Mitsubishi Lancer Evolution IX. Manual — part 620

TRANSMISSION ASSEMBLY

MANUAL TRANSMISSION (FF)

22A-163

TRANSMISSION ASSEMBLY

REMOVAL AND INSTALLATION

M1221002700590

CAUTION

• If the Brembo brake caliper is used, be careful not to hit parts and tools against the caliper when

servicing because the paint of the caliper may delaminate.

• *: Indicates parts which should be initially tightened, and then fully tightened after placing the

vehicle horizontally and loading the full weight of the engine on the vehicle body.

Pre-removal and Post-installation Operation

• Transfer Assembly Removal and Installation (Refer to

).

• Battery and Battery Tray Removal and Installation.

• Strut Tower Bar Removal and Installation (Refer to

GROUP 42

− Strut Tower Bar

).

• Strut assembly mounting bolt temporary Installation

<Pre-removal only>

• Air duct, Air Cleaner Assembly and Air Intake Hose

Removal and Installation (Refer to GROUP 15

− Air

Cleaner ).

• Air By-pass Hose, Air Hose E, Air Pipe C and Air Hose D

Removal and Installation (Refer to GROUP 15

• Starter Assembly Removal and Installation (Refer to

GROUP 16

AC211629AC

1

2

3

4

5

6

7

8

18 ± 3 N·m

18 ± 3 N·m

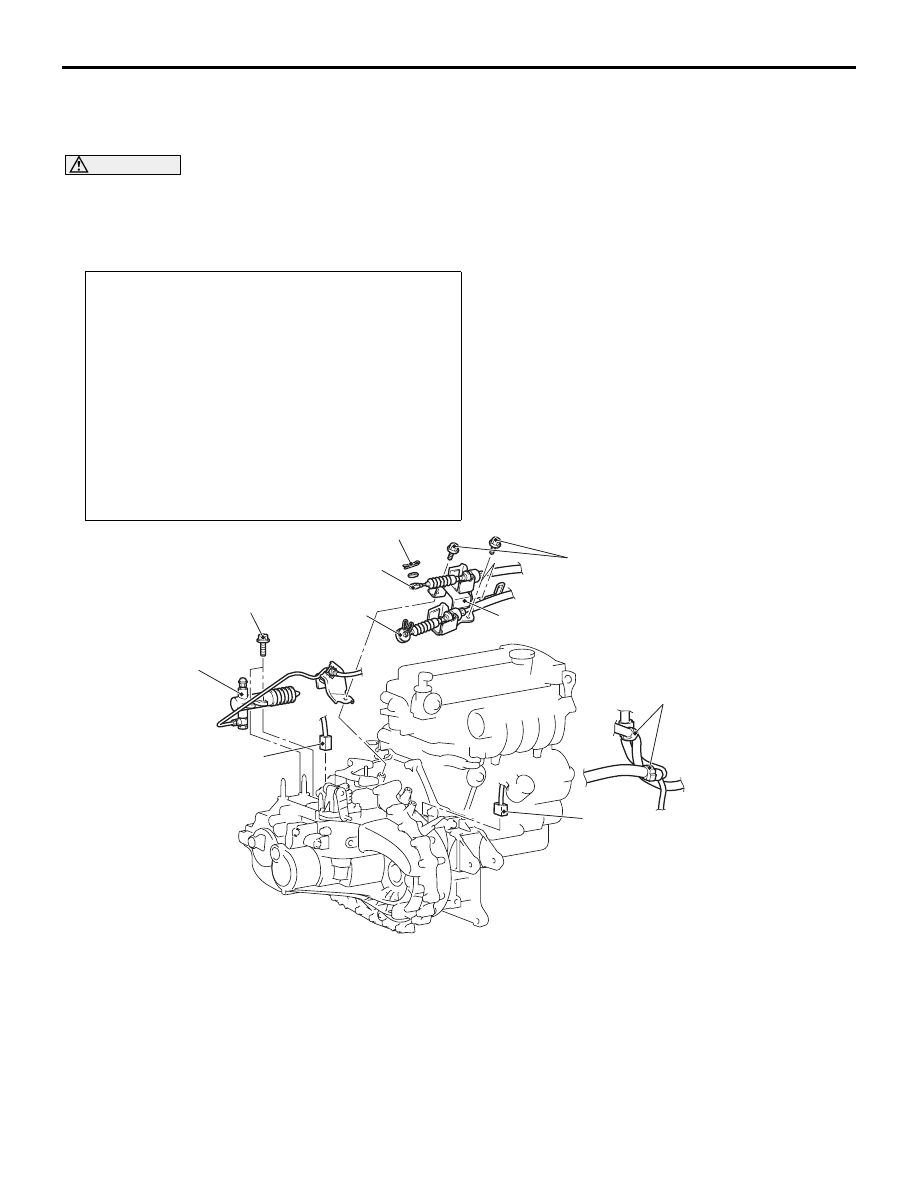

Removal steps

1.

Main harness clamp connection

2.

Back-up lamp switch connector

connection

3.

Vehicle speed sensor connector

connection

4.

Snap pin

5.

Shift cable connection

<<

A

>>

6.

Select cable connection

7.

Control cable assembly and

bracket

8.

Clutch release cylinder and clutch

oil pipe

Removal steps (Continued)

TRANSMISSION ASSEMBLY

MANUAL TRANSMISSION (FF)

22A-164

REMOVAL SERVICE POINTS

<<A>> SELECT CABLE CONNECTION

REMOVAL

Set the clip of the select cable as shown in figure 1

and 2, and disconnect the select cable.

<<B>> TRANSMISSION MOUNTING

INSULATOR ASSEMBLY REMOVAL

Jack up and support the engine and transmission

assembly, and remove the transmission mounting

insulator assembly.

AC211628AC

11

12

12

13

16

14

15

15

9

10

9

9

10

82 ± 7 N·m*

47 ± 7 N·m*

26 ± 5 N·m

9.0 ± 1.0 N·m

48 ± 5 N·m

48 ± 5 N·m

48 ± 5 N·m

48 ± 5 N·m

8.8 ± 1.0 N·m

48 ± 5 N·m

Removal steps

9.

Transmission assembly upper part

coupling bolt

10. Harness clump

<<

B

>>

11. Transmission mounting insulator

assembly

>>

A

<< 12. Transmission mounting insulator

stopper

13. Transmission mounting insulator

<<

C

>>

•

Engine assembly supporting

•

Raise the vehicle.

14. Bell housing cover

<<

D

>>

•

Clutch release bearing separation

15. Transmission assembly lower part

coupling bolt

16. Transmission assembly

Removal steps (Continued)

AC211243

AC

1

2

Select cable

AC211722

AC

Engine and transmission assembly

Garage jack

TRANSMISSION ASSEMBLY

MANUAL TRANSMISSION (FF)

22A-165

<<C>> ENGINE ASSEMBLY SUPPORTING

1. <Engine hanger (special tool MB991895) is used>

(1) Set special tool MB991895 to the strut

mounting nuts and the radiator support upper

insulator mounting bolts, which are located in

the engine compartment, as shown.

(2) Set special tool MB991454 to hold the engine

and transmission assembly.

2. <Engine hanger (special tool MB991928) is used>

(1) Assemble the engine hanger (special tool

MB991928). Set the following parts to the

base hanger.

• Slide bracket (HI)

• Foot (standard) (MB991932)

• Joint (90) (MB991930)

(2) Set the engine hanger (special tool

MB991928) to the strut mounting nuts and the

radiator support upper insulator mounting

bolts, which are located in the engine

compartment, as shown.

NOTE: Adjust the engine hanger balance by

sliding the slide bracket (HI).

(3) Set special tool MB991454 to hold the engine

and transmission assembly.

<<D>> CLUTCH RELEASE BEARING

SEPARATION

1. Remove the service hole cover of the clutch

housing.

CAUTION

• Do not insert the flat-tipped driver before

pressing the release fork towards direction A.

• Do not insert the flat-tipped driver between

the wedge collar and the wave spring.

2. Insert the flat-tipped driver between the release

bearing and wedge collar while slightly pressing

the release fork towards direction A by hand.

CAUTION

If the driver cannot be turned slightly (the release

bearing cannot be disconnected), remove the

flat-tipped driver and press the release fork sev-

eral times towards direction A, then retry again. If

the release bearing is pried off forcibly, it may be

damaged.

3. Disconnect the release bearing with the wedge

collar while prying off slightly by the flat-tipped

driver (turn the driver's handle 90

°).

NOTE: When the release bearing is discon-

nected, the release fork is moved to the direction

B fully by the return spring.

AC211734

AC

MB991895

MB991454

AC209516AB

Slide bracket (HI)

Joint (90)

(MB991930)

Foot (Standard)

(MB991932)

Front side

AC211735

AC

Slide bracket (HI)

MB991928

MB991934

MB991932

MB991930

MB991932

MB991527

MB991454

AC211679AD

A

B

Release

bearing

Wedge collar

Refer to CAUTION 2.

Service hole

Release fork

TRANSMISSION ASSEMBLY

MANUAL TRANSMISSION (FF)

22A-166

INSTALLATION SERVICE POINT

>>A<< TRANSMISSION MOUNTING INSU-

LATOR STOPPER INSTALLATION

Install so that the arrow on the transmission mount-

ing insulator stopper faces the top of the vehicle.

AC310943 AC

Transmission

mounting

insulator

stopper

Engine side

Transmission

mounting

insulator

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст