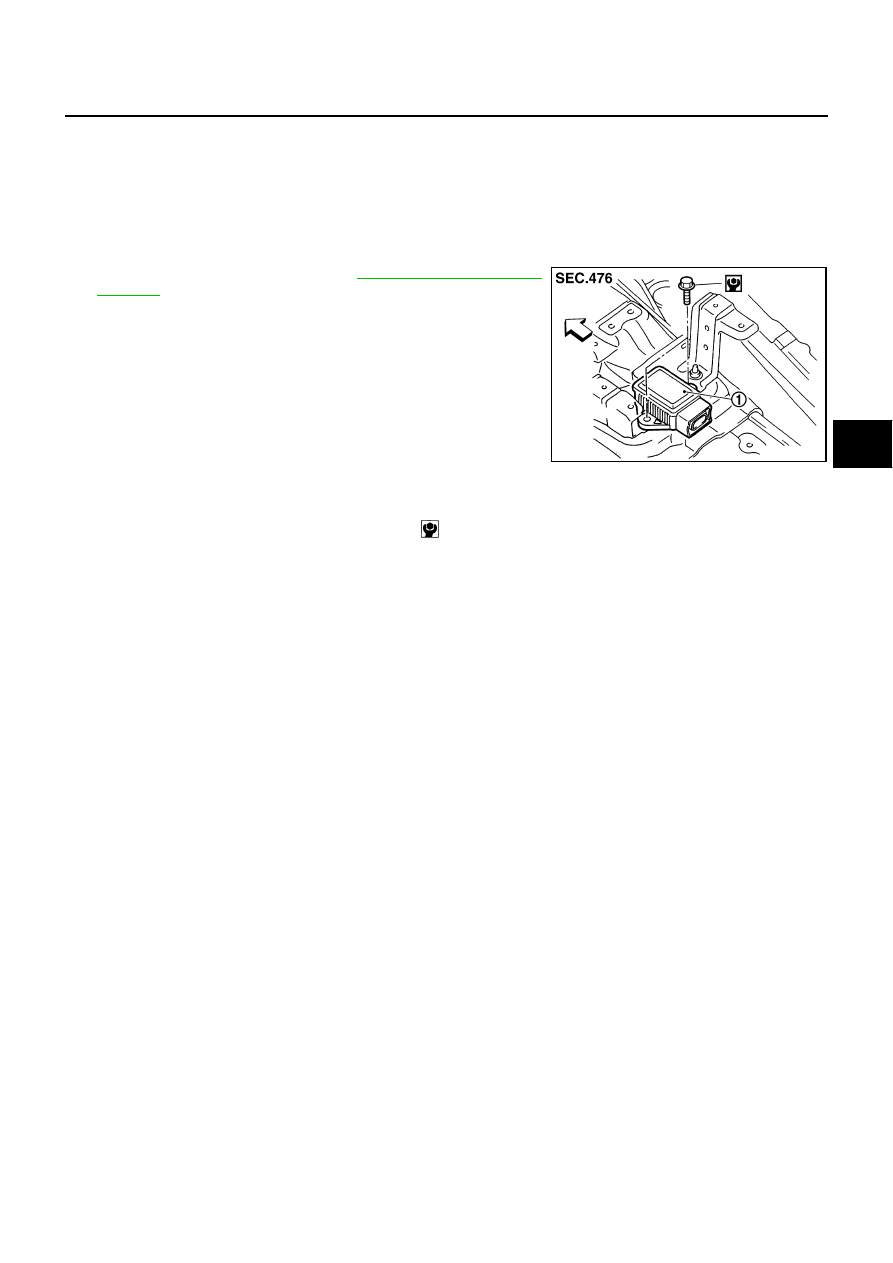

REMOVAL

1.

Remove center console. Refer to

2.

Disconnect yaw rate/side G sensor harness connector.

3.

Remove mounting bolts. Remove yaw rate/side G sensor (1).

INSTALLATION

Installation is the reverse order of removal.

SFIA2725J

Yaw rate/side G sensor mounting bolt

: 6.5 N·m (0.66 kg·m, 58 in-lb)

BRC-60

[VDC/TCS/ABS]

STEERING ANGLE SENSOR

STEERING ANGLE SENSOR

PFP:25554

Removal and Installation

NFS000RE

REMOVAL

1.

Remove spiral cable assembly. Refer to

2.

Remove steering angle sensor from spiral cable assembly.

INSTALLATION

Installation is the reverse order of removal.

CAUTION:

After work, make sure to adjust neutral position of steering angle sensor. Refer to

of Steering Angle Sensor Neutral Position"

SFIA1404E

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст