Mitsubishi Lancer Evolution IX. Manual — part 335

CRANKSHAFT OIL SEAL

ENGINE MECHANICAL

11A-29

CRANKSHAFT OIL SEAL

REMOVAL AND INSTALLATION

M1112003100444

CAUTION

If the vehicle is equipped with the Brembo

™ disc brake, during maintenance, take care not to contact

the parts or tools to the caliper because the paint of caliper will be scratched.

AC210943

AB

1

2

3

(Lip section)

Engine oil

3

6

6

5

4

N

N

132 ± 5 N·m

(Lip section)

Crankshaft front oil seal removal

steps

•

Valve timing belt, balancer timing

belt (Refer to

).

>>

D

<<

1.

Crankshaft balancer shaft drive

sprocket

2.

Crankshaft key

>>

C

<<

3.

Crankshaft front oil seal

Crankshaft front oil seal removal

steps

•

Transfer assembly (Refer to

GROUP 22A, Transfer Assembly

).

•

Transmission assembly (Refer to

GROUP 22A, Transmission

Assembly

).

<<

A

>>

>>

B

4.

Flywheel bolts

5.

Flywheel assembly

>>

A

6.

Crankshaft rear oil seal

CRANKSHAFT OIL SEAL

ENGINE MECHANICAL

11A-30

REMOVAL SERVICE POINT

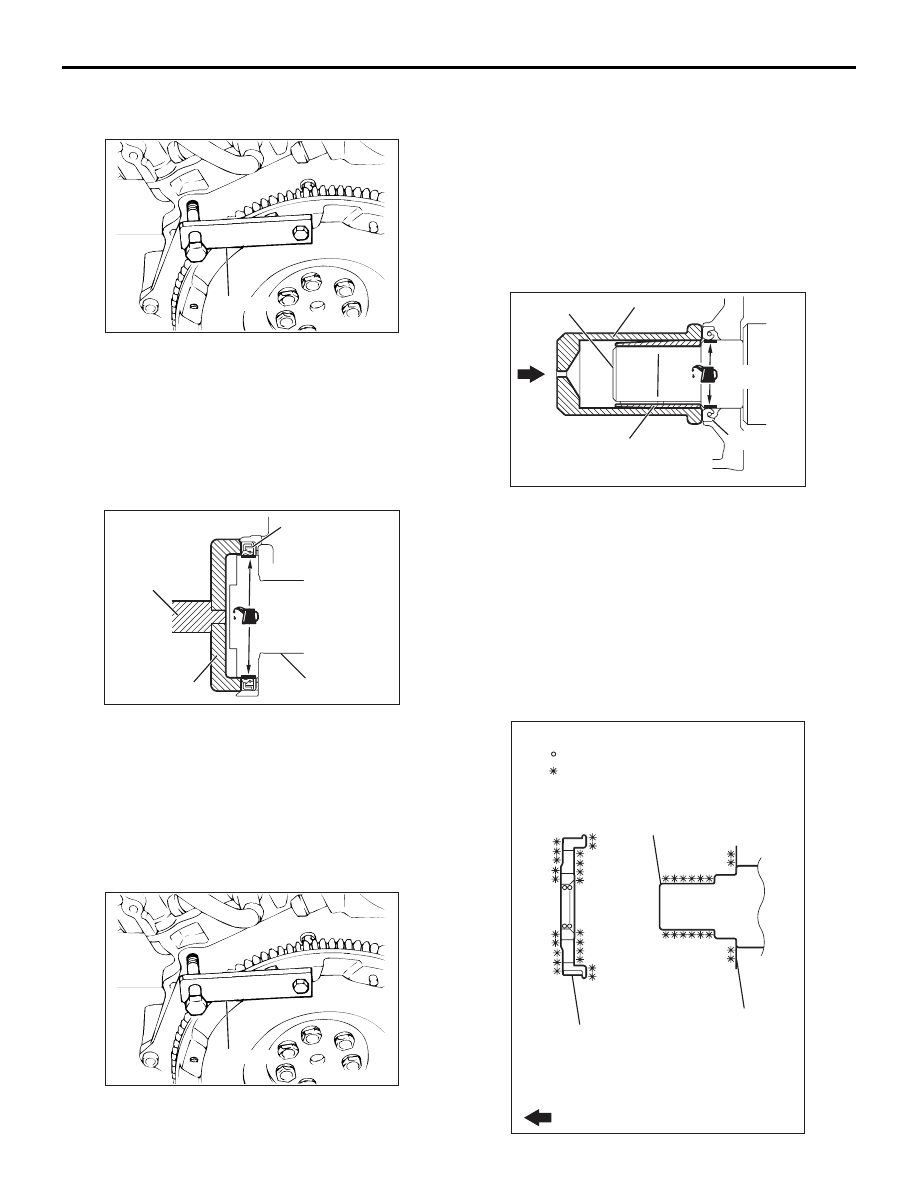

<<A>> FLYWHEEL BOLTS REMOVAL

AC211171AB

MD998781

1. Use special tool flywheel stopper (MD998781) to

secure the flywheel.

2. Remove the flywheel mounting bolts.

INSTALLATION SERVICE POINTS

>>A<< CRANKSHAFT REAR OIL SEAL

INSTALLATION

AC102328 AB

Oil seal

MB990938

MD998776

Crankshaft

(Engine oil)

1. Apply a small amount of engine oil to the entire

inner diameter of the oil seal lip.

2. Use the following special tools to press-fit the oil

seal.

• Installer bar (MB990938)

• Crankshaft rear oil seal installer (MD998776)

>>B<< FLYWHEEL BOLTS INSTALLATION

AC211171AB

MD998781

1. Use special tool flywheel stopper (MD998781) to

secure the flywheel in the same manner as

removal.

2. Tighten the flywheel mounting bolts to the

specified torque.

Tightening torque: 132

± 5 N⋅m

>>C<< CRANKSHAFT FRONT OIL SEAL

INSTALLATION

AC102329AC

MD998285

(Engine oil)

(Oil applied to the

circumference)

Oil seal

Crankshaft

MD998375

1. Apply a small amount of engine oil to the entire

inner diameter of the oil seal lip.

2. Apply a small amount of engine oil to the outer

diameter of special tool crankshaft front oil seal

guide (MD998285) and install it to the crankshaft.

3. Use special tool crankshaft front oil seal installer

(MD998375) to press-fit the oil seal.

>>D<< CRANKSHAFT BALANCER SHAFT

DRIVE SPROCKET INSTALLATION

AC211222

Crankshaft

balancershaft

drive sprocket

Engine front

Front case

Crankshaft

AB

: Clean

: Clean and degrease

CYLINDER HEAD GASKET

ENGINE MECHANICAL

11A-31

1. Clean or degrease the front case, the crankshaft

and the crankshaft balancer shaft drive sprocket

as shown.

NOTE: Also clean the degreased surfaces.

2. Install the crankshaft balancer shaft drive sprocket

in the direction shown in the illustration.

CYLINDER HEAD GASKET

REMOVAL AND INSTALLATION

M1112004001744

CAUTION

If the vehicle is equipped with the Brembo

™ disc brake, during maintenance, take care not to contact

the parts or tools to the caliper because the paint of caliper will be scratched.

Pre-removal Operation

• Fuel Line Pressure Reduction [Refer to GROUP 13A,

On-vehicle Service

− Fuel Pump Connector Disconnec-

tion (How to Reduce Pressurized Fuel Lines)

].

• Under Cover Removal (Refer to GROUP 51, Front

).

• Side Cover Removal

• Engine Coolant Draining (Refer to GROUP 14, On-vehicle

Service

− Engine Coolant Replacement

• Engine Oil Draining (Refer to GROUP 12, On-vehicle

Service

− Engine Oil Replacement

).

• Strut Tower Bar Removal (Refer to GROUP 42, Strut

Tower Bar

• Air Cleaner Assembly Removal (Refer to GROUP 15, Air

Cleaner

).

• Air Hose E, Air Pipe C and Air Hose D Removal (Refer to

GROUP 15, Intercooler

).

• Battery Removal

• Accelerator Cable Removal (Refer to GROUP 17, Accel-

erator Cable and Pedal

• Rocker Cover Centre Cover Removal (Refer to

• Radiator Assembly Removal (Refer to GROUP 14, Radia-

).

• Front Axle Crossmember Bar Removal (Refer to GROUP

32, Engine Roll Stopper and Centermember

• Front Exhaust Pipe Removal (Refer to GROUP 15,

Exhaust Pipe and Main Muffler

• Starter Assembly Removal (Refer to GROUP 16, Starter

Motor Assembly

).

• Valve Timing Belt Removal (Refer to

).

Post-installation Operation

• Valve Timing Belt Installation (Refer to

).

• Starter Assembly Installation (Refer to GROUP 16, Starter

Motor Assembly

).

• Front Exhaust Pipe Installation (Refer to GROUP 15,

Exhaust Pipe and Main Muffler

• Front Axle Crossmember Bar Installation (Refer to

GROUP 32, Engine Roll Stopper and Centermember

).

• Radiator Assembly Installation (Refer to GROUP 14,

Radiator

).

• Rocker Cover Centre Cover Installation (Refer to

• Accelerator Cable Installation (Refer to GROUP 17,

Accelerator Cable and Pedal

• Battery Installation

• Air Hose E, Air Pipe C and Air Hose D Installation (Refer

to GROUP 15, Intercooler

).

• Air Cleaner Assembly Installation (Refer to GROUP 15,

Air Cleaner

).

• Strut Tower Bar Installation (Refer to GROUP 42, Strut

Tower Bar

• Engine Oil Refilling (Refer to GROUP 12, On-vehicle

Service

− Engine Oil Replacement

).

• Engine Coolant Refilling (Refer to GROUP 14, On-vehicle

Service

− Engine Coolant Replacement

• Drive Belt Tension Check (Refer to

• Side Cover Installation

• Under Cover Installation (Refer to GROUP 51, Front

).

• Accelerator Cable Adjustment (Refer to GROUP 17,

On-vehicle Service

− Accelerator Cable Check and

Adjustment

).

• Fuel Leak Check

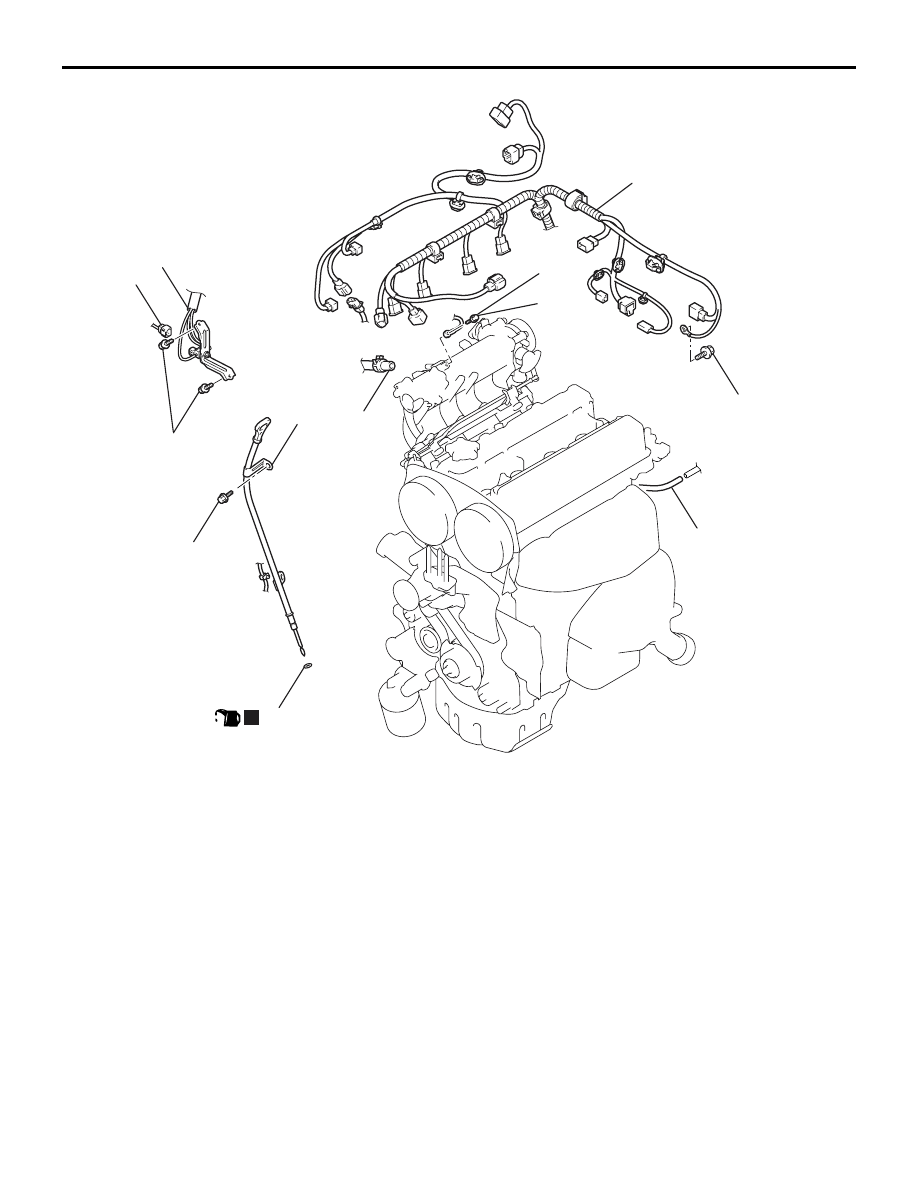

AC310567

5.0 ± 1.0 N·m

AB

13 ± 1 N·m

5.0 ± 1.0 N·m

N

(Engine oil)

9.0 ± 1.0 N·m

7

4

3

6

5

2

8

1

Removal steps

1.

Control wiring harness connection

2.

Earth cable connection

3.

EGR solenoid valve connector

4.

EGR solenoid valve and bracket

assembly

5.

Brake booster vacuum hose

connection

6.

Oil level gauge and guide assembly

7.

O-ring

8.

Purge hose connection

CYLINDER HEAD GASKET

ENGINE MECHANICAL

11A-32

Removal steps (Continued)

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст