Mitsubishi Eclipse / Eclipse Spyder (2000-2002). Service and repair manual — part 553

SPECIAL TOOLS

TSB Revision

FRONT SUSPENSION

33A-5

INSPECTION PROCEDURE 5: Noise

DIAGNOSIS

STEP 1. Check for lack of lubrication.

Q: Is lubrication inadequate?

YES :

Lubricate it, then go to Step 5.

NO :

Go to Step 2.

STEP 2. Check the tightened parts for looseness

as well as the bushings for wear.

Q: Are the tightened parts and bushings in good

condition?

YES :

Go to Step 3.

NO :

Replace it, then go to Step 5.

STEP 3. Check for broken coil spring.

Q: Is the coil spring broken?

YES :

Replace it, then go to Step 5.

NO :

Go to Step 4.

STEP 4. Check for strut assembly damage.

Q: Is the strut assembly damaged?

YES :

Replace it, then go to Step 5.

NO :

Go to Step 5.

STEP 5. Check symptoms.

Q: Is the malfunction eliminated?

YES :

Return to Step 1.

NO :

This diagnosis complete.

SPECIA L TO O LS

M1332000600060

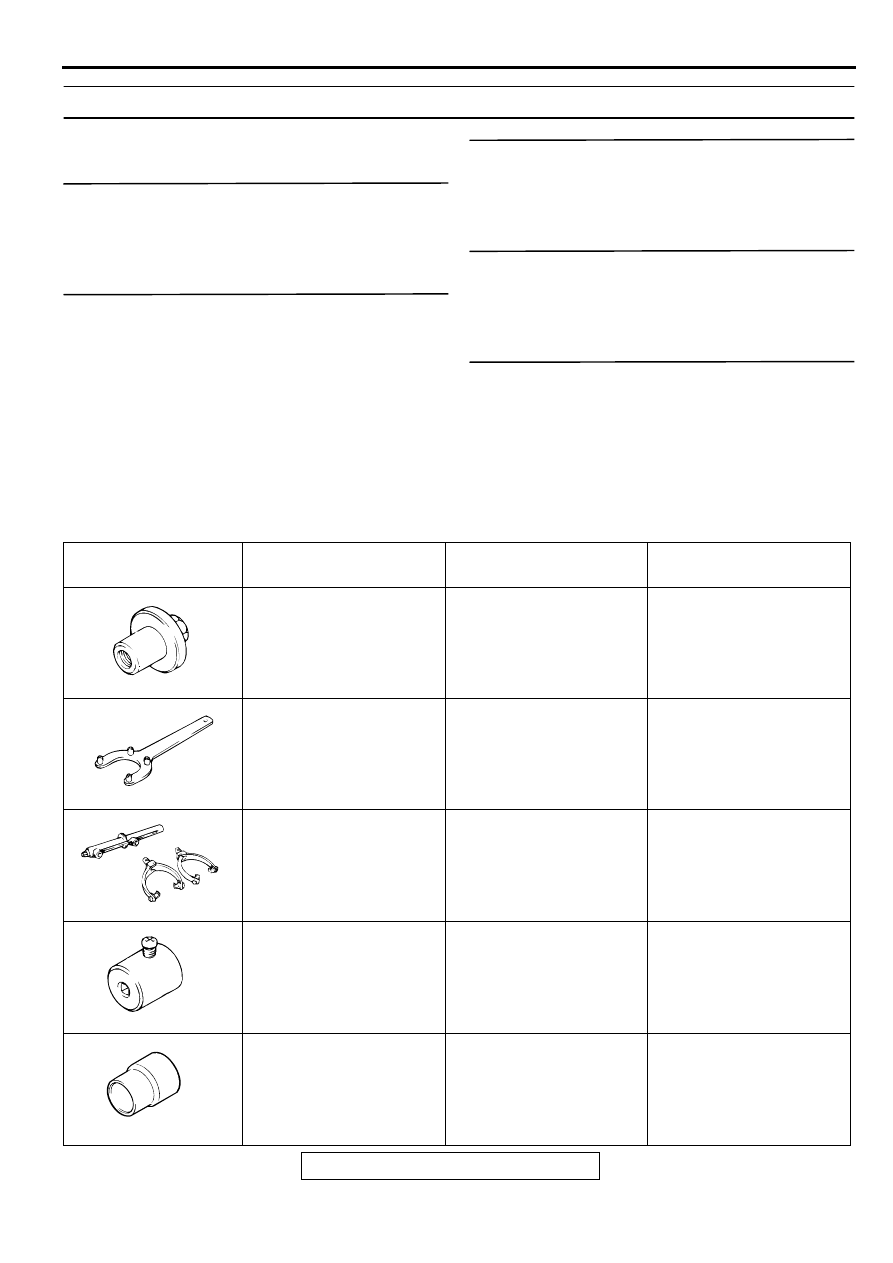

TOOL

TOOL NUMBER AND

NAME

SUPERSESSION

APPLICATION

MB991004

Wheel alignment gauge

attachment

MB991004-01 or General

service tool

Wheel alignment

measurement

MB991176

Spring seat holder

General service tool

Strut disassembly and

assembly

•

A: MB991237

Spring compressor

body

•

B: MB991238

Arm set

MIT221369

Front coil spring

compression

MB991006

Preload socket

MB990228-01

Lower arm ball joint

breakaway torque check

MB990799

Ball joint dust cover

installer

MB990799-01

Lower arm ball joint dust

cover installation

MB991004

MB991176

MB991237

A

B

MB991006

MB990799

ON-VEHICLE SERVICE

TSB Revision

FRONT SUSPENSION

33A-6

O N -VEH IC LE SERVIC E

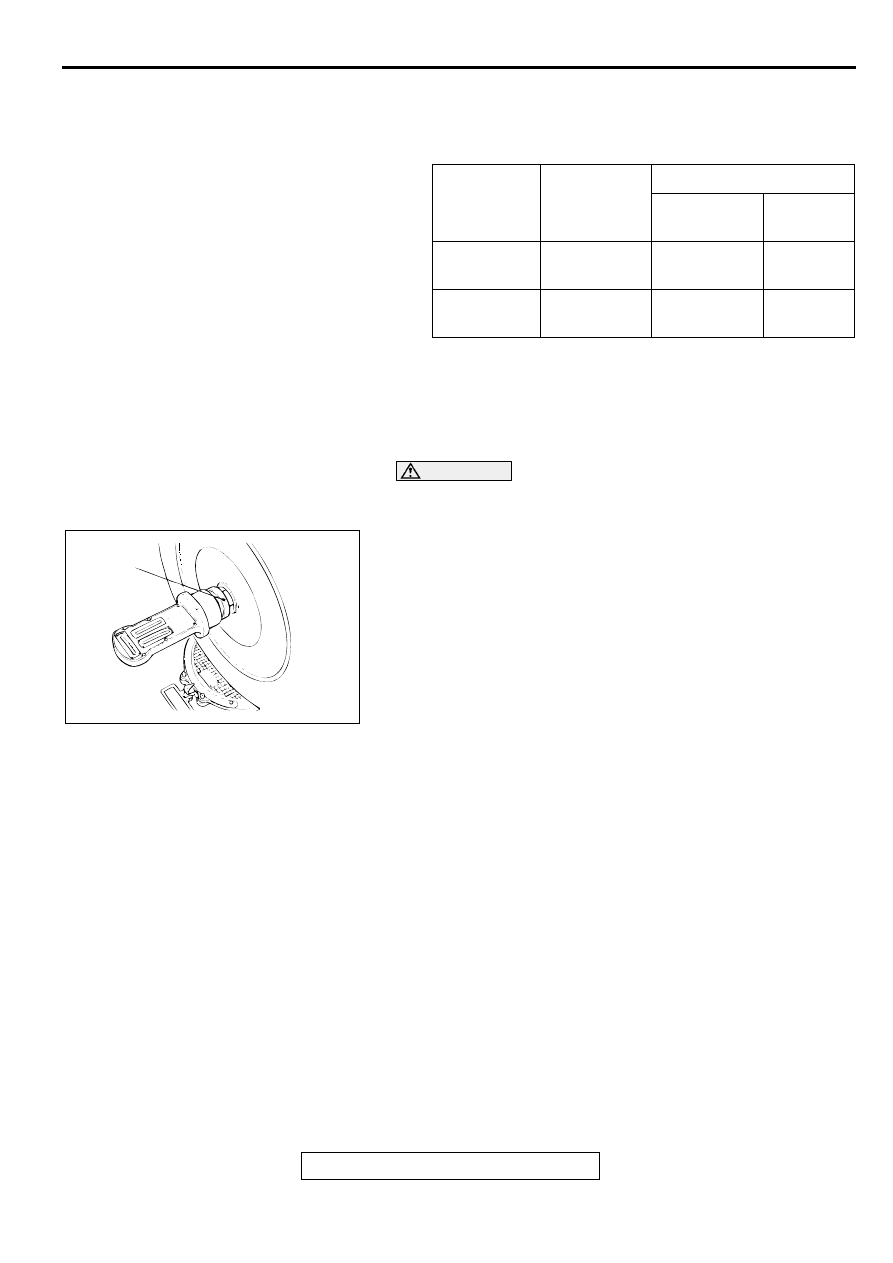

FRONT WHEEL ALIGNMENT CHECK AND

ADJUSTMENT

M1331000900080

Required Special Tool:

•

MB991004: Wheel Alignment Gauge Attachment.

Measure wheel alignment with alignment equipment on a level

surface. The front suspension, steering system, and wheels

should be serviced to normal condition before measuring wheel

alignment.

TOE-IN

Standard value: 0

±

3 mm (0

±

0.12 inch)

NOTE: If the toe-in is not within the standard value, adjust the

toe-in by undoing the clips and turning the left and right tie rod

turnbuckles by the same amount (in opposite directions).

NOTE: The toe will move out as the left turnbuckle is turned

toward the front of the vehicle and the right turnbuckle is turned

toward the rear of the vehicle.

For each one turn of the left and right tie rods, the toe-in will be

adjusted by approximately 1

°

05' (per wheel).

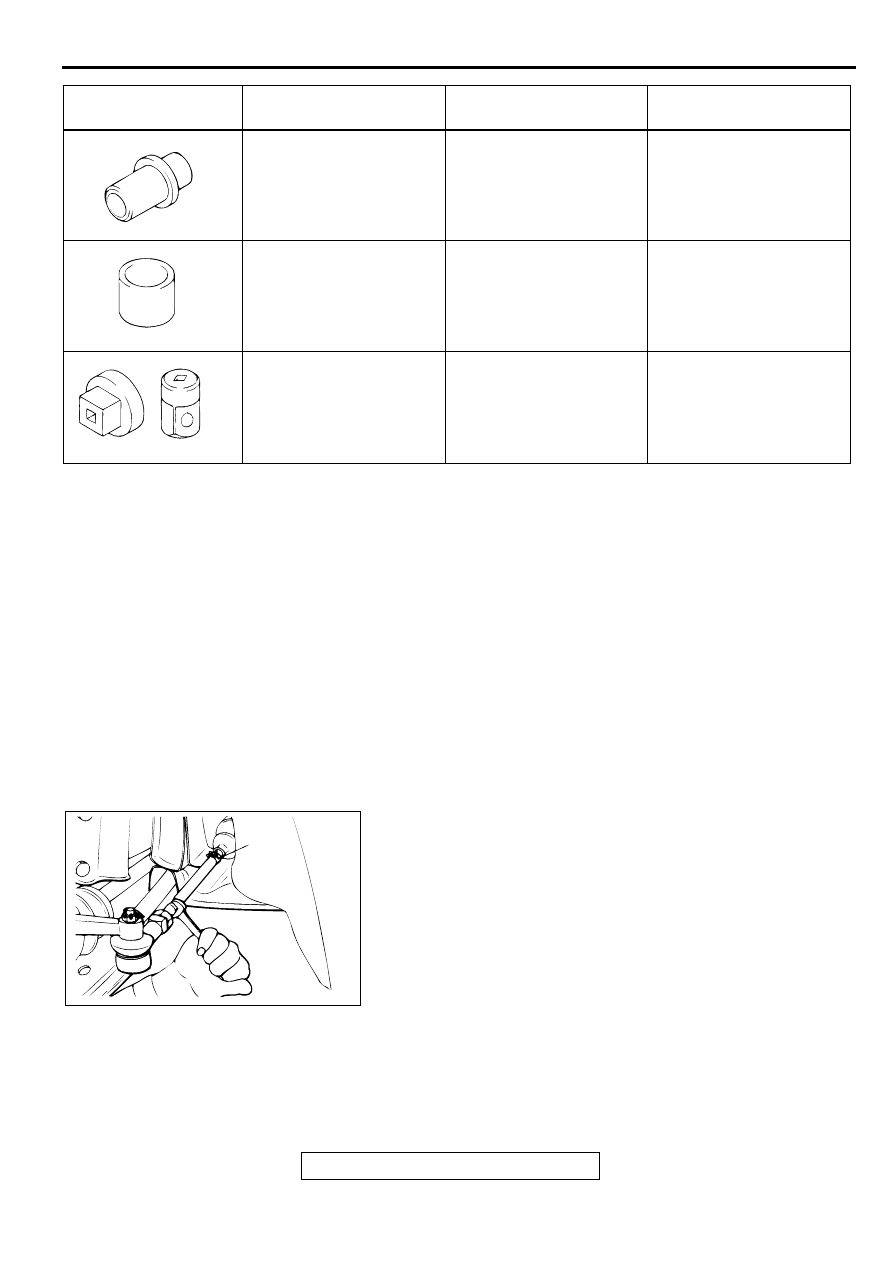

MB991007

Bearing installer

Tool not available

Press-fitting of lower arm

ball joint dust cover

MB991446

Bushing remover and

installer spacer

Tool not available

Press-fitting of lower arm

bushing

MB990326

Preload socket

General service tool

Stabilizer link ball joint

breakaway torque

measurement

TOOL

TOOL NUMBER AND

NAME

SUPERSESSION

APPLICATION

MB991007

MB991446

MB990326

AC001078 AB

CLIP

ON-VEHICLE SERVICE

TSB Revision

FRONT SUSPENSION

33A-7

STEERING ANGLE

Use a turning radius gauge to check that the steering angle is

at the standard value.

Standard value:

CAMBER AND CASTER

Standard value:

Camber 0

°

00'

±

30' (Left/right deviation within 30')

Caster 3

°

00'

±

30' (Left/right deviation within 30')

NOTE: Caster is preset at the factory and cannot be adjusted.

CAUTION

Never subject the wheel bearings to the vehicle load when

the drive shaft nuts are loosened.

NOTE: For vehicles with aluminum type wheels, attach the

camber/caster/kingpin gauge to the driveshaft by using special

tool MB991004. Tighten special tool MB991004 to the same

torque 226

±

29 N

⋅

m (167

±

21 ft-lb) as the driveshaft nut.

ITEM

2.4L ENGINE 3.0L ENGINE

ECLIPSE

ECLIPSE

SPYDER

Inner wheel

36

°

12'

±

2

°

00' 31

°

00'

±

2

°

00' 33

°

60'

±

2

°

00'

Outer wheel

(reference)

30

°

24'

27

°

00'

28

°

30'

AC001079

MB991004

AB

ON-VEHICLE SERVICE

TSB Revision

FRONT SUSPENSION

33A-8

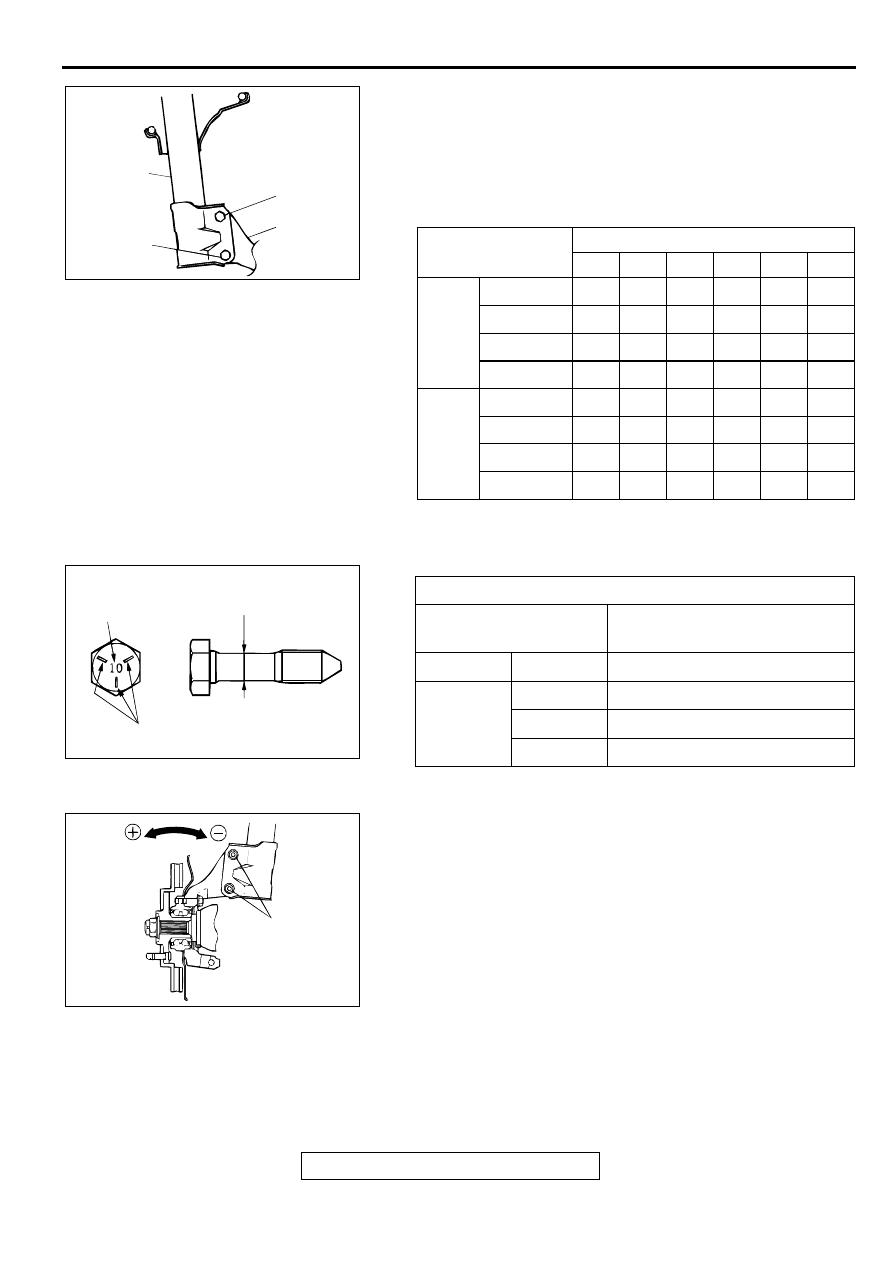

If the camber is outside of the standard value, perform the

following adjustment procedures.

1. Estimate how much additional camber adjustment is

required. Using the table below, select the camber adjusting

bolt, and then replace the knuckle and strut assembly

connection bolts (upper bolt, lower bolt) with the selected

bolts.

NOTE: If the camber adjusting value that is required is

greater than 1

°

30', check for bent or damaged parts and

replace as necessary.

NOTE: Set bolt is the bolt installed at factory. "10" embossed

on bolt head is head mark.

2. Tighten the nuts temporarily, and then pull or push the front

axle to adjust the camber.

NOTE: Pulling the upper side of the front axle to the outside

of the vehicle will increase the camber. Pushing it to the

inside of the vehicle will decrease the camber.

3. Tighten the nuts to 275

−

324 N

⋅

m (203

−

239 ft-lb).

4. Recheck the camber.

BOLT DIAMETER

mm (in)

CAMBER ADJUSTING VALUE

0

°

15' 0

°

30' 0

°

45' 1

°

00' 1

°

15' 1

°

30'

Upper

bolt

16.0 (0.63)

•

•

14.9 (0.59)

•

•

14.1 (0.56)

•

13.6 (0.54)

•

Lower

bolt

16.0 (0.63)

•

14.9 (0.59)

•

•

14.1 (0.56)

•

•

13.6 (0.54)

•

BOLT IDENTIFICATION

DIAMETER A mm (in)

NUMBER OF IDENTIFICATION

PROJECTION

Set bolt

16.0 (0.63)

0

Adjusting

bolt

14.9 (0.59)

1

14.1 (0.59)

2

13.6 (0.54)

3

AC001080

STRUT

ASSEMBLY

LOWER BOLT

UPPER BOLT

KNUCKLE

AB

AC001081 AB

A

A

HEAD MARK

IDENTIFICATION

PROJECTION

AC001082

275 – 324 N·m

203 – 239 ft-lb

AC

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст