Mitsubishi Lancer Evolution IX. Manual — part 569

STRUT ASSEMBLY

FRONT SUSPENSION

33-9

ASSEMBLY SERVICE POINTS

>>A<< STRUT NUT INSTALLATION

1. Ensure that the bearing is seated correctly.

AC001085AB

MB991238

MB991237

2. Install following special tools to the strut assembly

same as its removal.

• Spring compressor body (MB991237)

• Arm set (MB991238)

CAUTION

Do not use an impact wrench to tighten the bolt

of special tool spring compressor body

(MB991237), otherwise the special tool will break.

3. While the coil spring is being compressed by the

special tools, temporarily tighten the strut nut.

AC310747AB

Rod

4. Align the hole in the strut spring lower seat with

the hole in the upper spring seat.

NOTE: Using a rod as shown facilitates the align-

ment.

5. Correctly align both ends of the coil spring with

the grooves in the spring seat, and then loosen

the special tools.

CAUTION

Do not use an impact wrench to tighten the strut

nut, otherwise the strut nut will be damaged.

Vibration of the impact wrench will cause the

valve inside the strut to dropout.

AC211766AB

MB991681

MB991682

6. Using following special tools, tighten the strut nut

to 60

± 10 N⋅m.

• Wrench (MB991681)

•

AC211769

Socket (MB991682)

7. After tightening the strut nut, fill the multi purpose

grease to the bearing part of strut insulator.

INSPECTION

M1332001400229

• Check the strut bearing for wear or rust.

• Check the rubber parts for damage or deteriora-

tion.

• Check the coil spring for deformation, deteriora-

tion or damage.

• Check the front suspension strut for deformation.

LOWER ARM

FRONT SUSPENSION

33-10

LOWER ARM

REMOVAL AND INSTALLATION

M1332001600405

CAUTION

• During maintenance, take care not to contact the parts or tools to the caliper because the paint of

caliper will be scratched. And if there is brake fluid on the caliper, wipe off quickly.

•

Post-installation Operation

• Check the Dust Cover for Cracks or Damage by Pushing

it with Your Finger.

• Front Wheel Alignment Check and Adjustment (Refer to

).

AC310744AB

5

3

186 ± 10 N·m*

108 ± 10 N·m

39 ± 5 N·m

2

5

4

1

39 ± 5 N·m

167 ± 9 N·m

3

Removal steps

1.

Stabilizer link nut

2.

Lower arm and knuckle connection

<<

A

>>

3.

Lower arm and crossmember

connection

4.

Stabilizer bar bracket

5.

Lower arm assembly

*

: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle

on the ground in an unladen condition.

Removal steps (Continued)

LOWER ARM

FRONT SUSPENSION

33-11

REMOVAL SERVICE POINT

<<A>> LOWER ARM AND CROSSMEM-

BER DISCONNECTION

AC006133AE

Mounting bolt

Piece of wood

Garage jack

As for the L.H. lower arm assembly, withdraw the

lower arm bolt (front) with the transmission lift up by

using a transmission jack.

INSPECTION

M1332001700491

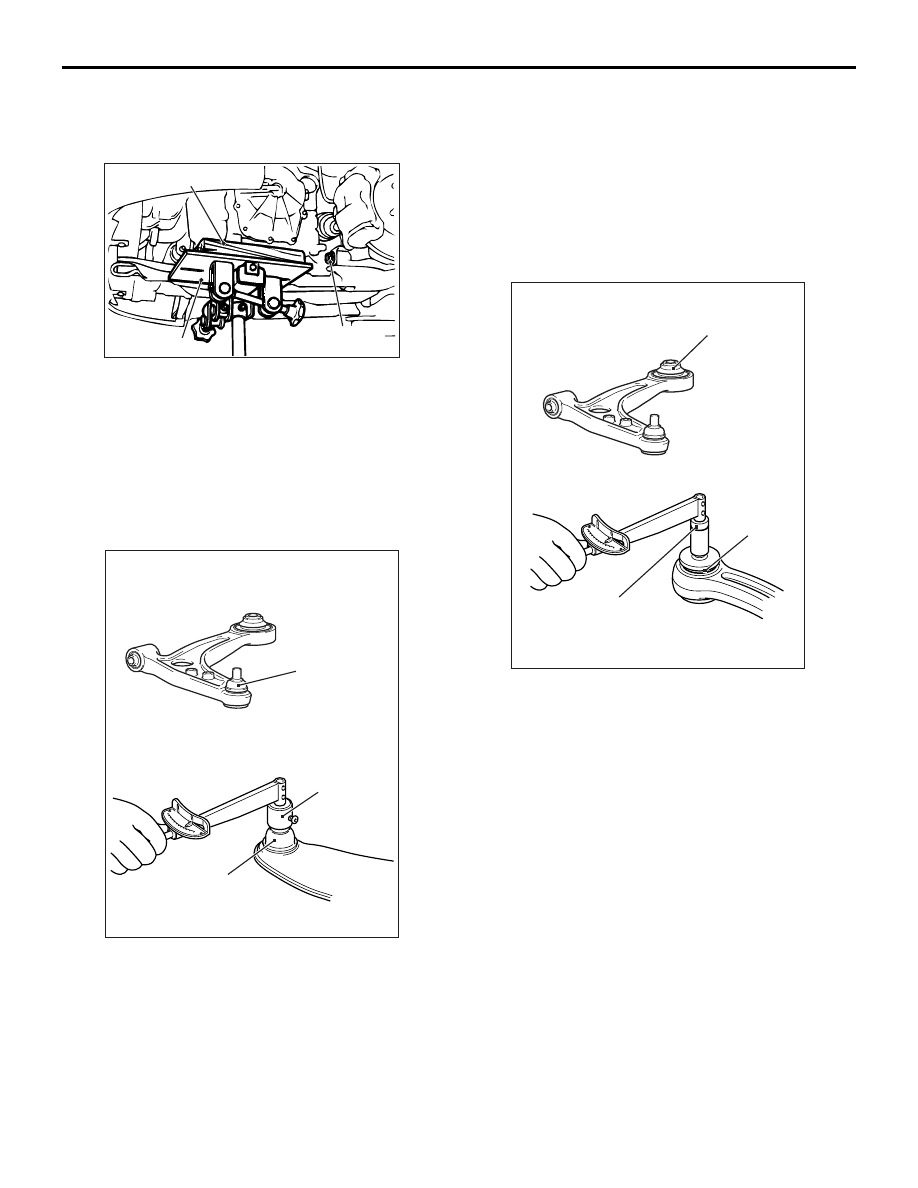

LOWER ARM BALL JOINT STARTING

TORQUE CHECK

AC504613AB

Ball joint

MB991006

Ball joint

1. After shaking the lower arm ball joint stud several

times, use special tool preload socket

(MB991006) to measure the starting torque of the

ball joint.

Standard value: 0.5

− 3.4 N⋅m

2. When the measured value exceeds the standard

value, replace the lower arm assembly.

3. When the measured value is lower than the

standard value, check that the lower arm ball joint

turns smoothly without excessive play. If there is

no excessive play, the ball joint can be reused.

PILLOW BALL BUSHING STARTING

TORQUE CHECK

AC504614AB

Pillow ball joint

Pillow ball

bushing

MB990326

1. Insert the bolt to the lower arm pillow ball bushing.

In the opposite direction, insert the washer then

install the nut. After rotating the inner sleeve

(contained washer) several times, measure the

starting torque of the lower arm pillow ball bushing

using special tool preload socket (MB990326).

Standard value: 0.5

− 3.0 N⋅m

2. When the measured value exceeds the standard

value, replace the pillow ball bushing.

3. When the measured value is lower than the

standard value, check that the lower arm pillow

ball bushing turns smoothly without excessive

play. If there is no excessive play, the pillow ball

bushing can be reused.

LOWER ARM

FRONT SUSPENSION

33-12

LOWER ARM BALL JOINT DUST COVER

CHECK

1. Check the dust cover for cracks or damage by

pushing it with your finger.

2. If the dust cover is cracked or damaged, replace

the lower arm.

NOTE: Cracks or damage to the dust cover may

cause damage to the ball joint. When it is dam-

aged during service work, replace the dust cover.

BALL JOINT DUST COVER

REPLACEMENT

M1332008200312

If the dust cover is damaged accidentally during

service work, replace the dust cover as follows:

1. Remove the dust cover.

2. Apply multipurpose grease to the lip and inside of

the dust cover.

AC006135 AB

MB990800

Dust cover

3. Using special tool ball joint remover and installer

(MB990800), press the dust cover until it contacts

the lower arm assembly.

4. Press the dust cover with your finger to check that

there are no cracks or damage in the dust cover.

LOWER ARM PILLOW BALL BUSHING

REPLACEMENT

M1332008100564

AC504566AB

Pillow ball

bushing

Replace the bushing as follows:

AC504563

MB990651

MB991576

Lower arm

assembly

MB991816

AB

1. Use following special tools to drive out the

bushing.

• Bar (MB990651)

• Base (MB991576)

•

AC504565

Marking

60˚

AB

Bushing remover & installer base (MB991816)

2. Set the bushing to the lower arm assembly so that

the bushing marking and the opening are as

shown in the illustration.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст