Mitsubishi Lancer Evolution IX. Manual — part 337

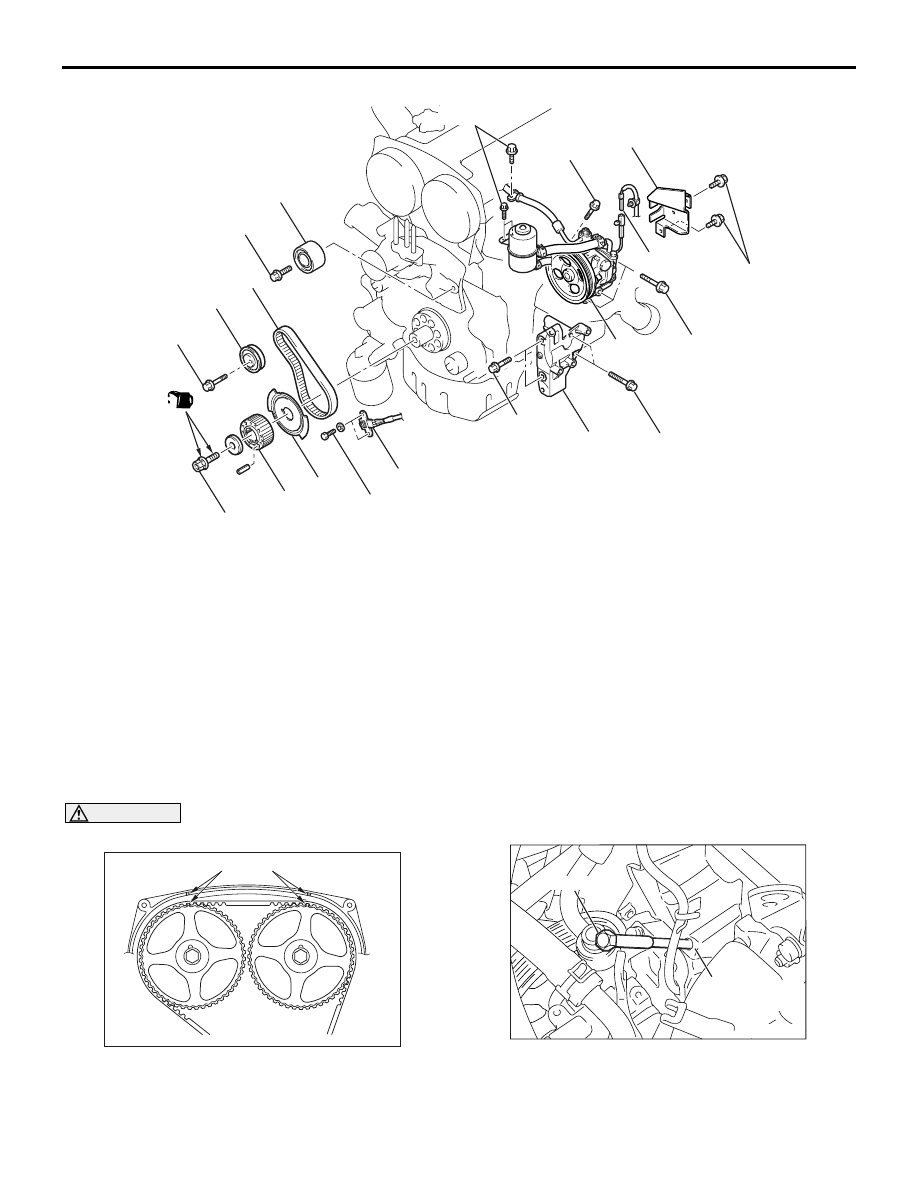

AC211076

(Engine oil)

35 ± 6 N·m

19 ± 3 N·m

167 N·m

8.8 ± 1.0 N·m

17

16

15

20

18

19

22 ± 4 N·m

49 ± 9 N·m

49 ± 9 N·m

40 ± 5 N·m

22 ± 4 N·m

11

12

13

14

12 ± 2 N·m

AD

Removal steps

11. Power steering pressure switch

connector

12. Power steering oil pump heat

protector

<<

B

>>

13. Power steering oil pump, bracket

and reservoir assembly

14. Power steering oil pump bracket

15. Timing belt Idler pulley

16. Crank angle sensor

<<

C

>>

>>

C

17. Crankshaft camshaft drive sprocket

>>

C

18. Crankshaft angle sensing blade

>>

B

•

Balancer timing belt tension

adjustment

>>

A

19. Balancer timing belt tensioner

<<

D

>>

>>

A

20. Balancer timing belt

TIMING BELT

ENGINE MECHANICAL

11A-37

REMOVAL SERVICE POINTS

<<A>> VALVE TIMING BELT REMOVAL

CAUTION

Never turn the crankshaft anti-clockwise.

AC102487

Timing mark

AC

1. Turn the crankshaft clockwise, align each timing

mark to set No.1 cylinder to TDC of its

compression stroke.

AC211534AB

MD998738

Timing belt

under cover

2. Remove the timing belt under cover rubber plug

and then set the special tool adjusting bolt

(MD998738).

Removal steps (Continued)

AC107289

MD998738

Timing belt

tensioner arm

AB

TIMING BELT

ENGINE MECHANICAL

11A-38

3. Screw in the special tool until it comes in contact

with the timing belt tensioner arm.

CAUTION

The special tool can be gradually installed at a

rate of a 30 degree turn per second. If it is

screwed in all at once, the timing belt tensioner

adjuster rod will not easily retract and the special

tool may bend.

AC102775AB

A

B

4. Gradually screw in the special tool. Then align the

timing belt tensioner adjuster rod set hole A with

the timing belt tensioner adjustor cylinder set hole

B.

AC107185AC

Wire or pin

Timing belt

tensioner pulley

mounting bolt

5. Insert a wire or pin in the set hole.

CAUTION

For reinstallation of the valve timing belt, draw an

arrow indicating the rotating direction (clock-

wise) on the back of the belt using chalk.

6. After removal of the special tool, loosen the timing

belt tensioner pulley mounting bolt and remove

the valve timing belt.

<<B>> POWER STEERING OIL PUMP,

BRACKET AND RESERVOIR ASSEMBLY

REMOVAL

With the hose installed, remove the power steering

oil pump assembly from the bracket.

NOTE: Secure the removed power steering oil pump

assembly with cord or rope at a position where they

will not interfere with the removal of the balancer tim-

ing belt.

<<C>> CRANKSHAFT CAMSHAFT DRIVE

SPROCKET REMOVAL

AC102332AB

MB991385

MB991367

Crankshaft

camshaft

drive

sprocket

1. Use the following special tools to support the

crankshaft camshaft drive sprocket.

• Special spanner (MB991367)

• Pin (MB991385)

2. Loosen the crankshaft pulley centre bolt and

remove the crankshaft camshaft drive sprocket.

<<D>> BALANCER TIMING BELT

REMOVAL

CAUTION

For reinstallation of the balancer timing belt,

draw an arrow indicating the rotating direction

(clockwise) on the back of the belt using chalk.

TIMING BELT

ENGINE MECHANICAL

11A-39

INSTALLATION SERVICE POINTS

>>A<< BALANCER TIMING BELT/BAL-

ANCER TIMING BELT TENSIONER

INSTALLATION

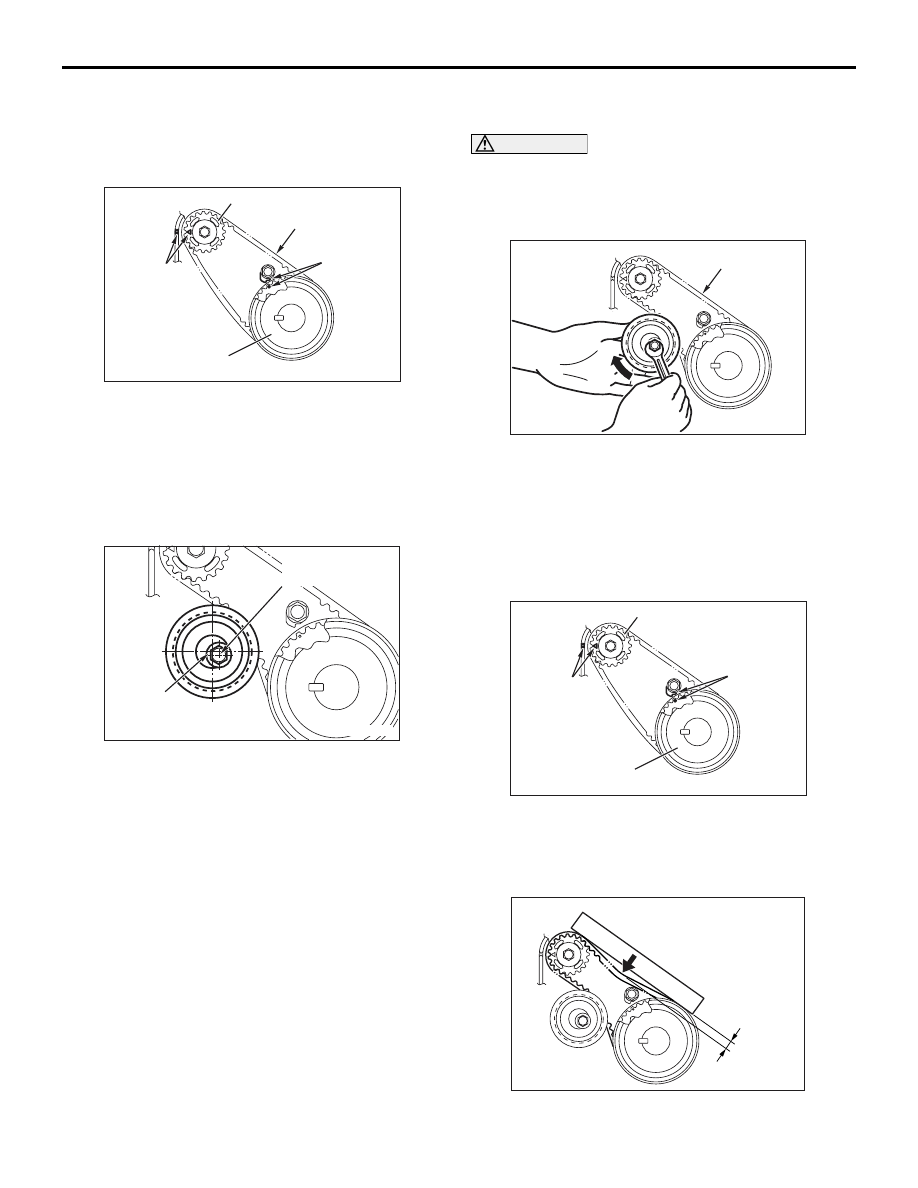

AC102689AB

Balancershaft sprocket

Belt tension side

Timing mark

Timing mark

Crankshaft

balancershaft

drive sprocket

1. Ensure that the crankshaft balancershaft drive

sprocket timing marks and balancershaft sprocket

timing marks are aligned.

2. Install the balancer timing belt on the crankshaft

balancershaft drive sprocket and balancershaft

sprocket. There should be no slack on the tension

side.

AC102690 AB

Centre of

the pulley

Centre of the

mounting bolt

3. Assemble and temporarily fix the centre of the

pulley of the balancer timing belt tensioner so that

it is at the top left from the centre of the

assembling bolt, and the pulley flange is at the

front-side of the engine.

4. Adjust the balancer timing belt tension.

>>B<< BALANCER TIMING BELT

TENSION ADJUSTMENT

CAUTION

When tightening the mounting bolts, ensure that

the tensioner does not rotate with the bolts.

Allowing it to rotate with the bolts can cause

excessive tension of the belt.

AC102691AB

Belt tension side

1. With your fingers, lift the balancer timing belt

tensioner in the direction of the arrow. Apply

pressure of 3.0

± 0.4 N⋅m to the balancer timing

belt. Tighten the assembling bolt to the standard

torque. Then, fix the balancer timing belt

tensioner.

Tightening torque: 19

± 3 N⋅m

AC102689AC

Balancershaft sprocket

Timing mark

Timing mark

Crankshaft

balancershaft

drive sprocket

2. Turn the crankshaft clockwise two turns to set

No.1 cylinder to TDC of its compression stroke

and check that the sprocket timing marks are

aligned.

AC102693AB

Deflection

Approximately 100 N

TIMING BELT

ENGINE MECHANICAL

11A-40

3. Apply a pressure of approximately 100N at the

centre (arrow area) between the sprocket as

shown, then inspect whether the belt deflection is

within the standard value.

Standard value:

At adjustment: 5

− 7 mm

At replacement: 5

− 7 mm

4. If not within the standard value, adjust the belt

tension again.

>>C<< CRANKSHAFT ANGLE SENSING

BLADE/CRANKSHAFT CAMSHAFT

DRIVE SPROCKET INSTALLATION

AC211535AC

Crankshaft camshaft

drive sprocket

Crankshaft pulley

centre bolt

Crankshaft

Crankshaft angle

sensing blade

Crankshaft

pulley washer

Engine front

: Clean

: Clean and degrease

: Apply engine oil

1. Clean or degrease the crankshaft, the crankshaft

angle sensing blade, the crankshaft camshaft

drive sprocket and crankshaft pulley washer as

shown.

NOTE: Also clean the degreased surfaces.

2. Install the crankshaft angle sensing blade and

crankshaft camshaft drive sprocket in the direction

shown.

3. Place the larger chamfer side of the crank shaft

pulley washer in the direction shown and then

assemble on the crankshaft pulley centre bolt.

4. Apply some engine oil to the crankshaft pulley

centre bolt bearing surface and screw.

AC102332AB

MB991385

MB991367

Crankshaft

camshaft

drive

sprocket

5. Use the following special tool as during removal to

support the crankshaft camshaft drive sprocket.

• Special spanner (MB991367)

• Pin (MB991385)

6. Tighten the crankshaft pulley centre bolts to the

specified torque.

Tightening torque: 167 N

⋅m

>>D<< TIMING BELT TENSIONER

ADJUSTER INSTALLATION

1. Install according to the following procedures when

the timing belt tensioner adjuster rod is fully

extended.

CAUTION

If the compression is too fast, the procedure may

damage the rod.

AC102334AB

A

B

(1) Slowly compress the timing belt tensioner

adjuster rod using a press or vice, then align

the set hole A of the rod with set hole B of the

timing belt tensioner adjuster cylinder.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст