Mitsubishi Lancer Evolution IX. Manual — part 561

SENSORS

HEATER, AIR CONDITIONER AND VENTILATION

55-117

REMOVAL SERVICE POINT

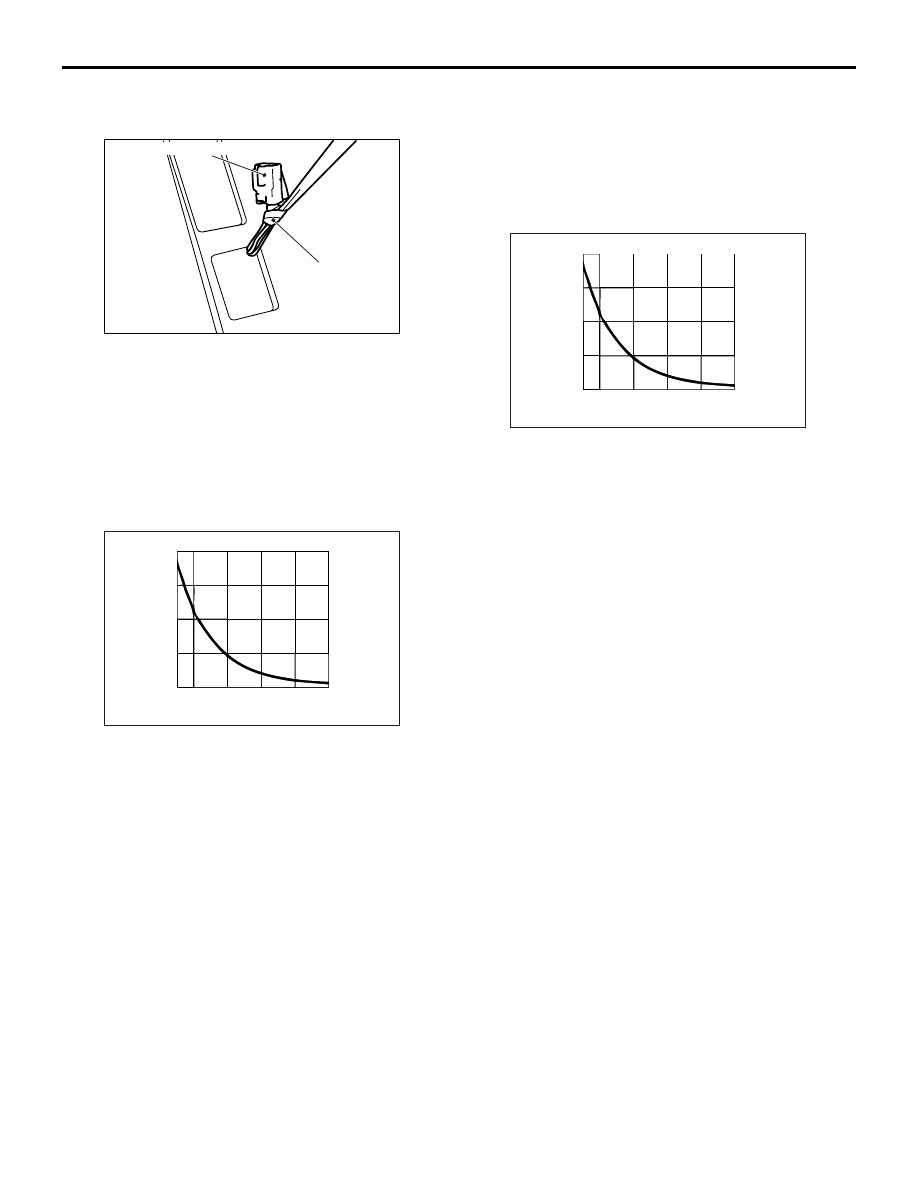

<<A>> PHOTO SENSOR REMOVAL

1. Remove the photo sensor together with the

defroster nozzle.

2. Suspend the connector with a string to avoid the

connector drops behind the instrument panel.

INSPECTION

M1552014302150

INTERIOR TEMPERATURE SENSOR

CHECK

Check to see that the resistance shown in the graph

is almost satisfied when measuring the resistance

between the terminals under two or more different

temperature conditions.

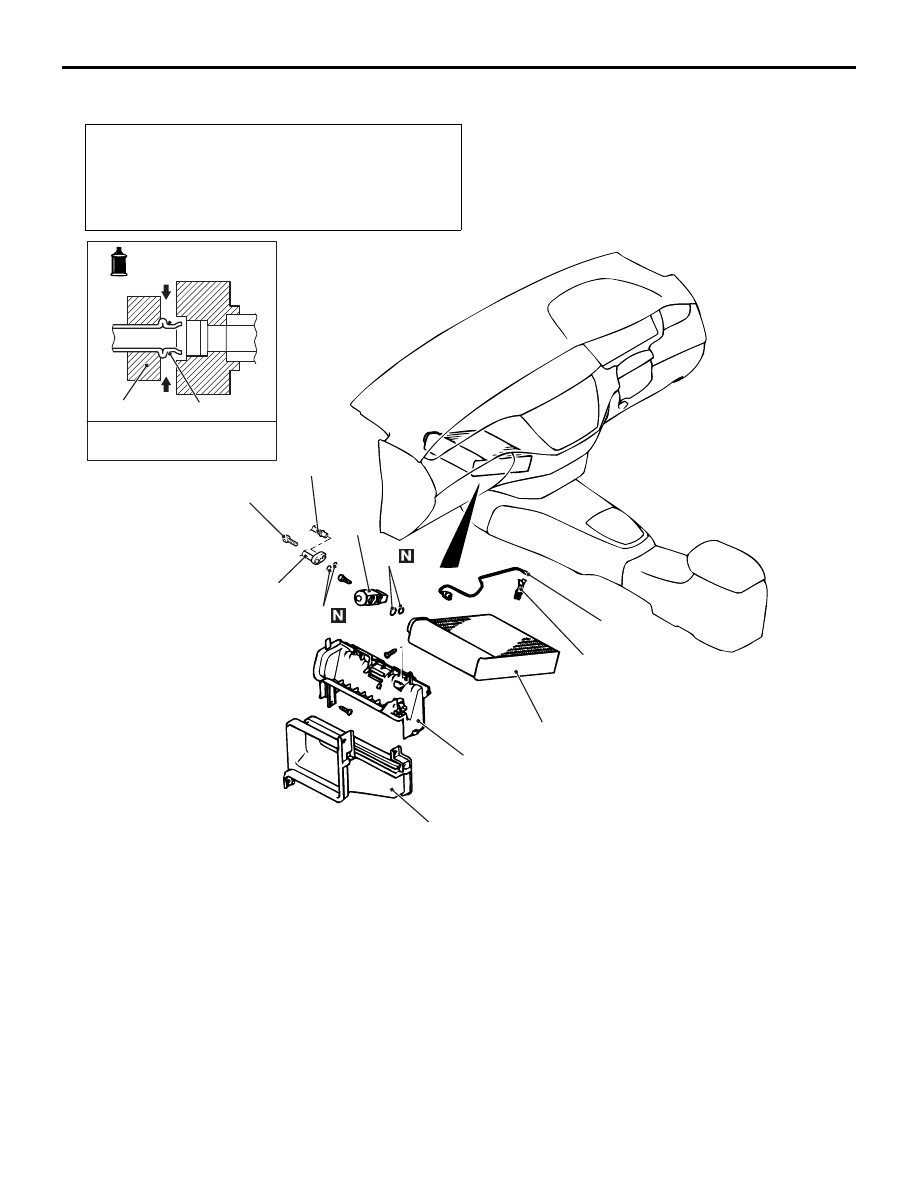

HEATER WATER TEMPERATURE SEN-

SOR CHECK

Check to see that the resistance shown in the graph

is almost satisfied when measuring the resistance

between the terminals under two or more different

temperature conditions.

PHOTO SENSOR CHECK

Check that the blower rotation comes down if the

photo sensor is covered with hands, when the auto-

matic A/C is operating (in summer sunbeam). If not

the rotation comes down, replace the photo sensor.

AC504803AB

String

Photo sensor connector

AC503134

20

15

10

5

0

-10 0

20

40

60

80

AB

Resistance

(k )

Temperature (˚C)

AC503134

20

15

10

5

0

-10 0

20

40

60

80

AB

Resistance

(k )

Temperature (˚C)

EVAPORATOR ASSEMBLY

HEATER, AIR CONDITIONER AND VENTILATION

55-118

EVAPORATOR ASSEMBLY

REMOVAL AND INSTALLATION <LHD>

M1552003600496

REMOVAL SERVICE POINT

<<A>> FLEXIBLE SUCTION HOSE/LIQUID

PIPE B DISCONNECTION

CAUTION

As the compressor oil and receiver are highly

moisture absorbent, use a non-porous material

to plug the hose and nipples.

To prevent the entry of dust or other foreign bodies,

plug the dismantled hose and the nipples of the

expansion valves.

Pre-removal and Post-installation Operation

• Refrigerant draining and Refilling (Refer to Charging and

discharging

• Air cleaner and air cleaner air flow sensor assembly

Removal and Installation (Refer to GROUP 15, Air

cleaner

).

AC504937

1, 2, 4, 7

A/C compressor oil:

SUN PAG 56

O-ring

-Pipe coupling

2

10

1

3

4

7

6

5

9

8

8

12 ± 2 N·m

AB

Removal steps

<<

A

>>

1.

Flexible suction hose connection

<<

A

>>

2.

Liquid pipe B connection

3.

Expansion valve

4.

Joint

•

Glove box (Refer to GROUP 52A,

Instrument Panel

•

Engine-ECU (Refer to GROUP

13A, Engine-ECU

).

5.

Joint duct

•

Foot duct (RH), Rear heater duct A

(RH) upper side (Refer to

6.

Evaporator cover

7.

Evaporator

8.

O-ring

9.

Air thermo sensor clip

10. Air thermo sensor

Removal steps (Continued)

EVAPORATOR ASSEMBLY

HEATER, AIR CONDITIONER AND VENTILATION

55-119

REMOVAL AND INSTALLATION <RHD>

M1552003600504

Pre-removal and Post-installation Operation

• Refrigerant draining and Refilling (Refer to Charging and

discharging

• Air cleaner and air cleaner air flow sensor assembly

Removal and Installation (Refer to GROUP 15, Air

cleaner

).

AC304886AC

12 ± 2 N·m

7

7

2

1

9

8

6

5

4

3

1, 2, 6

A/C compressor oil:

SUN PAG 56

O-ring

-Pipe coupling

Removal steps

<<

A

>>

1.

Flexible suction hose connection

<<

A

>>

2.

Liquid pipe B connection

3.

Expansion valve

•

Glove box (Refer to GROUP 52A,

Instrument Panel

•

Engine-ECU (Refer to GROUP

13A, Engine-ECU

).

4.

Joint duct

•

Foot duct (RH), Rear heater duct A

(RH) upper side (Refer to

).

5.

Evaporator cover

<<

B

>>

6.

Evaporator

7.

O-ring

8.

Air thermo sensor clip

9.

Air thermo sensor

Removal steps (Continued)

EVAPORATOR ASSEMBLY

HEATER, AIR CONDITIONER AND VENTILATION

55-120

REMOVAL SERVICE POINT

<<A>> FLEXIBLE SUCTION HOSE/LIQUID

PIPE B DISCONNECTION

CAUTION

As the compressor oil and receiver are highly

moisture absorbent, use a non-porous material

to plug the hose and nipples.

To prevent the entry of dust or other foreign bodies,

plug the dismantled hose and the nipples of the

expansion valves.

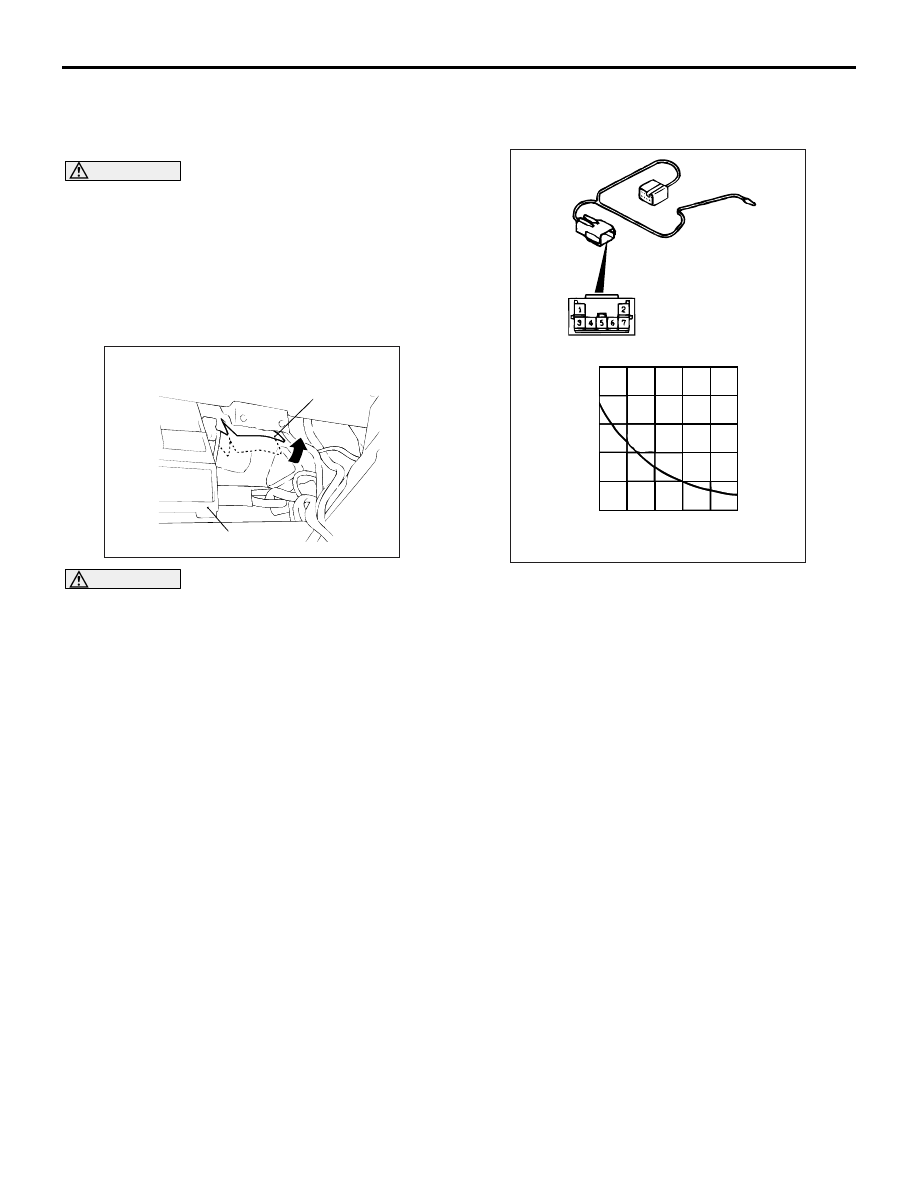

<<B>> EVAPORATOR REMOVAL

CAUTION

Do not cut the upper side of the pad.

1. When removing the evaporator, cut and fold back

the dashboard pad as in the diagram (The thick-

ness of the pad interferes with the removal of the

evaporator).

2. Remove the evaporator.

INSPECTION

M1552014302161

AIR THERMO SENSOR INSPECTION

Measure the resistance between connector terminals

4 and 5 under at least two different temperatures.

The resistance values should generally match those

in the graph.

NOTE: The temperature at the check should not

exceed the range in the graph.

AC305312 AB

Dashboard pad

Blower unit

AC103376

Resistance

Temperature (˚C)

-10

0

10

20 30 40

(k )

0

5

10

15

20

25

AB

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст