Mitsubishi Eclipse / Eclipse Spyder (2000-2002). Service and repair manual — part 24

ENGINE ASSEMBLY

TSB Revision

ENGINE MECHANICAL <2.4L ENGINE>

11A-13

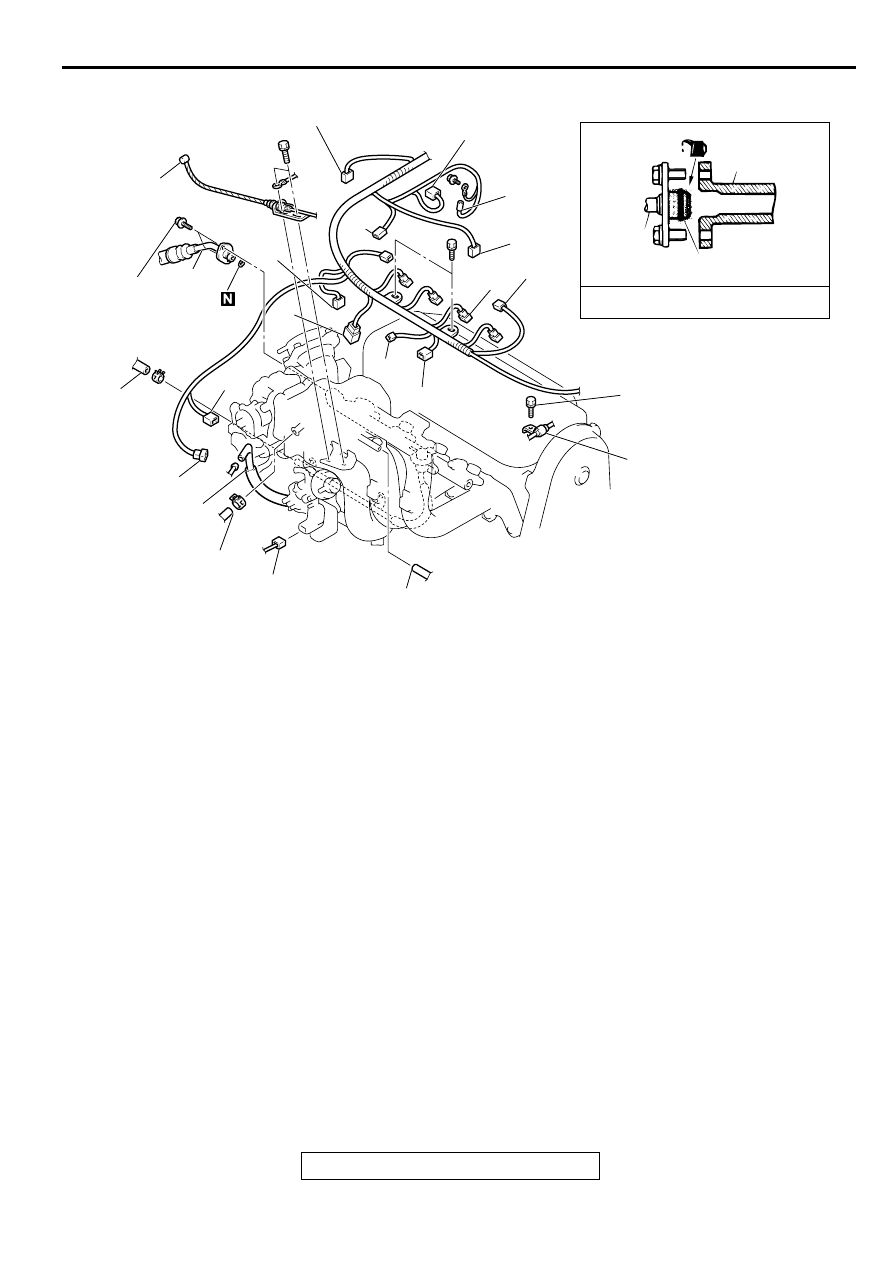

AC001692

1

19

4.8 ± 1.0 N·m

44 ± 8 in-lb

20

17

16

2

3

18

4

14

15

9

8

7

6

5

10

11

12

19

O-RING

FUEL RAIL

ENGINE OIL

12 ± 2 N·m

100 ± 22 in-lb

21

AB

13

REMOVAL STEPS

1.

ACCELERATOR CABLE

CONNECTION

2.

PURGE HOSE CONNECTION

3.

BRAKE BOOSTER VACUUM

HOSE CONNECTION

4.

VACUUM HOSE CONNECTION

5.

IGNITION COIL CONNECTOR

6.

INJECTOR CONNECTOR

7.

IGNITION FAILURE SENSOR

CONNECTOR

8.

MANIFOLD DIFFERENTIAL

PRESSURE SENSOR

CONNECTOR

9.

THROTTLE POSITION SENSOR

CONNECTOR

10. HEATED OXYGEN SENSOR

(FRONT) CONNECTOR

11. CAPACITOR CONNECTOR

12. ENGINE COOLANT

TEMPERATURE SENSOR

CONNECTOR

13. CAMSHAFT POSITION

SENSOR CONNECTOR

14. KNOCK SENSOR CONNECTOR

15. ENGINE COOLANT

TEMPERATURE GAUGE UNIT

CONNECTOR

16. IDLE AIR CONTROL MOTOR

CONNECTOR

17. EVAPORATIVE EMISSION

PURGE SOLENOID VALVE

CONNECTOR

18. EGR SOLENOID VALVE

CONNECTOR

>>D<<

19. HIGH-PRESSURE FUEL HOSE

CONNECTION

20. FUEL RETURN HOSE

CONNECTION

21. PRESSURE HOSE

CONNECTION

REMOVAL STEPS (Continued)

ENGINE ASSEMBLY

TSB Revision

ENGINE MECHANICAL <2.4L ENGINE>

11A-14

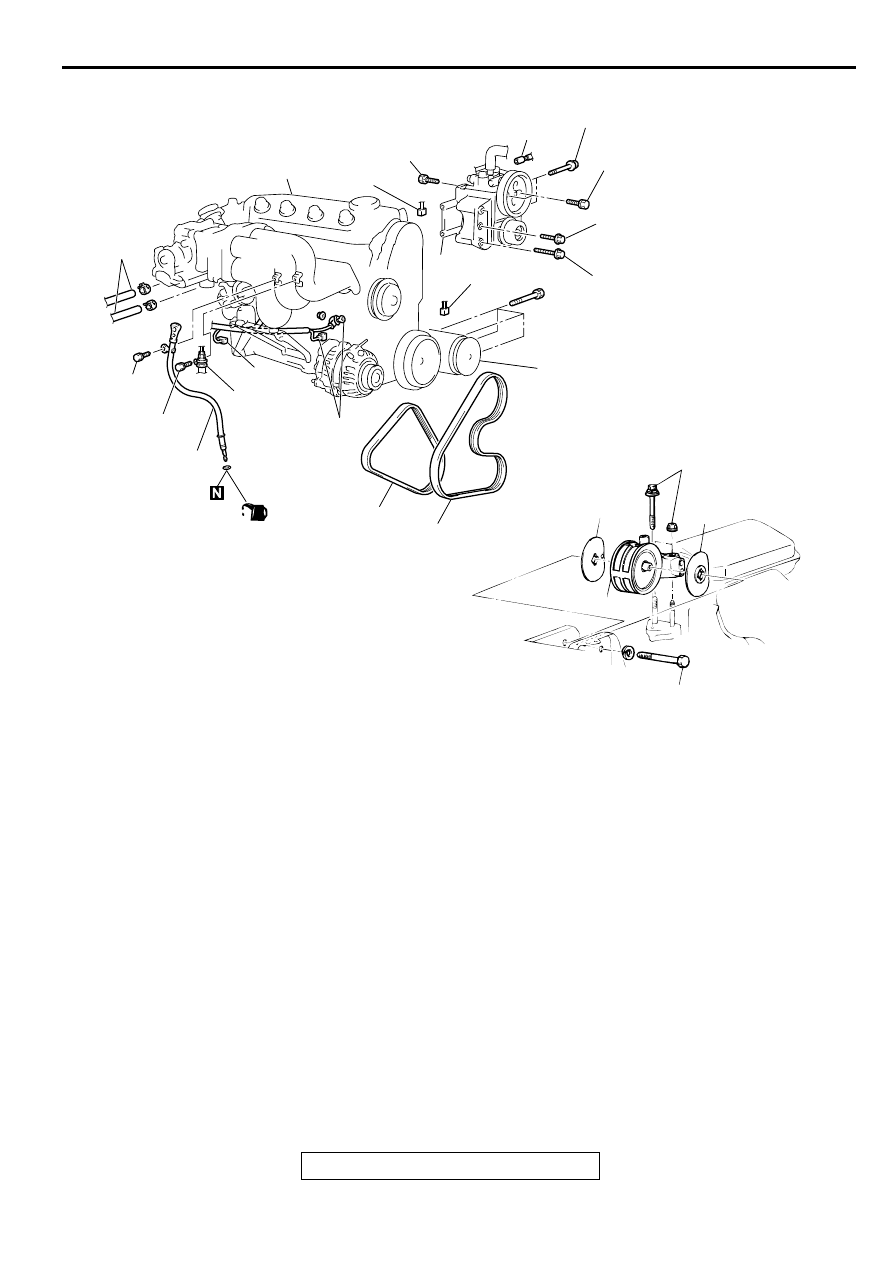

Required Special Tools:

•

MB991453: Engine Hanger Assembly

•

MZ203827: Engine Lifter

AC001694

24

14 ± 1 N·m

117 ± 13 in-lb

12 ± 2 N·m

100 ± 22 in-lb

22

(ENGINE OIL)

26

23

25

28

27

33

29

29 ± 3 N·m

21 ± 3 ft-lb

36

30

49 ± 10 N·m

36 ± 7 ft-lb

29 ± 3 N·m

21 ± 3 ft-lb

11 ± 1 N·m

96 ± 8 in-lb

49 ± 10 N·m

36 ± 7 ft-lb

31

32

86 ± 12 N·m

64 ± 8 ft-lb

35

35

34

81 ± 12 N·m*

60 ± 9 ft-lb*

AB

22. OIL DIPSTICK AND DIPSTICK

GUIDE

23. PRESSURE HOSE CONNECTION

24. HEATER HOSE CONNECTION

25. GENERATOR CONNECTOR

26. OIL PRESSURE SWITCH

CONNECTOR

27. DRIVE BELT (POWER STEERING

OIL PUMP AND A/C

COMPRESSOR)

28. DRIVE BELT (GENERATOR)

29. CRANKSHAFT POSITION SENSOR

CONNECTOR

30. POWER STEERING PRESSURE

SWITCH CONNECTOR

<<A>>

31. POWER STEERING OIL PUMP AND

BRACKET ASSEMBLY

32. A/C COMPRESSOR ASSEMBLY

CONNECTOR

<<B>>

33. A/C COMPRESSOR

<<C>>

•

TRANSAXLE ASSEMBLY

<<D>> >>C<<

34. ENGINE MOUNT BRACKET

>>B<<

35. ENGINE MOUNT STOPPER

<<E>> >>A<<

36. ENGINE ASSEMBLY

ENGINE ASSEMBLY

TSB Revision

ENGINE MECHANICAL <2.4L ENGINE>

11A-15

REMOVAL SERVICE POINTS

<<A>> POWER STEERING OIL PUMP AND BRACKET

ASSEMBLY REMOVAL

Remove the power steering oil pump and bracket assembly

from the engine with the hose attached.

NOTE: Place the removed power steering oil pump in a place

where it will not be a hindrance when removing and installing

the engine assembly, and secure it with a cord or wire.

<<B>> A/C COMPRESSOR REMOVAL

Remove the compressor from the compressor bracket with the

hose still attached.

NOTE: Place the removed A/C compressor where it will not be

a hindrance when removing and installing the engine assembly,

and secure it with a cord or wire.

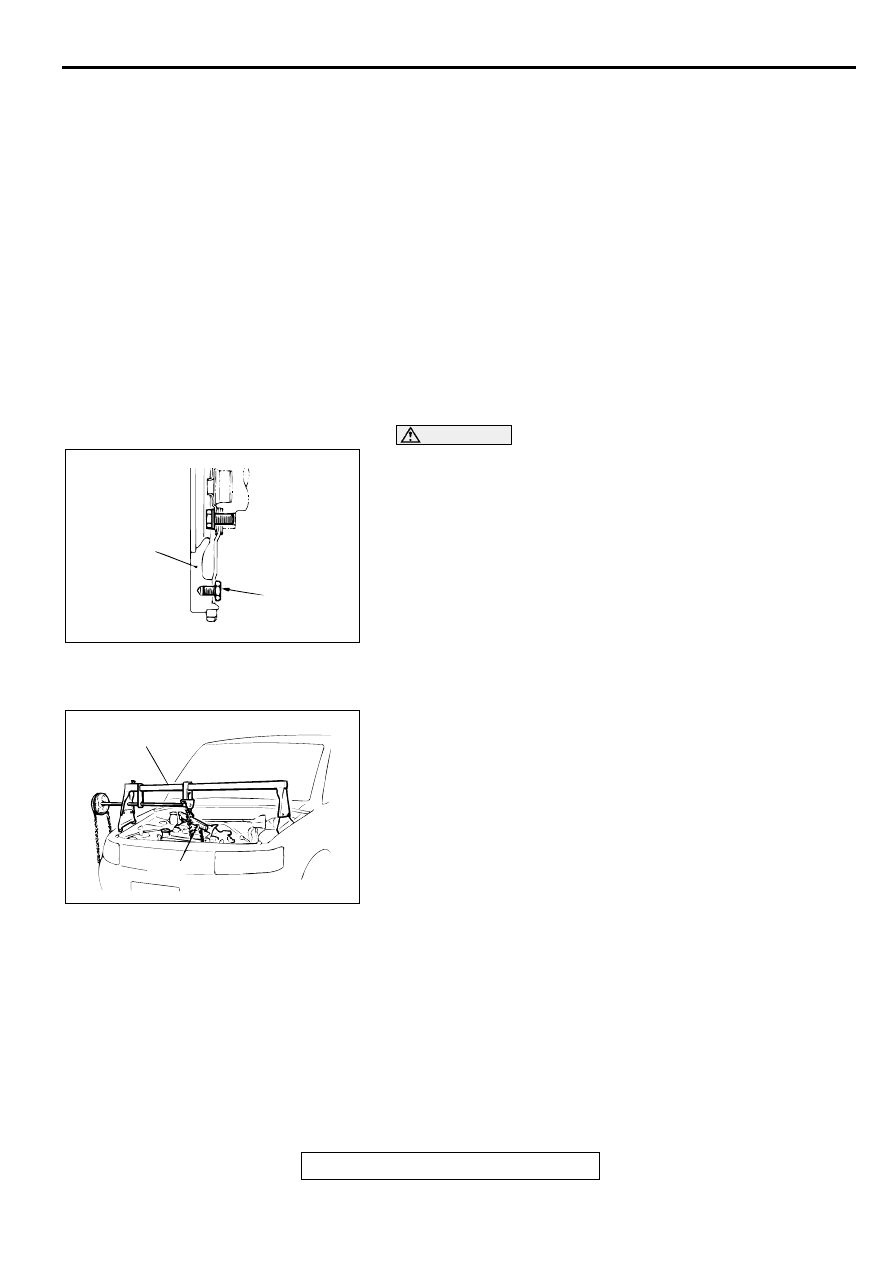

<<C>> TRANSAXLE ASSEMBLY REMOVAL

CAUTION

Do not remove the flywheel mounting bolt shown by the

arrow. If this bolt Is removed, the flywheel will become out

of balance and damaged.

<M/T>: Refer to GROUP 22A, Transaxle Assembly

<A/T>: Refer to GROUP 23A, Transaxle Assembly

.

<<D>> ENGINE MOUNT BRACKET REMOVAL

1. Support the engine with a garage jack.

2. Remove special tools MB991453 and MZ203827 which was

attached when the transaxle assembly was removed.

3. Hold the engine assembly with a chain block or similar tool.

4. Place a garage jack against the engine oil pan with a piece

of wood in between, jack up the engine so that the weight of

the engine is no longer being applied to the engine mount

bracket, and then remove the engine mount bracket.

<<E>> ENGINE ASSEMBLY REMOVAL

After checking that all cables, hoses and harness connectors,

etc., are disconnected from the engine, lift the chain block

slowly to remove the engine assembly upward from the engine

compartment.

INSTALLATION SERVICE POINTS

>>A<< ENGINE ASSEMBLY INSTALLATION

Install the engine assembly, checking that the cables, hoses,

and harness connectors are not clamped.

AC000126

FLYWHEEL

BOLT

AB

<M/T>

AC000127

MZ203827

MB991453

AB

ENGINE ASSEMBLY

TSB Revision

ENGINE MECHANICAL <2.4L ENGINE>

11A-16

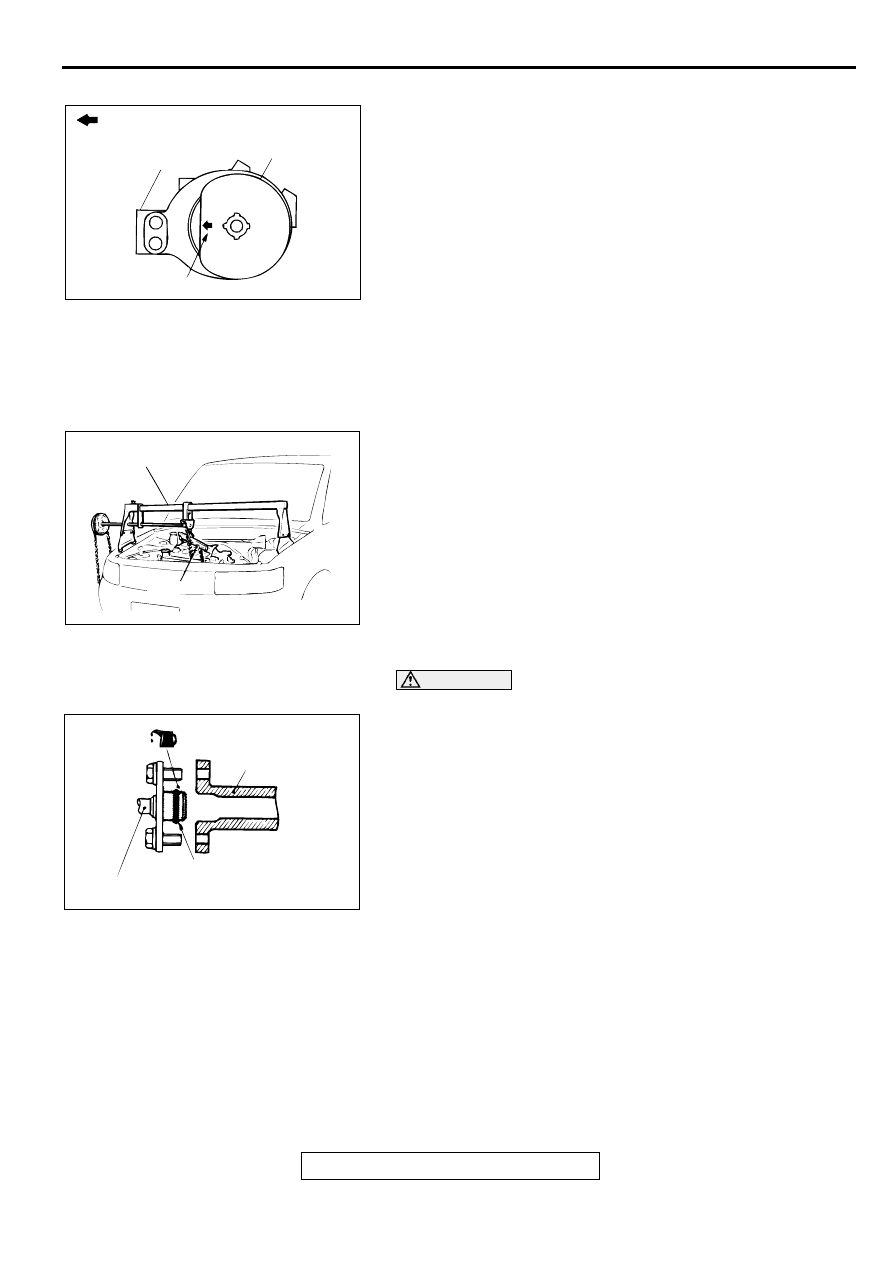

>>B<< ENGINE MOUNT STOPPER INSTALLATION

Clamp the engine mount stopper so that the arrow points in the

direction as shown in the diagram.

>>C<< ENGINE MOUNT BRACKET INSTALLATION

1. Place a garage jack against the engine oil pan with a piece

of wood in between, and install the engine mount bracket

while adjusting the position of the engine.

2. Support the engine with the garage jack.

3. Remove the chain block and support the engine assembly

with special tools MB991453 and MZ203827.

>>D<< HIGH-PRESSURE FUEL HOSE INSTALLATION

CAUTION

Do not allow any engine oil to enter the fuel rail.

1. Apply a small amount of new engine oil to the O-ring.

2. While turning the high-pressure fuel hose to the right and

left, install it to the fuel rail, while being careful not to

damage the O-ring. After installing, check that the hose

turns smoothly.

3. If the hose does not turn smoothly, the O-ring is probably

being clamped. Disconnect the high-pressure fuel hose and

check the O-ring for damage. Replace if necessary.

4. Re-insert the fuel rail and confirm the hose turns smoothly.

AC000128

ENGINE SIDE

ENGINE MOUNT

BRACKET

ENGINE MOUNT

STOPPER

ARROW

AB

AC000127

MZ203827

MB991453

AB

AC000129 AB

FUEL RAIL

HIGH-PRESSURE

FUEL HOSE

O-RING

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст