Mitsubishi Lancer Evolution IX. Manual — part 651

SEAT BELTS WITH PRE-TENSIONER

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

52B-117

SEAT BELTS WITH PRE-TENSIONER

REMOVAL AND INSTALLATION

M1524004100390

WARNING

•

Never attempt to disassemble or repair the seat belt pre-tensioner. If faulty, replace it.

•

Be extremely careful when handling the seat with pre-tensioner. Do not subject it to

shocks, drop it, bring it close to strong magnets or allow contact with water, grease or oil.

Always replace it with a new part if any dents, cracks or deformation is found.

•

Do not place anything on top of the seat belt pre-tensioner.

•

Do not expose the seat belt with pre-tensioner to temperatures over 90

°

C.

•

After operating the seat belt pre-tensioner, replace the seat belt with pre-tensioner with a

new part.

•

Gloves and protective goggles should be worn when handling a seat belt pre-tensioner

once it has been used.

•

If disposing of a seat belt with pre-tensioner which has not yet been operated, its seat belt

pre-tensioner should be operated first before disposal (Refer to

).

Pre-removal Operation

• Turn the ignition switch to the "LOCK" (OFF) position.

• Disconnect the Negative Battery Terminal.

AC101710 AC

1

2

3

4

5

6

44 ± 10 N·m

44 ± 10 N·m

SEAT BELTS WITH PRE-TENSIONER

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

52B-118

NOTE: The figure shows the seat belt with pre-ten-

sioner (RH).

REMOVAL SERVICE POINTS

<<A>>PRE-TENSIONER CONNECTOR

DISCONNECTION

1. Use a flat-tipped screwdriver to pull out forward

and unlock the locking button of the harness-side

connector.

2. Disconnect the pre-tensioner connector.

INSTALLATION SERVICE POINTS

>>A<< PRE-INSTALLATION INSPECTION

WARNING

When discarding the seat belt with pre-ten-

sioner, operate the pre-tensioner as speci-

fied in the service procedure (Refer to

1. Even new seat belt with pre-tensioner require

inspection before installation.

2. Connect the negative battery cable.

CAUTION

To prevent damage to M.U.T.-II/III, always turn the

ignition, switch to the “LOCK” (OFF) position

before connecting or disconnecting M.U.T.-II/III.

3. Connect M.U.T.-II/III to the diagnosis connector.

Removal steps

1. Sash guide cover

2. Seat belt shoulder anchor bolt

3. Seat belt lower anchor bolt

•

Centre pillar trim, lower (Refer to

GROUP 52A

<<

A

>>

4. Pre-tensioner connector connection

5. Bracket

6. Seat belt with pre-tensioner

Installation steps

>>

A

<< • Pre-installation inspection

6. Seat belt with pre-tensioner

5. Bracket

>>

B

<< 4. Pre-tensioner connector connection

•

Centre pillar trim, lower (Refer to

GROUP 52A

3. Seat belt lower anchor bolt

2. Seat belt shoulder anchor bolt

1. Sash guide cover

•

Negative battery cable connection

>>

C

<< • Post-installation inspection

AC300147 AS

Pre-tensioner

connector

Flat-tipped

screwdriver

Locking button

Harness side connector

AC304777

Steering shaft

AB

MB991502

<Using the M.U.T.-II>

AC211686

MB991911

16-PIN

MB991827

MB991824

AE

<Using the M.U.T.-III>

SEAT BELTS WITH PRE-TENSIONER

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

52B-119

4. Turn the ignition switch to the ON position.

5. Check diagnosis codes using M.U.T.-II/III to

ensure that the SRS operates properly.

Confirm that the diagnosis codes other than 26

and 28 are not set.

6. Turn the ignition switch to "LOCK" (OFF) position.

DANGER

Wait at least 60 seconds after the disconnec-

tion of the battery cable before any further

job (Refer to

7. Disconnect the negative battery cable and

insulate with tape.

>>B<< PRE-TENSIONER CONNECTOR

CONNECTION

Connect the pretensioner connector then securely

lock the locking button of the harness-side connec-

tor.

>> C<< POST-INSTALLATION

INSPECTION

1. Connect the negative battery cable.

2. Turn the ignition switch to "ON" position.

3. Does the SRS warning lamp illuminate for about 7

seconds and then goes out?

4. If no, refer to troubleshooting (Refer to

).

INSPECTION

M1524004200245

WARNING

•

If any component damage is found during

the following inspection, replace the seat

belt with pre-tensioner with a new one.

Dispose of the old one according to the

specified procedure (Refer to

).

•

Never attempt to measure the circuit

resistance of the seat belt pre-tensioner

even if you are using the specified tester.

If the circuit resistance is measured with a

tester, accidental seat belt pre-tensioner

operation will result in serious personal

injury.

1. Check the seat belt pre-tensioner deployment

section for dents and deformation.

2. Check the harness and connector for damage and

the terminals for deformation.

AC311044

SRS warning lamp

AB

AIR BAG MODULE AND SEAT BELT PRE-TENSIONER DISPOSAL PROCEDURES

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

52B-120

AIR BAG MODULE AND SEAT BELT PRE-TENSIONER

DISPOSAL PROCEDURES

M1524001200989

Before disposing of an air bag or a vehicle equipped

with an air bag, follow the procedures below to

deploy the air bag.

UNDEPLOYED AIR BAG MODULE DIS-

POSAL

WARNING

•

If the vehicle is to be scrapped or other-

wise disposed of, deploy the air bags and

operate the seat belt pre-tensioner inside

the vehicle. If the vehicle will continue to

be used and only the air bag modules and

seat belt pre-tensioner are to be disposed

of, deploy the air bags and operate the

seat belt pre-tensioner outside the vehi-

cle.

•

Since a large amount of smoke is pro-

duced when the air bag is deployed and

the seat belt pre-tensioner is operated,

avoid residential areas whenever possi-

ble.

•

Since there is loud noise when the air

bags are deployed and when the seat belt

pre-tensioner are operated, avoid residen-

tial areas whenever possible. If anyone is

nearby, give warning of the impending

noise.

•

Suitable ear protection should be worn by

personnel performing these procedures

or by people in the immediate area.

DEPLOYMENT INSIDE THE VEHICLE

(WHEN DISPOSING OF A VEHICLE)

<DRIVER'S AIR BAG MODULE>

1. Move the vehicle to an isolated spot.

DANGER

Wait at least 60 seconds after the disconnec-

tion of the battery cable before any further

job (Refer to

2. Disconnect the negative and positive battery

cables from the battery terminals, and then

remove the battery from the vehicle.

3. Remove the column cover lower (Refer to

GROUP 37

− Steering shaft

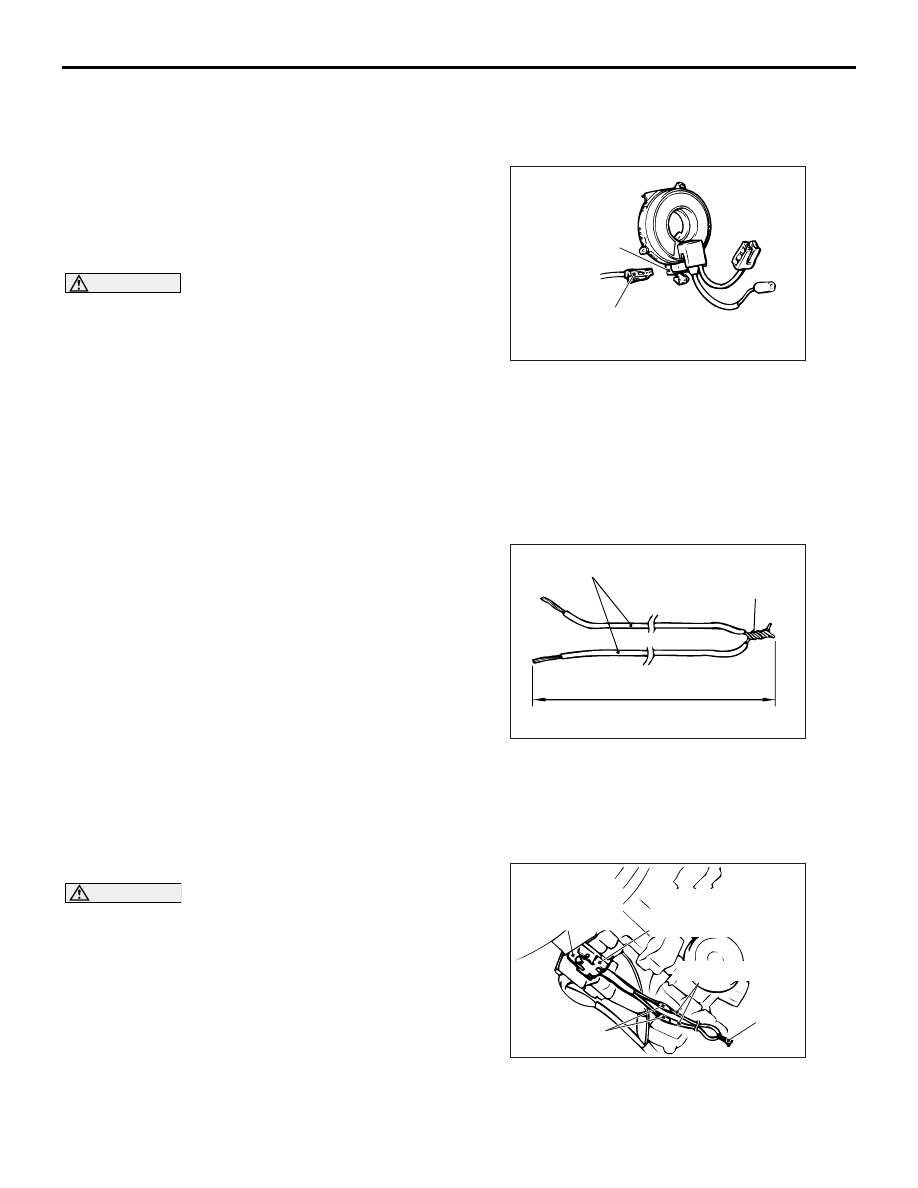

4. Remove the connection between the C-205 clock

spring connector (4-pin) and the harness side

connector (4-pin, yellow).

NOTE: Once disconnected from the instrument

panel wiring harness, both electrodes of the clock

spring connector short automatically. This pre-

vents the driver's air bag from accidental deploy-

ment caused by static, etc.

5. Obtain two suitable wires, which are 6 meters or

longer, as deployment wires. Then connect the

wires at one end to short.

6. Touch the vehicle's body with bare hands to

discharge static in you.

AC300379

C-205 Clock spring

connector (4-pin)

C-205 Harness side

connector

(4-pin, yellow)

AD

AC300381AD

Deployment wires

Connection

6 m or longer

AC300384

Deployment wire

AC

Insulator tape

C-205 Clock spring

connector (4-pin)

Connection

C-205 Harness side

connector

(4-pin, yellow)

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст