Infiniti M35/M45 Y50. Manual — part 1020

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

RFD-7

C

E

F

G

H

I

J

K

L

M

A

B

RFD

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

PFP:00003

NVH Troubleshooting Chart

NDS000F1

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

×

: Applicable

Reference page

R

e

fe

r to

.

R

e

fe

r to

.

R

e

fe

r to

.

R

e

fe

r to

.

R

e

fe

r to

.

R

e

fe

r to

.

NV

H

in

PR

s

e

c

ti

o

n

.

NV

H

in

F

AX,

RAX, FSU

a

n

d

RSU

s

e

c

ti

o

n

s

.

NV

H

in

W

T

s

e

c

tio

n

.

NV

H

in

W

T

s

e

c

tio

n

.

N

V

H

i

n

F

AX and R

AX sec

ti

on.

NV

H

in

BR

s

e

c

ti

o

n

.

NV

H

in

PS

s

e

c

ti

o

n

.

Possible cause and SUSPECTED PARTS

G

e

ar

t

oot

h r

o

u

g

h

G

e

ar

con

ta

c

t

im

pr

o

per

T

oot

h sur

fa

c

es w

o

rn

B

a

ckl

as

h i

n

c

o

rr

ect

C

o

m

pani

on f

lan

ge exc

e

ssi

ve

r

unou

t

G

e

ar

oi

l

im

pr

o

per

P

R

OPE

LLER SHAFT

A

X

LE AND

SUSPENSION

TI

R

E

S

ROAD W

H

EEL

DRIVE SHAFT

BR

AK

E

S

S

T

EERI

N

G

Symptom

Noise

×

×

×

×

×

×

×

×

×

×

×

×

×

RFD-8

DESCRIPTION

DESCRIPTION

PFP:00000

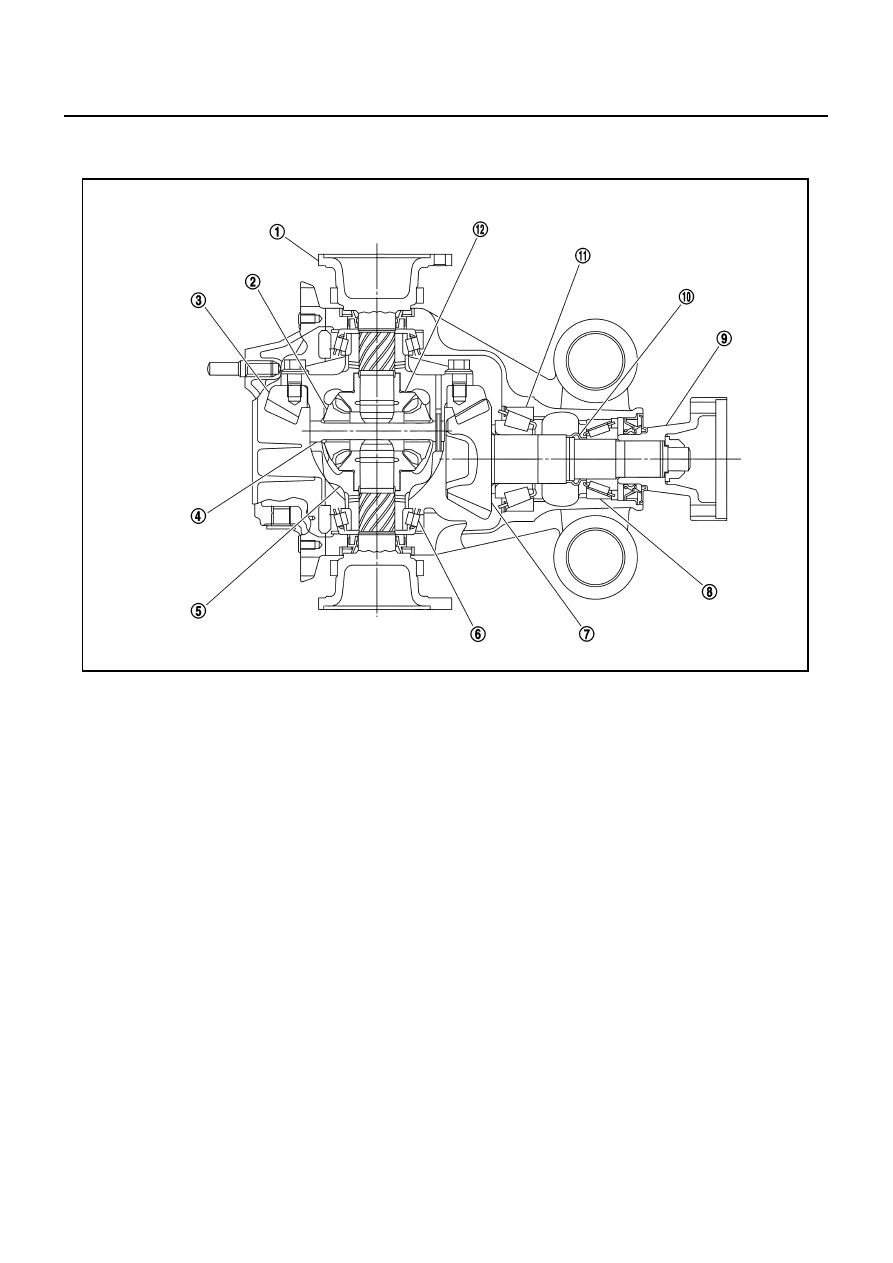

Cross-Sectional View

NDS000F2

1.

Side flange

2.

Pinion mate gear

3.

Drive gear

4.

Pinion mate shaft

5.

Differential case

6.

Side bearing

7.

Drive pinion

8.

Pinion front bearing

9.

Companion flange

10. Collapsible spacer

11.

Pinion rear bearing

12. Side gear

PDIA0476E

DIFFERENTIAL GEAR OIL

RFD-9

C

E

F

G

H

I

J

K

L

M

A

B

RFD

DIFFERENTIAL GEAR OIL

PFP:KLD30

Changing Differential Gear Oil

NDS000F3

DRAINING

1.

Stop engine.

2.

Remove drain plug (1) and drain gear oil.

3.

Set a gasket on drain plug (1) and install it to final drive assem-

bly and tighten to the specified torque. Refer to

CAUTION:

Do not reuse gasket.

FILLING

1.

Remove filler plug (1). Fill with new gear oil until oil level reaches

the specified level near filler plug mounting hole.

2.

After refilling oil, check oil level. Set a gasket to filler plug (1),

then install it to final drive assembly. Refer to

CAUTION:

Do not reuse gasket.

Checking Differential Gear Oil

NDS000F4

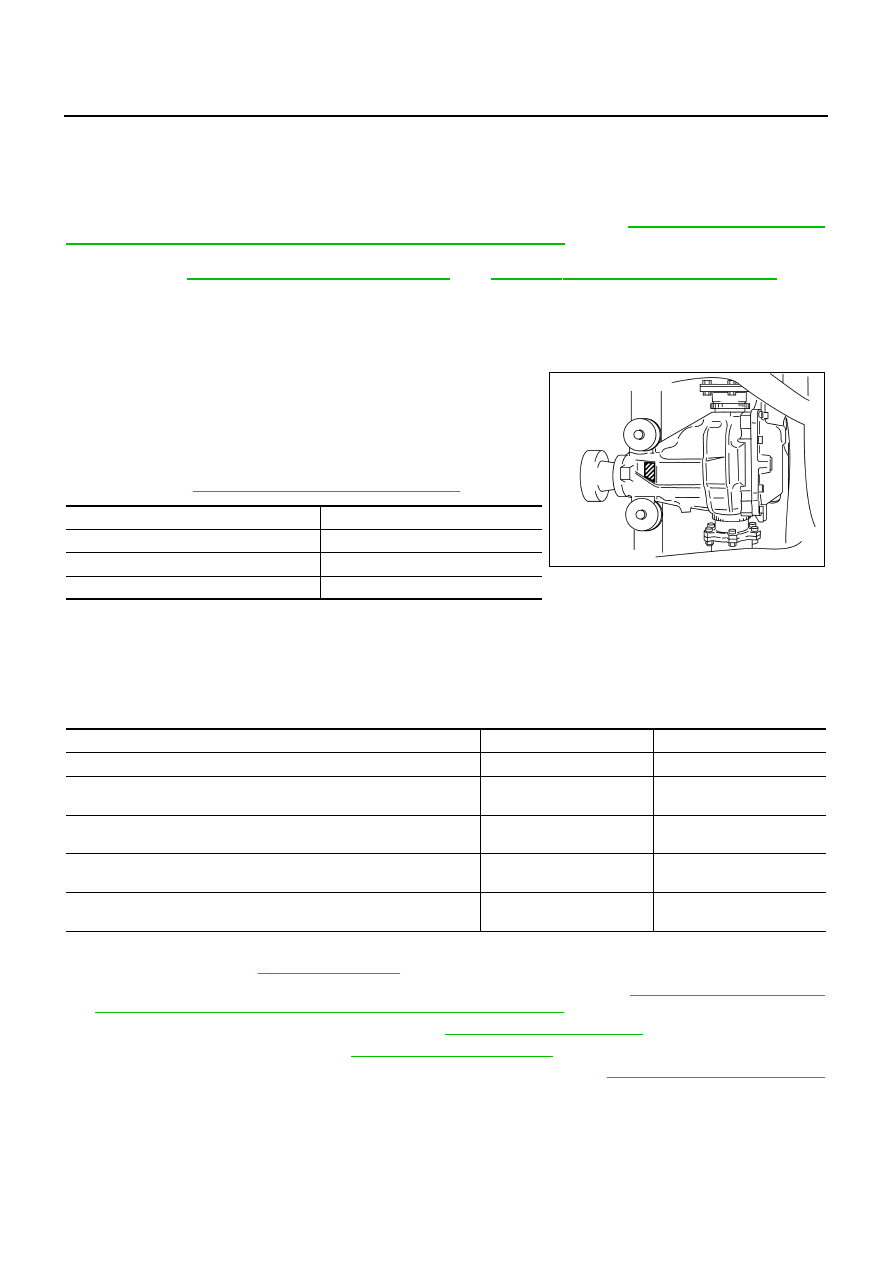

OIL LEAKAGE AND OIL LEVEL

●

Make sure that oil is not leaking from final drive assembly or around it.

●

Remove filler plug (1) and check oil level from filler plug mount-

ing hole as shown in the figure.

CAUTION:

Do not start engine while checking oil level.

●

Set a gasket on filler plug (1) and install it on final drive assem-

bly. Refer to

.

CAUTION:

Do not reuse gasket.

PDIA0748J

Oil grade and Viscosity:

Refer to

MA-12, "Fluids and Lubricants"

.

Oil capacity:

Approx. 1.4 (3 US pt, 2-1/2 Imp pt)

PDIA0749J

PDIA0749J

RFD-10

FRONT OIL SEAL

FRONT OIL SEAL

PFP:38189

Removal and Installation

NDS000F5

CAUTION:

Verify identification stamp of replacement frequency put in the lower part of gear carrier to determine

replacement for collapsible spacer when replacing front oil seal. Refer to

STAMP OF REPLACEMENT FREQUENCY OF FRONT OIL SEAL"

. If necessary collapsible spacer

replacement, remove final drive assembly and disassemble it to replace front oil seal and collapsible

spacer. Refer to

RFD-16, "Removal and Installation"

and

RFD-18, "Disassembly and Assembly"

NOTE:

The reuse of collapsible spacer is prohibited in principle. However, it is reusable on a one-time basis

only in cases when replacing front oil seal.

IDENTIFICATION STAMP OF REPLACEMENT FREQUENCY OF FRONT OIL SEAL

●

The diagonally shaded area in the figure shows stamping point

for replacement frequency of front oil seal.

●

The following table shows if collapsible spacer replacement is

needed before replacing front oil seal.

When collapsible spacer replacement is required, disassemble

final drive assembly to replace collapsible spacer and front oil

seal. Refer to

RFD-18, "Disassembly and Assembly"

.

CAUTION:

Be sure to make a stamping after replacing front oil seal.

●

After replacing front oil seal, make a stamping on the stamping point in accordance with the table below in

order to identify replacement frequency.

CAUTION:

Stamping shall be made from left to right.

REMOVAL

1.

Drain gear oil. Refer to

2.

Make a judgment if a collapsible spacer replacement is required. Refer to

STAMP OF REPLACEMENT FREQUENCY OF FRONT OIL SEAL"

3.

Remove center muffler with a power tool. Refer to

4.

Remove rear wheel sensor. Refer to

5.

Remove drive shaft from final drive. Then suspend it by wire etc. Refer to

.

Stamp

collapsible spacer replacement

No stamp

Not required

“0” or “0” on the far right of stamp

Required

“01” or “1” on the far right of stamp

Not required

PDIA0976E

Stamp before stamping

Stamping on the far right

Stamping

No stamp

0

0

“0”

(Front oil seal was replaced once.)

1

01

“01”

(Collapsible spacer and front oil seal were replaced last time.)

0

010

“0” is on the far right.

(Only front oil seal was replaced last time.)

1

...01

“1” is on the far right.

(Collapsible spacer and front oil seal were replaced last time.)

0

...010

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст