Mitsubishi Lancer Evolution IX. Manual — part 563

COMPRESSOR ASSEMBLY AND TENSION PULLEY

HEATER, AIR CONDITIONER AND VENTILATION

55-125

REASSEMBLY SERVICE POINTS

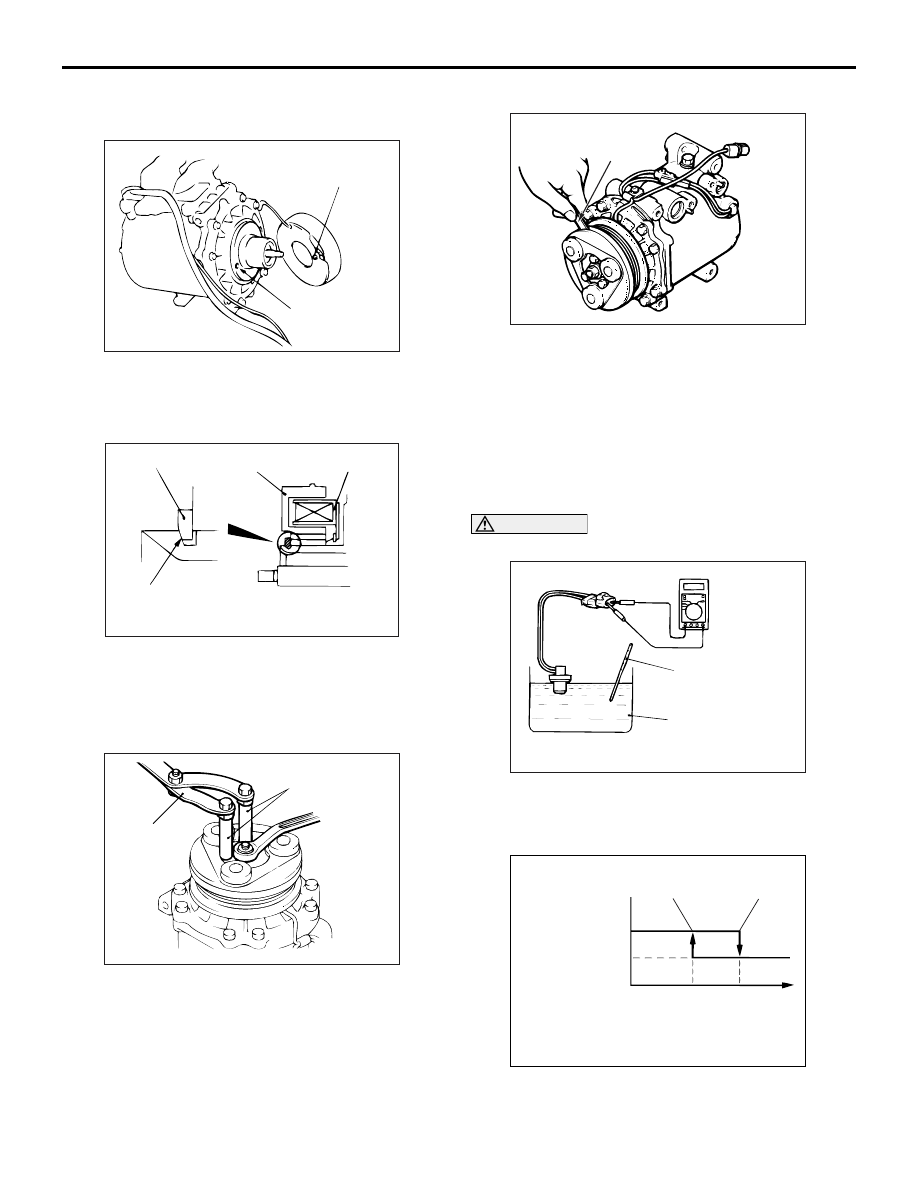

>>A<< FIELD CORE

Line up the pin hole on the compressor unit with the

field core projection and attach.

>>B<< SNAP RING INSTALLATION

Using snap ring pliers, fit the snap ring so that the

snap ring’s tapered part is on the outside.

>>C<< SELF-LOCKING NUT

INSTALLATION

Use the special tools to install the self-locking nut.

• Special spanner (MB991367)

• Pin (MB991386)

>>D<< AIR GAP ADJUSTMENT

Apply voltage from the battery to the magnetic clutch

and check that the clutch air gap is inside the stand-

ard value. If outside the standard value, use a shim

to adjust the gap.

Standard value: 0.3

− 0.5 mm

INSPECTION

M1552014301340

REFRIGERANT TEMPERATURE SWITCH

CAUTION

Do not heat more than necessary.

1. Dip the metal part of the cooling temperature

switch into engine oil and increase the oil

temperature using a gas burner or similar.

2. When the oil temperature reaches the standard

value, check that voltage is supplied between the

terminals.

AC100634 AB

Field core projection

Compressor

unit pin hole

AC001412

Snap ring

Rotor

Clutch coil

Tapered part

AB

AC100633AB

MB991386

MB991367

AC100637AB

Thickness

gauge

AC100787

Thermometer

Engine oil

AB

AC100810

Continuity

No continuity

Oil temperature

AD

120˚C

150˚C

CONDENSER AND CONDENSER FAN MOTOR

HEATER, AIR CONDITIONER AND VENTILATION

55-126

Standard value:

NOTE: When the oil temperature is 150

°

C or

more and there is no continuity, the resistance will

not be 2

Ω

or lower until the oil temperature

reduces to 120

°

C or less.

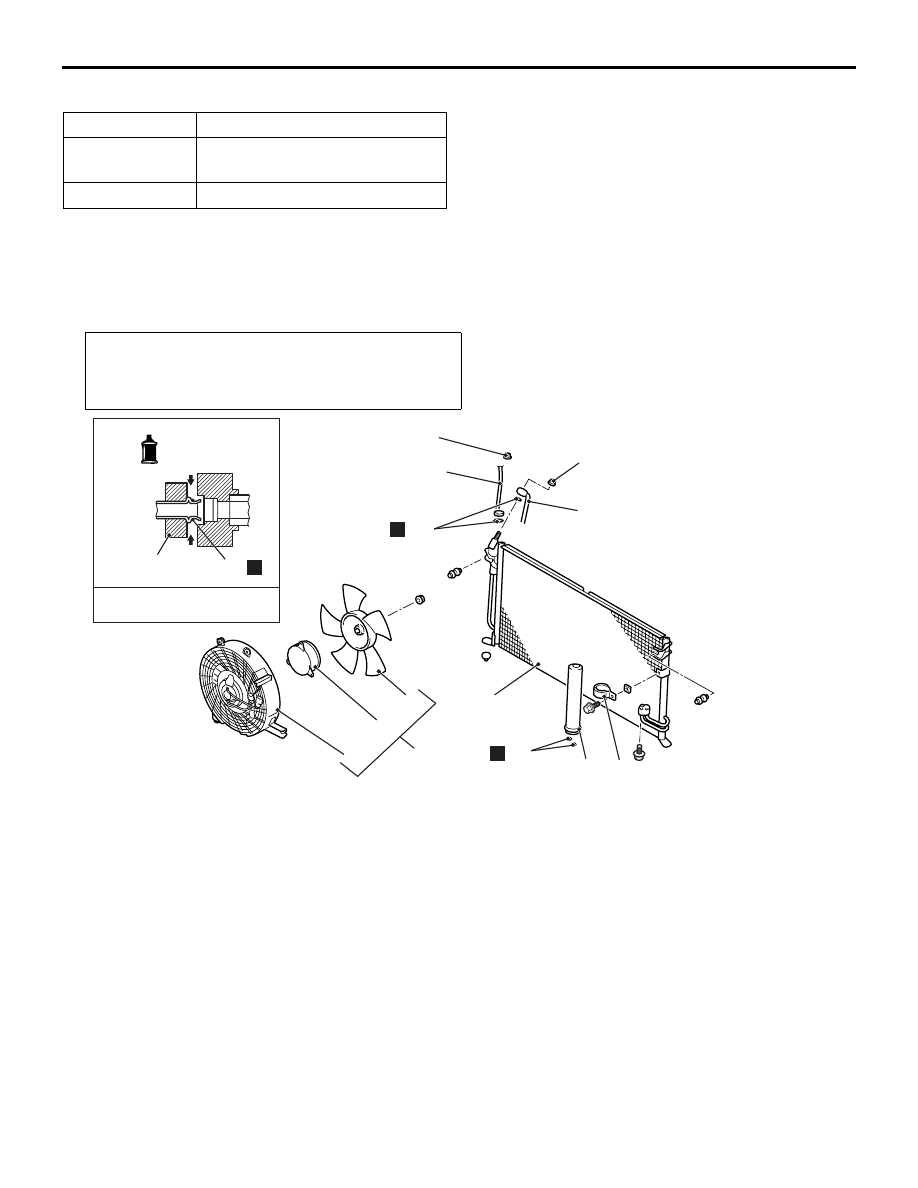

CONDENSER AND CONDENSER FAN MOTOR

REMOVAL AND INSTALLATION

M1552006700674

Item

Temperature

Less than 2

ohms

Slightly below 150

°C

No continuity

150

°C or more

Pre-removal and Post-installation Operation

• Refrigerant Draining and Refilling (Refer to

• Front Bumper Removal and Installation (Refer to GROUP

).

AC211410

N

2

3

4

1

10

7

9

8

N

10

6

5

AC

12 ± 2 N·m

-Pipe coupling

A/C compressor oil:

SUN PAG 56

5, 6

N

10

4.9 ± 0.9 N·m

Fan shroud assembly removal

steps

<<

A

>>

1.

Fan shroud assembly

2.

Fan

3.

Fan motor

4.

Fan shroud

Condenser removal steps

<<

B

>>

5.

Flexible discharge hose connection

<<

B

>>

6.

Liquid pipe A connection

>>

A

7.

Condenser

8.

Clamp

9.

Receiver

10. O ring

CONDENSER AND CONDENSER FAN MOTOR

HEATER, AIR CONDITIONER AND VENTILATION

55-127

REMOVAL SERVICE POINT

<<A>> FAN SHROUD ASSEMBLY

REMOVAL

1. Remove the intercooler mounting bolts/nuts and

pull the intercooler forward.

2. Move the fan motor/shroud assembly upward for

removal.

<<B>> FLEXIBLE DISCHARGE

HOSE/LIQUID PIPE A DISCONNECTION

CAUTION

As the compressor oil and receiver are highly

moisture absorbent, use a non-porous material

to plug the hose and nipples.

To prevent the entry of dust or other foreign material,

plug the dismantled hose and condenser assembly

nipples.

INSTALLATION SERVICE POINT

>>A<< CONDENSER INSTALLATION

When replacing the condenser, refill it with a speci-

fied amount of compressor oil and install it to the

vehicle.

Compressor oil: SUN PAG 56

Quantity: 15 cm

3

(0.5 floz)

INSPECTION

M1552014301351

CONDENSER FAN MOTOR CHECK

AC211409AC

BATTERY CONNECTION

CONDENSER

FAN MOTOR

OPERATION

• Connect connector A-34

terminal 2 to the positive

battery terminal

• Connect connector A-35

terminal 2 to the negative

battery terminal

Condenser fan

motor LO

operation

• Connect connector A-34

terminal 1 to the positive

battery terminal

• Connect connector A-35

terminal 2 to the negative

battery terminal

Condenser fan

motor HI

operation

AC211409

2

1

1 2

AC

A-34

A-35

REFRIGERANT LINE

HEATER, AIR CONDITIONER AND VENTILATION

55-128

REFRIGERANT LINE

REMOVAL AND INSTALLATION <LHD>

M1552006401063

REMOVAL SERVICE POINT

<<A>> HOSE/PIPE DISCONNECTION

CAUTION

As the compressor oil and receiver are highly

moisture absorbent, use a non-porous material

to plug the hose and nipples.

To prevent the entry of other foreign bodies, plug the

condenser, compressor, and expansion valve nip-

ples.

Pre-removal and Post-installation Operation

• Refrigerant Draining and Refilling (Refer to

• Air Cleaner Removal and Installation (Refer to GROUP

15, Air cleaner

• Radiator Grille Removal and Installation (Refer to

GROUP 51, Front bumper

AC304553

1

2

3

4

5

6

7

8

N

N

N

N

N

8

8

8

8

High-pressure

side service valve

Low-pressure side

service valve

12 ± 2 N·m

13 ± 1 N·m

4.9 ± 0.9 N·m

25 ± 4 N·m

AE

6

A/C compressor oil: SUN PAG 56

-Pipe coupling

O-ring

O-ring

1, 2, 3,

5, 6

12 ± 2 N·m

Removal steps

<<

A

>>

1.

Dual pressure switch

<<

A

>>

2.

Liquid pipe A

<<

A

>>

3.

Flexible discharge hose

4.

Expansion valve cover

<<

A

>>

>>

A

<<

5.

Flexible suction hose

<<

A

>>

6.

Liquid pipe B

7.

Expansion valve cover

8.

O-ring

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст