Mitsubishi Lancer Evolution IX. Manual — part 477

TROUBLESHOOTING

MULTIPORT FUEL INJECTION (MPI)

13A-383

CHECK CHART FOR RESISTANCE AND

CONTINUITY BETWEEN TERMINALS

1. Turn the ignition switch to "LOCK" (OFF) position.

2. Disconnect the engine-ECU connector.

3. Measure the resistance and check for continuity

between the terminals of the engine-ECU

harness-side connector while referring to the

check chart.

NOTE:

.

1. When measuring resistance and checking

continuity, a harness for checking contact pin

pressure should be used instead of inserting a

test probe.

2. Checking need not be carried out in the order

given in the chart.

CAUTION

If the terminals that should be checked are mis-

taken, or if connector terminals are not correctly

shorted to earth, damage may be caused to the

vehicle wiring, sensors, engine-ECU and/or ohm-

meter. Be careful to prevent this!

4. If the ohmmeter shows any deviation from the

standard value, check the corresponding sensor,

actuator and related electrical wiring, and the

repair or replace.

5. After repair or replacement, recheck with the

ohmmeter to confirm that the repair or

replacement has corrected the problem.

83

A/C switch

Engine: Idle speed

Turn the A/C switch

OFF

0.5 V or less

Turn the A/C switch

ON (A/C compressor

is operating)

System voltage

96

Transmission oil

temperature sensor

Ignition switch: "ON"

Transmission oil

temperature is

−20°C

3.9

− 4.5 V

Transmission oil

temperature is 0

°C

3.2

− 3.8 V

Transmission oil

temperature is 20

°C

2.3

− 2.9 V

Transmission oil

temperature is 40

°C

1.3

− 1.9 V

Transmission oil

temperature is 60

°C

0.7

− 1.3 V

Transmission oil

temperature is 80

°C

0.3

− 0.9 V

99

Ignition switch-IG

Ignition switch: "ON"

System voltage

Terminal

No.

Check item

Check condition (Engine condition)

Normal condition

TROUBLESHOOTING

MULTIPORT FUEL INJECTION (MPI)

13A-384

Engine-ECU Harness Side Connector Terminal Arrangement

Terminal

No.

Inspection item

Normal condition (Check condition)

1

− 47

No. 1 injector

2

− 3 Ω (At 20°C)

9

− 47

No. 2 injector

24

− 47

No. 3 injector

2

− 47

No. 4 injector

47

− 48

Fuel pressure control solenoid valve

28

− 36 Ω (At 20°C)

14

− 47

Stepper motor coil (A1)

26

− 33 Ω (At 20°C)

28

− 47

Stepper motor coil (A2)

15

− 47

Stepper motor coil (B1)

29

− 47

Stepper motor coil (B2)

6

− 47

EGR control solenoid valve

29

− 35 Ω (At 20°C)

16

− 47

Purge control solenoid valve

30

− 34 Ω (At 20°C)

41

− 47

Waste gate solenoid valve

29

− 35 Ω (At 20°C)

3

− 47

Oxygen sensor heater (rear)

11

− 18 Ω (At 20°C)

26

− 47

Oxygen sensor heater (front)

4.5

− 8.0 Ω (At 20°C)

33

− 47

Oil feeder control valve

6.9

− 7.9 Ω (At 20°C)

46

− Body

earth

ECU earth

Continuity (2

Ω or less)

58

− Body

earth

42

− 62

Intake air temperature sensor

13

− 17 kΩ (When intake air temperature is −20°C)

5.3

− 6.7 kΩ (When intake air temperature is 0°C)

2.3

− 3.0 kΩ (When intake air temperature is 20°C)

1.0

− 1.5 kΩ (When intake air temperature is 40°C)

0.56

− 0.76 kΩ (When intake air temperature is 60°C)

0.30

− 0.42 kΩ (When intake air temperature is 80°C)

42

− 44

Engine coolant temperature sensor

14

− 17 kΩ (When coolant temperature is −20°C)

5.1

− 6.5 kΩ (When coolant temperature is 0°C)

2.1

− 2.7 kΩ (When coolant temperature is 20°C)

0.9

− 1.3 kΩ (When coolant temperature is 40°C)

0.48

− 0.68 kΩ (When coolant temperature is 60°C)

0.26

− 0.36 kΩ (When coolant temperature is 80°C)

TROUBLESHOOTING

MULTIPORT FUEL INJECTION (MPI)

13A-385

INSPECTION PROCEDURE USING

OSCILLOSCOPE

M1131154501483

The output signals of the sensors and the conditions

of the actuation signals of the actuators can be

inspected visually by observing the waveforms on

the oscilloscope.

AIR FLOW SENSOR (AFS)

Measurement Method

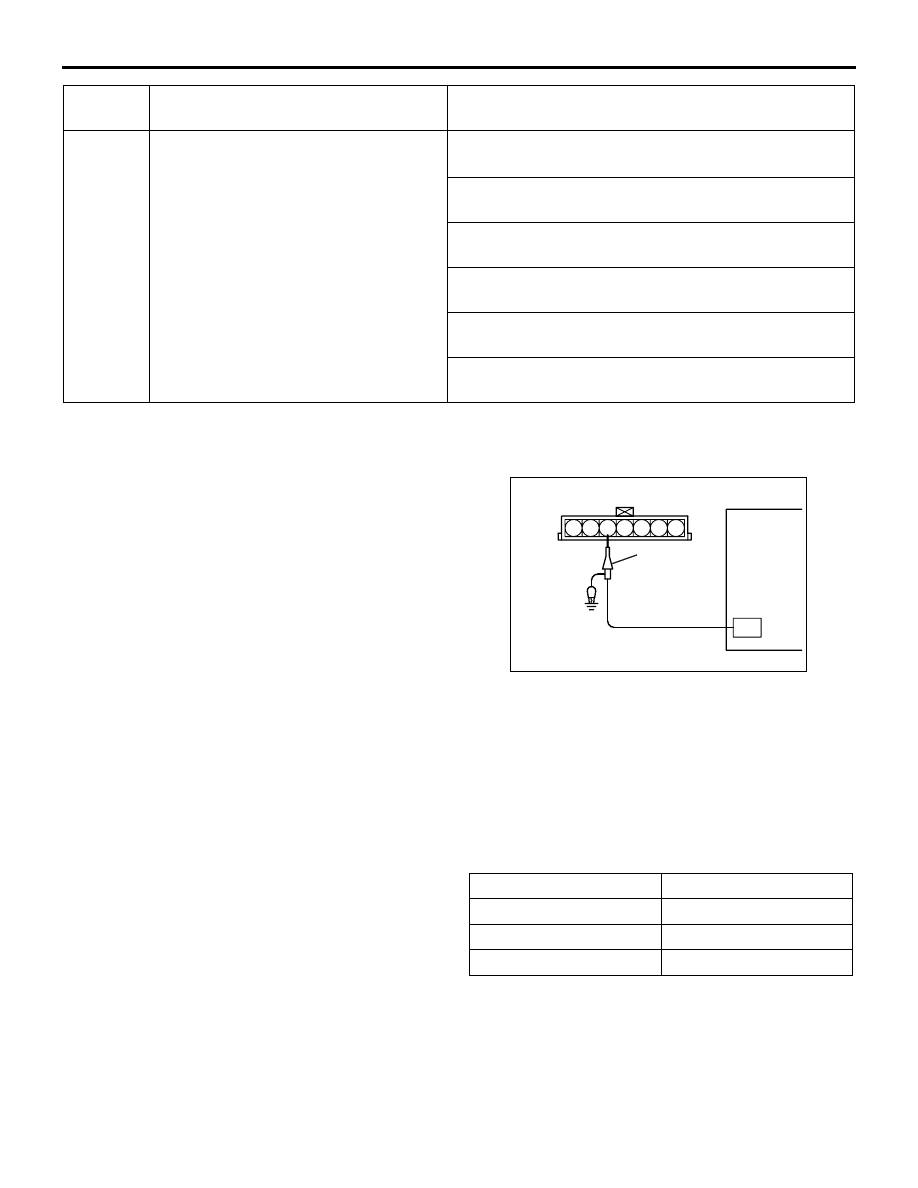

1. Disconnect the air flow sensor connector, and

connect the special tool test harness (MB991709)

in between (All terminals should be connected).

2. Connect the oscilloscope special patterns pickup

to air flow sensor connector terminal No. 3.

Alternate Method (Test harness not available)

1. Connect the oscilloscope special patterns pickup

to engine-ECU terminal No. 61.

Standard Wave Pattern

Observation conditions

42

− 96

Transmission oil temperature sensor

14

− 17 kΩ (When transmission oil temperature is

−20°C)

5.1

− 6.5 kΩ (When transmission oil temperature is

0

°C)

2.1

− 2.7 kΩ (When transmission oil temperature is

20

°C)

0.9

− 1.3 kΩ (When transmission oil temperature is

40

°C)

0.48

− 0.68 kΩ (When transmission oil temperature is

60

°C)

0.26

− 0.36 kΩ (When transmission oil temperature is

80

°C)

Terminal

No.

Inspection item

Normal condition (Check condition)

AK000786

4 5 6

1 2 3

7

AE

Special

patterns

pickup

Oscilloscope

Function

Special patterns

Pattern height

Low

Pattern selector

Display

Engine speed

Idle

TROUBLESHOOTING

MULTIPORT FUEL INJECTION (MPI)

13A-386

Wave Pattern Observation Points

Check that cycle time T becomes shorter and the fre-

quency increases when the engine speed is

increased.

Examples of Abnormal Wave Patterns

• Example 1

Cause of problem

Sensor interface malfunction

Wave pattern characteristics

Rectangular wave pattern is output even when

the engine is not started.

• Example 2

Cause of problem

Damaged rectifier or vortex generation column

Wave pattern characteristics

Unstable wave pattern with non-uniform fre-

quency. However, when an ignition leak

occurs during acceleration, the wave pattern

will be distorted temporarily, even if the air

flow sensor is normal.

AK202334

(V)

10

T

T1

T2

0

Time

The time (cycle time) T is reduced when

the amount of intake air increases.

Standard wave pattern

Times T1 and T2 are equal.

AC

AK202335

(V)

10

T

0

Time

Observation conditions (from conditions above engine is increased by racing.)

AB

AKX01597

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст