Mitsubishi Lancer Evolution IX. Manual — part 333

CAMSHAFT AND VALVE STEM SEAL

ENGINE MECHANICAL

11A-21

<<C>> VALVE SPRING RETAINER LOCKS

REMOVAL

CAUTION

When removing valve spring retainer locks, leave

the piston of each cylinder in the TDC (Top Dead

Centre) position. The valve may fall into the cylin-

der if the piston is not properly in the TDC posi-

tion.

AC201799

MD998772

AB

Use special tool valve spring compressor

(MD998772) to compress the valve spring, remove

the valve spring retainer locks.

INSTALLATION SERVICE POINTS

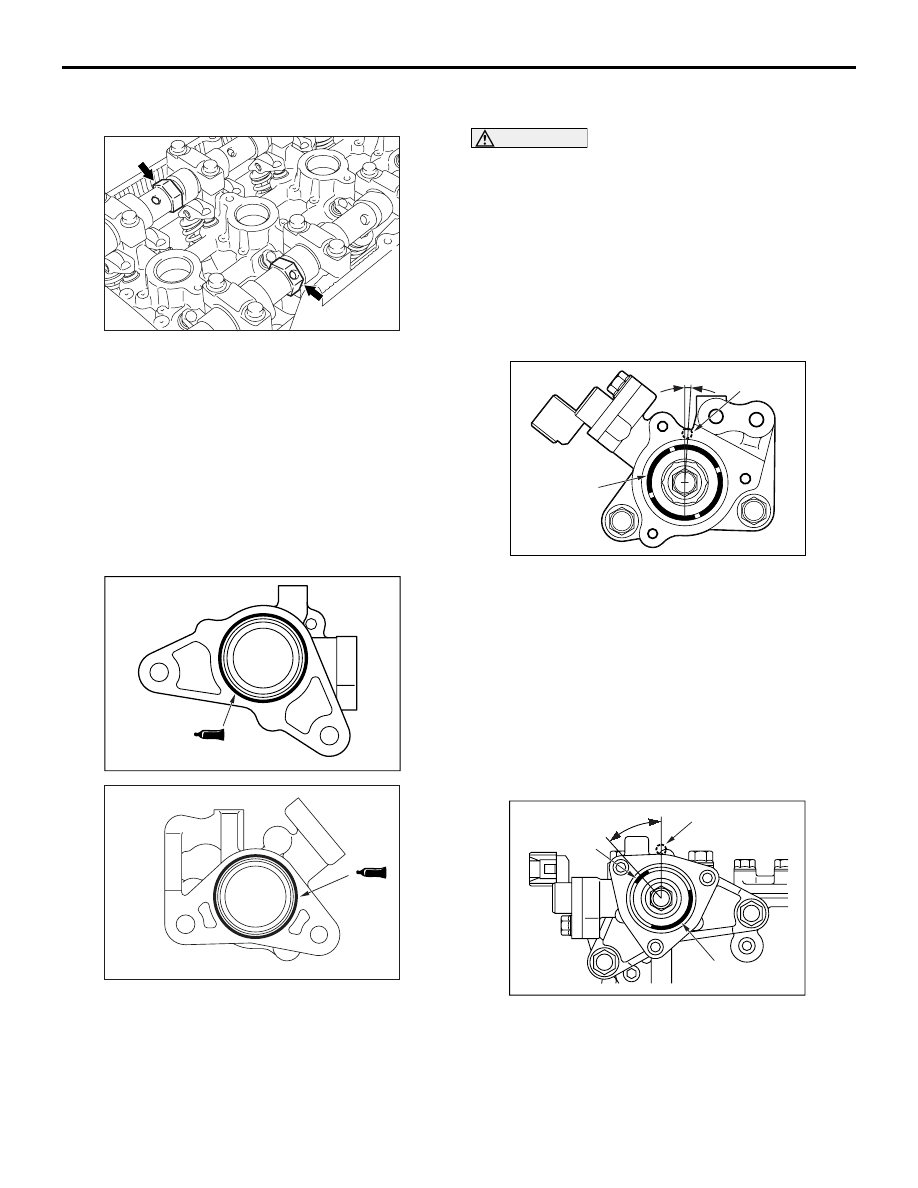

>>A<< EXHAUST VALVE STEM

SEALS/INLET VALVE STEM SEALS

INSTALLATION

1. Apply a small amount of engine oil to the valve

stem seals.

CAUTION

• Valve stem seals cannot be reused.

•

AC308920AB

MD998737

Valve

Valve stem

seal

Valve guide

The special tool valve stem seal installer

(MD998737) must be used to install the valve

stem seal. Improper installation could result

in oil leaking past the valve guide.

2. Use the special tool to fill a new valve stem seal in

the valve guide using the valve stem area as a

guide.

AC201542

AB

Exhaust side

Inlet side

Grey

Grey green

NOTE: Check the valve stem seal colour to iden-

tify the inlet side or exhaust side.

>>B<< VALVE SPRINGS INSTALLATION

AC211159AB

Rocker arm side

Small end

The small end of the valve spring should face the

rocker arm.

>>C<< VALVE SPRING RETAINER LOCKS

INSTALLATION

AC201799

MD998772

AB

Use special tool valve spring compressor

(MD998772) to compress the valve spring in the

same manner as removal.

CAMSHAFT AND VALVE STEM SEAL

ENGINE MECHANICAL

11A-22

>>D<< ROCKER ARM LASH ADJUSTERS

INSTALLATION

CAUTION

If the rocker arm lash adjuster is reused, always

clean and check it before installation. (Refer to

GROUP 11B, Rocker Arms and Camshaft

−

Inspection

).

>>E<< EXHAUST CAMSHAFT/INLET

CAMSHAFT INSTALLATION

1. Remove sealant remained on the cylinder head.

2. Apply engine oil to the cam and the journal of the

camshaft.

CAUTION

Do not install wrong camshaft on the side of inlet

or exhaust. The exhaust camshaft has a slit at the

rear surface.

AC407425

Engine front

<Inlet side>

<Exhaust side>

Slit

Slit

AC

3. Install the camshaft to the cylinder head.

>>F<< CAMSHAFT BEARING CAPS, NO.

4/CAMSHAFT BEARING CAPS, NO.

3/CAMSHAFT BEARING CAPS, NO.

5/CAMSHAFT BEARING CAPS, NO.

2/CAMSHAFT BEARING CAPS,

REAR/CAMSHAFT BEARING CAPS,

FRONT INSTALLATION

AC201459AC

Dowel pin

Exhaust side

Inlet side

Approximately 4˚

1. Set the dowel pin of the camshaft to the position

as shown in the illustration.

AC201460

E 4

AB

Bearing

cap No.

Identification of

inlet side and

exhaust side

Engine front

2. Since the shape of camshaft bearing caps No.2

−

5 is identical, check the identification marks so

that the bearing cap No., inlet side, or exhaust

side is installed in the direction shown in the

illustration.

Identification mark (engraved on the front

and bearing caps No.2

− 5)

I: Inlet side

E: Exhaust side

AC201461AC

Engine front

3. Apply sealant to the positions (8 areas) of the

upper side of the cylinder head as shown in the

illustration.

Specified sealant: MITSUBISHI GENUINE

PART MD970389 or equivalent

AC406643

AE

<Inlet side>

Engine front

Front

marking

AC406642

AF

<Exhaust side>

Engine front

Front

marking

CAMSHAFT AND VALVE STEM SEAL

ENGINE MECHANICAL

11A-23

4. Position the camshaft bearing caps, rear in the

direction as shown in the illustration for

installation.

5. Check the identification marks on the camshaft

bearing caps, front so that inlet side and exhaust

side is installed in the same way as that of bearing

caps No.2

− 5.

6. Tighten the bearing cap mounting bolts increasing

the pressure in 2 to 3 times and finally tighten to

the specified torque.

Tightening torque: 20

± 1 N⋅m

7. Ensure that the rocker arms are installed properly.

NOTE: Remove an excess sealant completely.

>>G<< CAMSHAFT OIL SEALS

INSTALLATION

AC102323AB

MD998713

1. Apply engine oil to the entire inner diameter of the

oil seal lip.

2. Use special tool camshaft oil seal installer

(MD998713) to press-fit the oil seals.

>>H<< CAMSHAFT SPROCKET (INLET

SIDE) INSTALLATION

AC500123AC

Engine front

Camshaft

sprocket

(Engine oil)

1. Apply engine oil to the tip of the camshaft and the

camshaft installation side of the camshaft

sprocket.

2. Align the dowel pin hole of the camshaft sprocket

with the dowel pin of the camshaft, and install the

camshaft sprocket to the camshaft.

3. While holding the hexagonal area of the camshaft

with a wrench, check that the camshaft sprocket

does not turn.

NOTE: This is necessary, because you cannot

confirm that the camshaft dowel pin is inserted

into the pin hole.

AC504842AB

Engine front

Camshaft

sprocket

(Engine oil)

4. Apply the engine oil to the threads and the face of

the camshaft sprocket mounting bolt. Then fix the

camshaft with a wrench in the same way as

removal and tighten the camshaft sprocket

mounting bolt to the specified torque.

Tightening torque: 65

± 5 N⋅m

CAMSHAFT AND VALVE STEM SEAL

ENGINE MECHANICAL

11A-24

>>I<< CAMSHAFT SPROCKET (EXHAUST

SIDE) INSTALLATION

AC407095AC

1. Hold the hexagon part of the camshaft with a

wrench in the same manner as removal.

2. Tighten the camshaft sprocket mounting bolts to

the specified torque.

Tightening torque: 89

± 9 N⋅m

>>J<< CAMSHAFT POSITION SENSOR

SUPPORT INSTALLATION

1. Remove sealant from the camshaft position

sensor support and cylinder head surfaces.

AC201463

3 mm

AC

<Exhaust side>

AC406663

3 mm

AC

<Inlet side>

2. Apply the sealant to the camshaft position sensor

support flange in a continuous bead as shown in

the illustration.

Specified sealant: MITSUBISHI GENUINE

PART MD970389 or equivalent

NOTE: Install the camshaft position sensor sup-

port within 15 minutes after applying liquid gasket.

3. Install the camshaft position sensor support to the

cylinder head.

CAUTION

Wait at least one hour. Never start the engine or

let engine oil or coolant touch the adhesion sur-

face during that time.

4. Tighten the camshaft position sensor support

mounting bolts to the specified torque.

Tightening torque: 14

± 1 N⋅m

>>K<< CAMSHAFT POSITION SENSING

CYLINDER (INLET SIDE) INSTALLATION

AC406644

AE

(4˚ 1')

Dowel pin

Vane

1. Set the dowel pin of the inlet camshaft to the

position (No.1 cylinder at compression TDC) as

shown in the illustration.

2. Tighten the camshaft position sensing cylinder

mounting bolts to the specified torque.

Tightening torque: 22

± 4 N⋅m

>>L<< CAMSHAFT POSITION SENSING

CYLINDER (EXHAUST SIDE)

INSTALLATION

AC201464AB

Dowel pin

Vane (large)

Vane (small)

Approximately 45˚

1. Set the dowel pin of the exhaust camshaft to the

position (No.1 cylinder at compression TDC) as

shown in the illustration.

NOTE: Use the force of the exhaust valve spring

to rotate anti-clockwise.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст